In the world of manufacturing businesses, workflow management must be efficient and accurate. Work in Progress (WIP) is an important factor that directly influences operational success.

Furthermore, it emphasizes the significance of integrating new solutions to successfully address industrial inefficiencies. Work in progress (WIP) refers to tasks, projects, or goods that have been started but are not yet complete and are actively being developed or improved.

In Singapore, a global commerce and industrial hub, effective WIP management is vital to maintaining competitiveness. The term of work in progress commonly used in many different sectors, such as manufacturing, software development, retail, and construction.

According to data from the Singapore Economic Development Board, the manufacturing sector accounts for around 20% of the country’s GDP, highlighting the necessity of optimizing workflows and minimizing inefficiencies.

Here is a complete explanation, starting from examples in inventory and accounting, on how it works, to work in progress vs work in process and finished goods.

What Is Work in Progress (WIP)?

The term “work in progress” describes any task or project that is still underway and not yet complete, whether it’s a personal endeavor, a manufacturing process, or software development.

It can broadly refer to ongoing activities or specifically denote an accounting or project management metric known as work-in-progress (WIP). The major goal of WIP tracking is to provide visibility into production phases, enable optimal resource allocation, and manage delays proactively to reduce costs.

WIP is also a term used across industries like manufacturing, software development, construction, and healthcare to track unfinished tasks or projects.

In Singapore’s fast-paced industry, where precision and timing are key, good WIP management may give companies a competitive advantage by optimizing operations and reducing waste.

Tracking work-in-progress (WIP) is crucial for managing the production efficiency flow, allocating resources, and understanding project management timelines.

Insight into Accounting Practices for WIP

In accounting, Work in Progress (WIP) represents the value of goods or projects that are partially completed but not yet ready for sale. How it’s recorded depends on the industry and project duration.

For example, manufacturers might calculate WIP using inventory valuation methods like FIFO to track production costs accurately, while industries handling long-term projects such as construction often use the percentage-of-completion method to recognize revenue and expenses proportionally as work advances.

This approach ensures financial statements reflect the true progress and value of ongoing work. Along with that, WIP also forms an essential component of a company’s inventory on the balance sheet; it is classified as an asset until the goods are finished and sold.

The accounting method used for WIP can influence its valuation and reporting, so investors need to understand how a company evaluates its production stages.

How Is Work in Progress (WIP) Calculated?

Work in Progress (WIP) is calculated by determining the value of partially completed goods or projects in a production process. It involves adding the costs of direct materials, direct labor, and manufacturing overhead incurred during the period. The formula for calculating WIP is:

Ending WIP = Beginning WIP + Manufacturing Costs – Cost of Goods Manufactured (COGM)

This means that WIP starts with the inventory at the beginning of the period, adds the costs of materials, labor, and overhead used in production, and subtracts the inventory of unfinished goods at the end of the period.

This calculation helps companies to track the progress of production and assess the operational efficiency of work in progress.

Custom ERP software automates computations, minimizes errors, enhances productivity, and gives real-time information to assist organizations in making quick, informed decisions. This technique saves time and ensures that the overall operational goals are met.

The Importance of Work in Progress (WIP)

WIP (Work in Progress) serves as an important indicator to allow teams to assess efficiency, streamline workflows, and achieve improved outcomes. Effectively, WIP is essential for organizations to assess efficiency, allocate resources appropriately, and forecast final results.

Furthermore, the use of the latest technical tools is becoming increasingly important, especially in a region like Singapore, where innovation drives competitiveness with easily simplified operations.

Using tools like Manufacturing Execution Systems (MES) is crucial for tracking and analyzing production metrics in real-time, ensuring operational efficiency and accuracy. This process is one of the reasons for good manufacturing practices, as it helps maintain quality and consistency.

With the role of WIP in several industries, here are some important things about WIP as a whole that must be understood, including:

1. Monitor Efficiency and Productivity

WIP allows businesses to assess their operational efficiency. By tracking the status of work at various stages, companies can pinpoint areas where resources might be underutilized or processes are slower than expected.

2. Manage Resources Effectively

Effective resource management ensures businesses allocate resources where needed most. Real-time data helps make informed decisions about labor, materials, and equipment, minimizing waste. Integrating material requirement planning (MRP) ensures optimal material usage and timely production.

3. Predict Final Output or Completion

Provides an essential forecast of project timelines and final outputs. By evaluating current progress, businesses can predict project completion, improving scheduling, customer expectations, and cash flow management. Because of that, utilizing takt time in production helps streamline these predictions.

4. Identify Bottlenecks and Optimize Processes

Helps businesses spot delays and bottlenecks in the production or service process. Identifying these areas enables companies to streamline processes, reallocate resources, and reduce downtime.

5. Improve Decision-Making and Forecasting

Enables businesses to make more informed decisions by providing visibility into ongoing processes. Companies can adjust production plans, allocate resources more efficiently, and forecast future demand or potential delays.

Work in Progress WIP Example

Work in progress is used in various industries to help companies optimize production schedules and improve supply chain management. By understanding how WIP is used, you can optimize production flow and maintain resource efficiency.

It can also help every industry assess where bottlenecks are occurring, allocate resources effectively. Here are some industries and business processes where it is important to manage WIP, including:

1. Project Management

WIP (Work in Progress) in project management assists teams in monitoring their progress, allocating resources effectively, and forecasting completion timelines.

Through the examination of Work in Progress (WIP), project managers can evaluate the distribution of resources, thereby guaranteeing that the appropriate personnel and materials are accessible at every phase of the project.

2. Accounting

WIP is regarded as an inventory asset in accounting, signifying the value associated with goods that are neither finished goods nor raw materials.

Documenting the value of Work in Progress (WIP) enables accountants to present a clearer representation of a company’s assets and its overall financial condition.

Accountants employ several techniques to measure Work in Progress (WIP), such as the percentage of overhead incurred, the percentage of labor expenses, and the percentage of raw material costs.

Additionally, it aids in calculating the Cost of Goods Sold (COGS) for a designated timeframe. WIP in accounting can be calculated to provide a clear picture of the value of inventory that is in the production process.

This is the WIP formula in accounting that can be used:

WIP Value = Raw Materials + Direct Labor + Manufacturing Overheads

3. Monitoring Efficiency

WIP enables organizations to pinpoint bottlenecks and identify opportunities for enhancement. Monitoring the progression of tasks or goods allows businesses to identify the sources of delays or inefficiencies.

A significant accumulation of work in progress (WIP) at a specific stage may indicate that resources are not being fully utilized or that barriers are hindering timely advancement.

4. Resource Allocation

WIP assists organizations in effectively distributing resources. Monitoring the advancement of tasks or products enables businesses to pinpoint which phases of the process need greater focus or supplementary resources, such as labor, materials, or equipment.

5. Supply Chain Management

WIP is important in supply chain management because it ensures that assembly manufacturing proceeds smoothly. Accurate tracking ensures that bottlenecks are discovered early on and resources are used efficiently.

To calculate work in progress in this context, you must first grasp the formula:

WIP = Beginning Inventory + Manufacturing Costs – Ending Inventory

6. Warehouse or Inventory

In warehouses, managing WIP involves tracking partially completed goods and ensuring efficient transitions between stages. Effective WIP management is crucial for maintaining production continuity and meeting customer demand promptly, especially when considering product customization in make-to-order production.

The formula for WIP here is similar:

WIP = Raw Materials + Labor Costs + Overhead Expenses – Completed Goods

This formula determines the value of items still in production by adding direct and indirect production costs and subtracting finished goods. By automating these computations with ERP software such as ScaleOcean, you can speed the process, decrease errors, and gain actionable insights for better decision-making.

Stages of Work in Progress (WIP)

Understanding the various stages of work in progress is critical for effective oversight. Each process is a vital step toward ensuring production efficiency and quality. Singapore Companies must use systematic tracking to detect bottlenecks and optimize workflow. Here are the 4 main phases:

1. Raw Material Allocation

Gathering and allocating supplies to production lines. This stage guarantees that production teams receive the essential materials on schedule, hence avoiding disruptions.

According to Forbes, inefficient material management, such as a lack of centralized inventory teams or inconsistent data, can lead to disruptions and reduced productivity.

It also entails prioritizing material delivery depending on production schedules to improve workflow. Businesses that properly manage this period can reduce idle time and increase overall productivity.

2. Production Process

The transformation of raw materials into semi-finished commodities. This stage involves worker input, machine operations, and adherence to quality requirements. In a mass production system, standardized processes and automation play a crucial role in optimizing efficiency and reducing variability.

Efficient management during this phase ensures that production timelines are fulfilled while minimizing waste. Businesses that focus on operational excellence can cut expenses while improving product consistency.

3. Inspection and Adjustment

Inspection and adjustment entail checking for flaws and making required changes. This step guarantees that production concerns are discovered early on, avoiding delays and minimizing waste.

Businesses that resolve faults swiftly can preserve product quality and increase customer happiness. Effective inspection techniques also aid in compliance with industry norms and regulations.

4. Pre-Final Assembly

Preparing things for ultimate manufacture. This phase entails organizing components and ensuring that all pieces are in place for a smooth assembly.

It comprises final quality tests and changes to ensure compliance with product standards. Businesses that focus on this step can enhance assembly speed while maintaining uniform product standards.

How to Track Work in Progress

Work in progress can be tracked with a company’s accounting system as part of manufacturing inventory. Tracking Work in Progress (WIP) might seem like a mundane task, but it’s one of the most crucial elements of a successful manufacturing operation.

By effectively managing WIP and tracking seamlessly, businesses not only maintain control over costs but also optimize their production capacity in manufacturing and avoid bottlenecks.

Here’s how you can master the WIP tracking process:

1. Implement Real-Time Tracking Systems

Real-time tracking systems provide instant visibility into production stages, material usage, and labor costs. They allow managers to identify delays, bottlenecks, or resource inefficiencies as they occur.

With continuous updates, companies can maintain accurate WIP management records and make quick, data-driven decisions.

2. Define Clear WIP Limits

Setting clear WIP limits helps prevent production overload and maintain workflow efficiency. By restricting how many items can be in progress at once, teams can focus on completing tasks faster without overwhelming resources.

This approach improves throughput and ensures smoother production management.

3. Use Visual Management Tools

Visual management tools like Kanban boards or dashboards make it easier to monitor WIP at a glance. They help teams identify which tasks are pending, in progress, or completed, reducing confusion and enhancing collaboration.

Visualization simplifies communication and keeps the entire production process transparent.

4. Regularly Analyze Performance Metrics

Tracking performance metrics such as lead time, manufacturing cycle time, and throughput provides valuable insights into WIP efficiency. Regular analysis helps detect process inefficiencies and predict potential slowdowns.

With these insights, managers can adjust schedules, optimize resource allocation, and maintain balanced workflow.

5. Automate Workflow Processes

Automation tools minimize manual entry errors and speed up repetitive processes such as inventory updates or cost tracking. Automated workflows ensure that WIP data remains accurate across departments.

This integration for WIP management and tracking enhances coordination between production, finance, and inventory management.

6. Initial Recording

The WIP process begins with initial recording, where all direct materials, labor, and overhead costs are captured as work starts. Accurate initial entries are essential to ensure that total production costs reflect the actual resources consumed during the early stages of manufacturing or project development.

7. Periodic Updates

During production, WIP management records must be updated regularly to include new costs, progress, or adjustments.

These updates maintain data accuracy and help management track whether the project remains within budget and timeline. Consistent updates also ensure reliable reporting for financial statements.

8. Ending Balance

At the end of an accounting period, the WIP ending balance represents unfinished goods still in production. This balance is calculated by summing the accumulated production costs and adjusting for completed items. It provides a clear picture of the value of ongoing work for financial reporting.

9. Final Reporting

The final stage involves transferring WIP costs to finished goods once production is complete. Accurate reporting ensures the cost of goods sold (COGS) and inventory values are correct. This step finalizes the WIP accounting cycle and supports transparent, compliant financial documentation.

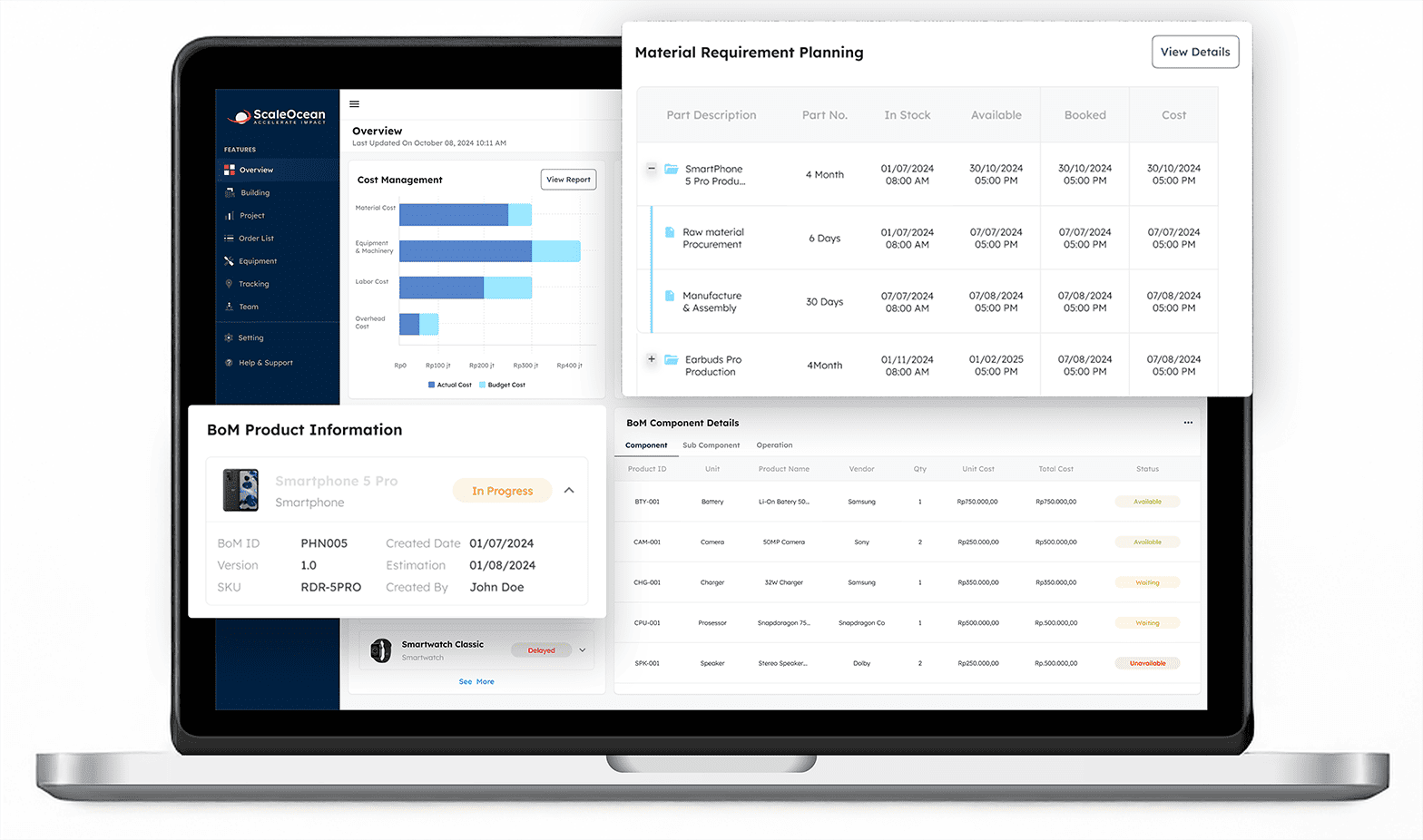

You can use Scaleocean manufacturing software that can track WIP for processes, goods, and costs automatically and within a single platform.

This system is integrated, automated, and flexible, enabling companies to minimize downtime, prevent waste, and improve overall WIP efficiency.

Take a free demo to get a solution that suits your business needs.

Special Considerations of WIP in Singapore Companies

Managing WIP involves several factors, such as industry type, production scale, and financial reporting requirements. Companies must adapt their WIP strategies to suit these variables while ensuring compliance with relevant standards.

Leveraging technology such as supply chain optimization software can further enhance these strategies, enabling better forecasting and improved scalability. In dynamic markets like Singapore, these adaptations are crucial for maintaining a competitive edge and driving innovation.

Technology for Better WIP Management

WIP management can be challenging, particularly in industries with complex workflows. Fortunately, technological advancements are simplifying the process of tracking, monitoring, and optimizing WIP across various sectors.

There are tools you can use to enhance WIP management:

1. Enterprise Resource Planning (ERP) Systems

ERP systems integrate multiple business functions into a centralized platform designed to track work in progress (WIP). These systems provide real-time updates on inventory levels, production status, and resource allocation.

By automating data collection, ERP software reduces human error and facilitates timely decision-making. Moreover, the system offers insights into production bottlenecks, allowing businesses to optimize their processes.

With ERP, companies can effectively monitor WIP, enhancing workflow and decreasing idle time, which ultimately boosts overall operational efficiency and profitability.

2. Inventory Management Software

Advanced inventory management software allows companies to track work in progress (WIP) in real-time, offering a clear view of material bills and products at each production stage.

With automated monitoring of raw materials and finished goods, these tools ensure accurate stock levels and reduce delays.

By using barcode scanning and RFID technology, businesses can quickly update inventory and identify supply chain issues, helping to prevent stockouts and production interruptions for smoother operations.

3. Project Management Tools

Project management tools are essential for WIP management in service-oriented businesses. They facilitate real-time collaboration, task tracking, and efficient resource allocation. By visualizing timelines and deadlines, these tools help teams stay organized and meet project goals.

They also enable managers to spot potential issues early and adjust resources accordingly, ensuring WIP is completed on time and within budget, ultimately boosting productivity and project success.

4. Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are transforming Work in Progress (WIP) management by predicting and optimizing production processes. AI analyzes historical data to forecast needs, reducing downtime and improving resource efficiency.

Machine learning continuously enhances decision-making and identifies patterns in production that may be missed by human managers. This leads to actionable insights and smoother workflows.

5. IoT (Internet of Things) Sensors

IoT sensors provide real-time data on work-in-progress (WIP) status, allowing businesses to track items throughout the production process. By monitoring factors like temperature, humidity, and machine performance, these sensors help maintain quality and reduce delays.

Connecting them to centralized software gives companies instant visibility into WIP, enabling early issue detection. This streamlines workflows, improves production efficiency, and lowers WIP management costs.

Difference Between Work in Process and Work in Progress

Although the two terms are frequently used as synonyms, work in process (WIP) is occasionally intended to specifically describe the expenses associated with incomplete products within a manufacturing setting, whereas work in progress can refer to broader projects or initiatives.

Although the terms are frequently used interchangeably, work in progress is typically used to report capital assets on longer schedules, and also can refer to larger, longer-term projects that have not yet been finished, whereas work in process usually refers to inventory items that are currently being constructed.

In addition to using the Work in Progress method, other strategies can be used to manage each stage of production. One of them is a work in process; both refer to items and tasks that have not been completed, but the context of their use can vary. Here are the differences between the two processes:

1. Context

- Work-in-Progress: This is commonly used to describe long-term projects such as construction or software development, when duties span extensive periods. Utilizing enterprise application software can greatly aid in managing such projects by streamlining resource allocation and ensuring timely execution.

- Work-in-Process: This is narrowly focused on manufacturing activities, stressing the rapid passage of goods through a production line.

2. Industry Focus

- Work-in-Progress: Refers to industries such as construction, where projects are dynamic and require longer timescales.

- Work-in-Process: This is more commonly used in manufacturing to refer to objects progressing through production.

3. Completion Timeline

- Work-in-Progress: Refers to projects that are ongoing and require continuous oversight and adjustments, often without immediate deadlines. These projects typically involve managing complex workflows and ensuring resources are allocated effectively for the long term.

- Work-in-Process: Highlights shorter, structured production lifecycles aimed at quickly transforming raw materials into market-ready goods. This approach prioritizes operational efficiency and rapid turnover to meet production demands.

4. Application

- Work-in-Progress: This is employed in broader business contexts, such as construction, software development, or creative industries when jobs include numerous parts and necessitate meticulous resource management.

- Work-in-process: This is more focused on factory operations and inventory management, with an emphasis on the smooth passage of things along the manufacturing line.

To optimize this process, manufacturing cost estimating software helps businesses accurately predict expenses, allocate resources efficiently, and ensure production remains cost-effective.

Work-in-Progress frequently has a strategic component, emphasizing long-term planning, whereas Work-in-Process is motivated by efficiency and quick turnaround to fulfill production deadlines.

Comparing Works in Progress with Finished Goods

Work in process or work-in-process, work in progress, goods in process, or in-process inventory refers to a company’s partially finished goods waiting for completion and eventual sale, or the value of these items.

Finished goods are also another strategy that you can use besides work in progress and work in process. It is important to understand the difference between efficient inventory management and financial reporting. Here are the important characteristics that distinguish WIP from finished goods:

1. Production Stage

- WIP: refers to objects that are still in the manufacturing process and require extra work before completion.

- Finished Goods: Products that have finished the entire production process are now ready for sale or distribution.

2. Value Status

- WIP: Has a partial value because it includes the costs of materials, labor, and overhead that contribute to its production, but it is not yet a complete product.

- Finished Goods: Have a full value since they are completely manufactured and ready for sale or use, reflecting the total production cost.

3. Storage Requirements

- WIP: Requires specialized storage to keep items organized and to prevent incomplete products from being damaged or mixed up during production.

- Finished Goods: Are usually stored in a warehouse or retail setting, often in bulk, until they are sold or shipped to customers.

4. Inventory Management

- WIP: This is closely monitored throughout the production process to track progress, identify bottlenecks, and allocate resources efficiently.

- Finished Goods: These are managed as part of the finished inventory, emphasizing sales forecasts, shipping logistics, and stock levels to ensure customer fulfillment.

Optimize WIP with Manufacturing ERP ScaleOcean

ScaleOcean’s ERP software offers customized solutions for effectively managing work in progress, helping businesses stay ahead of their operational objectives.

As one of the best ERP software in Singapore, this complex application handles unique issues in tracking and optimizing work-in-progress operations in various sectors.

Businesses may boost their performance by leveraging real-time data and automation. ScaleOcean’s ERP software offers capabilities for streamlining processes and increasing productivity.

You can do a free demo and get recommendations for the best manufacturing ERP features and modules for each specific need.

- Automated Calculations: Reduce manual effort and minimize errors, making WIP management more seamless and efficient.

- Real-Time Tracking: Provides up-to-date insights into production stages, helping businesses maintain efficiency and accuracy.

- Improved Resource Allocation: Ensures optimal use of materials and labor, enhancing productivity and minimizing resource wastage across operations.

- Seamless Integration: Connects Work-in-Progress data with accounting and supply chain systems, enabling unified oversight and smoother decision-making processes.

- Enhanced Reporting: Generates detailed reports for better decision-making, enabling businesses to identify trends, address inefficiencies, and support strategic planning with actionable insights.

Conclusion

Work in Progress (WIP) is an important aspect of business operations, especially in the manufacturing sector, to influence productivity, cost efficiency, and financial correctness.

Businesses that grasp its definition, applications, and calculating methodologies can streamline their workflows, improve resource allocation, drive operational excellence, and boost their competitive position in dynamic marketplaces.

Consider ScaleOcean’s ERP manufacturing software, which is built to match the particular demands of enterprises while increasing productivity, accuracy, and efficiency in work-in-progress management.

This technology guarantees the seamless integration of data and processes, allowing businesses to make smarter decisions in real-time. Request a free demo to see how ScaleOcean can transform your operations while seamlessly simplifying difficult tasks.

Here’s the detailed explanation about the work in progress:

| what it is | Refers to goods or projects that are not fully completed. |

| What component includes | Direct materials, direct labor, and manufacturing overhead cost |

| What the Important | Monitor productivity, predict final output, and identify bottlenecks. |

| How to calculated | Ending WIP = Beginning WIP + Manufacturing Cost – COGM |

| How it used | Optimize production flow, which is in project management, accounting, SCM, and inventory |

| The stages include | Raw material allocation, production, inspection, and pre-final assembly |

| How to track | Manufacturing accounting software can help in cost analysis. |

| What technology for better WIP | ERP, inventory software, project tools, AI, IoT |

FAQ:

1. How to calculate WIP in Excel?

To calculate Work in Progress (WIP) in Excel, use the SUMPRODUCT function to multiply corresponding elements in arrays, such as material costs, labor, and overhead, and then sum the results. This method effectively calculates the total WIP based on the work completed and the costs incurred.

2. What is the accounting treatment for WIP?

Work in Progress (WIP) is treated as an asset on the balance sheet, reflecting an investment that will generate future value once completed or sold. If the project is expected to finish within a year, it is classified as a current asset. Costs such as materials, labor, and overhead are accumulated in WIP until the project is completed.

3. What is the WIP principle?

The WIP principle in the accounting system tracks costs for goods still in production. In agile development, WIP limits define the maximum work allowed at each workflow stage. By limiting work in progress, inefficiencies become more apparent, helping teams streamline their processes. Similarly, in accounting, WIP ensures accurate cost allocation for incomplete products.

4. How to control work in progress?

To effectively control Work in Progress (WIP), establish policies that prevent workers from exceeding WIP limits and highlight when these limits are surpassed. A Kanban board can be an effective tool for this. Gradually reduce WIP limits to uncover bottlenecks and address inefficiencies, ensuring a smooth and efficient workflow.

PTE LTD..png)

.png)

.png)

.png)

.png)