Last-mile delivery has become a crucial part of the logistics process, affecting everything from customer satisfaction to how smoothly businesses operate. With rising expectations for fast and reliable deliveries, optimizing this final stretch of transportation is essential for any business aiming to stay competitive.

In fact, according to Mordor Intelligence, standard delivery services held onto 52.34% of Singapore’s last-mile delivery market share in 2025. This shows the importance of cost-conscious habits and well-planned 1-to-3-day networks. These insights emphasize the need to focus on streamlining last-mile delivery for success.

So, in this article, we’ll unpack what Singapore last mile delivery really means, why it matters more than ever, and what solutions can help CEOs and operations teams tackle it head-on.

Whether you’re running a growing e-commerce platform or managing supply chain efficiency, understanding last-mile delivery service can be a serious game-changer.

- Last-mile delivery is basically the last leg of the journey for the supply chain, which is when a product leaves the warehouse or hub and heads toward the customer’s actual address.

- The delivery process includes order intake, sorting, dispatching, route planning, and proof of delivery, all of which must work seamlessly to avoid delays.

- Optimizing delivery requires real-time data, smart routing, flexible options, and a focus on cost-efficiency throughout the process.

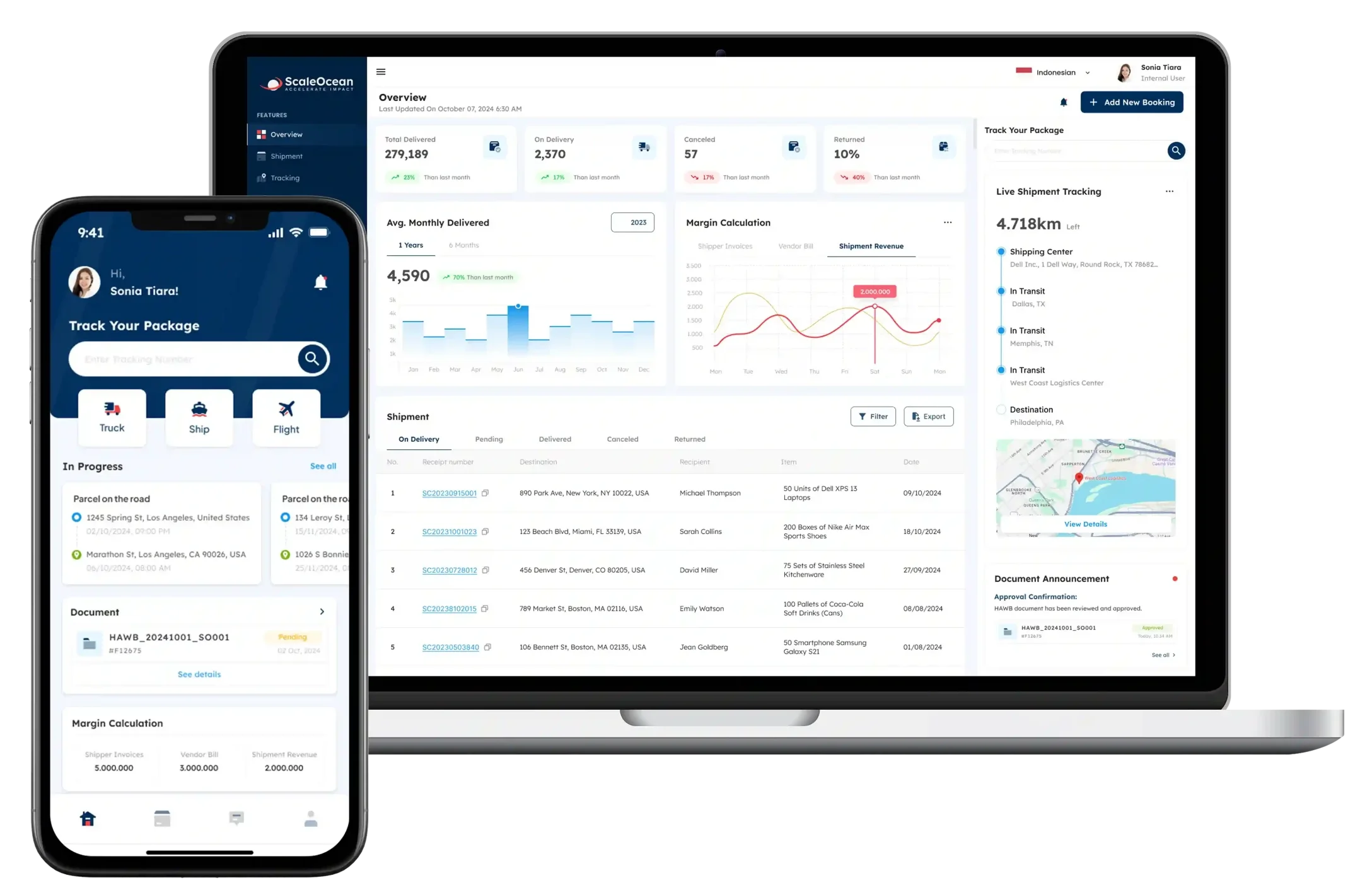

- ScaleOcean’s software helps overcome last-mile delivery issues by automating route planning, improving tracking, and enhancing delivery performance at scale.

What is Last Mile Delivery?

Last-mile delivery is basically the last leg of the journey for the supply chain, which is when a product leaves the warehouse or hub and heads toward the customer’s actual address. It might sound simple, but this final stretch of delivery is often where most of the pressure builds, especially when timelines are tight or areas are harder to reach.

When we define last-mile delivery, it’s not only about how far the package has to go. What really matters here is how fast and accurately it gets there, and whether the cost of doing so makes sense, particularly in busy city centers or more out-of-the-way places.

Why is Last Mile Delivery Important?

This is the part of the process that customers actually see. So if something goes wrong here, it sticks. Even if everything before that point ran smoothly, a late or failed delivery can quickly undo all that effort.

And from the business side, it’s not exactly cheap. In many cases, last-mile delivery ends up being the most expensive leg of the journey, often taking up more than half the total delivery cost, which is why companies spend serious time trying to get it right.

How Does the Last Mile Delivery Process Work?

The last-mile delivery process is the final leg of a product’s journey to the customer. This phase includes several steps, like sorting packages at local hubs and making sure everything is delivered on time. Since this step is key to customer satisfaction, optimizing it can significantly improve the overall delivery experience.

Let’s take a closer look at how the last-mile delivery process works:

Step 1: Order Entry & Arrival at the Local Hub

As soon as a customer places an order, it moves through the system and gets routed to a local hub. This is usually where the shift from long-distance shipping to local delivery starts to happen.

Once the package hits the hub, it’s scanned in, logged, and set up for the next leg of the journey. This part plays a big role in keeping delivery accuracy on track and cutting down on hold-ups.

Step 2: Strategic Sorting & Assignment

Packages are grouped based on things like area, urgency, and the type of service selected. The idea here is to sort in a way that limits errors and keeps things moving quickly.

After sorting, deliveries are matched with available drivers or vehicles nearby. That sort of smart assignment tends to help avoid wasted trips and makes better use of time on the road.

Step 3: Route Optimization & Dispatch

At this point, systems kick in to figure out the best possible routes for drivers, factoring in things like traffic or distance. These route plans can save a lot of time and hassle when done right.

Once everything’s mapped out, drivers get their dispatch instructions through mobile devices. Here, route optimization isn’t just about speed. It also helps keep fuel and labor costs manageable.

Step 4: Loading & Out for Delivery

Drivers then load their vehicles in a way that matches the order of deliveries on their route. It may sound small, but the way packages are loaded can make a big difference.

After loading up, the delivery run officially begins. The accuracy of loading can really affect how smooth or frustrating the rest of the route turns out to be.

Step 5: Final Drop-Off & Proof of Delivery (POD)

The driver reaches the customer and makes the final handoff attempt, which sometimes is straightforward, sometimes not. If the customer isn’t around, backup steps like a safe drop location or a later attempt come into play.

To close things out, a proof of delivery gets recorded, which could be a signature, a quick photo, or even a geotag. It’s just something to show the job’s done and accounted for.

What are the Common Challenges of Last Mile Delivery?

Last-mile delivery plays a crucial role in the logistics process, but it comes with several challenges. From high costs to the pressure of meeting customer expectations for real-time tracking, this final leg of the journey can be tricky.

Here are some of the key challenges of last-mile delivery:

High Delivery Costs

When it comes to last-mile delivery, the costs can add up quickly, including fuel, driver wages, and vehicle maintenance. With routes often having fewer delivery points, each stop can be more expensive than expected. These added costs can strain businesses trying to keep operations running smoothly.

Without proper planning or automation, costs can quickly spiral out of control. Customers now expect faster and more flexible delivery options, making it even harder for businesses to balance affordability with the need for efficiency.

Solutions:

- Optimize Route Planning: Implement route optimization software to reduce unnecessary mileage. This helps to save on fuel costs and improve delivery efficiency by selecting the shortest and least congested routes.

- Use Automation for Scheduling: Automating the scheduling and dispatch process reduces labor costs and ensures more efficient use of vehicles, allowing businesses to handle more deliveries with fewer resources.

Lack of Real-Time Tracking Visibility

Today’s customers want to know exactly where their package is and not just get a vague “out for delivery” notice. Without real-time tracking updates, businesses lose sight of where things stand, making it harder to fix problems as they arise. This lack of visibility can lead to dissatisfaction.

On the business side, real-time tracking helps managers keep an eye on schedules and spot delays early. This gives them the chance to address any issues before they grow, improving the process and ensuring smoother delivery for everyone involved.

Solutions:

- Implement Real-Time Tracking Systems: Use GPS and tracking software that provides live updates to customers and internal teams. This ensures visibility throughout the delivery process, helping both parties stay informed.

- Integrate with Customer Communication Tools: Combine real-time tracking with automated notifications via apps or SMS to keep customers updated on delivery status, reducing anxiety and improving satisfaction.

Optimizing Routes Amidst Congestion

City deliveries are often challenging, with traffic jams, road closures, and unexpected delays being common obstacles. If your routing system isn’t flexible enough, drivers can easily end up wasting time, which leads to inefficiency and unnecessary delays.

Real-time route optimization tools that adjust to traffic conditions make a big difference. This is especially true in places like Singapore, where congestion is a daily reality. With the right tools in place, businesses can reduce delays and ensure deliveries stay on schedule.

Solutions:

- Use Dynamic Traffic Data: Integrate real-time traffic data into your routing system to account for traffic jams, accidents, or road closures. This allows for dynamic rerouting to avoid congestion and improve delivery times.

- Plan Delivery Windows: Schedule deliveries during off-peak hours or in time blocks when traffic is lighter. This helps to minimize delays caused by congestion and ensures faster service.

Accommodating Custom Customer Requirements

Not all deliveries are simple drop-offs. Some customers request specific delivery times or need fragile items handled with extra care. Missing these important details can quickly result in a negative experience for customers and may affect the business’s reputation.

Being able to adapt to these special requests is key, especially when handling high-value items or serving business clients. Offering flexible delivery options helps businesses build stronger relationships with customers and keeps them coming back.

Solutions:

- Offer Flexible Delivery Options: Provide customers with a range of delivery windows, such as same-day, time slots, or specific dates, ensuring they can choose what works best for them.

- Implement Special Handling Instructions: Create a system where customers can easily specify special delivery needs, such as fragile item handling or specific delivery times, ensuring these requests are met without error.

Late Delivery

There are many reasons why deliveries can be delayed, whether it’s traffic, incorrect addresses, or warehouse delays, but every late delivery risks losing customer trust. Customers who expect quick service can easily become frustrated when delays happen, and that can damage a company’s reputation.

Late deliveries also put extra pressure on support teams who need to handle complaints and resolve issues. This creates more complexity and drives up operational costs, making it crucial for businesses to focus on meeting delivery deadlines to keep customers satisfied.

Solutions:

- Establish Backup Plans: Set up contingency plans for late deliveries, such as alternative routes or additional drivers, to avoid further delays. This helps to quickly adapt to unforeseen circumstances.

- Improve Communication with Customers: Notify customers promptly if there are delays and provide a clear timeframe for the delivery. Transparency reduces frustration and helps maintain customer trust.

Handling Reverse Logistics and Missed Drop-offs

Returns and missed deliveries are just part of the process, but they add an extra layer of complexity to the system. A missed drop-off can cause a ripple effect that disrupts the entire schedule. Businesses need to be prepared for these situations to avoid falling behind.

If businesses don’t have a solid system to handle returns or missed deliveries, they risk losing money and wasting valuable time. A smooth process for reverse logistics is crucial for maintaining efficiency and preventing bottlenecks in the supply chain.

Solutions:

- Create a Reverse Logistics System: Implement a streamlined process for returns, such as pre-paid return labels or designated return points, making it easier and quicker to handle product returns.

- Reschedule Missed Deliveries Quickly: Automate rescheduling for missed deliveries, ensuring customers can quickly choose another delivery time without hassle, reducing frustration and improving satisfaction.

The Logistics of Low-Density Remote Deliveries

Some areas are just tough to reach, whether it’s long drives, poor roads, or only one package to deliver. These types of deliveries are often inefficient, consuming more time and resources than they’re worth. Remote deliveries can easily impact profitability and stretch budgets thin.

Margins are particularly affected when there’s no way to consolidate deliveries or offset the costs of long, remote routes. Having a plan in place to manage these deliveries more efficiently helps businesses minimize costs while still meeting customer expectations.

Solutions:

- Group Deliveries for Remote Areas: Consolidate deliveries in remote areas to maximize delivery efficiency and reduce costs. Grouping multiple orders into one trip helps minimize fuel costs and time spent on the road.

- Use Local Hubs or Pickup Points: Set up local hubs or designated pickup points in remote areas to reduce the cost and complexity of delivering to sparsely populated locations. This allows customers to pick up packages at their convenience.

How to Optimize Last Mile Delivery

Optimizing last-mile delivery is essential to improving efficiency and keeping customers happy. It involves more than just getting packages from point A to point B. It’s about using smart systems, real-time updates, and customer-centric approaches to make each delivery as smooth as possible.

Here are the key strategies to optimize last-mile delivery:

Use the Best Logistics Software

ScaleOcean’s logistics software plays a practical role here. It gives logistics teams the tools to plan routes more efficiently, follow shipments in real-time, and ease that tricky gap from the hub all the way to the doorstep.

ScaleOcean software is also eligible for the CTC grant, making it a great investment for businesses looking to streamline operations. With the CTC grant, companies can claim up to 70% of the cost. Plus, ScaleOcean offers a free demo, allowing you to experience the benefits firsthand.

Tracking Systems and Real-Time Updates

Being able to show customers exactly where their package is makes a big difference. It often cuts down on unnecessary support calls and avoids those frustrating missed deliveries.

And with real-time updates, dispatchers don’t have to guess because they can step in fast, whether that’s rerouting a driver or giving a customer a heads-up before something goes wrong.

Cost Management Techniques

To keep costs under control, bundling orders together and applying smart pricing strategies are both useful. Predicting demand ahead of time also helps keep things running more smoothly.

Another approach that tends to work well is reviewing historical data, which helps you make better decisions around fleet utilization and future delivery patterns.

Customize Delivery Experience

Giving customers the choice to select time slots or leave specific delivery notes often leads to better satisfaction. It’s also a simple way to avoid second attempts, which eat up time and fuel.

Allowing people to customize deliveries might seem like extra work, but it actually streamlines operations, which results in less guessing and more successful drop-offs the first time around.

Flexible Pick-Up and Delivery Options

Click-and-collect locations, smart lockers, or even nearby partner stores. These alternatives are especially helpful in busy urban settings. They give people more control over how and when they receive orders.

Offering more delivery options tends to lower the risk of failed attempts and leads to smoother customer experiences, particularly in places like apartment complexes or tight delivery zones.

By implementing these strategies, you can optimize last-mile delivery and create a more efficient process. Also, ScaleOcean’s logistics software supports all these efforts by streamlining tracking, optimizing delivery routes, and managing costs, helping your business meet customer expectations effectively.

Trends of Last Mile Delivery Singapore

The last-mile delivery landscape in Singapore is rapidly evolving to meet customer demands for faster, more efficient services. As customer expectations grow, companies are adopting new strategies and technologies to stay competitive. These trends aim to reduce delivery times, increase convenience, and improve sustainability.

Here’s a closer look at the emerging trends of last-mile delivery in Singapore:

Multi-Warehousing for Localized Distribution

To move things faster, many companies are now setting up smaller warehouses that sit closer to where customers actually are. It’s a simple shift, but it helps cut down travel time and makes it easier to respond to local demand.

Last-mile delivery in Singapore efforts are leaning more into this kind of decentralised setup, especially with more people expecting same-day service now.

Crowdshipping Delivery Models

More businesses are testing out crowdshipping. Basically, using regular people or gig drivers to drop off packages. It’s a flexible way to handle short-range deliveries without needing a big fleet.

That said, crowdshipping only works well if there’s strong tech behind it to manage routing, payments, and updates in real time.

Green Logistics and Sustainability

What used to be a “nice to have” thing, like EVs, reusable packaging, and carbon-neutral delivery, is quickly turning into a must. Sustainability is becoming a central part of logistics planning, not just a marketing checkbox.

According to Apollo Reports, the Singapore last-mile delivery market was valued at $1,211.0 Million in 2022 and is projected to reach $2,639.6 Million by 2032, making it clear that demand for sustainable solutions is growing rapidly.

As pressure builds from both policy and consumers, sustainable delivery is something companies can’t really afford to put off anymore.

Micro-Fulfillment Centers

These are like mini warehouses tucked into cities, not massive spaces, but just enough to pack and ship common items quickly. The idea is to keep popular products close to the customers who need them.

By cutting down the distance traveled, micro-fulfilment makes it possible to do things like one-hour delivery in crowded areas.

Alternative Delivery Points

Instead of delivering straight to the doorstep, more companies are offering lockers, convenience stores, or retail counters as pick-up options. It gives the customer more say in when and how they get their stuff.

Using alternative delivery points also helps reduce failed drop-offs, which can really add up during peak shopping seasons.

Electronic Proof of Delivery (ePOD)

Digital tools like timestamps, signatures, and geo-tags are becoming standard to confirm a delivery’s been made. It’s especially helpful when customers raise issues or when something goes wrong.

On top of that, ePOD systems can provide data for reporting and help logistics teams catch bottlenecks or recurring delays.

Automation and AI in Route Planning

With AI, logistics teams can now adjust delivery routes in real time, which is depending on traffic, weather, or even customer habits. It’s not perfect, but it gets better the more data you feed it.

Adding AI-based automation into routing helps reduce fuel usage and late deliveries, which adds up over time.

24/7 Access to Parcels

Smart lockers and pick-up boxes are popping up more often in condos, malls, and even train stations. They’re solving one of the biggest issues, such as customers not being home during delivery hours.

By giving round-the-clock access, businesses avoid costly redelivery runs, and customers get more flexibility too.

Delivery by Driverless Vehicles

Robotic delivery systems are still in trial mode, which are like small autonomous vans or robots on sidewalks. But the early signs are promising, especially in closed environments like campuses.

Right now, driverless delivery is being tested in selected zones in Singapore, and it could be a major cost-saving shift down the road.

AI/Bot Assisted Planning

Machine learning is helping companies make sense of where deliveries fail, where returns spike, or when orders peak. It’s not about guessing anymore. It’s about data-backed planning.

Using AI-assisted planning gives teams a clearer view of what’s working, what’s not, and how to keep things moving more smoothly.

Conclusion

Last-mile delivery isn’t just a step in logistics. It’s where your brand meets the customer face-to-face, sometimes literally. It’s also the messiest, most expensive, and most emotionally charged part of the entire delivery experience. When it goes well, nobody notices. But when it doesn’t, everyone hears about it.

That’s why optimization matters, because it’s from software tools to route logic, and so the details make a difference.

With platforms like ScaleOcean logistics software, logistics teams can simplify complex processes, cut delivery costs, and elevate performance across the board. So for that reason, ScaleOcean also offers a free demo so that you can try it firsthand.

FAQ:

1. What does it mean that your package arrived at the last-mile delivery station?

This indicates that your package has reached the final station before delivery. It will now be sorted, loaded, and prepared for the final step to your address, and you can expect it soon, depending on the route and schedule.

2. What are the top 5 logistics service providers?

The leading logistics companies include DHL, FedEx, Japan Post Holdings, SF Express, and Kuehne + Nagel, known for their vast networks and reliability. ScaleOcean, however, offers similar flexibility and robust features, providing an integrated and customizable solution for last-mile and logistics operations.

3. Who delivers last-mile packages?

Last-mile deliveries are made by various carriers, including postal services, courier companies, e-commerce delivery teams, and gig drivers. These entities are responsible for the crucial step of getting packages from local hubs to customers’ doorsteps.

4. How long does last-mile delivery take to arrive?

Last-mile delivery times typically range from same-day to next-day delivery, once the package reaches the local station. The actual time can vary depending on factors like route planning, driver availability, and local demand.

PTE LTD..png)

.png)

.png)

.png)

.png)