Mass production has become essential in Singapore’s manufacturing sector, addressing challenges like cost efficiency and meeting high demand. As businesses look for quicker and scalable solutions, mass production plays a crucial role in keeping up with global needs and minimizing delays.

According to the Singapore Economic Development Board (EDB), manufacturing made up 21.6% of the country’s GDP in 2022. This shows how important mass production is in helping industries scale up to meet growing global demand while staying efficient.

The country has embraced automation and smart manufacturing to increase efficiency, making mass production an important economic strategy. Companies in Singapore can improve their production capacity by leveraging technological breakthroughs, assuring cost-effectiveness and worldwide competitiveness.

- Mass production is a strategy for large-scale, standardized product manufacturing that boosts output, reduces costs, and ensures consistent quality.

- Key principles of mass production include standardization, division of labor, and automation, which streamline workflows and improve scalability.

- Disadvantages of mass production include limited flexibility, high initial investment, potential worker monotony, and environmental effects.

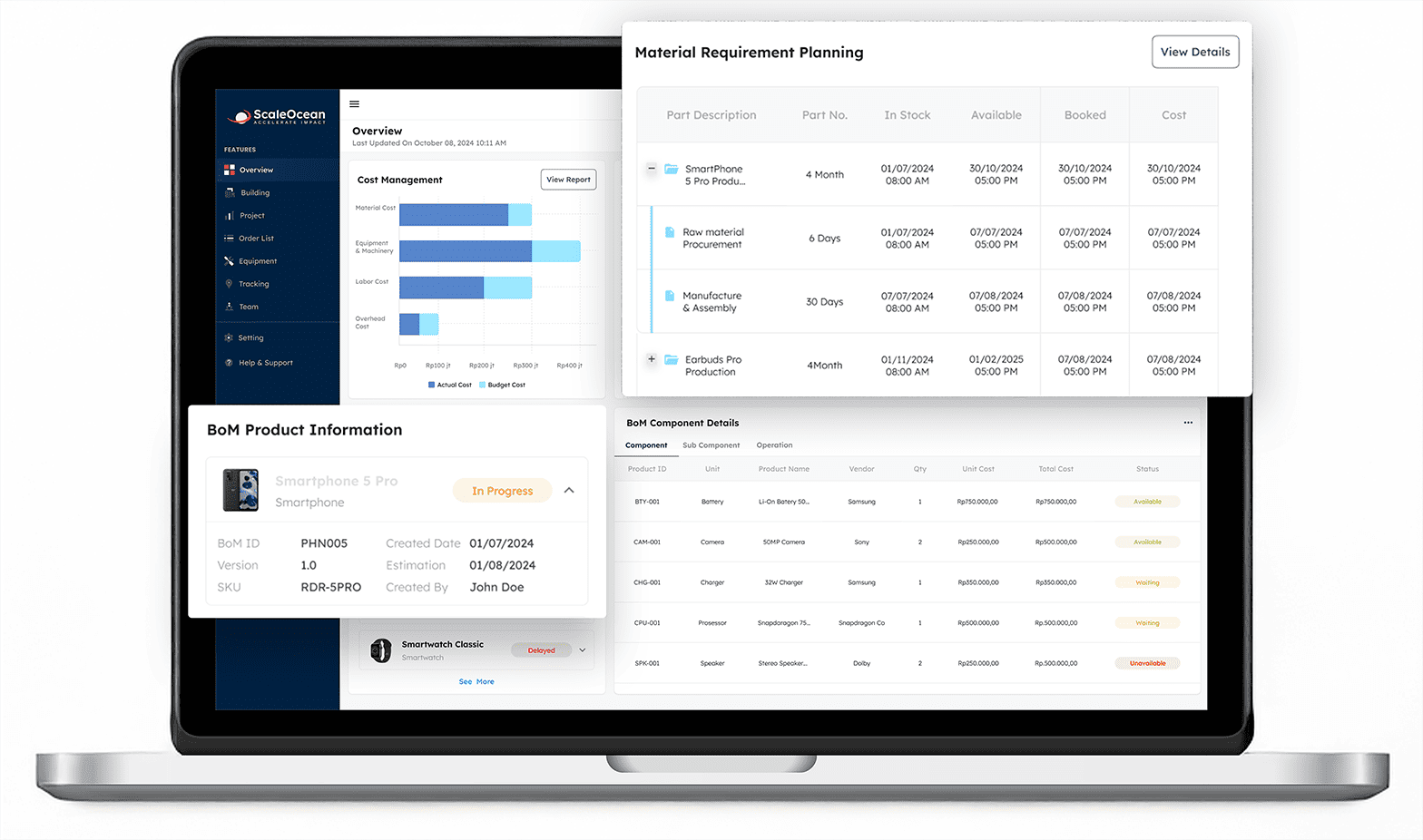

- ScaleOcean’s manufacturing software helps simplify production, cut costs, and boost efficiency.

What is Mass Production?

Mass production is the large-scale manufacture of standardized products using assembly lines and automation. This strategy tries to maximize efficiency by lowering manufacturing costs while increasing output.

It uses repeated processes and standardization to manufacture items at a high rate. Historically, the concept first emerged during the Industrial Revolution, enabling corporations to produce goods at unprecedented rates.

Over time, technological advances have perfected mass production, making it important in industries such as the automobile, electronics, and food manufacturing. Modern mass production is evolving through the adoption of robotics, artificial intelligence, and data analytics, resulting in greater precision, reduced waste, and greater scalability.

goods that are being mass-produced, include (but are not limited to):

- Automotive

- Electronics

- Consumer Goods

- Food & Beverages

- Textiles & Apparel

- Pharmaceuticals

Key Principles of Mass Production

To achieve efficiency and consistency, mass production follows a number of essential principles. Manufacturers can improve scalability, reduce waste, and optimize workflow by following these concepts, including assembly manufacturing practices, which help streamline the production process and ensure high-quality output.

Here are the essential ideas for streamlining manufacturing operations and lowering production costs:

Standardization of Parts

Interchangeable components provide seamless assembly and maintenance, eliminating production difficulties. This technique enables producers to produce things at scale without needing specific parts for each unit, increasing efficiency.

Standardized parts also make repairs and replacements easier, maintaining consistent quality across all products while lowering downtime and operating expenses.

Division of Labor

Assigning specialized duties to workers increases efficiency and shortens production time. By breaking down the production process into different jobs, personnel can gain competence in their respective responsibilities, resulting in increased precision and productivity.

This strategy not only reduces errors but also shortens production cycles, making it an essential component of mass production.

Automation and Assembly Lines

Automation and assembly lines play a key role in speeding up production while ensuring quality. Machines and automated systems reduce human error, enhance precision, and streamline repetitive tasks, making the production process faster and more consistent.

A well-integrated Material Requirement Planning system ensures materials are available when needed, preventing shortages and excess. Additionally, using robotics and AI in assembly lines improves efficiency, while cost estimating software helps manage budgeting and resource allocation effectively.

Advantages of Mass Production

Manufacturers benefit greatly from mass production since it allows them to meet market demands more effectively. This production method not only increases productivity but also enables businesses to retain competitive pricing.

Businesses can improve their operational stability by embracing enhanced automation and process optimization. Here are the advantages of mass production:

1. Cost Efficiency

Large-scale production reduces per-unit costs, hence increasing profitability. Manufacturers gain from economies of scale by producing things in large quantities, lowering material costs and operational expenses.

Furthermore, automated methods, supported by MRP systems, optimize inventory management, lower labor costs, and reduce the risk of manufacturing delays. This makes mass production an economically viable option for enterprises looking to increase profits while maintaining efficiency.

2. Increased Output

High manufacturing volumes assure a steady supply of items on the market. This capability enables manufacturers to satisfy rising consumer needs more efficiently, avoiding shortages and maintaining ongoing availability.

Businesses may increase operations smoothly while retaining product consistency and dependability by leveraging automation and modern manufacturing techniques.

3. Consistency and Quality Control

Standardized processes enhance product consistency, leading to higher customer satisfaction. By integrating robust quality control measures, manufacturers can ensure that every item meets predefined specifications.

This contributes to a more efficient product life cycle supply chain, ensuring that each stage from production to delivery meets the highest standards.

4. Efficient Distribution and Marketing Strategies

One major advantage of mass production is its ability to streamline distribution and marketing efforts. With standardized products produced in bulk, businesses can quickly distribute goods to various markets, reducing delays and improving market reach.

Mass production also enables companies to run more cost-effective marketing campaigns. As products are produced at a lower cost per unit, businesses can allocate more resources toward targeted advertising, ensuring wider brand visibility and increased sales.

Disadvantages of Mass Production

Despite its advantages, mass production presents problems that organizations must overcome. Issues such as manufacturing rigidity, environmental concerns, and reliance on large initial capital investments can all have an impact on corporate sustainability.

Furthermore, organizations must continuously innovate in order to retain efficiency and respond to market changes. Below are the key disadvantages associated with mass production:

1. Limited Flexibility

Because mass manufacturing is intended to be efficient, design changes are costly and time-consuming. According to Packaging Digest, advancements like Siemens and OPTIMA’s Multi-Carrier System enable producers to swiftly swap between products, decreasing setup time.

Despite breakthroughs, redesigning machinery and retraining workers still involve significant expenditure, posing a challenge for businesses to strike a balance between flexibility and cost-effectiveness.

2. High Initial Investment

Establishing automated production lines necessitates a significant capital commitment. Businesses must set aside capital for specialized machinery, infrastructure upgrades, and software systems.

Furthermore, continuing expenses such as personnel training and equipment upkeep increase the financial strain.

3. Potential for Worker Monotony

Repetitive jobs can reduce job satisfaction and productivity. Constantly performing the same duties can lead to mental weariness and decreased employee engagement.

Over time, this monotony may lead to decreased motivation, more absenteeism, and higher turnover rates, reducing overall operating efficiency.

4. Environmental Effects

A downside of mass production is its environmental impact. The large amount of raw materials needed, energy use, and waste produced can lead to serious environmental harm and depletion of resources that affect both nature and future generations.

Mass production also often causes more packaging waste and higher transportation emissions, contributing to pollution. On top of that, relying on standardized processes reduces the use of eco-friendly materials, making it harder to adopt sustainable practices.

Examples of Mass Production

Mass production is common throughout industries, demonstrating its ubiquitous use. This technology enables organizations to make things in large quantities while remaining cost-efficient and consistent.

By implementing a manufacturing execution system, companies can streamline production workflows, monitor real-time operations, and enhance overall efficiency. Businesses can meet market expectations by optimizing manufacturing with improved automation and assembly lines.

The following are examples of industries that rely on mass production:

Automotive Industry

Assembly lines transformed automobile manufacturing by dramatically boosting production efficiency and lowering costs. Ford’s Model T was the first mass-produced vehicle to employ this technology, making automobiles more affordable and accessible to the general public.

This discovery reduced the manufacturing process, resulting in speedier assembly, consistent quality, and lower labor costs, laying the groundwork for current car production.

Consumer Electronics

In countries like South Korea and China, massive production lines for electronics such as smartphones and laptops have become the norm. These countries have adopted advanced manufacturing techniques to meet the ever-growing global demand with speed and efficiency.

Robotic assembly lines and precision technology allow manufacturers to produce millions of electronics annually, ensuring consistent quality. This production method has made consumer electronics affordable and accessible to people worldwide, maintaining high standards.

Food and Beverage

In places like Europe and the United States, mass production has transformed the food and beverage industries. Automated systems ensure that packaged goods are produced on a large scale, maintaining consistent taste, safety, and freshness across different batches.

By using standardized recipes and automation, manufacturers can produce vast quantities of food while maintaining high quality. This has made it possible for companies to meet global demand while keeping costs down and ensuring the availability of food products year-round.

Textile

Countries like India and Bangladesh have become major global textile producers thanks to mass production. Automated weaving and stitching processes have made it possible to produce large quantities of garments quickly and at lower costs, meeting the demands of international markets.

In these regions, textile factories use automation to ensure consistent fabric quality, reducing the risk of human error. This has contributed to a booming global garment industry, offering affordable clothing to millions of consumers worldwide.

Pharmaceuticals

Mass production has also played a key role in the pharmaceutical industry, especially in places like Switzerland and India. Advanced manufacturing techniques allow the production of life-saving drugs at scale, ensuring availability in both developed and developing countries.

By standardizing processes and using automation, pharmaceutical companies can produce medications quickly and in large quantities. This approach has been crucial in addressing global health needs, ensuring that essential medicines are available to people around the world.

Mass production drives efficiency and affordability across industries, from cars to pharmaceuticals. By streamlining production and ensuring quality, it meets global demand. So for that reason, ScaleOcean’s manufacturing software can optimize workflows, enhance automation, and boost overall efficiency.

Does Mass Production Produce Quality Items?

Mass production can indeed deliver high-quality items when proper quality control is in place. With standardized processes and automated systems, the risk of human errors is reduced, making the production process more consistent and reliable.

However, the drive for efficiency and speed can sometimes affect quality. Standardized materials and processes may limit the opportunity to create unique or custom products that need extra attention or craftsmanship to make them stand out.

Still, mass production has made it easier to offer affordable and high-quality products to a broader audience. Thanks to advancements in automation and robotics, the precision and consistency of mass-produced items have improved significantly, ensuring high standards.

Mass Production vs. Batch Production vs. Job Shop Manufacturing

Each production technique, including various types of manufacturing processes, has unique qualities that are best suited to certain company requirements. Understanding these variations enables firms to choose the best solution depending on product demand, cost considerations, and flexibility needs.

The following are the primary distinctions between mass production, batch production, and job shop manufacturing:

Batch Production

Produces goods in limited numbers, providing flexibility for products with varying demand. This strategy allows producers to make things in predetermined batches while balancing efficiency and adaptability.

It is especially useful for seasonal products or things with fluctuating market demand, ensuring cost-effective production while avoiding overproduction.

Job Shop Manufacturing

Focuses on custom, small-batch manufacture, which allows for extensive customisation. This method is appropriate for specialty products that necessitate custom designs or adjustments based on customer requirements.

Because production is tailored to specific orders, job shop manufacturing prioritizes trained workers and adaptive machinery, making it ideal for industries such as aerospace, medical devices, and high-end manufacturing.

Comparison

Mass production is efficient and cost-effective, making it perfect for high-volume, standardized products. It uses automation and optimized operations to save expenses and increase output. In contrast, batch production and job shop manufacturing place an emphasis on flexibility and personalization.

Batch production enables producers to change output in response to changing demand, whereas job shop manufacturing concentrates on making highly specialized or custom-made products. Each strategy addresses a particular business need while balancing efficiency, adaptability, and cost factors.

Mass Production vs. Mass Customization

With changing consumer tastes, firms are exploring mass customization alongside mass production. This method enables businesses to strike a balance between efficiency and customisation, while also meeting the different needs of their customers.

Manufacturers can provide customized items while maintaining scalability by combining sophisticated technologies. The following are significant elements of mass customization and their comparison to traditional mass production:

| Mass Production | Mass Customization |

|---|---|

| Standardization and efficiency High-volume, identical products Low, difficult to adapt to market changes Lower per-unit cost due to economies of scale Limited variety, one-size-fits-all approach Fixed production lines and automation Shorter, as production is streamlined Assembly lines, robotics, automation | Personalization with efficiency High-volume with individualized elements High, allows for variations and custom features Slightly higher costs due to customization Adapts to diverse consumer needs Modular components and flexible processes Slightly longer, due to customization steps AI, data-driven design, flexible manufacturing |

A Step-by-Step Guide to the Mass Production Process

Mass production employs a planned workflow to maximize efficiency and quality. Manufacturers can improve uniformity and reduce production bottlenecks by following a methodical approach. This strategy increases production and lowers expenses while maintaining high standards.

The following is an outline of the essential steps in mass production:

Step 1: Design and Planning

At this stage, the focus is on defining the product details, selecting materials, and planning how everything will be made. A solid plan helps ensure production runs smoothly, is cost-effective, and meets market demands, making the workflow more efficient.

Planning helps manufacturers spot potential issues early. By addressing them upfront, they can avoid bottlenecks, make better use of resources, and create a product that meets both quality standards and market expectations.

Step 2: Procurement of Materials

This stage involves sourcing the raw materials needed for production, while ensuring they meet quality, cost, and delivery requirements. Building strong supplier relationships and having solid inventory management in place helps avoid delays and keeps things moving smoothly.

Strong procurement practices are key to keeping production on track. By working with trusted suppliers and managing inventory effectively, businesses can avoid shortages or excess, keeping production steady and focused on meeting deadlines.

Step 3: Setting Up Production Lines

Here, the production lines and automation are set up for smooth operations. This includes arranging machinery for an efficient flow, integrating robots where needed, and ensuring all equipment is calibrated to meet production standards for consistent output.

Setting up the production line correctly makes a huge difference in maintaining smooth operations. With the right machinery in place and automation that flows seamlessly, the process stays efficient, helping manufacturers meet their production goals without disruptions.

Step 4: Production and Assembly

In this step, components are carefully assembled using efficient methods to maintain consistency. With automated systems and regular quality checks built into the process, errors are minimized and production speed increases, allowing for seamless large-scale manufacturing.

The assembly process relies on automated systems and constant quality control to keep things running smoothly. This step ensures that the products are made efficiently while maintaining high quality, making large-scale production both effective and reliable.

Step 5: Quality Control

Entails conducting rigorous inspections to guarantee conformity with industry standards and regulations. This process combines automated testing, manual inspections, and real-time monitoring to find flaws early.

Manufacturers can eliminate waste, increase reliability, and improve overall product uniformity by adhering to high-quality standards.

Step 6: Packaging and Distribution

At this stage, finished products are securely packaged to protect them during transportation and storage.

Efficient logistics and supply chain management ensure that products are delivered to retailers and customers on time while retaining their integrity. Proper labeling, adherence to laws, and inventory tracking systems all improve the distribution process.

Step 7: Evaluation and Enhancement

After the initial production stages, evaluating the process is crucial for identifying areas of improvement. Monitoring production flow and quality helps pinpoint inefficiencies and ensures the final product meets the required standards.

Once issues are identified, enhancements can be made by refining workflows, adjusting machinery, or improving training. These adjustments improve production speed, reduce errors, and enhance overall output, ensuring long-term success in mass production.

Mass Production Methods and Tools

To improve mass production efficiency, manufacturers can use a variety of techniques and tools. By utilizing modern technologies, they can optimize workflows, reduce waste, and improve overall output. Automation and data-driven strategies are essential for maintaining consistency and scalability.

The following are the key methods and tools used to achieve this:

1. Assembly Lines

Conveyor belts and workstations work hand in hand to ensure smooth production by keeping goods moving continuously. This approach cuts down on manual handling, reduces delays, and helps keep things flowing efficiently, ensuring high output without compromising quality.

By organizing tasks and automating the movement of goods, assembly lines reduce hold-ups in production. This method boosts both efficiency and consistency, ensuring that products are made with the same level of quality every time, even at large scales.

2. Automation and Robotics

Machines take over repetitive tasks with great precision, which helps eliminate errors and improve overall productivity. Robotics automates complex tasks, speeding up production while ensuring everything is done accurately, which ultimately lowers labor costs.

Automated systems also improve safety by handling the riskier tasks that humans would usually do. By letting machines take over these jobs, workers can focus on more strategic roles, creating a safer and more efficient workplace for everyone involved.

3. Lean Manufacturing

Lean manufacturing focuses on cutting waste and using resources more effectively to improve efficiency. By optimizing processes, businesses can minimize excess inventory, remove unnecessary steps, and organize workflows better for a more seamless operation.

This approach not only helps save money but also creates a more flexible production system. By applying lean principles, companies can adapt quickly to changing demand and build a more sustainable and cost-effective production process.

ScaleOcean Manufacturing Software: A Solution for Mass Production in Singapore

ScaleOcean’s manufacturing software helps simplify production, cut costs, and boost efficiency. With its advanced tools, it enables businesses to adapt quickly to changing market demands and maintain a competitive edge.

ScaleOcean offers a solution that can elevate your manufacturing operations and improve scalability. With the support of the CTC grant, you can optimize your production while making better use of your budget. See how ScaleOcean can help take your business to the next level.

Below are the key features that make ScaleOcean an essential tool for mass production:

- Automated Financial Reporting: Real-time insights streamline financial decision-making by providing accurate, up-to-date financial data. This feature reduces manual effort, enhances reporting accuracy, and allows businesses to make informed strategic decisions efficiently.

- Expense Management: Simplifies cost tracking and control by providing real-time monitoring of expenses. This feature helps businesses optimize budget allocation, reduce unnecessary costs, and improve overall financial efficiency.

- Revenue Management: Enhances pricing strategies and revenue optimization by analyzing market trends and demand fluctuations. This feature helps businesses maximize profitability, streamline pricing adjustments, and improve overall financial planning.

- Tax Compliance: Ensures adherence to Singapore’s tax regulations, simplifying reporting and payments. This feature automates tax calculations, reduces errors, and ensures timely submissions to regulatory authorities, helping businesses stay compliant with evolving tax laws.

Conclusion

Mass production has transformed modern manufacturing, allowing companies to scale effectively while preserving product consistency. Despite the hurdles, its benefits in cost reduction, high output, and quality control make it an essential method for large-scale manufacturing.

ScaleOcean offers an industry-leading solution to Singaporean manufacturers seeking an optimized mass production system. Request a free demo today to learn how ScaleOcean’s ERP software can help you revolutionize your manufacturing operations and boost business success.

FAQ:

1. Who is the father of mass production?

Eli Whitney, Father of American Mass Production, is credited with pioneering the concept of mass production. His invention of interchangeable parts in the late 18th century laid the foundation for efficient, standardized manufacturing processes.

2. What are the three types of production?

1. Primary: Obtains raw materials (e.g., agriculture, mining)

2. Secondary: Creates finished products (e.g., automobile manufacturing)

3. Tertiary: Delivers services (e.g., finance, personal care)

3. What are the 4 P’s of manufacturing?

By focusing on purpose, practice, pursuit, and perfection, businesses can shape their manufacturing vision for the future. As discussed by Sath Rao, the factory of the future will usher in transformative changes for those ready to embrace intelligent manufacturing.

4. What is another word for mass production?

1. Assembly-line production

2. Large-scale manufacturing

3. Continuous-flow production

PTE LTD..png)

.png)

.png)

.png)

.png)