In today’s competitive manufacturing environment, ensuring high machine availability is critical to maintaining productivity and meeting market demands. In Singapore, the manufacturing sector contributes over 20% to the nation’s GDP, underscoring its significance to the economy.

Recent data indicate that Singapore’s manufacturing output increased by 10.6% in December 2024 compared to the previous year, highlighting the sector’s robust performance. However, such achievements are closely tied to the efficiency and reliability of machinery.

Understanding machine availability is essential for manufacturers aiming to minimize downtime and optimize operations. This article discusses the concept of machine availability, its impact on manufacturing efficiency, and strategies for improving it in industrial operations.

- Machine availability refers to the proportion of time a machine operates relative to its scheduled operational time. This metric is commonly referred to as uptime.

- The key function of machine availability ensures smooth production, reduces downtime, and improves scheduling accuracy. High availability boosts OEE, lowers maintenance costs, and prevents delays.

- How to calculate machine availability is using the formula: Availability = Planned Operating Time / Actual Operating Time

- With ScaleOcean Manufacturing Software, you can track, manage, and optimize machine performance by up to 80% across the board.

What Is Machine Availability?

Machine availability refers to the proportion of time a machine operates relative to its scheduled operational time. This metric is commonly referred to as uptime. It represents the percentage of time that machines are available for production without unexpected breakdowns or lengthy maintenance.

High availability can also promote smooth operations, reduce downtime, and increase overall productivity. Businesses can improve this metric by implementing preventive maintenance, streamlining workflows, and utilizing advanced monitoring systems.

Machine availability in manufacturing and industrial settings has a direct impact on output, cost efficiency, and overall equipment effectiveness (OEE) score, making it essential to achieve operational excellence and maximize production capacity.

This will reduce downtime, whether in terms of planned downtime in preventive maintenance, changeovers in planned downtime, unplanned downtime, bottlenecks, or other unexpected stoppages.

The Function of Machine Availability

Machine availability plays a critical role in ensuring operational efficiency and minimizing downtime in manufacturing and production environments. Understanding the function of machine availability helps businesses identify areas for improvement and implement effective maintenance strategies.

Here are the key functions of a machine availability, including:

1. Essential for Production Planning

Machine availability ensures a consistent production schedule by minimizing unexpected downtime. Manufacturers rely on precise availability data to effectively allocate resources and meet demand.

Without consistent availability, planning becomes unpredictable, resulting in inefficiencies, missed deadlines, and increased operational costs. A properly maintained system keeps production running smoothly and improves overall workflow efficiency.

2. Helps Assess Capacity, Schedules, and Breakdowns

Monitoring machine availability provides insights into production capacity and delivery timelines. It allows businesses to identify potential bottlenecks and anticipate equipment failures before they disrupt operations.

By analyzing downtime patterns, companies can optimize scheduling, prevent overloads, and maintain a smooth production flow. Integrating material requirement planning improves scheduling accuracy and resource allocation.

3. Key to Overall Equipment Effectiveness (OEE)

Machine availability is a core component of OEE, alongside performance and quality. High availability means equipment is ready for use, contributing to better productivity.

Downtime, whether planned or unplanned, reduces OEE scores, highlighting inefficiencies. Improving availability through proactive maintenance and real-time monitoring enhances equipment utilization and operational efficiency.

4. Higher Availability Reduces Maintenance Needs

Machines with high availability require fewer emergency repairs, lowering unexpected maintenance costs. Preventive maintenance strategies contribute to longer equipment lifespans and more efficient production schedules.

Businesses can better allocate maintenance resources by reducing unplanned downtime, avoiding costly disruptions, and ensuring a smooth, uninterrupted manufacturing process that improves overall efficiency.

5. Low Availability Leads to Delays and Downtime

Limited machine availability directly impacts production timelines, causing missed deadlines and financial losses. Frequent breakdowns and extended repair times reduce output and disrupt supply chains.

Identifying the root causes of low availability, such as inadequate maintenance or outdated equipment, allows businesses to take corrective action to improve reliability and operational continuity.

6. Reducing Operational Costs

Consistently available machines lower emergency repair costs and reduce resource wastage. Well-maintained equipment operates more efficiently, consuming less energy and minimizing unnecessary expenditures, leading to significant cost savings.

7. Enhancing Product Quality

Stable machine availability ensures smooth production processes, which is critical for maintaining high product quality. Unplanned downtimes can disrupt workflows, leading to rushed operations that may compromise quality standards.

How to Calculate Machine Availability?

Machine availability is a crucial metric that evaluates the reliability and efficiency of equipment in manufacturing, production, and industrial environments. It represents the percentage of time a machine is fully operational and capable of performing its intended function.

To determine machine availability accurately, businesses can use the following formula:

Availability = Planned Operating Time / Actual Operating Time

- Planned Operating Time: The time that was scheduled for the machine to operate. This might include time allocated for production, with no disruptions assumed.

- Actual Operating Time: The actual time that the machine was operating and contributing to production. This will exclude any downtime (either planned maintenance or unplanned failure).

Example:

- Planned Operating Time: 120 hours

- Actual Operating Time: 100 hours (this is the time the machine actually operated, excluding downtime)

Availability = 120 hours / 100 hours

Availability = 1.2 or 120%

An availability rate of 120% means the machine exceeded its planned operating time. This could happen if the machine worked overtime or was scheduled for more hours than initially planned.

However, if the number were less than 100%, it would indicate that the machine was not operating as planned, possibly due to downtimes.

How to Improve Machine Availability

Maximizing machine availability ensures smooth operations, optimal capacity, and minimal downtime. A strategic approach enhances reliability, streamlines workflows, and boosts efficiency. By implementing effective maintenance, optimizing processes, and leveraging technology, businesses can improve uptime. Here are three key strategies:

1. Preventive Maintenance

Conducting regular maintenance, which includes performing maintenance, quality checks, and safety checks, as well as quality and safety assessments. This aids in detecting potential problems before they result in equipment failure. This forward-thinking strategy guarantees that machinery remains functional and minimizes unexpected downtime.

2. Real-Time Machine Monitoring

Using real-time monitoring tools allows operators to track the performance of machines continuously. Predictive analytics can identify early signs of wear and tear, enabling proactive repairs or adjustments.

This minimizes unplanned downtime and improves machine reliability by addressing issues before they escalate.

3. Downtime Analysis

Analyzing downtime data helps identify recurring issues that cause machines to stop working.

By pinpointing the root causes, such as whether mechanical, process-related, or operator errors, companies can implement corrective actions to prevent future occurrences, thus improving overall machine availability and productivity.

4. Optimize Changeover Times

Reducing the time required for machine changeovers and setup operations increases machine availability. Streamlining these processes involves minimizing waiting times, simplifying setups, and training operators for faster transitions, ultimately boosting overall production efficiency and reducing downtime.

5. Production Monitoring Software

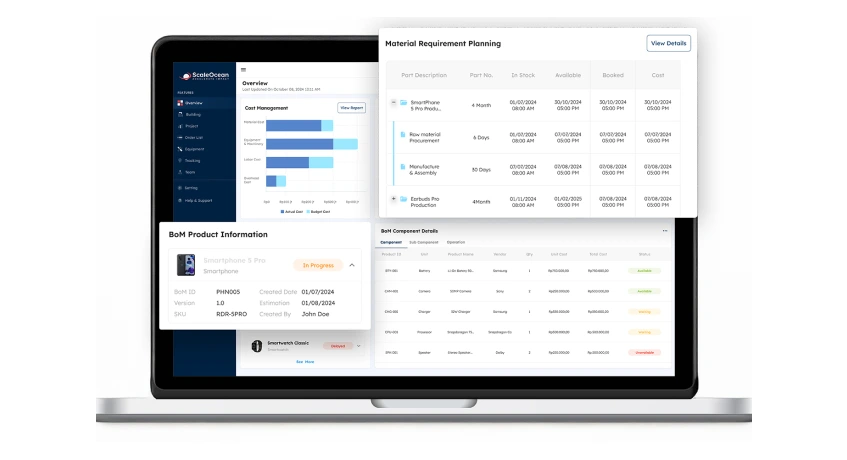

You can invest in technology, such as production monitoring software that can help monitor factory conditions and identify problems proactively, preventing any impact on availability.

The adoption of production monitoring software facilitates real-time insights into factory operations, allowing for the early detection of potential issues. You can use an Enterprise Resource Planning (ERP) system to streamline production monitoring comprehensively.

A system that can integrate maintenance scheduling, inventory tracking, and performance monitoring into a centralized platform. Real-time insights enable businesses to anticipate maintenance needs, optimize resource allocation, and automate workflows.

By leveraging ERP technology, companies can make informed decisions that improve equipment reliability and overall operational efficiency.

6. Efficient Purchasing

Ensuring spare parts are ready to replace equipment. Strategic procurement of essential components leads to faster repair times and less downtime, thereby enhancing machine availability and overall production efficiency.

7. Adopt a Balanced Maintenance Approach

A well-balanced maintenance strategy integrates preventive and predictive maintenance to minimize unexpected failures.

Routine inspections, real-time condition monitoring, and data-driven maintenance schedules all contribute to the early detection of potential problems. This proactive approach can extend equipment life, and also reduces maintenance costs and avoids costly disruptions.

8. Optimize Operational Workflows

Inefficient workflows cause unnecessary machine downtime. Standardizing procedures, automating repetitive tasks, and allocating resources efficiently help streamline operations.

Clear communication and continuous process improvements enhance machine utilization, reducing idle time and improving production flow. Minimizing inefficiencies also lowers the costs of goods sold, boosting profitability and resource efficiency.

9. Invest in Employee Training

Employees play an important role in guaranteeing machine availability. Proper training in equipment operation, troubleshooting, and maintenance best practices enables employees to identify and resolve minor issues before they escalate.

A properly trained workforce increases equipment reliability, reduces errors, and boosts overall productivity.

10. Monitor Key Performance Indicators (KPIs)

Tracking essential KPIs such as uptime, downtime, and mean time between failures (MTBF) helps businesses assess equipment performance. Regular analysis of these metrics enables early identification of inefficiencies and recurring issues.

Companies can use data-driven insights to implement targeted improvements that improve machine availability and lower operational risks.

11. Upgrade Outdated Equipment

Older machinery is more prone to failures and inefficiencies. Replacing or retrofitting old equipment with newer, more energy-efficient models improves reliability and reduces maintenance requirements.

Advanced diagnostics, smart factory automation, and IoT-enabled monitoring in newer machines increase uptime, ensuring smooth and cost-effective operations. To easily improve machine availability, consider using Scaleocean’s manufacturing ERP software, which integrates and automates various production processes.

With this integrated solution, you can monitor and manage the entire production process in real-time, ensuring optimal machine availability, planning and scheduling maintenance, and reducing downtime easily and effectively. Request a free demo now to improve this solution for your business.

How Can We Enhance Machine Availability?

Improving machine availability is critical to productivity and minimizing costly downtime. This goal requires a strategic blend of organizational culture, maintenance practices, optimized processes, and advanced technologies such as IoT platforms. Here are the elements that contribute to efficiency:

1. Culture

Fostering a culture of continuous improvement and collaboration ensures that all employees are dedicated to maintaining machine availability. By motivating staff to focus on machine maintenance and proactive problem-solving, organizations can identify and address issues before they escalate, leading to improved performance and care.

2. Maintenance

Consistent and preventive maintenance is vital for keeping machines in optimal condition. Through regular inspections, early intervention for potential issues, and strict adherence to maintenance schedules, businesses can significantly reduce the likelihood of unexpected breakdowns, thereby extending the lifespan of machines and enhancing their availability.

3. Optimized Processes

Streamlining production processes is key to ensuring that machines operate smoothly and efficiently. By refining workflows, eliminating unnecessary steps, and improving task coordination, companies can alleviate stress on equipment and prevent unnecessary downtime, ultimately increasing machine availability.

4. Industrial Internet of Things Platforms

The adoption of Industrial Internet of Things (IIoT) platforms provides real-time data and predictive analytics for monitoring machine performance. Utilizing these platforms enables organizations to foresee potential failures and optimize maintenance schedules, thereby enhancing overall machine uptime and availability.

The Connection Between Availability and OEE

Availability is a critical component of Overall Equipment Effectiveness (OEE), a metric used to measure manufacturing efficiency. OEE evaluates performance based on three factors, including availability, performance, and quality.

Availability specifically measures the percentage of time equipment is operational compared to planned production time. High availability ensures that machines are operational when needed, thereby increasing OEE.

However, OEE also considers performance speed and product quality, meaning even with high availability, inefficiencies or defects can lower overall effectiveness. By improving availability through reduced downtime and proactive maintenance, businesses can enhance OEE, driving greater productivity, reduced waste, and improved profitability.

The Difference Between Machine Availability and Machine Reliability

Both machine availability and machine reliability are important for keeping operations running smoothly, but they measure different aspects of equipment performance.

Machine availability refers to how often a machine is ready for use compared to its scheduled runtime. It focuses on reducing downtime, whether planned (maintenance) or unplanned (breakdowns), to keep equipment running when needed. High availability means the machine is well-maintained and efficiently managed.

Machine reliability, on the other hand, measures how consistently a machine operates without failure over time. It looks at how often breakdowns happen and how long they last. A highly reliable machine experiences fewer failures, which helps minimize disruptions and reduce maintenance costs.

Difference Between Machine Uptime and Machine Availability

Machine uptime refers to the total amount of time a machine is running and functioning properly during a given period, without interruptions. It measures the actual operational time when the machine is actively contributing to production.

On the other hand, machine availability is a broader metric that considers the proportion of time a machine is available for use, factoring in both uptime and downtime.

It takes into account any planned or unplanned stoppages, including maintenance or failures, and calculates the percentage of time a machine is ready to operate. While uptime focuses on active production, availability provides a comprehensive view of a machine’s readiness and overall efficiency in a production environment.

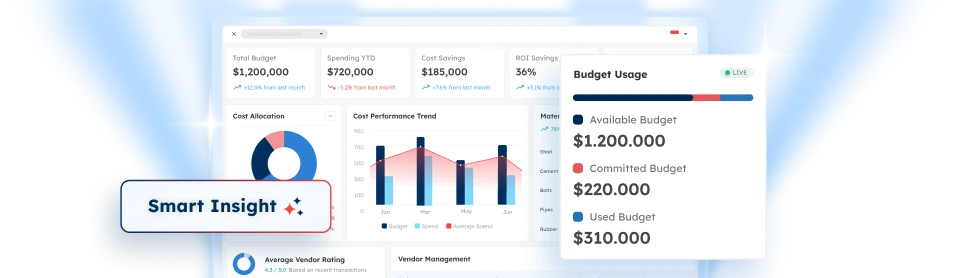

Reduce Downtime and Increase Machine Availability with ScaleOcean

Unexpected machine downtime can disrupt production and cut into profits. With ScaleOcean Manufacturing Software, you can track, manage, and optimize machine performance to keep operations running smoothly.

Our advanced monitoring tools help detect potential issues early, allowing for proactive maintenance and reducing costly breakdowns.

By improving machine availability, ScaleOcean ensures your production stays on schedule and operates at peak efficiency. To minimize disruptions and boost uptime with our powerful solution, you may experience it firsthand with a free demo and discover how it enhances your production operations.

Key Features:

- Real-Time Machine Monitoring: Track equipment status, performance, and usage patterns in real-time to detect potential issues before they lead to downtime.

- Predictive Maintenance Alerts: Utilize AI-driven insights to predict when maintenance is needed, reducing unexpected breakdowns and costly repairs.

- Automated Work Order Management: Schedule and manage maintenance tasks efficiently, ensuring that servicing is performed at optimal intervals.

- Integrated IoT Connectivity: Connect machines with IoT sensors to gather continuous data and improve operational efficiency.

- Root Cause Analysis (RCA): Identify recurring issues and implement corrective actions to prevent future failures.

With ScaleOcean Manufacturing Software, businesses can achieve higher production efficiency, lower maintenance costs, and improved overall equipment effectiveness (OEE). By reducing unplanned downtime, manufacturers can maintain a steady workflow, fulfill customer demands on time, and optimize resource utilization.

Whether you’re looking to scale operations or improve reliability, ScaleOcean provides the tools you need for seamless and efficient manufacturing.

Conclusion

Maximizing machine availability is important for maintaining productivity and meeting market demand. In Singapore’s growing manufacturing sector, reliable equipment reduces downtime, enhances production planning, and improves Overall Equipment Effectiveness (OEE).

Preventive maintenance, real-time monitoring, and data-driven strategies help sustain efficiency and minimize disruptions. ScaleOcean Manufacturing Software offers advanced tools for monitoring, predictive maintenance, and workflow automation to help keep operations running smoothly.

Manufacturers can avoid costly breakdowns and improve performance by leveraging real-time insights and IoT-driven solutions. Try a free demo today to see how ScaleOcean manufacturing software improves efficiency and long-term success.

FAQ:

1. How to check machine availability?

To determine machine availability, you can calculate it by dividing the actual operating time by the planned operating time. For example, if the actual operating time is 480 minutes and the planned operating time is 500 minutes, the machine availability is calculated as 480/500 = 0.96, or 96%. This means the machine is available for 96% of the planned operating time.

2. What is the machine availability factor?

The machine availability factor refers to one of the three key components used to calculate Overall Equipment Effectiveness (OEE) in manufacturing. It accounts for all events that may have disrupted planned production time, particularly when the machine has been halted for an extended period.

3. What are the three types of availability?

The three types of availability, including Inherent, Achieved, and Operational Availability, are related metrics that offer various insights into a system’s reliability and performance. Inherent Availability reflects the system’s reliability, while Achieved Availability helps in maintenance planning by minimizing unplanned downtime.

4. What affects machine availability?

Machine availability is a key component of overall equipment effectiveness, indicating the proportion of time a machine is operational compared to its planned production time. Factors that influence machine availability include unplanned downtime, changeover durations, and the quality of maintenance performed.

PTE LTD..png)

.png)

.png)

.png)

.png)