Maximizing production capacity is crucial for manufacturing companies, especially in competitive regions like Singapore. According to ITA, manufacturing has driven Singapore’s economy for over 50 years, evolving from low-cost, labor-intensive production to high-value manufacturing. As a global economic hub, Singapore offers many opportunities for manufacturers. To stay competitive, businesses must focus on improving efficiency, reducing costs, and increasing their ability to meet customer demands, ultimately driving long-term growth and boosting their market position.

This essay will look at the importance of increasing production capacity and how firms may achieve operational excellence by embracing contemporary technology. It will discuss the advantages of optimizing production, the role of modern ERP systems in streamlining manufacturing processes, and how businesses can enhance resource allocation and production scheduling. The article will also cover crucial techniques and technology that can help organizations stay competitive while growing over time.

- Production capacity is the maximum volume of goods and materials a company can produce under normal conditions, factoring in time, personnel, machinery, and supplies.

- Understanding production capacity is crucial for improving efficiency, reducing waste, and streamlining operations, leading to more cost-effective manufacturing.

- Key factors influencing production capacity include equipment and machinery, labor force, materials and supply chain, and production scheduling.

- ScaleOcean’s manufacturing software enhances production capacity by streamlining operations, optimizing output, and providing solutions for MRP, cost management, order management, and warehouse management.

What is Production Capacity?

Production capacity is the maximum volume of goods and materials that a corporation can create under normal conditions, taking into account elements such as time, personnel, machinery, and supplies. It describes a company’s potential production, determining how much product may be produced during a given time period, such as daily, weekly, or annual. Understanding this capacity is critical for efficiently managing production and ensuring smooth operations.

This capacity is critical for guaranteeing a company’s operational efficiency and ability to meet client demand. Businesses that precisely determine production capacity may plan their workflows, distribute resources more efficiently, and avoid overproduction and underproduction. This helps to maximize resources, align production with market demand, and consistently meet consumer expectations.

Why is Production Capacity Crucial?

Production capacity is essential for improving efficiency and meeting market demand. By understanding production capacity, businesses can better utilize resources, reduce waste, and streamline operations, leading to cost-effective manufacturing. According to Enterprise Singapore, companies like Tai Sin Electric have maintained efficiency despite workforce reductions by adopting Industry 4.0 technologies. Real-time data dashboards and digitalized processes have optimized shifts and boosted operational efficiency. Additionally, recognizing production capacity helps in scheduling production, reducing downtime, and increasing productivity.

Furthermore, matching production capacity to market demand is crucial for retaining customer loyalty and achieving a competitive advantage. When production capacity is appropriately tuned to match demand changes, firms can ensure product delivery on time, directly improving customer experiences. Consistently meeting client expectations not only leads to repeat business, but it also fosters brand loyalty, making it easier for businesses to retain long-term customer relationships and increase their market position.

Factors Influencing Production Capacity

Several main elements influence a company’s production capacity, which determines how much it can create. These elements are crucial to ensuring that planning for manufacturing processes works smoothly and efficiently. Understanding and managing these aspects allows organizations to improve their production capacities and efficiently satisfy client demand. The following are the main elements that determine production capacity:

1. Equipment and Machinery

The type, condition, and maintenance of machinery have a direct impact on output rates. Regular maintenance and timely upgrades are required to avoid downtime and ensure that manufacturing operations continue to operate smoothly. Well-maintained equipment lowers the chance of faults and delays, increasing overall capacity.

2. Labor Force

Skilled and well-trained employees contribute greatly to increased production. Employees that have received adequate training may work faster and more efficiently, ensuring that the production process runs smoothly. Businesses can also temporarily enhance production capacity by altering work shifts or adding overtime to satisfy rising demand.

3. Materials and Supply Chain

Reliable suppliers and efficient inventory management ensure the timely availability of high-quality materials. A bill of materials helps streamline this process, supporting just-in-time inventory systems that reduce storage costs and prevent production delays from supply shortages.

4. Production Scheduling

Effective scheduling links production processes with demand estimates, reducing bottlenecks and improving resource usage. Setting takt time for production schedules helps manage workloads efficiently, ensuring tasks are completed on time, optimizing capacity, and increasing overall production flow.

Measuring Production Capacity

Understanding how to estimate production capacity is critical for evaluating a company’s manufacturing efficiency and identifying opportunities for improvement. Companies can acquire useful insights into their operational performance and make data-driven production decisions by utilizing a variety of calculating methods and tools.

1. Calculation Methods

Businesses utilize a variety of calculating methodologies to accurately assess production capacity, providing insights into the efficiency and utilization of their manufacturing processes. These strategies enable businesses to analyze how well they are using their resources and find opportunities for improvement. The following are some popular approaches for calculating production capacity:

a. Machine-Hour Capacity

Machine-hour capacity is the total number of hours that machines may be used for production. It assists firms in determining how much time equipment can be used, indicating machine availability and potential output. This statistic is critical for analyzing production efficiency and planning resource utilization properly.

b. Throughput Time

Throughput time is the total time required to complete a product from start to finish. By applying cycle time methods, organizations can reduce delays, streamline production, and satisfy client demands faster, ultimately lowering operational expenses.

c. Capacity Utilization Rate

The capacity utilization rate measures how effectively a corporation utilizes its manufacturing capacity. It is calculated by dividing the actual output by the maximum possible output and multiplying by 100. This metric assists businesses in evaluating their efficiency, with a higher rate indicating better use of available resources. It’s calculated with the following formula:

Capacity Utilization Rate = (Actual Output / Maximum Possible Output) ×100

2. Tools and Techniques

Advanced solutions such as Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) software, including Manufacturing ERP software Singapore, give real-time data and analytics, enabling organizations to precisely monitor and assess their production capacity.

These solutions offer insights into performance and resource consumption, allowing businesses to make informed decisions. By tracking work in progress (WIP), companies can optimize their manufacturing processes, improving efficiency and reducing bottlenecks for better outcomes.

Strategies to Enhance Production Capacity

To increase production capacity, organizations must implement strategies to enhance efficiency, match resources to demand, and eliminate bottlenecks. A personalized make-to-order approach can help by aligning production with specific customer needs, maximizing output, and ensuring adaptability in a competitive market.

The following are some significant techniques for increasing manufacturing capacity:

1. Process Optimization

Identifying and reducing inefficiencies through techniques like lean manufacturing can boost production. Reorganizing workflows and optimizing Material Requirement Planning (MRP) leads to smoother operations, increased throughput, and reduced waste, all without additional resource investment.

2. Technological Integration

Adopting automation and modern production technology improves speed and precision, while real-time monitoring systems resolve faults instantly, increasing overall capacity. Integrating these technologies enables organizations to streamline their operations, making every stage of the manufacturing process faster and more precise.

3. Capacity Planning

Aligning the production lifecycle framework with demand predictions helps to reduce overproduction and underproduction. Improving capacity utilization requires dynamically adjusting resources to suit fluctuations in demand. Effective capacity planning guarantees that organizations can respond promptly to market changes without overburdening their resources or experiencing stock shortages.

4. Outsourcing and Partnerships

Collaboration with third-party manufacturers enables organizations to manage surplus demand without making substantial capital investments, which is especially useful during peak periods. Partnering with other manufacturers allows you to quickly scale operations while reducing the costs associated with developing internal manufacturing capabilities.

Challenges in Managing Production Capacity

Managing production capacity presents its own set of issues, particularly when organizations seek to balance demand, resources, and external influences. If not addressed properly, these difficulties might result in inefficiencies and interruptions. Here are some of the main issues encountered with managing manufacturing capacity.

1. Demand Variability

Fluctuations in market demand are a significant concern for organizations because they can result in underutilization or overburdening of resources. When demand is unexpected, businesses may find themselves overproducing, resulting in surplus inventory, or underproducing, causing delays and missed opportunities. Maintaining a balance between production levels and market demand is critical for avoiding these inefficiencies.

2. Resource Constraints

Limitations in machinery, skilled personnel, or raw materials might limit a company’s ability to expand its capacity. These limits become more difficult during moments of unexpected demand surges. Without the proper resources, firms may struggle to satisfy market demands, resulting in missed deadlines or quality difficulties that can hurt a company’s brand and bottom line.

3. Supply Chain Disruptions

External factors like supplier delays, transportation challenges, and geopolitical events can all have a significant impact on the timely availability of supplies, causing production delays. A disrupted supply chain can cause halted production processes, reducing a company’s ability to deliver on time and perhaps resulting in revenue loss owing to unfilled orders. Adopting GMP (Good Manufacturing Practices) ensures that businesses maintain quality control and compliance during supply chain disruptions, minimizing impacts on production and safety.

Best Practices for Effective Capacity Management

Effective capacity management is critical for ensuring that a company can satisfy market demand without overcommitting its resources. Companies that use best practices can optimize their production processes, increase productivity, and be better equipped to tackle problems. The following are some of the major tactics that firms should implement to improve their capacity management.

1. Continuous Improvement

Developing a culture of continuous improvement entails regularly assessing manufacturing processes to discover areas for improvement. Businesses may remain competitive and adaptable to changing market needs by being proactive in analyzing workflows and implementing new technology, assuring continuing efficiency and reduced waste.

2. Employee Training

Proper training is critical for increasing production capacity. Ensuring that personnel stay up to date on the newest technology and processes allows them to execute their jobs more efficiently. Well-trained employees can better manage complicated systems and boost productivity, resulting in higher manufacturing output.

3. Data-Driven Decisions

Using analytics to monitor production performance gives firms real-time data, allowing them to make more educated decisions. Companies can maximize capacity and resource utilization by finding areas for improvement via data analysis, assuring efficient and cost-effective manufacturing.

4. Flexible Strategies

In a constantly changing market, establishing adaptable strategies is critical. Businesses can efficiently manage production capacity by adapting swiftly to variable demand, unexpected disruptions, or supply chain concerns. This versatility means that firms may continue to operate smoothly even when faced with unexpected problems.

Enhance Your Production Capacity with ScaleOcean’s Manufacturing Software

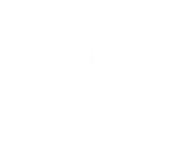

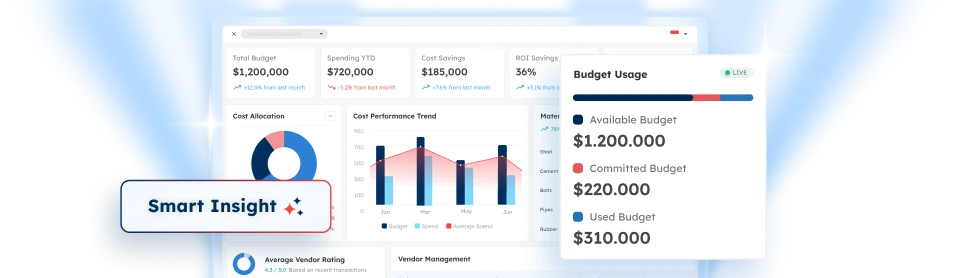

Enhancing production capacity is critical for organizations that want to remain competitive and meet client demand efficiently. ScaleOcean’s manufacturing software provides a comprehensive solution for streamlining production operations and optimizing output. ScaleOcean’s primary features include Manufacturing Resource Planning (MRP), cost management, order management, and warehouse management, allowing organizations to optimize every area of their operations.

These solutions deliver real-time data insights, automate mundane operations, and assist firms in better resource allocation, resulting in increased production and growth. To see firsthand how ScaleOcean may improve your production capacity, we provide a free demo to assist you explore the system’s potential. Furthermore, enterprises in Singapore might qualify for CTC subsidies while installing ScaleOcean’s ERP system. Here are the USPs of ScaleOcean software.

- Manufacturing Production Scheduling, This feature allows companies to plan production schedules based on demand forecasts, helping optimize production performance and improve customer satisfaction.

- Multilevel BOM (Bill of Materials), With multilevel BOM support, companies can plan material requirements more thoroughly, ensuring that the necessary materials for production are available according to plan.

- Module Integration, The production module can be directly integrated with other modules like Purchasing, Inventory, and Accounting, enabling more coordinated workflows, reducing the risk of material shortages, and optimizing procurement processes.

- Manufacturing Gantt Chart Schedule Management, Helps in planning and managing production schedules using a Gantt chart, ensuring resources like machinery and labor are allocated efficiently.

- Real-time Production Data, With features like Kiosk Mode and IoT integration, businesses can monitor production status in real-time, enhancing visibility and control over production capacity.

Conclusion

Optimizing production capacity is critical to the success of any manufacturing organization. Businesses must adapt to changing market conditions as the industry faces increased expectations for efficiency, operational scalability, and competitive advantage. Maximizing production capacity promotes smoother operations, lower costs, and the ability to meet client needs quickly, which is crucial for long-term success. Companies who do not optimize their production processes risk falling behind in today’s fast-paced, competitive world.

To remain competitive and increase production capacity, firms should implement innovative technologies such as ScaleOcean’s ERP system. ScaleOcean enables enterprises to optimize production scheduling and resource allocation by connecting processes, automating workflows, and providing real-time visibility, resulting in increased efficiency and sustainable growth. ScaleOcean’s Manufacturing ERP is intended to streamline processes and increase productivity, enabling firms to stay ahead of the competition. Learn more about how our software can transform your manufacturing processes on our product page.

FAQ:

1. What is meant by production capacity?

Production capacity is the maximum volume of goods and materials a company can produce within a given period, factoring in time, labor, resources, and machinery. It defines the limit of production output under normal operating conditions, helping businesses optimize their resources and plan effectively.

2. How is production capacity measured?

Production capacity is measured using methods such as machine-hour capacity, throughput time, and capacity utilization rate. Machine-hour capacity represents the total machine hours available for production, while throughput time refers to the duration required to produce a product. The capacity utilization rate compares actual output to the maximum output possible, expressed as a percentage.

3. How to calculate productivity capacity?

Productivity capacity can be calculated using the capacity utilization formula: Capacity Utilization Rate = (Actual Output / Maximum Possible Output) ×100. This formula helps determine the efficiency of production by comparing the actual output against the potential maximum output.

4. What is the meaning of production capability?

Production capability refers to a company’s ability to produce goods in line with market demand while considering available resources. It involves assessing the company’s potential to meet customer orders within given constraints, ensuring that production processes are efficient and aligned with business goals.

PTE LTD..png)

.png)

.png)

.png)

.png)