Construction asset management (CAM) is critical for improving operations, lowering costs, and extending asset life cycles. It guarantees that equipment, tools, and machinery are properly maintained, used efficiently, and in accordance with rules.

In Singapore, where the building sector is rapidly expanding, installing good CAM is critical to remaining competitive. According to Business Wire, the industry is predicted to increase at a 5.5% CAGR between 2024 and 2028, with construction production reaching SGD 20.08 billion by 2028, indicating significant development potential.

This article investigates the advantages of construction asset management, namely how it enhances efficiency, decision-making, and compliance.

It also discusses best practices for asset management and the role of technology in improving performance, enabling businesses to make educated decisions while maintaining control over their assets throughout their lifecycle.

- Construction asset management (CAM) is a comprehensive system to manage and sustain physical assets throughout their lifecycle process.

- The benefits of CAM (Construction Asset Management) include boosting productivity, improving decision-making, ensuring regulatory compliance, and extending asset lifespan.

- Best practices for CAM include assigning assets to specific users and job sites, using barcodes and QR codes for easy tracking, and more.

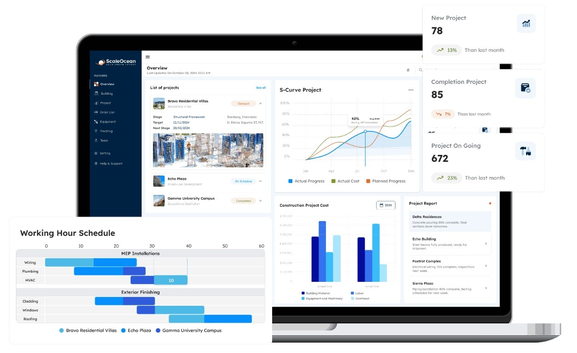

- ScaleOcean’s software provides comprehensive management of construction assets, from preventive maintenance to full lifecycle management.

What is Asset Management Construction?

Construction asset management (CAM) is a comprehensive system to manage and sustain physical assets throughout their lifecycle process. It entails the systematic monitoring, maintenance, and optimization of physical assets such as machinery, tools, and equipment to ensure their continued functionality and efficiency.

Construction businesses can improve efficiency by employing effective CAM tactics that maximize asset use, reduce wasteful costs, and minimize downtime.

CAM uses advanced technology, efficient processes, and industry best practices to monitor asset performance. This approach enables construction site companies to make data-driven decisions about equipment upkeep, replacement, and utilization.

Companies that remain ahead of maintenance schedules and ensure assets are in peak functional condition can improve project outcomes, eliminate operational disruptions, and increase overall construction project efficiency.

Benefits of CAM Construction Asset Management

Construction Asset Management (CAM) offers various advantages to construction organizations. Businesses that use successful CAM techniques can increase productivity, maintain regulatory compliance, make better decisions, and extend the life of their assets.

These advantages not only improve operational performance but also help to ensure the overall success of construction projects. Here are the benefits of construction asset management:

- Efficiency: CAM helps improve operational efficiency by reducing downtime and minimizing costs. Regular maintenance keeps unexpected breakdowns at bay, which helps avoid delays in projects. This proactive approach boosts productivity and ensures equipment is reliable for smoother project execution.

- Compliance: CAM makes it easier for organizations to stay compliant with industry regulations by keeping track of maintenance, certifications, and contract renewals. By ensuring compliance, companies can avoid fines, legal issues, and prevent delays caused by regulatory hurdles.

- Decision-making: CAM provides firms with detailed information about asset performance, value, and maintenance requirements. This visibility improves decision-making in construction management by allowing managers to prioritize asset maintenance, replacement, or repairs based on real-time data.

- Asset Lifespan: CAM extends the life of assets through regular maintenance. Scheduling maintenance and managing service contracts ensures that equipment stays in good shape for longer, reducing the need for early replacements and lowering repair costs, which increases the return on investment.

Construction Asset Management CAM Best Practices

Effective construction asset management is crucial for increasing operational efficiency, lowering costs, and prolonging asset lifespans. Adopting best practices for asset management allows construction organizations to track, maintain, and maximize their resources.

A detailed cost breakdown structure helps businesses manage expenses more effectively, maintain smooth operations, prevent downtime, and increase overall project performance. The following are some significant best practices in construction asset management that can help you reach your goals:

Assign Assets to Users, Job Sites, and Vehicles

One of the most important best practices in construction asset management is assigning assets to specific users, job locations, and vehicles. This strategy improves accountability by associating each asset with a responsible entity or location, simplifying tracking and monitoring.

When assets are assigned to specific teams or project sites, it is easier to measure their utilization, prevent theft, and ensure correct upkeep.

Use Barcode and QR Codes to Simplify Asset Lookups

Implementing barcodes and QR codes for asset tracking increases efficiency by simplifying the lookup process. Scanning these codes gives you fast access to essential asset information, including maintenance schedules, ownership, service history, and location.

This technology lowers manual errors, speeds up inventory audits, and allows for real-time tracking, making it easier to manage assets across huge building projects.

Schedule Maintenance Notifications to Extend Equipment Life

Maintenance notifications should be scheduled to ensure that assets are serviced on time, which can extend their operational life. Companies may stay proactive in maintenance by establishing reminders for routine inspections, repairs, and service.

This helps to prevent unexpected malfunctions, lowers the need for expensive emergency repairs, and ensures that equipment runs smoothly throughout its useful life.

Track Asset Performance and Progress

Monitoring asset performance and progress is critical for maximizing asset utilization and spotting any issues that may impede operations. Companies that analyze how assets function in real time on a regular basis can gather data on their effectiveness, identify underperforming assets, and make adjustments as needed.

This method enables firms to take a more strategic approach to asset management, resulting in increased operational efficiency and reduced downtime.

Use Asset Kitting to Bundle Equipment Together for Rapid Actions

Asset kitting is a method in which the appropriate equipment and tools are packaged together for certain operations. This strategy enhances operational efficiency, particularly on big building sites, by ensuring that teams have timely access to all necessary supplies.

Instead of hunting for individual products, workers may simply grab a kit containing everything they need for a certain operation, saving time and lowering the danger of losing critical tools.

Use Contract Management to Track When Contracts Are Set to Expire

Contract management is essential for keeping all service agreements, warranties, and maintenance contracts up to date. Companies can minimize gaps in service coverage by keeping track of when contracts are about to expire, ensuring that their assets are fully serviced.

Effective contract management also aids in budgeting by allowing businesses to forecast renewal expenses and ensuring timely contract renewals for continuous service and support.

Tips for Effective Construction Asset Management

Effective construction asset management is critical to maintaining the optimal performance and longevity of assets during a project. To achieve this, businesses must use tactics that prioritize accuracy, efficiency, and proactive decision-making.

The following are some important ideas for efficiently managing construction assets:

Regularly Audit Assets

Regular audits are critical for keeping accurate records of all assets. Companies can detect differences between actual assets and system records by examining the physical inventory on a regular basis.

This helps to prevent asset misplacement, ensures that equipment is properly accounted for, and reduces the danger of untracked assets being neglected for maintenance or replacement.

Invest in Employee Training

To be effective, an asset management system requires staff to be properly trained on how to use the tools and software involved.

Investing in training ensures that employees are knowledgeable about asset management systems, allowing for more accurate data entry, effective tracking, and proper utilization of maintenance plans. A well-trained crew is vital for maximizing the potential of asset management systems.

Centralized Asset Management

A centralized asset management system, often facilitated by CMMS facilities management software, streamlines the process of acquiring and managing assets. Construction organizations may streamline asset tracking, maintenance scheduling, and compliance reporting by combining all asset-related data into a single system.

This ensures that all asset management departments have real-time access to correct data, which allows for speedier decision-making and better team communication.

Assess Asset Performance

Regularly evaluating asset performance is critical for identifying inefficiencies or possible concerns before they become costly problems.

Monitoring key performance indicators (KPIs) such as asset utilization, downtime, and repair frequency allows businesses to identify underperforming assets and take corrective action, whether through maintenance, upgrades, or replacement.

Leverage Data Analytics

Data analytics can be an effective tool for predicting future asset requirements and maintenance needs. Companies can estimate when assets will need to be maintained, repaired, or replaced by evaluating past asset performance data.

This proactive strategy enables firms to better prepare, eliminate unplanned downtime, and guarantee that assets operate efficiently throughout the project lifecycle.

How to Implement Construction Asset Management Strategies

Implementing effective construction asset management strategies requires a combination of planning, technology, and best practices, including construction management procurement, to ensure smooth operations and efficient use of resources.

Here’s how you can successfully implement construction asset management strategies:

1. Evaluating Asset Requirements

The first step in implementing asset management is assessing your company’s asset needs. Identifying key equipment and resources ensures that operations run smoothly and the necessary tools are always available.

Understanding these needs allows you to make informed decisions about investments and future requirements. It also helps you plan for maintenance, replacement, and utilization, which optimizes performance and cost.

2. Setting Clear Goals

Setting clear, measurable goals is crucial for managing assets effectively. Your goals should align with the project’s needs and your team’s capabilities, ensuring everyone is on the same page.

Having specific goals helps measure asset performance and track progress. This keeps the project on schedule and within budget, ultimately improving the chances of success.

3. Choosing the Right Software

Choosing the right asset management software is essential for smooth operations. It should fit your company’s unique needs, supporting key features like asset tracking and maintenance scheduling.

An ERP platform for construction companies streamlines asset management by centralizing tasks. This makes it easier to access data and track performance, enabling quick, informed decisions that drive project success.

4. Collecting and Integrating Data

Efficient data collection and integration are essential for managing assets effectively. By gathering real-time data and unifying it into one system, you get a complete view of asset performance.

This integrated system helps managers make better decisions by providing instant access to accurate data. With this approach, issues can be addressed before they cause delays, maximizing asset utilization and boosting performance.

5. Tracking and Identifying Assets

Using tools like barcodes or RFID tags to track assets is key to managing construction equipment. These tools provide real-time visibility into asset location, status, and maintenance needs, reducing mismanagement risks.

Monitoring and identifying assets this way ensures resources are used efficiently. It helps prevent theft and misplacement, ensuring equipment is available when needed and improving project efficiency.

6. Managing Inventory Effectively

Real-time inventory tracking ensures your team always has the supplies and tools they need. It prevents stockouts and excess inventory, which can tie up capital and resources.

This system streamlines workflows by providing quick access to the necessary materials. It minimizes downtime, optimizes resource use, and helps with cost management, ensuring smooth project execution.

7. Meeting Compliance and Regulatory Requirements

Staying current with industry regulations and safety standards is crucial for maintaining compliance in asset management. Keeping up with these requirements helps avoid fines and delays that could affect the project.

Regularly checking compliance ensures the project stays on track and within legal boundaries. By following safety and environmental guidelines, you prevent disruptions and build trust with stakeholders.

8. Training and Getting Users Onboard

Training your team is key to successfully using asset management systems. Properly trained staff can enter data accurately, track assets efficiently, and fully utilize the software.

Ensuring users are comfortable with the software plays a big role in the strategy’s success. When everyone understands the system, it leads to higher productivity, better resource management, and more successful project outcomes.

9. Fostering Continuous Improvement

Continuous improvement ensures your asset management strategy stays effective. Regularly reviewing processes and gathering feedback allows for necessary adjustments.

This approach improves asset utilization, cuts costs, and optimizes project efficiency over time. By adapting and refining strategies, you ensure long-term success and better project results.

So, by implementing ScaleOcean’s construction software, the software streamlines asset management, boosts efficiency, and ensures compliance. It also optimizes asset tracking and data integration, driving project success and operational excellence.

Challenges in Construction Asset Management

While building asset management offers many benefits, it also presents challenges that require proactive solutions. If not properly addressed, these issues can affect efficiency, compliance, and profitability.

According to Asian Insiders, Singapore’s construction sector faces challenges from a labor shortage and increasing demands for sustainable building methods. The Singapore Building and Construction Authority (BCA) is enhancing decarbonisation efforts. It focuses on low-emission buildings and efficient building management.

Here are some of the main issues in construction asset management:

Asset Depreciation Challenges

Asset depreciation is a significant challenge in construction asset management as equipment loses its value over time due to continuous use. This impacts budgeting and long-term planning since companies need to factor in the decreasing value of their assets.

To manage this effectively, construction companies should schedule regular maintenance to extend the life of their assets. Using the best construction cost management software helps track depreciation in real time, providing better financial forecasts and helping decide when to replace or repair assets.

Compliance with Regulations

Staying compliant with ever-changing industry regulations is a major hurdle in construction asset management. Keeping up with safety, environmental, and operational laws can be difficult as they often vary depending on the region and specific project requirements.

The key to overcoming this challenge is to use a digital system that centralizes compliance tracking. This system helps businesses track certifications and inspections while automated reminders ensure deadlines are met, reducing fines and delays.

Theft and Misplacement of Assets

Construction assets are often stolen or misplaced on construction sites due to their size and the constantly changing environment. This mismanagement can result in significant financial losses and delays in projects.

You can solve this issue by using asset tracking technologies like RFID tags or GPS systems. These tools track assets in real time and keep them accounted for, helping reduce theft and improve overall equipment management.

How Technology Can Help With the Construction Asset Management Process

Digital tools and software are transforming construction asset management. These systems automate tracking, maintenance, and compliance, reducing errors and saving time. By streamlining manual tasks, companies ensure that assets are monitored and well-maintained efficiently.

Real-time visibility into asset performance is crucial for construction management. Software systems, combined with mobile apps and IoT devices, provide live data on assets. This helps managers make quick decisions and address any issues, ensuring smooth project execution and optimal resource use.

Data analytics in asset management allows companies to optimize resource allocation and predict maintenance needs. Analyzing performance data helps businesses reduce downtime, extend asset lifespan, and align with project goals, boosting productivity.

Manage Assets from Prevention to Maintenance with ScaleOcean Construction Software

ScaleOcean’s construction ERP software is a comprehensive solution that streamlines asset tracking, maintenance, and optimization. The software’s capabilities enable firms to increase operational efficiency, minimize downtime, and extend asset life.

Its unique features enable businesses to manage assets smoothly, from preventive maintenance to full lifecycle management. ScaleOcean is a powerful solution that expands with your business, ensuring that every asset is fully exploited and maintained.

Furthermore, ScaleOcean can be utilized in conjunction with the CTC grant, lowering costs for qualified enterprises. The following are some of the primary features of ScaleOcean software:

- Construction Equipment Maintenance & Efficiency: Optimize equipment maintenance with tracking, alerts, and downtime analysis to improve operational efficiency.

- Customizable Equipment Maintenance Workflow: Customize maintenance tracking, dashboards, and alerts to fit your company’s specific operational needs.

- Real-time GPS/RFID Tracking: Track equipment location and status in real time with GPS or RFID for better asset management.

- Preventative Maintenance Scheduling: Schedule preventative maintenance tasks to reduce downtime and extend equipment lifespan.

- Mobile Access for Field Teams: Access equipment data and schedules on the go, enabling real-time updates for field teams.

- Inventory Management (Stock Tracking/Reordering): Manage stock levels and reorder supplies automatically, ensuring essential inventory is always available.

Conclusion

Effective construction asset management (CAM) enhances efficiency, reduces costs, and extends asset lifespans. Construction companies can improve asset utilization, reduce downtime, and achieve better outcomes by using the right strategies and technologies.

ScaleOcean provides a comprehensive solution targeted to the specific needs of enterprises wishing to improve their asset management procedures. Take advantage of the free demo to explore how ScaleOcean can streamline your operations while saving costs.

FAQ:

1. What does an asset manager do in construction?

An asset manager in construction is responsible for overseeing the maintenance, usage, and lifecycle of construction assets. They ensure proper management, track asset performance, handle maintenance, and decide on replacements to maximize asset value and efficiency.

2. What are the 5 pillars of asset management?

The 5 P’s of asset management are people, processes, products, performance, and planning. These pillars are fundamental in supporting efficient asset management strategies for long-term operational success and strategic decision-making.

3. What are the 5 M’s of construction management?

The 5 M’s of construction management are money, manpower, materials, machinery, and methods. These are the key factors construction managers must balance and optimize to ensure the smooth execution of projects.

4. What are the 7 stages of construction?

1. Design.

2. Pre-Construction.

3. Procurement.

4. Construction.

5. Commissioning.

6. Owner Occupancy.

7. Project Closeout.

PTE LTD..png)

.png)

.png)

.png)

.png)