Successful manufacturers consistently surpass their competitors by improving production efficiency, which refers to the ability to maximize output while minimizing waste, time, and costs. Singapore’s manufacturing sector is recognized for its innovation and high-quality standards.

To stay competitive, businesses need to improve efficiency to boost productivity and cut operational costs. In December 2024, Singapore’s manufacturing output increased by 10.6% year-on-year. For the full year of 2024, output was 4.3% higher compared to 2023.

Efficient manufacturing processes not only increase profits but also ensure long-term growth. But what exactly is production efficiency, and how can businesses effectively measure it? Understanding its key components and the factors that influence it is essential for companies striving to refine their operations.

In this article, we’ll explore what production efficiency means, how to calculate it, and the critical elements that impact overall performance.

- Production efficiency refers to a company’s ability to maximize output while minimizing input, ensuring that resources are used optimally without compromising quality.

- Key factors influencing production efficiency include effective resource utilization, process optimization, technology integration, and workforce management.

- Key benefits of production efficiency include reduced costs, higher revenue, a strategic market edge, and the ability to detect and address bottlenecks.

- ScaleOcean manufacturing software also offers comprehensive solutions designed to enhance production efficiency.

What is Production Efficiency?

Production efficiency is an economic term that refers to a company’s ability to maximize output while minimizing input, ensuring that resources are used optimally without compromising quality. Businesses can boost their productivity and operational effectiveness by streamlining processes, reducing waste, and leveraging technology.

Achieving high production efficiency leads to cost savings, increased profitability, and competitiveness. Adjusting takt time to match production demand helps businesses meet market needs faster, improve customer satisfaction, and adapt to trends, driving long-term growth in today’s fast-paced market.

Core Concept in Production Efficiency

Production efficiency is all about making goods or services at the lowest possible cost by making the most of your labor, materials, and machinery. The main goal is to cut out waste and ensure every single resource in your production line is reaching its full potential.

The idea is to get the highest output from the least input, finding that perfect balance between saving money and keeping quality high. By sharpening your processes, you can stop wasting resources and give your overall operational performance a real boost.

In the end, hitting peak efficiency means smoothing out your workflows and constantly improving. This leads to better profits since you’re producing more with less, helping your business stay sustainable and ahead of the competition for the long haul.

Key Factors Influencing Production Efficiency

Production efficiency is influenced by several critical factors that work together to optimize operations. These include resource utilization, process optimization, technology integration, and labor management, all of which contribute significantly to increased productivity and cost reduction.

Here are the key factors influencing production efficiency:

1. Resource Utilization

Effective management of materials, labor, and machinery ensures minimal waste and downtime. Companies that optimize resource allocation and track cycle time can avoid inefficient spending, maintain output, and boost operational efficiency, especially in mass manufacturing sectors where meeting high demand is crucial.

2. Process Optimization

Streamlining production processes eliminates bottlenecks and reduces cycle times. This includes analyzing workflows, identifying inefficiencies, and implementing improvements to ensure smoother and faster production cycles.

Standardizing procedures and incorporating lean manufacturing principles, such as effective WIP management, can help to increase speed, reduce defects, and improve overall process reliability.

3. Technology Integration

Implementing advanced technologies such as automation, IoT, and data analytics improves production capacity. These tools enable real-time monitoring, predictive maintenance, and data-driven decision-making, resulting in increased efficiency and lower operating costs.

Businesses that use smart technologies can address potential issues before they escalate, ensuring uninterrupted operations.

4. Workforce Management

Skilled and motivated employees are essential for maintaining high production efficiency. Proper training, clear communication, and performance incentives ensure that the workforce operates at peak productivity, contributing to overall operational success.

Encouraging collaboration and offering continuous upskilling opportunities, employees adapt to technological advancements and evolving industry demands. A flexible build-to-order system also supports this by allowing customized workflows to align with employee skills and job roles.

5. Measuring Production Efficiency

Businesses must monitor and analyze key metrics to improve production efficiency, especially in make-to-order environments where performance depends on precise coordination between demand and production.

Accurate measurement enables data-driven decisions, process optimization, and inefficiency reduction. Benchmarking against industry standards assists in setting realistic goals.

Regular audits increase efficiency by revealing gaps. These strategies ensure that manufacturing operations experience long-term growth and competitiveness, particularly in mass production.

6. Performance Metrics

Key performance indicators (KPIs) like Overall Equipment Effectiveness (OEE) measure productivity, availability, and quality. Production yield tracks output consistency, while cycle time gauges speed. So, a list of bill materials is essential for tracking resource usage, optimizing production, and improving efficiency.

7. Benchmarking

Benchmarking compares a company’s performance to industry standards or competitors. It identifies inefficiencies, operational weaknesses, and areas for improvement. Businesses can set attainable performance goals by analyzing best practices.

Regular benchmarking encourages innovation and process optimization. This practice ensures that businesses remain competitive while continuously improving their production efficiency.

8. Regular Audits

Audits evaluate production efficiency by detecting bottlenecks, wasteful spending, and compliance issues. They aid in the optimization of workflows, increasing equipment usage, and lowering operational expenses.

Regular reviews foster continuous process improvement. Audits also guarantee that the requirements of efficiency are met. Businesses gain from increased productivity, better resource allocation, and higher profitability.

Key Benefits of Production Efficiency

When a business optimizes its production, the benefits are clear. From cutting costs to boosting revenue, efficiency makes everything run smoother. By using resources wisely and reducing waste, companies can increase their bottom line while staying competitive.

Here are some of the top advantages of improving production efficiency:

- Reduced Costs: By improving production efficiency, businesses reduce waste and get more out of every resource. This helps cut costs, whether it’s for raw materials, labor, or energy, leading to savings without sacrificing output or quality.

- Higher Revenue: Efficient production means quicker turnarounds and more products available for sale. With a steady and fast output, companies can better meet demand, increasing sales and ultimately boosting their revenue without adding extra cost.

- Strategic Edge: Having an efficient production system gives businesses a real advantage in the market. It makes it easier to adapt to changes, stay ahead of competitors, and offer faster, more reliable products, securing a stronger position in the industry.

- Detect Bottlenecks: Efficient production helps identify where slowdowns or blockages happen in the process. By spotting bottlenecks early, businesses can act fast to improve flow, reduce delays, and ensure smooth operations, leading to faster and more efficient production.

How to Calculate Production Efficiency?

Production efficiency is calculated to determine how effectively a company is utilizing its resources to achieve desired output levels. The formula for production efficiency is:

Efficiency = (Output Rate ÷ Standard Output Rate) × 100

Explanation:

– Actual Output Rate: The number of units actually produced within a specific time frame.

– Standard Output Rate: The maximum number of units that can be produced under ideal conditions, based on the production line’s capacity or design.

Example:

If a production line is designed to produce 300 units per day (standard output rate) but only manages to produce 180 units (actual output rate), the production efficiency is calculated as:

(180 ÷ 300) × 100 = 60%

This means the production line is operating at 60% efficiency, indicating room for improvement in resource utilization, process optimization, or technology integration to achieve higher output levels. Regularly calculating production efficiency helps businesses identify inefficiencies and implement targeted strategies for improvement.

Productivity vs. Production Efficiency

Productivity is all about how much you create with what you have, usually centered on worker or machine performance. It shows how well you’re turning resources into goods, though it doesn’t always account for whether you’re being wasteful in the process.

On the flip side, production efficiency is about cutting out waste while hitting max output. It’s all about fine-tuning your systems and resource use while keeping quality high. Efficiency ensures every single resource is working to its absolute full potential.

While productivity counts what you make, efficiency looks at the cost of making it. A company might be super productive but still inefficient if costs or waste are too high, which can really hurt your long-term profits. It’s about balance, not just volume.

How Does Market Competition Enhance Production Efficiency?

Market competition pushes companies to sharpen their workflows to stay in the lead. To keep that edge, businesses have to smooth out operations, embrace new tech, and cut out waste and all of which lead to much better production efficiency and lower overall costs.

On top of that, competition sparks innovation as brands find smarter ways to build things. This leads to better habits like lean manufacturing and automation, helping businesses keep up with what customers want while boosting their total production output.

What Makes Reaching Peak Production Efficiency Challenging?

Reaching peak production efficiency can feel like a tough goal to achieve, with numerous unpredictable obstacles along the way. Unexpected downtime, supply chain disruptions, and regulatory hurdles all play a part in slowing things down. Tackling these challenges head-on is key to improving efficiency.

Let’s dive into the key challenges that often stand in the way of reaching full production efficiency:

Unexpected Downtime

Unplanned downtime can hit hard, completely stopping production. Whether it’s equipment failure, power issues, or sudden malfunctions, these interruptions can lead to delays, increased costs, and a slowdown in overall output. It’s a major roadblock for businesses trying to maintain efficiency.

One way to tackle this problem is through predictive maintenance. By keeping an eye on equipment health with real-time monitoring, businesses can spot potential issues early and schedule maintenance before things break down, cutting down the risk of unexpected downtime.

Interruptions in the Supply Chain

Supply chain disruptions are another major challenge. Delays in receiving materials, transportation problems, or external factors like political unrest can cause bottlenecks, slowing production. These interruptions often lead to longer lead times and higher costs, impacting overall efficiency.

To address this, businesses should strengthen relationships with multiple suppliers and have backup options in place. Planning with contingency measures ensures production doesn’t stop, even when unexpected disruptions pop up.

Adherence to Regulatory Requirements

Regulatory requirements can complicate production, adding layers of checks, paperwork, and operational adjustments. While essential, complying with safety, environmental, and labor regulations can slow down the process and create delays in production timelines.

A practical approach is to automate compliance tracking where possible, reducing manual work. Clear processes and regular employee training ensure that regulations are met efficiently, keeping production running smoothly without missing a beat.

Strategies to Improve Production Efficiency

Improving production efficiency necessitates a comprehensive strategy that prioritizes process optimization, personnel empowerment, and equipment maintenance. Process standardization, employee training, and preventive maintenance are all important measures for improving operations and production.

1. Process Standardization

Developing standardized procedures ensures that every production step follows a consistent approach, reducing deviations and errors. Clear workflows help employees understand their roles, streamline tasks, and optimize resource utilization. Standardization also enhances product quality by minimizing variations, ensuring compliance with good manufacturing practices, and supporting scalability as the business grows.

2. Employee Training

Employees receive ongoing training to operate machinery safely and efficiently. This includes knowledge of material requirement planning (MRP), which ensures the right materials are available when needed. A trained team responds quickly to process changes, boosts productivity, and fosters improvement.

3. Preventive Maintenance

Regular maintenance schedules help detect potential issues before they lead to costly breakdowns, ensuring smooth production. Preventive maintenance includes routine inspections, part replacements, and system upgrades to optimize equipment performance. By minimizing unplanned downtime and extending machinery lifespan, businesses can maintain high operational efficiency and reduce repair costs.

4. Technology Adoption

Integrating technologies such as automation, IoT, and AI-driven analytics enhances production efficiency and decision-making. Real-time monitoring helps detect anomalies, predictive maintenance prevents unexpected failures, and data-driven insights improve resource allocation.

Embracing digital transformation, including the best manufacturing execution system, helps businesses optimize workflows, reduce waste, and stay competitive. Utilizing a work-in-progress indicator ensures better tracking of production stages, improving overall efficiency in a fast-evolving market.

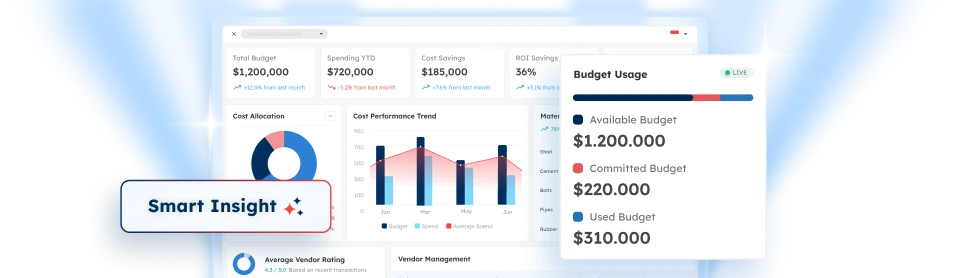

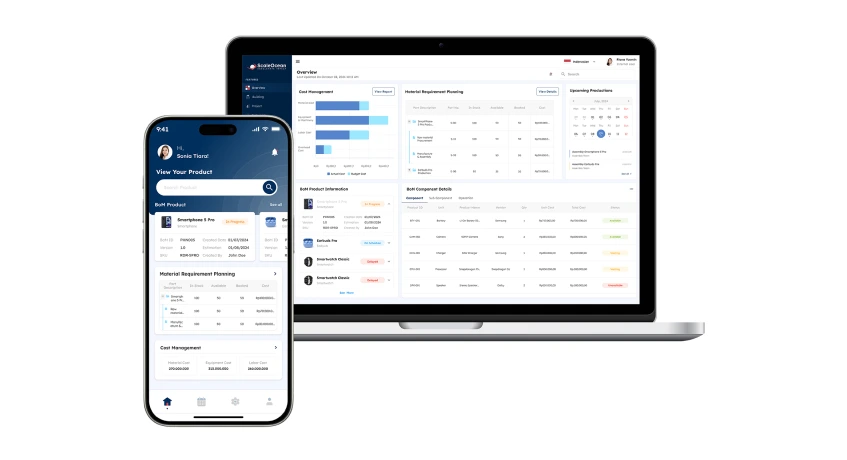

So with that in mind, ScaleOcean’s manufacturing software gives you all the tools you need to boost production. With live monitoring and smart analytics, it helps you smooth out workflows, cut down on waste, and run better strategies, making it much easier to achieve long-term operational success.

Leveraging Technology to Improve Efficiency

Technology enhances production efficiency through automation, data analytics, and IoT integration, improving accuracy and decision-making. To sustain these gains, businesses must measure performance, benchmark standards, and conduct regular audits.

1. Automation Solutions

Implementing automation streamlines repetitive tasks, improving efficiency and accuracy while minimizing human error. Automated systems enhance consistency in the product lifecycle, reducing delays and waste.

By handling routine operations, automation frees employees to focus on strategic tasks. This shift boosts innovation and problem-solving capabilities. Ultimately, automation drives productivity, cost savings, and operational excellence in manufacturing.

2. Data Analytics

Data analytics enables businesses to acquire greater insights into production performance. Analyzing real-time information allows you to identify inefficiencies and bottlenecks. Predictive analytics promotes proactive decision-making, waste reduction, and resource optimization.

Businesses can enhance workflows by spotting new trends. Data-driven techniques enable continual improvement, increased productivity, and a competitive edge in manufacturing. Understanding the importance of a manufacturing process plan ensures that these improvements align with business goals.

3. IoT Integration

IoT devices connect machines, sensors, and systems, enabling seamless data collection and monitoring. Real-time tracking improves equipment reliability and enhances predictive maintenance. IoT minimizes downtime by detecting faults before failures occur. Integrating IoT optimizes energy usage and resource allocation. This connectivity fosters smarter operations, increased efficiency, and long-term sustainability in manufacturing.

ScaleOcean’s Manufacturing Software for Streamlined Production

ScaleOcean manufacturing software offers comprehensive solutions designed to enhance production efficiency. By streamlining processes and minimizing inefficiencies, ScaleOcean helps manufacturers lower their Cost to Company (CTC), ensuring better resource allocation and higher profitability.

Whether you’re a small business or an enterprise, this software adapts to your needs, ensuring seamless operations and sustainable growth. Experience the future of manufacturing with ScaleOcean. Book a free demo to see how it can transform your production processes.

Key Features

- Real-Time Monitoring: Track production metrics in real time to identify inefficiencies and make data-driven adjustments for continuous improvement.

- Process Automation: Automate routine tasks to streamline operations, reduce manual errors, and allocate resources more efficiently.

- Data Analytics: Leverage in-depth analytics to gain actionable insights from production data, helping you make informed strategic decisions.

By implementing ScaleOcean’s manufacturing software, businesses can achieve significant operational advantages. One of the key advantages is cost savings, as the system reduces waste, optimizes resource allocation, and lowers operational costs.

Furthermore, ScaleOcean’s software is designed for scalability, allowing businesses to easily grow production in response to market demand without sacrificing efficiency or quality.

Conclusion

Enhancing production efficiency enables businesses to increase profits, reduce operational costs, and maintain a strong competitive edge. By streamlining workflows, minimizing waste, and optimizing resource utilization, companies can achieve greater output with fewer disruptions.

Implementing automation and leveraging data-driven strategies improves accuracy, speed, and decision-making, ultimately leading to higher productivity. In today’s rapidly evolving market, staying ahead requires continuous innovation and adopting the latest technologies to drive efficiency and long-term success.

Explore how ScaleOcean manufacturing software can be the catalyst for transforming your production processes and driving business success. With real-time monitoring, predictive analytics, and seamless integration, ScaleOcean empowers manufacturers to make smarter decisions and improve overall efficiency.

Don’t let inefficiencies hold your business back, so embrace innovation and take your manufacturing operations to the next level.

FAQ:

1. Why is production efficiency important?

Production efficiency is crucial as it focuses on optimizing processes, minimizing waste, and boosting productivity, which ultimately leads to higher profits and a more competitive market position. Improving efficiency allows manufacturers to increase output, cut costs, and enhance product quality.

2. What do you mean by productive efficiency?

Productive efficiency refers to the point where it’s impossible to produce more of one good without reducing the output of another. This happens when a company is operating at its most efficient level along the production possibility frontier.

3. What is an example of productivity and efficiency?

A good example of productivity and efficiency would be a factory upgrading its machinery to increase the number of products made per hour. Simultaneously, it reduces energy usage and material waste per unit, thus improving both productivity and efficiency.

4. What are the 5 KPIs for manufacturing?

The five KPIs commonly used in manufacturing are production volume, production costs, on-time delivery, first-time right, and revenue per employee. These are often selected based on a company’s needs and serve as useful benchmarks to evaluate performance.

PTE LTD..png)

.png)

.png)

.png)

.png)