Singapore has emerged as a key global manufacturing hub, thanks to its modern infrastructure, solid regulatory environment, and commitment to innovation. Maintaining efficient and cost-effective production processes is critical for remaining competitive in this dynamic market, which includes industries such as electronics and pharmaceuticals.

The Bill of Materials (BOM) is an essential document that offers a detailed breakdown of all raw materials, components, and subassemblies required to manufacture a finished product. By serving as a thorough blueprint, BOM allows manufacturers to streamline procurement, optimize inventory management, and improve production planning, resulting in increased efficiency and lower operational costs.

- Bill of materials is a key document listing all materials and components needed for production, ensuring smooth workflows and cost efficiency.

- Types of BOM include engineering, manufacturing, sales, and service BOMs, each serving different roles in design, production, sales, and maintenance.

- Creating a good BOM requires identifying product requirements, using BOM software, collaborating with teams, and reviewing regularly for accuracy.

- ScaleOcean is comprehensive manufacturing software streamlining BOM management, integrating real-time inventory, and improving production efficiency for manufacturers.

1. Definition of Bill of Materials (BOM)

A Bill of Materials (BOM) is a structured and comprehensive document that lists all the raw materials, components, subassemblies, and parts required to manufacture a finished product. It functions as the foundation of the production process, ensuring that every necessary item is identified, sourced, and available when needed.

Acting as a blueprint for manufacturing, a BOM specifies not only the materials but also their quantities, descriptions, and relationships within the final product. It helps manufacturers maintain accuracy, avoid production delays, and streamline inventory control. Whether for assembly manufacturing of complex machinery, producing consumer electronics, or manufacturing pharmaceuticals, a well-organized BOM ensures smooth production workflows, cost efficiency, and minimal waste.

2. Importance of BOM in Manufacturing

In today’s industry, efficiency and precision are critical to being competitive. A Bill of Materials (BOM) is essential for guaranteeing efficient production operations since it provides a clear and structured overview of all necessary materials and components. Without a precise bill of materials, firms risk production delays, material shortages, and cost inefficiencies.

Additionally, an inaccurate BOM can lead to miscalculations in manufacturing overhead, increasing unnecessary costs and reducing profitability. Businesses that properly manage their BOMs can optimize production planning, streamline inventory control, and ensure accurate cost estimation, all of which lead to increased operational efficiency and profitability.

a. Production Planning

An effective BOM serves as a road map for production teams, detailing material requirements to schedule production runs and allocate resources efficiently. Incorporating takt time and demand planning ensures that components are available before production begins, reducing downtime and increasing workflow efficiency.

b. Inventory Management

Maintaining an appropriate inventory balance is critical for cost-effective manufacturing. A well-structured BOM assists producers in tracking material usage, preventing overstocking, and reducing waste by ensuring that only the required quantities are acquired and stored.

By combining BOM with an inventory management system, firms can automate stock monitoring, avoid production halts due to stockouts, and reduce wasteful storage expenditures. This also helps optimize product capacity, ensuring efficient use of resources and better production planning.

c. Cost Estimation

A bill of materials (BOM) gives a complete analysis of material costs, allowing producers to accurately forecast production charges before beginning the manufacturing process. Accounting for all materials, components, and subassemblies allows organizations to anticipate overall manufacturing costs, develop suitable pricing strategies, and identify cost-cutting opportunities. Furthermore, an accurate BOM enables procurement teams to negotiate better supplier arrangements and optimize spending, resulting in increased profitability.

3. Types of BOM

Different stages of the manufacturing and sales processes necessitate different types of Bills of Materials (BOM) to ensure seamless operations. A bill of materials (BOM) is not a one-size-fits-all document; rather, it is adapted to certain company operations such as product design, manufacturing, sales, and after-sales service.

Understanding the variances of BOM enables businesses to increase productivity, eliminate errors, and improve departmental communication. The four most common forms of BOMs used in manufacturing and related activities are listed below.

a. Engineering BOM (EBOM)

An Engineering BOM (EBOM) is developed during the product design process and focuses on the product’s technical requirements. It outlines the components, materials, and subassemblies based on engineering drawings and design papers.

EBOMs are often created using CAD or PLM software to ensure that every detail meets engineering standards. Because EBOMs primarily serve design and development teams, they frequently include prototype components, alternative materials, and numerous modifications before being approved for production.

b. Manufacturing BOM (MBOM)

A Manufacturing BOM (MBOM) outlines all parts, assemblies, and raw materials required to produce the finished product. Unlike EBOM, MBOM converts engineering concepts into production-ready formats. It ensures compliance with GMP guidelines for production, ensuring quality and consistency.

The MBOM also contains information regarding procurement sources, assembly instructions, and workstations, which ensures that the manufacturing process operates smoothly and efficiently. To further enhance production efficiency, many businesses integrate MBOM with the best manufacturing execution system Singapore offers, allowing real-time tracking and process automation for optimized workflow management.

c. Sales BOM

A Sales Bill of Materials (BOM) is used when products are sold as kits, bundles, or packages rather than individually. This sort of BOM specifies the components included in a sale while ensuring that inventories and pricing are properly controlled.

For example, in the electronics business, a laptop package may include a charger, protective case, and external mouse, all of which are specified on the Sales BOM. Unlike EBOM and MBOM, which are used for production, Sales BOM is primarily utilized by sales and customer service teams to assure correct product offerings and pricing structures.

d. Service BOM

A Service BOM (or Maintenance BOM) is designed specifically for after-sales support, repairs, and maintenance services. It identifies all of the spare parts and components needed to service or repair a product, allowing service technicians to swiftly access and replace damaged parts.

Automotive, aerospace, and industrial equipment industries rely significantly on Service BOMs to keep products running well and extend their lives. A precise Service BOM improves maintenance efficiency, supports work in progress, saves downtime, and increases customer satisfaction by guaranteeing that the correct parts are accessible when needed.

4. Structure of a BOM

A Bill of Materials (BOM) structure defines how materials, components, and subassemblies are organized within a product. A well-structured BOM, along with an effective requirement material plan, ensures clarity in manufacturing, procurement, and inventory management, preventing inefficiencies.

The structure of a BOM follows a logical hierarchy, detailing the relationships between different components and how they contribute to the final product. Depending on the complexity of the product, BOMs can be organized in a single-level or multilevel format.

a. Hierarchical Organization

According to Fractory, a Bill of Materials (BOM) is organized hierarchically, like a pyramid, with the finished product at the top and subassemblies and individual components following as the hierarchy descends.

This hierarchical system enhances production clarity by allowing teams to trace dependencies, manage inventory, and identify essential components throughout the assembly process. By combining materials, manufacturers can better manage production workflows, streamline procurement, and eliminate assembly errors.

b. Single-Level vs. Multi-Level BOM

A single-level BOM solely includes the direct components needed to create a finished product, without any subassemblies or lower-level dependencies. This format is straightforward to manage, but it may not be adequate for complex items that require numerous assembly phases. In contrast, a multi-level BOM contains a complete analysis of all components, including subassemblies, intermediate materials, and raw materials.

This framework improves production transparency, allowing producers to trace materials throughout the process and better manage dependencies. While multi-level BOMs necessitate more thorough documentation and management, they are critical for businesses that manufacture complex items such as electronics, equipment, and automobiles.

5. Components of a BOM

An advanced Bill of Materials (BOM) should include a BOM level to describe its hierarchy, phase tracking for product lifecycle phases, and alternate parts to avoid supply chain interruption. These features help producers stay efficient and on schedule, transforming the BOM into a strategic tool.

a. Part Number

To distinguish between materials, each component in a BOM is allocated a unique identification or part number. This numbering method helps to avoid misunderstanding when a company’s inventory contains many copies or variations of a part. It also facilitates ordering, tracking, and inventory management, allowing production teams to find the right components fast and without delay.

b. Part Name

The part name assigns a descriptive description to each component, making it easier for teams from various departments to identify and refer to specific elements. This avoids confusion and ensures that the correct parts are chosen for production. Clear and consistent part names also help with inventory categorization, making it easier to sort and locate components when needed.

c. Quantity

The quantity element in a BOM indicates the exact number of units needed for each component to generate the finished product. This information is crucial for procurement teams to order the appropriate quantities, avoiding both shortages that could delay production and excess inventory that could result in excessive storage expenditures. Furthermore, proper quantity tracking improves material planning and cost control, ensuring that manufacturing remains efficient and cost-effective.

d. Unit of Measure

A BOM provides the unit of measurement (UOM) for each component, which could be pieces, kilos, meters, or liters. Standardizing units provides consistency in material computations and streamlines procurement processes when ordering from numerous sources. This information helps to minimize misinterpretations that could result in improper material quantities being purchased or used in manufacturing.

e. Supplier Information

A BOM frequently includes supplier information, such as vendor name, part source, and lead time, to aid easy purchase. With this information readily available, producers can immediately replenish goods, compare pricing, and assess supplier performance. Reliable supplier data also reduces the risk of supply chain disruptions by ensuring that vital products are available when required.

6. Why is an Effective BOM Important?

A Bill of Materials (BOM) is more than a list; it’s a strategic document that directly impacts manufacturing efficiency, cost, and product quality. Manufacturers who do not have a well-structured and accurate BOM risk experiencing material shortages, production delays, and cost overruns.

A successful BOM guarantees that the correct materials are available at the appropriate moment, eliminating inefficiencies and errors throughout the plan of manufacturing process. The following are some of the most important reasons why firms need a well-organized BOM.

a. Reducing Production Errors

A thorough and accurate BOM prevents errors in material selection, ensuring manufacturers use the correct components, especially in a make-to-order production. This reduces defective goods, wasted resources, and rework, maintaining consistency and minimizing risks to customers.

b. Enhancing Operational Efficiency

A well-structured BOM improves manufacturing efficiency by outlining material requirements and assembly stages. When production teams are given clear instructions, they may work more efficiently, reduce downtime, and optimize resource allocation. This also helps procurement teams arrange purchases on schedule, avoiding last-minute delays and guaranteeing seamless operations.

c. Facilitating Team Collaboration

A bill of materials (BOM) acts as a centralized reference point for numerous departments, such as engineering, procurement, and production. When all departments use the same precise BOM, misunderstanding is reduced and cooperation increases. Engineering teams can guarantee that product designs are compatible with available materials, whilst manufacturing teams can perform assembly more accurately.

7. How to Create a Good Bill of Materials

A Bill of Materials (BOM) forms the foundation of an effective manufacturing process, ensuring accurate documentation and control of all necessary components. A badly organized BOM can result in material shortages, manufacturing delays, and cost inefficiencies. To avoid these challenges, organizations must take a systematic approach to building and maintaining their BOM. The following are critical steps for creating an effective BOM.

a. Identifying Product Requirements

The first step in establishing a BOM is identifying all components, raw materials, and subassemblies needed for the product. This includes part numbers, quantities, and units of measurement. Additionally, calculating cycle time helps optimize production, avoiding delays and ensuring smooth manufacturing.

b. Using BOM Software

Manually managing a BOM increases the likelihood of errors, version mismatches, and inefficiency. Using BOM software automates the creation, updating, and tracking of materials, assuring data correctness. Integrated ERP or inventory management systems can boost productivity by connecting BOM details to procurement, costing, and stock levels.

c. Involving All Stakeholders

Engineering, manufacturing, procurement, and inventory management teams should collaborate to create a BOM, ensuring alignment across departments. Collaboration reduces confusion, guarantees material availability, and optimizes costs. When all stakeholders agree on the BOM structure, manufacturing processes become more efficient and predictable.

d. Conducting Regular Reviews

Manufacturers must regularly update a Bill of Materials (BOM) to reflect design changes, material substitutions, and supplier updates. Periodic reviews help to maintain correctness, avoid outdated requirements, and assure manufacturing uniformity. Keeping the BOM up to date reduces costly errors and promotes efficient decision-making in the long run.

8. Examples of BOM Application in Singapore’s Industry

In Singapore’s diversified manufacturing industry, the Bill of Materials (BOM) is critical to maintaining efficiency, accuracy, and compliance across industries. Firms across industries, including electronics, pharmaceuticals, and logistics, use BOMs to simplify manufacturing, manage inventory, and comply with regulations. Below are key examples of BOM applications in different sectors.

a. Electronics Companies

Singaporean electronics manufacturers, especially in IoT and semiconductors, use Bill of Materials (BOMs) to manage complex components and ensure precise assembly. A well-structured BOM helps track microchips, circuit boards, and sensors, ensuring compliance with design and industry standards. Furthermore, BOMs allow manufacturers to purchase materials from multiple sources while ensuring quality and uniformity.

b. Pharmaceutical Companies

Pharmaceutical manufacturers must adhere to stringent regulatory criteria, including the Indonesian Food and Drug Administration (BPOM) and international GMP (Good Manufacturing Practice) standards. A BOM assures that every ingredient, chemical compound, and packaging material used in drug manufacture is properly documented and traceable. This degree of detail is useful for quality control, regulatory audits, and preserving batch uniformity in drug production.

c. Logistics Companies

BOMs play a crucial role in logistics and supply chain management by tracking spare parts and maintenance inventory for fleets and warehouse equipment. By listing essential components like engine parts, tires, and sensors, logistics firms can prevent stockouts, streamline procurement, and minimize equipment downtime. This assures continuous operations and reduces disruptions in the delivery and distribution processes.

9. ScaleOcean: Manufacturing Software Solution for Easier BOM Management

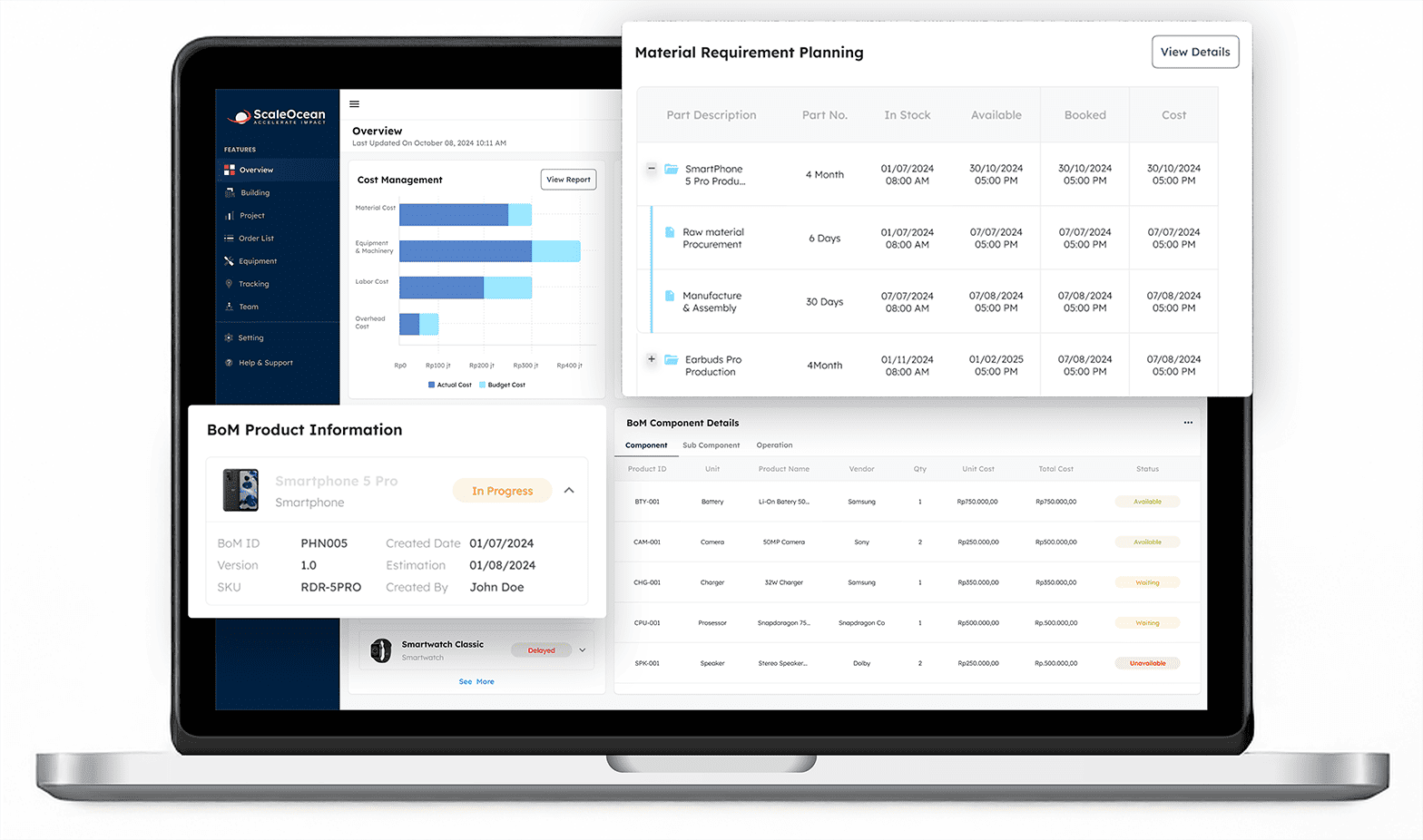

Managing a Bill of Materials (BOM) can be a difficult and time-consuming operation, particularly for manufacturers dealing with multi-level assemblies, changing product designs, and supply chain dependencies. Businesses that do not have an effective system run the danger of errors, delays, and departmental miscommunication. ScaleOcean provides a comprehensive manufacturing ERP solution that streamlines BOM management, ensuring accuracy, productivity, and seamless integration throughout operations.

With a free demo, manufacturers can explore how the system automates BOM procedures, optimizes inventory control, and improves communication. By offering user-friendly tools and advanced automation, ScaleOcean simplifies BOM management, helping organizations eliminate production errors, save time, and enhance overall efficiency.

a. Key Features

Managing a Bill of Materials (BOM) requires more than basic tracking—it demands automation, real-time data sync, and seamless collaboration. ScaleOcean streamlines BOM management, reducing manual effort and ensuring accurate material tracking for improved efficiency.

- Automated BOM Creation and Management, ScaleOcean simplifies the BOM creation process, eliminating the need for manual data entry. The system ensures accuracy by automatically updating material lists, reducing errors, and saving valuable production time.

- Inventory and Procurement System Integration, With real-time integration, businesses can sync BOMs with inventory and procurement modules, ensuring materials are always available when needed.

- Support for Multi-Level BOMs for Complex Products, For manufacturers dealing with intricate product structures, ScaleOcean’s multi-level BOM feature provides a detailed breakdown of components and subassemblies.

b. Local Advantages

ScaleOcean, built for Singapore firms, goes beyond traditional ERP systems to address local manufacturing challenges. From regulatory compliance to localized support, it enables a seamless shift to automation without added complexity.

- Singapore-Based Support Team, Our dedicated local support team ensures fast response times, personalized assistance, and in-depth understanding of Singapore’s business landscape.

- Competitive Pricing with Government Subsidies, ScaleOcean offers affordable pricing, making advanced BOM management accessible to businesses of all sizes.

10. Conclusion

A well-structured Bill of Materials (BOM) is vital for precise production planning, efficient inventory management, and cost savings. An effective BOM helps manufacturers eliminate errors, enhance collaboration, and streamline processes for greater efficiency and profitability. Studies show that a well-managed BOM can boost production efficiency by up to 25%, highlighting its critical role in modern manufacturing.

To reap the full benefits, producers require a sophisticated and automated BOM management solution. ScaleOcean streamlines BOM development, interacts smoothly with inventory and procurement, and maintains accuracy throughout the production process. Begin using ScaleOcean today and discover a more effective method to manage BOMs! Request a free demo today to see how automation can transform your production process.

PTE LTD..png)

.png)

.png)

.png)

.png)