The manufacturing industry has been a key driver of Singapore’s economy since its independence. And over the years, it has evolved from low-cost, labor-intensive production to high-value manufacturing that fosters innovation and technological advancements. According to research from Statista, Singapore’s manufacturing sector now contributes more than 20% to its gross domestic product (GDP), highlighting its significance in the nation’s economic landscape.

In recent months, the manufacturing sector has continued to show resilience. As reported by The Straits Times, factory production in Singapore increased for the seventh consecutive month in January, with local manufacturers expressing positive business sentiment for the first half of 2025, despite ongoing global uncertainty. Total output expanded by 9.1 percent year on year, following a 5.2 percent increase in December and a 10.8 percent rise in November.

With this continued growth and increasing competition, it has become crucial for companies to maintain a steady production pace to meet market demands efficiently. Takt time, defining the pace of production to match customer demand, becomes vital for maintaining production flow and meeting deadlines without overburdening resources. In this article, we will delve into the importance of takt time, its key benefits, and how utilizing technology can help businesses optimize real-time monitoring to ensure efficiency and stay competitive.

- Takt time is the pace at which production must occur to meet customer demand, helping businesses maintain efficient production flow and avoid overproduction.

- Takt time formula is calculated by dividing available production time by customer demand.

- The benefits of takt time include improved efficiency, optimized resource use, reduced waste, and enhanced quality.

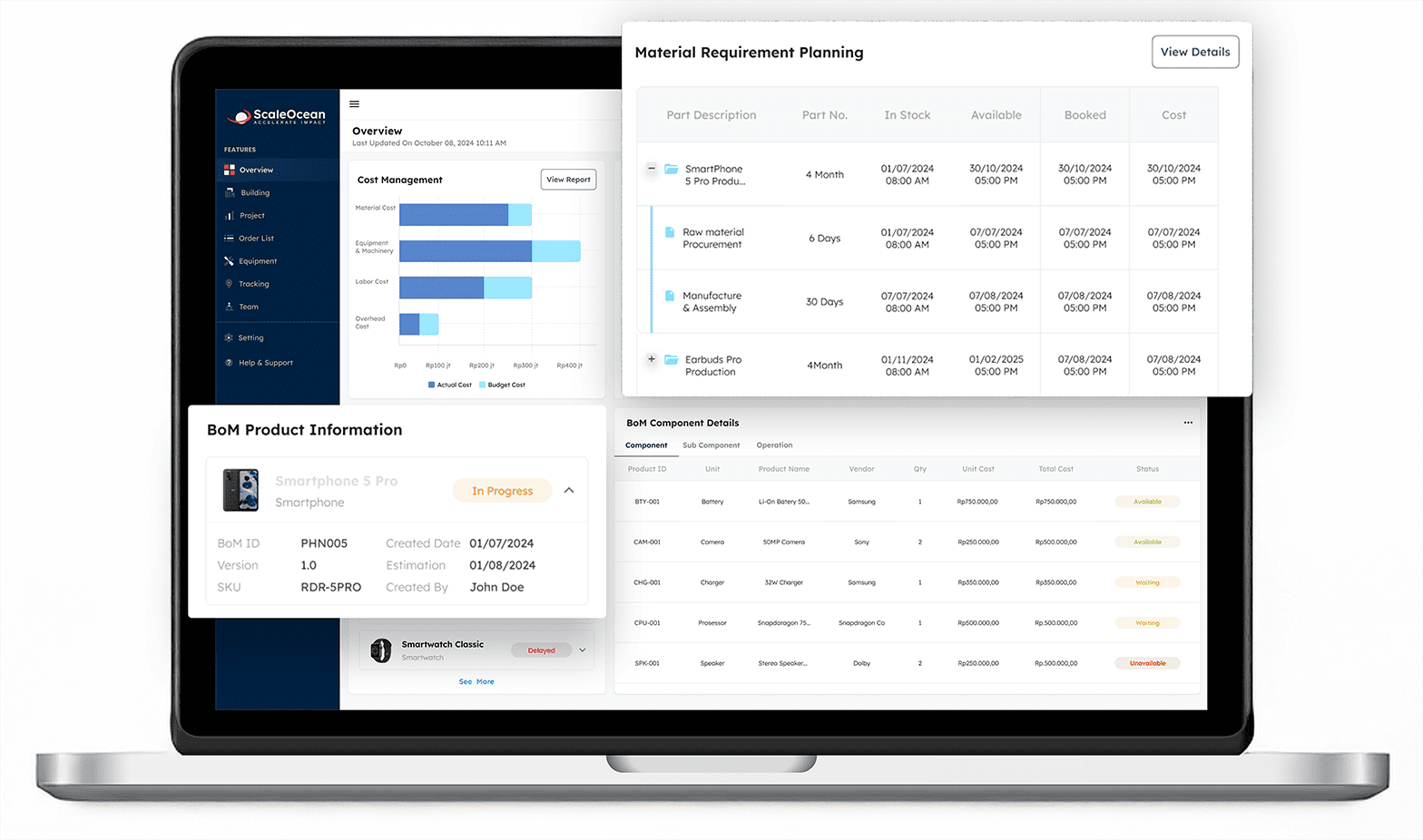

- ScaleOcean is all-in-one manufacturing software that helps businesses optimize real-time monitoring and streamline production processes.

What is Takt Time in Production?

Takt time refers to the pace at which a product needs to be manufactured to meet customer demand. This metric is determined by dividing the total available production time by the required customer demand.

Takt time plays a key role throughout the product lifecycle stages, ensuring efficiency and meeting market needs. The word “takt” originates from German, signifying “pulse” or “rhythm.”

This concept is instrumental in synchronizing production rates with customer requirements, thereby facilitating an efficient and balanced manufacturing process. By determining takt time, companies can prevent both overproduction and underproduction. It is a fundamental principle in lean manufacturing aimed at optimizing processes and fulfilling delivery commitments.

Takt Time Formula

Takt time is a key manufacturing metric that helps align production with customer demand. The calculation can be done as available production time divided by customer demand. Available production time refers to the total time available for production after accounting for breaks, maintenance, and downtime. Customer demand is the number of units required by the customer within a specific period.

Mathematically, takt time formula is:

Takt time = Available production time / Customer demand

For example, if there are 480 minutes of available production time in a day and the customer demands 240 units, the takt time would be:

Takt time = 480 minutes / 240 units = 2 minutes per unit

A takt time of 2 minutes per unit means that the production team needs to complete one unit of the product every 2 minutes to meet customer demand. In other words, for every 2-minute interval, a new unit must be finished and ready for delivery to stay on schedule and fulfill the required number of units within the available production time. This helps in maintaining a steady production pace and ensures that customer demand is met without delays.

How is Takt Time Used?

Why is takt time important? This method plays a crucial role in optimizing production processes by aligning output with customer demand. It is applied in various areas, including capacity planning, process design, scheduling, and daily operations, to maintain efficiency and productivity. Below are the aspects which takt time used.

1. Capacity Planning

By calculating takt time, businesses can evaluate whether their manufacturing process planning aligns with customer demand. This helps in identifying the right amount of resources, machines, and workforce needed to meet output goals. It prevents overproduction or underproduction, making resource use more effective.

2. Process Design

Using takt time calculation, companies can design production processes that meet the demand efficiently. It helps in optimizing the work pace at each stage, ensuring that the production flow stays in sync with required output. This method minimizes delays and improves overall system efficiency.

3. Production Scheduling

In production scheduling, this formula helps structure when and how tasks are carried out, ensuring each stage is completed on time. By setting clear targets for each work cycle, it optimizes cycle time and keeps the production process on track, avoiding missed deadlines.

4. Plant Floor Operations

On the production floor, the takt time formula acts as a benchmark for the pace at which work needs to be finished. It establishes a consistent tempo for the assembly line, making sure that tasks are carried out within the designated timeframe. This promotes efficient operations and reduces idle time between activities.

Benefits of Takt Time

The advantages of this method are extensive, providing enhancements in efficiency, quality, and cost control. In the following sections, we examine the primary benefits that this method contributes to manufacturing and business processes.

1. Improved Efficiency and Productivity

Calculating takt time optimizes production speed by setting a clear pace, minimizing waste and identifying bottlenecks. This clarity establishes targets and motivates teams for steady output. Adhering to GMP Compliance Standards ensures quality, while a manufacturing execution system in Singapore enhances overall efficiency.

2. Enhanced Quality and Customer Satisfaction

By maintaining a consistent pace in production, companies can achieve higher quality across all units. This is especially important in make-to-order strategies, where consistent workflows ensure products meet the same standards, helping meet deadlines, and improving customer satisfaction and loyalty.

3. Cost Reduction and Resource Optimization

By producing only what is necessary to meet demand, businesses can reduce inventory levels, cut storage costs, and optimize resource usage. The bill of materials importance in this process ensures accurate planning, reducing waste and improving efficiency while minimizing overtime and training time.

4. Continuous Improvement

Takt time formula fosters a culture of ongoing improvement by helping teams identify inefficiencies and areas for growth. As processes become more consistent, opportunities arise to improve performance and minimize waste. In Singapore, where businesses often prioritize innovation and operational excellence, this approach supports the drive for continuous progress. With a competitive market and emphasis on efficiency, this method allows companies to stay agile and responsive to both demand fluctuations and industry changes.

Takt Time vs. Cycle Time

Takt time and cycle time are both crucial metrics in production, but they serve different purposes. The takt time represents the rate at which products must be produced to meet customer demand. On the other hand, cycle time measures the actual time it takes to complete a single unit, from start to finish, including all steps in the process. Ideally, the cycle time should match or be less than the takt time to meet demand efficiently.

When cycle time exceeds takt time, it signals that the production process is running too slowly and cannot meet the required output. This discrepancy highlights the need for adjustments in workflow or resource allocation to speed up production.

Conversely, if cycle time is faster than takt time, it may lead to overproduction, resulting in excess inventory and higher costs. So, to optimize production, you also need a material requirement plan to balance takt time and cycle time, helping identify inefficiencies and improve workflow.

Limitation of Takt Time

While this method is a valuable tool for optimizing production, it does have some limitations that businesses must consider. Below, we explore the key challenges that can arise when relying on this calculation in dynamic production environments.

1. Reliance on Stable Demand

Takt time assumes a consistent customer demand, which may not always be the case. Industries with fluctuating demand, like seasonal markets, face challenges in maintaining steady production. This highlights the need to understand production efficiency and adjust for these fluctuations to avoid inefficiencies.

2. Inflexibility in Dynamic Markets

By takt time calculation, businesses may find it challenging to adjust in rapidly changing markets. As customer demands change or new requirements emerge, a fixed approach may not be able to keep up with these changes quickly. Relying too heavily on this can restrict a company’s flexibility, making it difficult to adapt to customer order changes or unexpected product modifications. This can limit the company’s ability to respond effectively to market shifts.

3. Need for Precise Coordination

Careful coordination is necessary across all production stages. A delay in one step such as work in progress product can affect the entire production process. Unforeseen problems, such as equipment failure or staffing issues, can cause bottlenecks, particularly when production timelines are tight. Effective coordination across each stage becomes crucial to prevent operational issues that can lower overall efficiency.

4. Overemphasis on Timing and Potential Quality Issues

Focusing too much on meeting deadlines can result in hurried work and possible quality problems. Teams may prioritize speed over attention to detail, which can result in lower-quality products. Balancing time pressure with careful quality control is essential to make sure fast processes consistently produce high-quality results.

Implementing Takt Time in Production Systems

Implementing this formula in production systems is a strategic approach to align production pace with customer demand. It helps streamline operations, optimize resources, and maintain consistent output. Below the key steps involved in effectively integrating this formula into production processes to achieve greater efficiency and productivity.

1. Setting Production Pace

Implementating this formula starts with identifying the necessary production rate to satisfy customer demand. This process includes assessing the total available production time and dividing it by the customer demand to determine the target time for each unit. By setting this pace, businesses can create a steady flow that aligns production capacity with market needs, ensuring that resources are used efficiently without exceeding demand.

2. Aligning Workstations with Takt Time

Once the production pace is set, each workstation must be adjusted to match the takt time formula. This may involve balancing workloads and reallocating tasks so that each station can complete its portion of work within the specified timeframe. Properly aligning workstations with this method ensures that the production line operates cohesively, preventing delays and bottlenecks while maintaining efficiency.

3. Identifying and Addressing Bottlenecks

During the production process, bottlenecks can occur when a workstation falls behind the required takt time. Detecting these delays early enables managers to make adjustments, such as adding resources, improving processes, or reorganizing workflows. By addressing bottlenecks quickly, the production line stays on track, preventing delays from affecting the entire system.

4. Continuous Monitoring and Adjustment

To maintain efficiency, it’s crucial to continuously monitor the production line as needed. Regular evaluations help pinpoint areas for improvement or shifts in demand that may require adjusting the production pace. This ongoing monitoring and adjustment allow businesses to remain flexible, adapt to shifting market conditions, and optimize production without compromising quality.

5. Utilizing Technology for Real-Time Monitoring

By leveraging AI integration, the software adapts automatically to fluctuating demand, adjusting takt time as needed to optimize production pace. As a result, businesses can maintain a steady flow of operations without unnecessary delays, all while continuously monitoring performance. With real-time tracking, companies can spot bottlenecks and quickly adjust workflows, keeping production running smoothly.

Plus, ScaleOcean offers a free demo, allowing businesses to experience the system firsthand before making any commitments. ScaleOcean is also eligible for CTC grants in Singapore, making it a cost-effective solution for businesses aiming to enhance their operations.

Key features of ScaleOcean manufacturing software:

- Order Management: Integrates with sales systems to prioritize production orders based on customer demand, ensuring timely deliveries.

- Predictive Analytics: Leverages historical data to forecast future production needs, helping businesses stay ahead of demand fluctuations.

- Maintenance Scheduling: Monitors equipment health and schedules preventive maintenance to avoid unexpected downtimes, ensuring continuous production flow.

- Automated Reporting: Generates real-time reports on production efficiency, resource usage, and performance against takt time, helping managers make data-driven decisions.

Conclusion

Takt time plays a crucial role in optimizing production by aligning manufacturing processes with customer demand. However, business needs to consider its limitations, such as the reliance on stable demand and the need for precise coordination. By integrating technology like ScaleOcean manufacturing software, you can better manage takt time, automate adjustments, and streamline production processes.

To see how ScaleOcean can improve your operations, try our free demo today and experience firsthand how our AI-powered software can optimize your production system and help you stay ahead of customer demand.

FAQ:

1. What is the takt time concept?

The takt time concept is the rate at which a product needs to be produced to meet customer demand within a specific timeframe. It helps businesses align production speed with demand, ensuring efficient use of resources and preventing overproduction or delays.

2. What is takt time vs cycle time?

Takt time is the required pace of production to meet customer demand, while cycle time is the actual time it takes to produce a single unit. Ideally, cycle time should match or be less than takt time to meet demand efficiently, avoiding delays or overproduction.

3. How to calculate takt time?

To calculate takt time, divide the available production time by the customer demand within a given period. The formula is Takt Time = Available Production Time ÷ Customer Demand.

PTE LTD..png)

.png)

.png)

.png)

.png)