Singapore’s manufacturing sector is evolving through the adoption of new technologies and sustainable practices, driven by emerging manufacturing trends. With the “Manufacturing 2030” agenda, Singapore strives to be a global leader in innovative manufacturing.

Adapting to these trends enables organizations to remain competitive and reduce costs. This article examines key manufacturing developments that are transforming the industry, including smart factories, sustainability, labor shifts, and ERP software.

Understanding these trends will enable Singaporean organizations to keep ahead of the competition, make smart decisions, and capitalize on these advances for long-term growth. Learn more here!

- The definition of manufacturing trends refers to the evolving practices, technologies, and strategies that shape how goods are produced, distributed, and consumed.

- The top latest manufacturing trends are included: smart factory (industry 5.0), additive manufacturing, proactive cybersecurity, cognitive industry, industrial extended reality (XR), generative design, supply chain reassessment and reshoring, sustainable and green manufacturing, and many others

- ScaleOcean’s manufacturing ERP software provides the tools needed to stay competitive, integrate modern manufacturing technologies, and optimize operations.

Defining Manufacturing Trends

Manufacturing trends refer to the evolving practices, technologies, and strategies that shape how goods are produced, distributed, and consumed. These trends emerge in response to technological advancements, market demands, and global challenges.

They highlight the industry’s ongoing efforts to improve efficiency, reduce costs, and enhance product quality. Key trends, such as automation, sustainability, and the integration of artificial intelligence, are reshaping production lines and transforming how manufacturers operate.

Understanding the latest manufacturing trends helps businesses stay competitive by adapting to innovations that drive growth, optimizing processes, and meeting consumer expectations.

Top Latest Manufacturing Trends

The manufacturing industry, especially in Singapore, is undergoing rapid transformations, driven by advancements in technology, sustainability initiatives, and evolving consumer demands.

From the integration of artificial intelligence and automation to the focus on eco-friendly practices, businesses are embracing innovative solutions to enhance productivity and competitiveness.

In this article, we’ll explore the top latest trends shaping the future of manufacturing, such as the smart factory, and how companies can stay ahead of the curve. Learn more here!

1. Smart Factory Revolution (Industry 5.0)

Smart factory revolution is reshaping production through AI, automation, and data-driven technology. These manufacturing trends drive smarter factories, boosting efficiency, agility, and flexibility, allowing businesses to adapt to changing market demands quickly.

Industry 5.0 will lead to more customized products, improved quality control, and greater flexibility, as humans leverage technology to perform more complex, strategic tasks in the production process.

Understanding the different manufacturing processes is key to fully leveraging these advancements. Here’s a closer look at the main technologies driving this revolution:

AI, Data Analytics, and Digital Twins

AI and data analytics enable predictive decision-making, which improves production efficiency and product quality. Digital twins enable virtual testing prior to modifications, lowering risk. In Singapore, the Smart Industry Readiness Index (SIRI) enables enterprises to implement new technologies that align with industrial trends.

These technologies provide insights into customer behavior, industrial bottlenecks, and supply chain optimization. By incorporating AI and data analytics, manufacturers can remain competitive and better meet consumer demands. The best manufacturing execution system can further enhance these capabilities.

Robotics and Automation

Robotics and automation make manufacturing more efficient by automating repetitive operations and increasing production speed. These technologies reduce human error, save expenses, and improve precision, making processes more dependable and speedier, especially for small and medium-sized organizations.

Automation becomes more accessible as its cost decreases. Robotics integration improves industrial efficiency and scalability by streamlining processes, reducing downtime, and allowing staff to focus on higher-value jobs. Integrating IoT in manufacturing further enhances this by providing real-time monitoring and smarter decision-making.

2. Additive Manufacturing (3D Printing)

Additive manufacturing, also known as 3D printing, allows for the manufacture of complex, unique items with minimal waste. It provides for faster prototyping, greater design flexibility, and shorter lead times. This method minimizes the need for massive inventories, which helps industries such as aircraft and medical products.

3D printing gives producers more control over product design and production, allowing for speedier innovation. It’s an important tool for sectors that require bespoke parts, as it reduces the prices and time required for traditional production methods.

3. Proactive Cybersecurity for Operational Technology (OT) in Manufacturing

Cybersecurity is critical as factories grow more automated, with more linked equipment and sensitive data. Protecting operational technology (OT) is crucial. Singapore’s Cyber Security Agency (CSA) offers recommendations for safeguarding OT, assuring the safety of production equipment, and maintaining data integrity.

Manufacturers must take cybersecurity precautions to prevent unwanted access, secure data, and ensure the safety of OT systems. Following CSA rules is critical for maintaining operations in a digitally connected manufacturing environment.

4. Cognitive Industry: Artificial Intelligence and Virtual Manufacturing Processes

Cognitive industries will harness artificial intelligence (AI) to enhance decision-making, improve process optimization, and enable virtual manufacturing. AI will enable predictive maintenance, autonomous systems, and real-time data analytics, resulting in increased efficiency and reduced operational costs.

Virtual manufacturing processes will also allow for more accurate simulations, reducing the need for physical prototypes, speeding up production, and minimizing waste.

5. Industrial Extended Reality (XR)

Industrial extended reality (XR) will play a crucial role in shaping the manufacturing landscape by combining augmented reality (AR), virtual reality (VR), and mixed reality (MR) technologies. In the future of manufacturing, XR will be used for training workers, designing prototypes, and conducting remote maintenance.

This immersive technology will enhance collaboration and improve operational efficiency, providing real-time insights and hands-on experience without being physically present on-site.

6. Generative Design

Generative design will revolutionize the manufacturing process by leveraging algorithms to create optimized designs based on specified parameters. This innovative approach allows manufacturers to generate multiple design options that maximize efficiency and material usage while minimizing waste.

With generative design, companies can create more lightweight, sustainable, and cost-effective products, improving performance and reducing environmental impact.

7. Supply Chain Reassessment and Intelligent

The supply chain will undergo a significant transformation, driven by intelligent systems and advanced analytics. Manufacturers will increasingly rely on AI-powered supply chain management tools to predict demand fluctuations, optimize inventory, and improve delivery efficiency.

Real-time data and smart logistics will enable manufacturers to create more resilient, adaptive supply chains that can respond swiftly to global disruptions, ensuring consistent production and customer satisfaction.

8. Supply Chain Diversification and Reshoring

Diversification and reshoring minimize reliance on a single supplier or area, which improves supply chain resilience. Singapore’s logistics infrastructure makes it a good location for diversification in Southeast Asia.

Companies are increasingly seeking to localize production for greater flexibility and faster delivery. Reshoring and diversification generate more robust supply chains, allowing enterprises to continue operating despite global disruptions.

Singapore’s significance as a logistics center allows for efficient supply chain management and regional market access. Manufacturing ERP software in Singapore helps streamline these processes for greater efficiency.

Agile Planning and Real-Time Visibility

Agile planning enables firms to respond to supply chain interruptions. Manufacturers can make timely decisions and avoid delays by having real-time visibility over their inventory, orders, and production.

This adaptability enables responsiveness to changing market needs and supply chain issues. Real-time data is critical for ensuring efficient operations and reducing disruptions.

Manufacturers can manage production schedules, change inventory levels, and keep customers happy by having access to crucial information at all times.

9. The Rise of Sustainable and Green Manufacturing

Sustainability will continue to dominate the manufacturing sector, as companies adopt green technologies to reduce their carbon footprints. Green manufacturing practices will involve using renewable energy, reducing waste, and optimizing resource efficiency.

In response to stricter environmental regulations and consumer demand for eco-friendly products, manufacturers will invest in technologies that enable cleaner production methods, such as 3D printing, recycling, and energy-efficient machinery.

Clean Technology and Circular Economy Principles

Manufacturers are adopting sustainable technologies like renewable energy and circular economy practices, focusing on recycling and reusing resources to reduce waste. These efforts align with Singapore’s Green Plan 2030, promoting sustainable manufacturing and eco-friendly solutions to lower environmental impact.

Clean technologies help achieve sustainability goals while saving operational expenses. Embracing circular economy principles minimizes waste, reduces resource consumption, and ensures compliance with environmental rules. Additionally, considering the product life cycle in manufacturing promotes long-term sustainability.

Development of Advanced, Sustainable Materials

The usage of sustainable materials is increasing, such as biodegradable plastics and eco-friendly metals. Manufacturers are looking into novel materials that comply with increasing environmental norms and consumer demand for green products, lowering carbon emissions and environmental impact.

These innovative materials not only assist manufacturers in achieving sustainability goals but also help them comply with ESG reporting regulations. By adopting eco-friendly materials, businesses reduce their environmental impact while meeting market demand. Manufacturing cost estimating software aids in budgeting these sustainable practices.

10. Smart Materials in Manufacturing

Smart materials will gain traction in manufacturing, offering enhanced functionality through self-healing, shape memory, and energy-efficient capabilities. These materials will enable the creation of more durable and sustainable products while reducing waste and energy consumption.

Manufacturers will utilize these advanced materials to design more efficient, long-lasting products, ranging from aerospace components to consumer electronics, aligning with the growing demand for sustainability.

11. The Battle for Skilled Talent

The demand for talented workers in robotics, artificial intelligence, and data analytics is increasing, and businesses must invest in training programs to fill these positions. Programs like SkillsFuture in Singapore are critical for teaching workers to manage sophisticated manufacturing technologies and ensuring a competent labor force.

As the manufacturing business grows more technology-driven, it is critical to close the skills gap. Workforce training and development programs are critical for attracting and maintaining skilled workers capable of generating innovation and managing modern production systems.

12. Enhanced Employee Safety and Well-being

Employee safety and well-being are high priorities as production becomes increasingly automated. Smart safety systems, wearables, and ergonomic tools keep workers safe. These measures not only boost worker morale but also reduce injuries, resulting in safer and more productive workplaces.

By investing in employee safety and health, manufacturers improve workplace productivity and morale. This focus on well-being contributes to long-term business success by reducing downtime and cultivating a more engaged, productive staff.

13. The Shift from B2B to B2C Models

Manufacturers are progressively shifting from B2B to B2C models, interacting directly with end users. This move enables speedier feedback, more tailored products, and greater control over the consumer experience, resulting in stronger brand loyalty and improved market placement.

The B2C approach allows producers to respond more flexibly to consumer preferences and customize their products more effectively. By interacting directly with customers, manufacturers may improve their offerings and increase market competitiveness.

14. Servitization: From Selling Products to Offering Services

Servitization is revolutionizing the manufacturing industry by allowing companies to offer services in addition to products. These services include maintenance, upgrades, and monitoring, which bring value to clients. This tendency increases consumer loyalty and generates extra revenue streams.

Manufacturers who embrace a service-oriented approach can create recurring revenue while also strengthening client relationships. Servitization increases value and enables manufacturers to diversify their business models, hence increasing profitability and client retention.

15. Data-driven Maintenance

Data-driven maintenance will become a cornerstone of manufacturing operations, revolutionizing how companies manage equipment and minimize downtime. By leveraging advanced sensors, IoT devices, and machine learning algorithms, manufacturers can collect real-time data from their machines to predict failures before they happen.

This manufacturing trend also proactive approach, known as predictive maintenance, which helps identify potential issues early, reducing the need for expensive repairs and extending the lifespan of equipment.

Additionally, data-driven maintenance enables manufacturers to optimize maintenance schedules, reduce operational disruptions, and enhance overall efficiency, ultimately leading to cost savings and improved productivity.

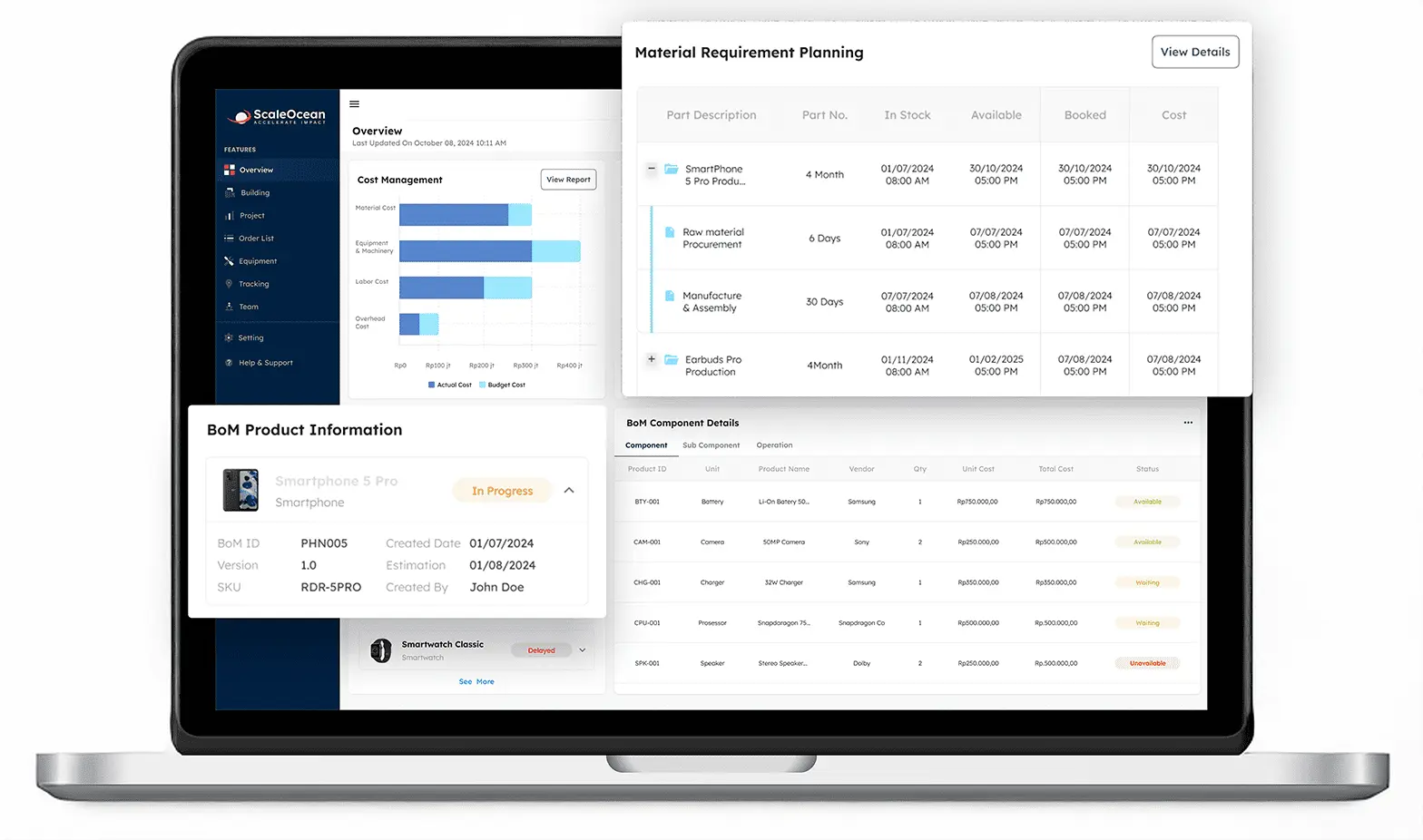

All of these manufacturing trends can be optimally implemented with the support of ScaleOcean’s leading manufacturing software. ScaleOcean provides seamlessly integrated solutions with a variety of renewable external devices, as well as optimization features that enhance operational visibility.

ScaleOcean ensures that manufacturing companies can keep up with the latest trends in operational efficiency, automation, and improved quality control. Request a free demo and discuss your manufacturing business needs with ScaleOcean’s leading team.

The Role of a Modern Manufacturing ERP

Modern manufacturing ERP systems integrate and streamline processes, providing real-time insights for efficient decision-making. According to IMDA, SMEs are crucial to Singapore’s economy, employing two-thirds of the workforce and contributing nearly half of the GDP, driving growth and efficiency.

ERP systems improve collaboration while reducing errors by removing silos. These solutions provide a consolidated perspective of operations, allowing manufacturers to streamline processes, boost visibility, and drive growth while maintaining high efficiency and accuracy.

Keep Up With Latest Manufacturing Trends with ScaleOcean’s Manufacturing Software

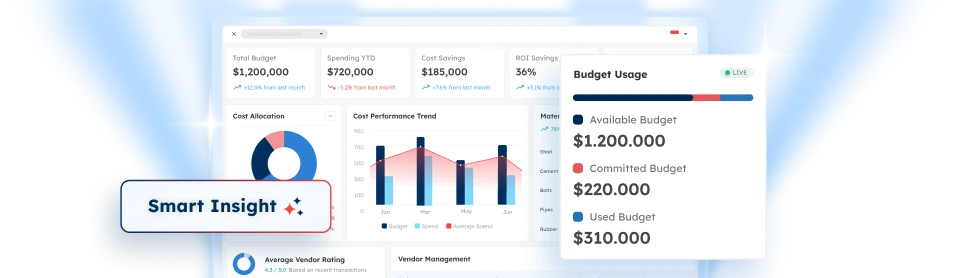

ScaleOcean’s manufacturing software helps Singapore enterprises stay competitive by providing solutions for operational excellence. It offers real-time insights, integrated workflows, and data analytics, enabling firms to quickly adapt to manufacturing trends and improve performance.

ScaleOcean provides a free demo to help organizations understand how its ERP software can revolutionize operations. Companies that get the CTC grant can use government funds to build scalable, smart solutions that boost efficiency. The following are the primary characteristics of ScaleOcean’s software:

- Resilient Operations: ScaleOcean’s ERP enables manufacturers to quickly adapt to market changes and disruptions, ensuring continuous operations with real-time insights and integrated workflows.

- Sustainable Production: The software optimizes inventory and production management, helping manufacturers reduce waste and align operations with sustainability goals while maximizing efficiency.

- Smart Automation: With automated processes from procurement to production scheduling, ScaleOcean enhances productivity and reduces errors, ensuring faster decision-making and agility.

- Data-Driven Decisions: ScaleOcean’s built-in analytics provide actionable insights, allowing businesses to monitor performance, forecast demand, and make informed decisions to stay competitive.

- Scalable and Future-Ready: The ERP system is built to grow with your business, integrating seamlessly with smart technologies and ensuring long-term scalability to meet evolving manufacturing trends.

Conclusion

Staying on top of the newest manufacturing trends is critical for firms to remain competitive and efficient. The introduction of technologies such as artificial intelligence, automation, and sustainable practices is influencing the industry’s future. To succeed in an ever-changing market, manufacturers must adapt.

To help with this shift, ScaleOcean’s manufacturing ERP software provides a full solution. ScaleOcean’s software is designed to connect real-time data, smart industrial technology, and sustainable practices, allowing firms to optimize operations and remain resilient in the face of industry difficulties.

FAQ:

1. What is the latest trend in advanced manufacturing?

The latest development in advanced manufacturing revolves around the adoption of Industry 4.0 technologies like AI, robotics, and IoT. These advancements are enhancing factory intelligence, enabling real-time decision-making, and automating production for greater efficiency.

2. What is the current trend in the industry?

Today’s manufacturing industry is witnessing a surge in automation, AI analytics, and eco-friendly manufacturing. Innovations such as smart factories, digital twins, and sustainable practices are transforming the production landscape, driving both efficiency and environmental responsibility.

3. What are the manufacturing challenges in 2026?

In 2026, manufacturers will face obstacles like workforce shortages, adapting to advanced technologies, safeguarding against cybersecurity threats, and managing global supply chain challenges. Striking a balance between sustainability goals and profitability will also remain a key challenge.

4. What is the most in-demand manufacturing?

The most sought-after manufacturing sectors are smart factory solutions, additive manufacturing (3D printing), and green manufacturing. Key industries, including aerospace, automotive, and medical devices, are focusing on these areas to boost innovation, reduce costs, and meet evolving market needs.

PTE LTD..png)

.png)

.png)

.png)

.png)