In Singapore’s highly competitive manufacturing sector, improving equipment performance is critical to retaining a strong market position. Companies in areas ranging from electronics to precise engineering are constantly under pressure to increase productivity while reducing downtime and expenses.

One of the most successful methods for measuring and improving operational effectiveness is OEE (Overall Equipment Effectiveness). OEE provides a thorough assessment of equipment utilization, taking into account essential criteria such as availability, performance, and quality.

According to EDB Singapore, the country is home to major semiconductor manufacturers, and the Electronics Industry Transformation Map (ITM) aims to boost sector growth through enhanced productivity and automation. By monitoring OEE, manufacturers in Singapore can identify inefficiencies, reduce downtime, and make data-driven decisions to improve productivity. This highlights the importance of leveraging performance metrics like OEE for sustained growth and operational excellence.

- OEE measures equipment efficiency, focusing on availability, performance, and quality to optimize production and minimize downtime.

- To improve OEE, eliminate unplanned downtime, optimize setup times, invest in predictive maintenance, and ensure proper operator training.

- Monitoring OEE improves productivity, enhances decision-making, boosts profitability, and helps in better resource allocation.

- ScaleOcean simplifies OEE monitoring and manufacturing processes by automating data tracking, providing real-time insights, and improving equipment performance through advanced analytics.

1. What Is OEE Overall Equipment Effectiveness?

OEE, or Overall Equipment Effectiveness, is an important indicator in manufacturing that measures how efficiently equipment is working. It considers three essential factors: availability, performance, and quality. Availability is the time that equipment is available for production as opposed to its planned operational time. Performance assesses how well the equipment functions in terms of speed, taking into account any losses caused by slower-than-expected output rates.

Quality refers to the percentage of items that satisfy the intended requirements without requiring rework or producing flaws. By examining these three elements, OEE assists manufacturers in identifying inefficiencies and opportunities for development, offering useful insights that can lead to improved equipment usage, reduced downtime, and increased overall productivity.

2. 10 Ways to Rapidly Improve OEE

To improve your OEE score, take a few measures to address inefficiencies and maximize equipment performance. By taking a proactive approach to these areas, you can significantly increase your OEE and overall productivity. Here are some techniques for significantly increasing your OEE:

a. Eliminate Unplanned Downtime

Unplanned downtime lowers the availability factor of OEE. By performing regular maintenance and implementing predictive technologies, you can foresee probable faults and avoid unplanned delays, allowing equipment to run smoothly. This preventive maintenance strategy not only lowers downtime but also increases the equipment’s lifespan.

b. Implement Predictive Maintenance

Predictive maintenance uses monitoring technologies to predict equipment problems. By analyzing data from sensors and other technologies, you may plan maintenance before a failure occurs, reducing downtime and enhancing availability. This strategy enables manufacturers to retain top performance while avoiding the unexpected pauses caused by unplanned repairs.

c. Optimize Setup Times

Long setup periods might cut into important production time. Streamlining changeovers, using quick-change tooling, and establishing standardized setups can reduce idle time and increase overall equipment efficiency. Efficient setups get machines back into production faster, optimizing their machine availability for maximum output.

d. Improve Operator Training

Operators play an important part in maintaining high OEE scores. Proper training ensures that workers understand how to operate machinery properly, identify problems early, and avoid mistakes that cause downtime or quality difficulties. Well-trained operators can make modifications on the fly, reducing the impact of minor difficulties before they become major problems.

e. Automate Where Possible

Automation may eliminate human error and improve consistency, thereby speeding up manufacturing. By automating repetitive processes, manufacturers may reduce variability, enhance throughput, and eliminate performance losses. Furthermore, automation systems can monitor equipment in real time, alerting operators to any problems that may occur.

f. Monitor Performance Metrics

Regularly tracking performance data allows you to detect places where machines are failing. Understanding machine speed, output, and cycle times enables firms to identify bottlenecks that reduce productivity. This data-driven strategy yields actionable insights that can assist boost productivity and enhance decision-making.

g. Focus on Quality Control

Quality concerns, such as flaws or scrap, impair production efficiency. Strengthening quality control methods ensures that goods satisfy standards, reducing rework and improving the quality component of OEE. Integrating quality checks throughout the manufacturing process allows you to detect errors early, reducing waste and improving product uniformity.

h. Invest in Equipment Upgrades

Older equipment typically has lesser performance and reliability. Upgrading machinery or investing in newer versions with more advanced technology can dramatically improve efficiency, lowering downtime and improving OEE. Newer equipment frequently includes built-in features such as increased sensors and energy efficiency, which provide further benefits to your OEE.

i. Reduce Changeover Times

Long changeover periods between production cycles might cause protracted downtime. Implementing lean manufacturing strategies, such as SMED (Single-Minute Exchange of Dies), can shorten this time and increase equipment availability. Faster changeovers allow production to flow more smoothly and without the delays caused by moving between different product lines.

j. Analyze Root Causes of Problems

When performance concerns emerge, it is critical to conduct a root cause analysis. By identifying the core causes of equipment failures or inefficiencies, manufacturers can take corrective action to avoid recurring issues, thereby improving OEE over time. This approach ensures that any solutions implemented address the root causes rather than the symptoms

3. OEE Score and Benchmarks

OEE scores range from 0% to 100%, with 100% indicating perfect production—no downtime, peak performance, and immaculate quality. Achieving this degree of efficiency is uncommon, but it provides an excellent baseline for manufacturers. A score of 85% is considered “World Class,” indicating minimal losses in availability, performance, and quality, and is generally viewed as excellent.

A score of 60% is labeled “Average,” meaning performance is acceptable, but significant improvements are still possible. On the other hand, a score of 40% is categorized as “Poor” and is common in newer businesses or those with clear opportunities for growth. This score identifies areas that require immediate attention and provides a foundation for optimization. Understanding your OEE score is critical for tracking progress and determining where efforts should be directed to improve efficiency and increase production output.

| OEE Score | Industry Standard |

|---|---|

| 100% 85% 60% 40% | Perfect – Manufacturing only good parts, as fast as possible, with no stop time World Class – Considered a top score for discrete manufacturers Average – Ok score, however there is significant room for improvement Poor – Common for new operations with easy wins to improve score |

4. What is the OEE Formula?

The OEE formula is a simple yet effective approach for calculating the overall efficiency of equipment in a manufacturing process. By assessing three essential factors—availability, performance, and quality—the algorithm identifies areas for improvement. The formula goes as follows:

OEE = Availability × Performance × Quality

Each of these components is calculated separately before being multiplied to determine the overall OEE score. Availability is the percentage of scheduled production time when the equipment is actually available for use, excluding downtime. Performance determines how efficiently the equipment operates in relation to its maximum feasible speed, taking into account any slowdowns. Quality refers to the percentage of manufactured parts that fulfill quality criteria, excluding defective or reworked goods.

5. Simple OEE Calculations

To calculate OEE, you must consider three main components: availability, performance, and quality. Each of these elements is important in establishing the overall performance of your equipment, and when combined, they provide useful information about how effectively the equipment is operating. Here’s how to compute every component:

a. Availability

Availability is determined by dividing actual production time by anticipated production time. It calculates the length of time the equipment is truly operational, excluding downtime, and indicates how frequently the equipment is accessible for production. High availability suggests that the equipment is operating as planned, with little interruptions.

b. Performance

Performance is defined as the ratio of actual production rate to maximum production rate. It accounts for any delays in the manufacturing process, assisting in the identification of inefficiencies and chances to improve production speed. A higher performance score indicates that the equipment is operating at or near its optimum speed.

c. Quality

Quality is the proportion of good products produced out of overall production. It reflects how many of the manufactured items fulfill the required quality criteria, excluding defective or reworkable products. Achieving a high quality score is critical for reducing waste and meeting customer expectations. Calculating these three elements will allow you to establish the OEE score and highlight areas that require optimization.

6. Preferred OEE Calculation

The preferred OEE calculation method takes a more precise approach to measuring equipment performance, breaking down each factor—Availability, Performance, and Quality—into distinct calculations. This enables firms to acquire a better knowledge of where losses are occurring and to take targeted steps to enhance efficiency. Businesses that focus on these particular components can more efficiently optimize their operations and achieve greater overall equipment effectiveness. Let’s take a closer look at how each factor is computed.

a. Availability Calculation

Availability refers to the proportion of time that equipment is actually available for production, excluding downtime. It is computed by dividing the operating time (the actual time the equipment is running) by the projected production time (the entire time the equipment is expected to run). This computation determines how much of the anticipated time is really spent on production and shows any periods of inactivity or equipment breakdown.

Availability = Operating Time / Planned Production Time

b. Performance Calculation

Performance indicates how rapidly the device operates during its available time. It compares the actual production rate to the maximum production rate, often known as the ideal cycle time. This method identifies speed losses during manufacturing by determining how near the actual output is to the ideal output. A higher performance score implies that the equipment is operating at or near its peak capacity, whereas a lower score shows speed inefficiencies.

Performance = Operating Time / Ideal Cycle Time × Total Units Produced

c. Quality Calculation

Quality determines how many of the items produced match the required quality standards, with no faults or the requirement for rework. It is computed by dividing the number of good units produced by the total number of units manufactured. This component has a direct impact on the final OEE score since producing defective or non-compliant items diminishes overall efficiency and increases waste.

Quality = Good Units Produced / Total Units Produced

d. OEE Calculation

Once Availability, Performance, and Quality have been calculated, multiply them together to get the final OEE score. This score provides a holistic assessment of equipment performance by combining the effects of downtime, speed losses, and quality concerns. The OEE formula is as follows:

OEE = Availability × Performance × Quality

e. Perfect Production

Ideal manufacturing involves no downtime, optimal speed, and every product meeting quality standards. While perfect production is the ultimate goal, it is seldom achieved in real-world scenarios due to various operational challenges. However, aiming for faultless manufacturing establishes a high standard and motivates constant progress.

7. How to Improve OEE Performance?

To improve OEE performance, manufacturers must address both short-term issues and long-term plans. Organizations may significantly increase equipment performance by addressing important issues such as downtime, efficiency, and technology. Here are five actionable measures for improving OEE performance:

a. Perform Root Cause Analysis

Investigating the fundamental causes of downtime or performance lags is critical for identifying specific production issues. Instead of simply treating symptoms, a thorough study enables organizations to adopt long-term solutions that directly eradicate the root causes of inefficiency. This proactive approach reduces reoccurring difficulties while increasing OEE over time.

b. Conduct Regular Preventive Maintenance

Regular preventive maintenance is critical for avoiding unexpected malfunctions that can impede operations. Manufacturers can minimize downtime by scheduling routine inspections and addressing small issues before they become severe ones. This method keeps machinery in good working order, which helps to maintain high OEE scores.

c. Optimize Process Efficiency

Optimizing production workflows and lowering changeover times can significantly boost equipment usage and help reduce manufacturing overhead. Manufacturers can reduce idle time and increase production speed by optimizing operations, reducing bottlenecks, and implementing uniform setups. Efficient processes improve overall performance and increase OEE because machines spend more time producing instead of waiting for setup or adjustments.

d. Empower Employees

Well-trained staff are essential for discovering inefficiencies and increasing OEE. Regular training ensures that employees understand the necessity of equipment operation, troubleshooting, and performance monitoring. Encouraging staff to take ownership and recommend improvements can help to promote continuous improvement efforts, creating a culture that seeks methods to optimize equipment utilization and performance.

e. Invest in Technology

Modern technologies, such as IoT sensors, automation, and machine learning, can provide useful information about equipment performance. Smart technologies enable manufacturers to track real-time data on machine health, discover anomalies early, and predict breakdowns before they occur. Leveraging this technology improves predictive maintenance techniques and reduces downtime, thus increasing OEE and operational efficiency.

8. Benefits of Monitoring OEE

Monitoring OEE provides various advantages that can greatly improve overall manufacturing efficiency and corporate operations. Organizations can find opportunities for optimization and ensure that resources are used efficiently by closely monitoring equipment efficacy. According to Manufacturing Tomorrow, many companies that previously relied on manual data collection methods, such as whiteboards or clipboards, can benefit significantly from automated OEE solutions. These automated systems ensure consistent and accurate data gathering, which is a critical step in any continuous improvement program. Here are the major advantages of monitoring OEE:

a. Improved Productivity

Businesses that identify inefficiencies and areas of underperformance might take specific initiatives to increase productivity. Addressing challenges like downtime, poor speeds, and quality flaws improves production rates and reduces unnecessary stoppages, resulting in a more efficient manufacturing process. This innovation directly increases overall productivity and contributes to meeting production targets.

b. Enhanced Decision-Making

Real-time OEE data gives managers vital insights into equipment performance, allowing them to make more educated scheduling, maintenance, and resource allocation choices. Managers may use reliable data to determine which machines are doing well, which require attention, and how to change schedules to maximize productivity, making decision-making more strategic and data-driven.

c. Increased Profitability

Optimizing equipment performance through OEE monitoring allows producers to boost output without making extra investments. Companies can increase profitability by reducing downtime, improving speed, and minimizing waste. Improved OEE translates to fewer operational inefficiencies and greater utilization of existing assets, which benefits the bottom line.

d. Better Resource Allocation

Monitoring OEE enables organizations to better manage resources including labor, materials, and equipment. Understanding which areas are underperforming allows businesses to change workforce levels, machine usage, and material flow to ensure that resources are maximized. This results in a more efficient use of assets and ensures that resources are directed toward the most vital sectors.

e. Continuous Improvement

Tracking OEE performance over time helps to develop an organizational culture of continuous improvement. Businesses that constantly monitor and evaluate their OEE ratings can detect patterns, track progress, and adopt continuous performance improvement methods. This continual endeavor, combined with effective manufacturing process planning, guarantees that manufacturers remain competitive, responding to changes and achieving long-term success through operational excellence.

9. Manufacturing Software ScaleOcean for Automating OEE Calculations

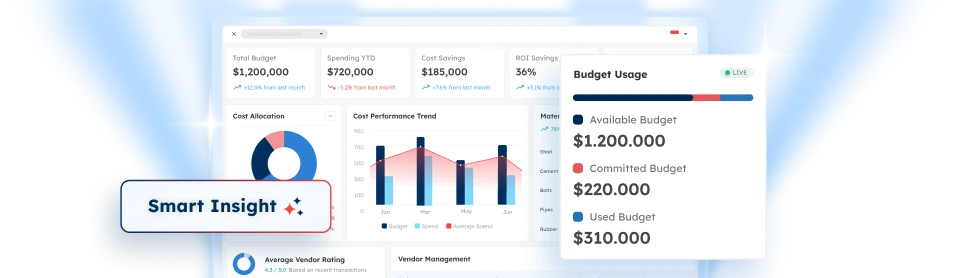

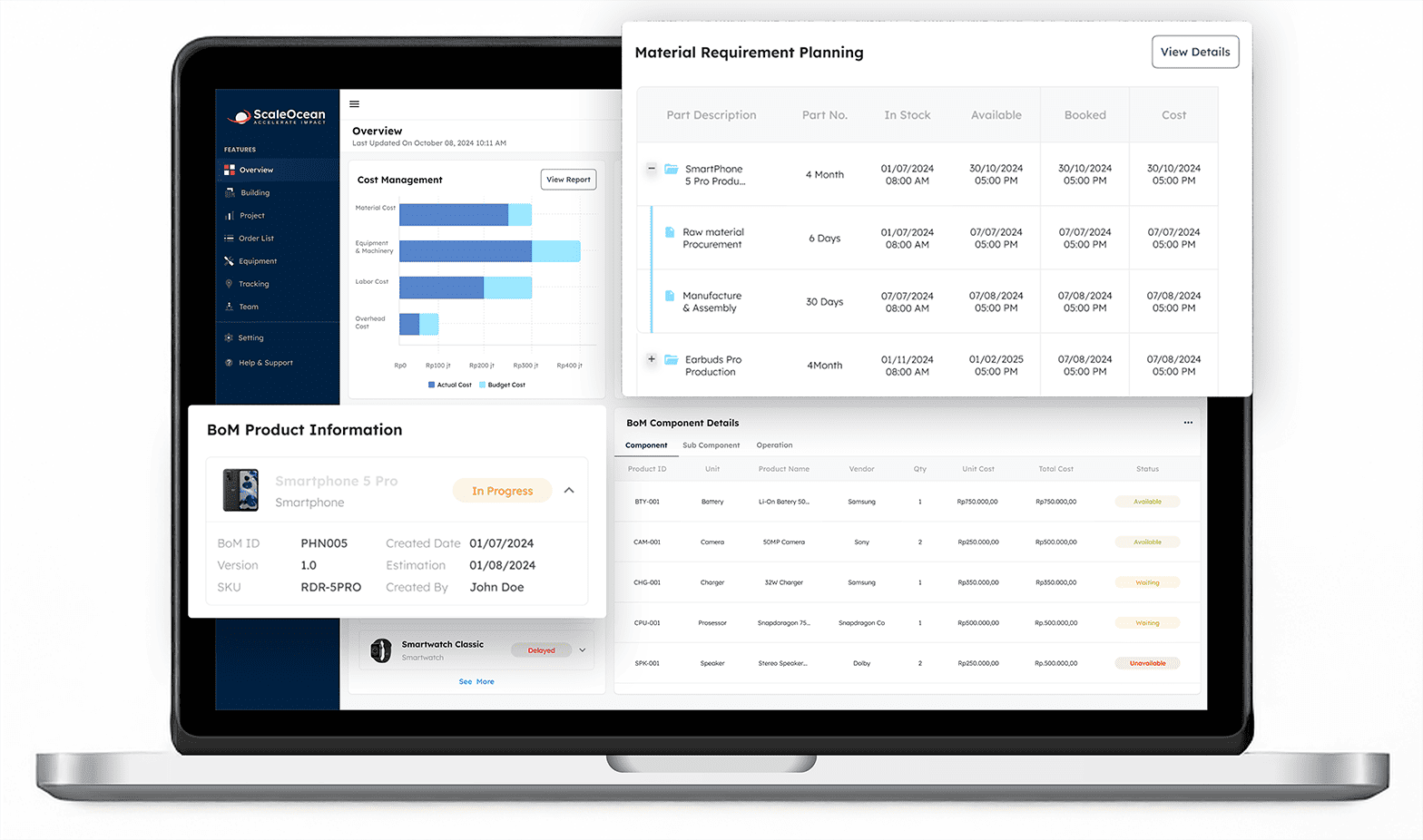

ScaleOcean manufacturing ERP offers an automated system for managing OEE estimates, enabling manufacturers to track and enhance equipment performance using real-time data and advanced analytics. ScaleOcean reduces errors, improves accuracy, and provides actionable insights by automating Availability, Performance, and Quality monitoring. The integration of industrial IoT provides a comprehensive 360-degree picture of operations, allowing for enhanced decision-making.

If you want to improve your OEE performance, ScaleOcean provides a free demo that shows how our all-in-one ERP system may optimize your manufacturing operations. Contact us today to set up a demo and see how ScaleOcean can help you streamline your operations. Here are a few essential features that make ScaleOcean the best option:

- Unlimited Users Without Additional Costs, ScaleOcean offers 100% unlimited user access without additional fees. This feature allows your business to scale freely without worrying about user restrictions or unexpected costs.

- All-in-One Solution – Complete Modules According to Your Needs, With over 200+ modules tailored to meet your business needs, ScaleOcean provides more than 1000 customizable features to ensure that every aspect of your operation is covered efficiently.

- Rational & Flat Pricing, Our flat pricing model with no hidden costs is perfect for medium to enterprise-scale businesses, offering great value while ensuring transparency and cost-effectiveness.

- Built from Best Business & Industry Practices, ScaleOcean is built on industry best practices, addressing operational, resource management, efficiency, and automation challenges to optimize your production and OEE performance.

- Cross-Branch Integration, Whether you have multiple branches or subsidiaries, ScaleOcean seamlessly integrates all your operations into one platform, enabling unified management across your entire organization.

10. Conclusion

OEE (Overall Equipment Effectiveness) is a powerful indicator that allows manufacturers to assess and optimize their equipment performance by focusing on availability, performance, and quality. Monitoring and enhancing OEE can result in enhanced productivity, better decision-making, less downtime, and more profits. Businesses can accomplish continuous improvement and operational excellence by addressing the underlying causes of inefficiency and utilizing contemporary technologies.

ScaleOcean provides a comprehensive ERP solution tailored to business needs that can streamline OEE calculations and drive operational improvements. Our technology automates OEE tracking and incorporates advanced analytics, making it easy to monitor and improve equipment performance. Schedule a free demo today to experience ScaleOcean’s benefits firsthand. Let us demonstrate how our all-in-one solution may improve your manufacturing operations and company success.

PTE LTD..png)

.png)

.png)

.png)

.png)