The key component of a successful and competitive company is an accurate manufacturing cost estimate. Manufacturing cost estimating software streamlines this critical process by providing precise calculations for materials, labor, and overhead costs.

Designed for efficiency, implementing this system is important to help businesses avoid costly miscalculations, optimize pricing strategies, and improve overall profitability.

According to a recent report, companies that utilize advanced manufacturing cost estimation software can reduce their production costs by up to 30% compared to those relying on traditional methods.

These solutions provide accurate forecasts by integrating advanced tools and data analytics, allowing manufacturers to make informed decisions and stay ahead in a competitive market.

Understanding and implementing costing software for manufacturing has become a crucial requirement in today’s fast-moving industry. Whether you’re aiming to boost efficiency or secure a competitive pricing advantage, this software equips you with the essential tools. Learn more here!

- Manufacturing cost estimating software calculates accurate costs for materials, labor, and overhead, optimizing pricing strategies and improving profitability.

- Key features of manufacturing cost estimating software include production planning, real-time cost tracking, BOM management, and integrated reporting tools, all designed to enhance operational.

- The importance of a manufacturing cost estimating system is can improve cost and profitability analysis, optimize pricing, and streamline inventory management.

- Examples of manufacturing cost estimating tools are ScaleOcean, Costimator, Sage Estimating, Controlata, EasyKost, CostPerform, and Proest.

- ScaleOcean’s Manufacturing Cost Estimating Software offers tailored manufacturing industry specific, including real-time cost management and resource planning, to support operational performance.

What is Manufacturing Cost Estimating Software?

Manufacturing cost estimating software enables businesses to generate precise and comprehensive estimates by automating calculations, monitoring real-time material and labor expenses, and analyzing past data.

Manufacturing cost estimating software helps companies calculate accurate product and service costs. It analyzes all cost factors, including raw materials, labor, overhead, and production-related expenses. Using the absorption cost method, it allocates fixed costs across all products for precise pricing.

The software ensures precision, streamlines budgeting, and optimizes resource allocation by integrating real-time data. Its advanced analytics enable manufacturers to forecast costs effectively, reduce errors, and maintain competitive pricing strategies.

Designed for businesses of all sizes, this software empowers companies to make informed decisions, enhance profitability, and meet market demands in an increasingly dynamic manufacturing environment.

Key Features of Manufacturing Cost Estimating Software

The manufacturing cost estimate system is designed to streamline the process of calculating and tracking the various costs involved in production. Automating critical functions helps manufacturers improve accuracy, save time, and make more informed decisions.

Below are some of the key features of these systems that enhance operational efficiency.

1. Automated Cost Calculation

This feature automates the process of calculating costs based on the bill of materials, labor rates, and overhead expenses. Removing manual inputs reduces the chances of human errors and speeds up the estimation process, ensuring a more reliable and consistent cost estimate for every project or product.

2. Real-time Material Pricing

A manufacturing cost estimate system integrates with suppliers to provide real-time material pricing, especially during the stages of the product lifecycle. This ensures cost estimates reflect market fluctuations, helping manufacturers avoid surprises and maintain profit margins.

3. Labor Cost Tracking

Accurate labor cost tracking is achieved through detailed time tracking and rate management. It helps businesses calculate the labor costs for each stage of production by monitoring employee hours, overtime, and wages, ensuring that labor expenses are reflected in the cost estimate in real time and with precision.

4. Overhead Allocation

Overhead costs, such as utilities, rent, and administrative expenses, can be allocated across multiple products using different allocation methods. To effectively manage this process, it’s essential to understand overhead costs and choose the right allocation methods for your business.

The software automatically distributes these costs based on predefined rules, helps manufacturers assign accurate overhead to each product, and improves overall cost visibility and financial analysis.

5. Historical Cost Analysis

Manufacturing cost estimate software enables businesses to access historical cost data, providing insights into past production costs. This feature helps identify cost trends over time, allowing manufacturers to refine their estimating processes, optimize resource allocation, and improve the accuracy of future cost projections.

6. Profit Margin Analysis

With built-in profit margin analysis tools, the software instantly calculates profit margins based on estimated costs and target prices. It ensures that manufacturers can assess the financial viability of a project or product early in the process, enabling better decision-making on pricing and production strategies.

7. Customization

Many manufacturing cost estimate system programs offer customization options to meet the specific needs of a company.

Customization in Singapore manufacturing ERP system includes adjusting for unique production processes, adding specific costing models, or integrating with existing ERP or supply chain systems, providing flexibility and tailored solutions for different business types.

Why Manufacturers Need Cost Estimating Software

Manufacturing cost estimating software plays an important role in the production process by providing precise cost calculations. This accuracy is essential for determining competitive pricing strategies, ensuring budgets are allocated efficiently, and maintaining consistent profitability.

As businesses adapt to manufacturing trends, implementing a manufacturing cost estimate system can also ensure that companies stay competitive and responsive to market changes.

By automating cost analysis, the top manufacturing execution system in Singapore helps businesses minimize errors, optimize resource allocation, and improve decision-making, ultimately strengthening their competitive edge.

This enables businesses to enhance efficiency and maintain a strong competitive advantage in the market while minimizing costly errors and improving overall financial performance.

Benefits of Manufacturing Cost Estimating Software

A manufacturing cost estimating system enhances cost management by automating complex calculations, tracking real-time data, and offering insights from historical trends. It also keeps manufacturers aligned with the latest manufacturing industry trends for more informed decision-making.

Here are the key benefits of implementing manufacturing cost estimating software, including:

1. Improve Cost and Profitability Analysis

Accurate cost tracking helps manufacturers determine profit margins and avoid financial inefficiencies. A manufacturing costing software provides real-time insights into direct costs, manufacturing overhead, and other expenses, ensuring transparent financial reporting.

With better cost analysis, businesses can optimize resource allocation and improve overall profitability.

2. Optimize Pricing and Quoting Processes

Setting competitive selling prices requires precise cost calculations. By integrating a manufacturing accounting system, companies can automatically factor in labor, materials, and manufacturing overhead when generating quotes.

This ensures pricing accuracy, reduces financial miscalculations, and enhances customer trust with faster, more reliable quotations.

3. Streamline Inventory and Order Management

Managing stock and production schedules efficiently is crucial to meeting customer demand. Material requirement planning (MRP) ensures that the right materials are available at the right time, preventing production delays.

With automated inventory tracking and real-time purchase order management, businesses can reduce excess stock and minimize supply chain disruptions.

So, Smart factory examples show how advanced automation and real-time data integration can further optimize inventory and order management, improving efficiency and reducing waste.

4. Enhance Financial Planning and Forecasting

Having real-time visibility into COGM, COGS, and cash flow enables better financial decision-making. The manufacturing cost estimation software helps businesses predict cash shortages and plan budgets more effectively, reducing financial risks.

With accurate forecasting, companies can optimize cost allocation and maintain financial stability. Understanding the importance of Cost of Goods Sold (COGS) is crucial in this process, as it directly impacts profitability and helps refine budgeting for better financial management.

5. Ensure Timely Follow-Ups and Order Tracking

Tracking customer orders from quotation to delivery ensures smoother operations and a better customer experience. Automated follow-ups help businesses stay on top of pending quotations, increasing sales opportunities.

With a clear production and delivery pipeline, companies can improve on-time delivery rates and maintain high customer satisfaction.

Challenges of Implementing Manufacturing Cost Estimating System

While a manufacturing execution system has many advantages, it also has several challenges that companies must overcome in order to make the best use of it. Below are the common challenges and their implications.

1. Data Accuracy

The manufacturing costing software relies on accurate data inputs. Incorrect or outdated information can lead to flawed estimates, affecting pricing and profitability. By understanding methods of manufacturing, businesses can implement better data management practices to ensure reliable results and avoid costly errors.

2. Integration

Integrating the software with existing systems, such as ERP or CRM platforms, can require technical expertise and resources. Compatibility issues may arise, leading to delays or additional costs. Proper manufacturing process planning and professional support are essential to ensure seamless integration and system efficiency.

3. User Training

Effective use of the manufacturing cost estimation software requires training for employees. Without proper knowledge, staff may struggle to utilize the tool’s features, limiting its potential benefits. Businesses should invest in comprehensive training programs to provide their employees with the skills required for effective software use.

7 Examples of Manufacturing Cost Estimating Systems and Tools

When seeking the best manufacturing cost‑estimating software, it is essential to compare solutions based on their definition, core functions, standout features, and the practical advantages and limitations each offers.

These vendors can help business owners identify tools aligned with operational needs, ensuring accurate cost estimation, stronger pricing strategies, and improved profitability. Below are detailed profiles of six prominent software options. Learn more here!

1. ScaleOcean

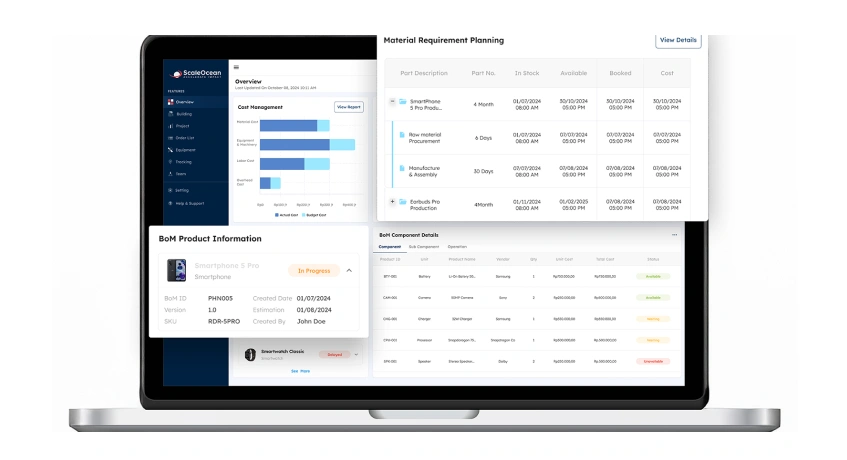

ScaleOcean ERP is a solution designed to increase manufacturing efficiency, lower costs, and streamline operations. With real-time data integration and intuitive tools, it helps businesses make more informed decisions while easily aligning with existing processes.

ScaleOcean offers an all-in-one solution with comprehensive modules that can be tailored to business needs. It allows companies to select and integrate various manufacturing functions and processes, from financial management, logistics, and distribution to HR, into one centralized system.

Scaling up or streamlining workflows often requires tools that can adapt to evolving business needs. ScaleOcean Manufacturing Costing Software also provides real-time insights through its complete transparency and control (CTC) features, allowing businesses to make informed decisions at every stage.

To better understand how this system fits your operations, consider scheduling a free demo to explore its benefits in action.

Key Features:

- Cost Management: Automated cost of goods manufactured calculations and highly accurate production cost monitoring.

- Smart MRP: Automated calculation of required raw materials based on production schedules and lead times.

- BOM Management: Automatically generates lists of raw materials, components, and subcomponents required for production.

- Order Management: Automated receipt and ordering, allowing for real-time production cost calculations.

- SCM Integration: Management of the entire manufacturing process in a single, centralized platform, allowing cost information to be directly linked to ongoing production data.

ScaleOcean has been successfully implemented in many companies with various specific industries, one of which is the Sobono Group, established in 2007 and based in Singapore, which is a privately-owned regional provider of clean energy solutions.

The company specializes in renewable energy, with a focus on waste-to-energy (biomass/biogas manufacturing), engineering (EPC), and circular economy initiatives. Sobono uses ScaleOcean’s integrated solution, which allows them to more easily monitor all operational aspects, such as inventory, projects, and budgets, in real time.

Furthermore, centralized data visibility allows the Sobono Group team to automatically compare planned costs with actual costs, identify variances, and reduce the risk of waste and unexpected costs. To learn more about the full case study, watch the following video:

| Pros | Cons |

|---|---|

|

|

Best For: ScaleOcean is a system with industry-specific solutions for medium to large enterprises, ideal for any type of manufacturing process, offering a comprehensive, flexible, and cost-effective solution for managing operations. You can customize the system to best suit your specific business needs.

2. Costimator

Costimator is cost‑estimating and quoting software tailored for manufacturing. It enables companies to model production costs (machining, fabrication, sheet‑metal, etc.) by using pre‑loaded cost models or custom calibrations to generate reliable cost estimates and quotes.

Key Features

- Automated cost calculation from bills of materials.

- Cycle time and shop rate calculators.

- Integration with ERP systems.

| Pros | Cons |

|---|---|

|

|

Best For: Manufacturers operating CNC machining, sheet metal fabrication, or job shops seeking high accuracy and detailed quoting models specific to discrete production

3. Sage Estimating

Sage Estimating is a manufacturing cost estimating tool that can automate the estimation process, focusing on construction but adaptable for manufacturing. It integrates cost databases and provides quick and accurate cost estimates with automated takeoffs.

Key Features

- Digital takeoff tools for cost quantity extraction.

- Integrated trade‑specific cost databases.

- Scenario planning and bid‑day analysis.

| Pros | Cons |

|---|---|

|

|

Best For: Companies in mixed or heavy‑industry contexts already using Sage ecosystems, looking for structured estimating workflows and cost databases (though less manufacturing‑tailored).

4. Controlata

Controlata specializes in accurate cost estimation for manufacturing by integrating material costs, labor, and overhead. It provides visibility into production costs and helps optimize profit margins.

Key Features

- Real‑time material pricing updates.

- Cost allocation for multi‑level production.

- Overhead cost tracking.

- In-depth cost reporting and analytics.

| Pros | Cons |

|---|---|

|

|

Best For: Small to mid‑sized manufacturers needing real‑time cost tracking (materials, labour, overhead) and multi‑level BOM cost visibility across production.

5. EasyKost

EasyKost is the next manufacturing cost estimating tool that is designed with leverage AI to provide quick and accurate product cost estimates. It’s ideal for manufacturers looking for fast turnarounds and AI-powered analysis for pricing and budgeting.

Key Features

- Instant generation of cost proposals.

- Cloud-based with scalable options.

- Benchmarking tools for cost comparisons.

- Reverse engineering of cost structures.

| Pros | Cons |

|---|---|

|

|

Best For: product development and R&D teams requiring rapid costing, benchmarking, and modeling for new products or services.

6. CostPerform

CostPerform is an enterprise-level cost management software that helps manufacturing companies optimize their cost structures and improve profitability through detailed cost analysis and scenario modeling.

Key Features

- Activity-based costing (ABC) methods.

- Multi‑method cost modeling.

- Advanced profitability analysis.

- Scenario simulation for cost planning.

| Pros | Cons |

|---|---|

|

|

Best For: Companies that operate project‑based manufacturing or contracting where bid preparation, take‑offs, and cloud‑based collaboration matter more than discrete machine‑shop costing.

7. ProEst

ProEst is a cloud-based cost estimation tool primarily for construction firms but adaptable for manufacturing. It provides automated cost calculations, digital takeoffs, and project tracking features for improved estimating.

Key Features

- Integrated digital takeoff functionality.

- Historical data for past project cost insights.

- Reporting and analytics for estimate accuracy.

| Pros | Cons |

|---|---|

|

|

Best For: Companies that need advanced costing, profitability & capacity modelling across products, services or business units, with strong transparency.

Trends and Technologies in Manufacturing Cost Estimating

Technology trends in manufacturing cost estimation software have experienced significant development. By adopting the latest innovations, industries can improve efficiency and accuracy in calculating production costs. Here are some trends increasingly being applied in manufacturing cost estimation.

AI with Machine Learning and Predictive Analytics

AI technology combined with machine learning and predictive analytics enables cost estimation software to learn production patterns and provide more accurate predictions. This helps reduce the risk of unexpected costs and improve long-term budget planning.

Simulation-Driven

Software-based simulations enable testing of various production scenarios without the need for physical processes. This technology supports more informed planning, allowing companies to quickly and efficiently assess potential cost changes before implementation.

Digital Twins

Digital twins create digital copies of physical processes or equipment in a virtual world. With this modeling, companies can analyze operational performance and costs in real time, and make continuous improvements, optimizing production without direct intervention in the real world.

Real-Time Data Integration

Real-time data integration enables cost estimation software to directly access and process current data from machines or other systems. This improves the accuracy of cost estimates, accelerates decision-making, and enables rapid response to production changes.

You can use recommended manufacturing cost estimating tools that seamlessly cover all these trends and technologies, such as Scaleocean. You can request a free demo to discover solutions tailored to your specific business.

Conclusion

Manufacturing cost estimating tools are an important tool for improving accuracy, streamlining processes, and maintaining profitability. By providing insights into materials, labor, and overhead costs, it helps businesses optimize pricing, allocate resources & takt time, and stay competitive.

Despite challenges like data accuracy and integration, its benefits make it indispensable for modern manufacturers. ScaleOcean’s Manufacturing ERP provides a tailored solution designed to simplify and optimize manufacturing operations, from cost management to resource planning.

Its adaptable features ensure a seamless fit for businesses of any size. If you’re curious to see how ScaleOcean can support your business goals, exploring a demo could be a great next step.

FAQ:

1. How to estimate manufacturing costs?

In simple terms, the total manufacturing cost represents the total amount of money needed to produce a product. It is determined by adding up all expenses incurred during production, including the cost of direct materials, labor expenses, and other overhead manufacturing costs.

2. How to track manufacturing costs?

Step 1: Determine the cost of direct materials by using the direct material inputs. Step 2: Calculate direct labor costs by using the direct labor inputs. Step 3: Calculate manufacturing overhead by considering the overhead costs. Step 4: Calculate the total manufacturing cost (TMC) by adding the three cost components..

3. What are the three basic manufacturing costs?

The three primary types of manufacturing costs are direct materials, direct labor, and manufacturing overhead.

4. What is the biggest cost in manufacturing?

Labor is typically the largest cost in manufacturing. It includes wages, taxes, payroll, benefits, and additional expenses such as occupational injuries. It also encompasses costs from human errors, like defective products and wasted materials.

PTE LTD..png)

.png)

.png)

.png)

.png)