Getting the procurement life cycle right is vital for any business to run smoothly and save money. However, many teams still find the process a bit of a struggle, which often leads to annoying errors, wasted time, and missed chances to cut down on costs.

According to PWC, the target for digitalising procurement in the Asia Pacific is 63% by 2027, just behind the 70% global goal. This gap shows that businesses in our region really need to speed up their use of digital tools to stay competitive and keep things efficient.

In this article, we’ll dive into the procurement life cycle and how to master its key stages. We’ll also chat about the best tools and strategies to help you streamline your workflow, making your buying process much faster and more cost-effective.

- The procurement life cycle refers to the series of stages involved in acquiring goods or services.

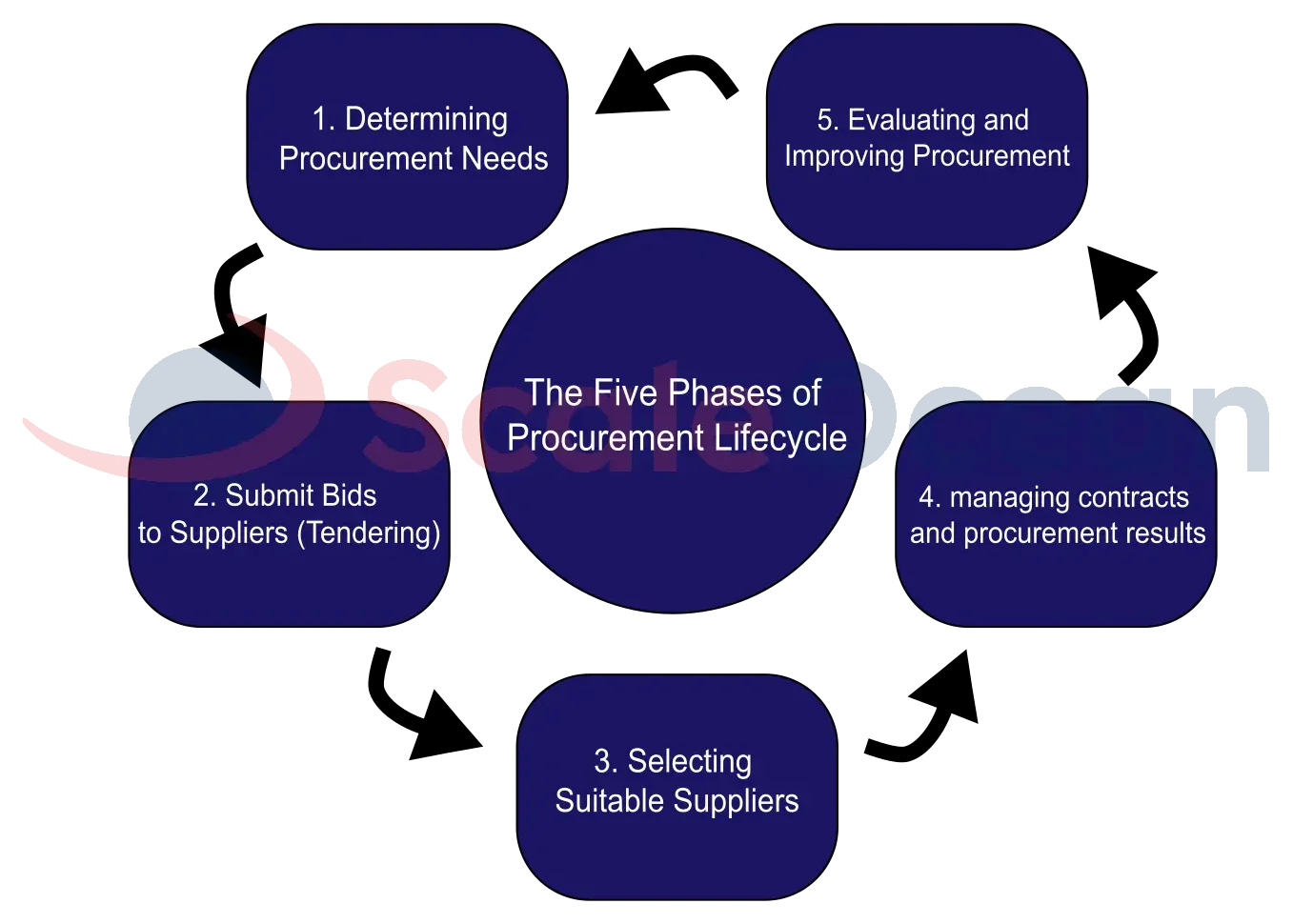

- A procurement life cycle flowchart includes determining procurement needs, submitting bids to suppliers, selecting suitable suppliers, and more.

- The 20-step procurement life cycle includes identifying procurement need, performing a market analysis, conducting a needs Assessment, and more.

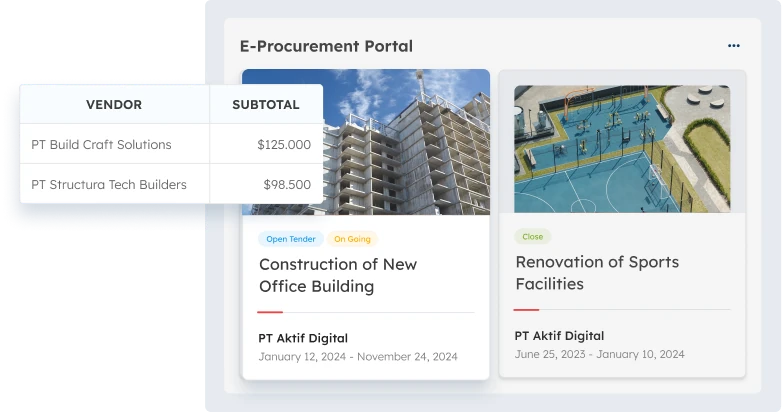

- ScaleOcean e-procurement system connects with your accounting management, vendor management, and inventory, making data flow easily.

What Is the Procurement Life Cycle?

The procurement life cycle refers to the series of stages involved in acquiring goods or services. It covers everything from spotting a need and picking the right suppliers to negotiating deals and keeping things running smoothly after you’ve bought them.

Managing this cycle well is a total win for cutting costs and keeping quality high. It connects every step of your sourcing and buying into one structured flow, making it way easier to manage risks and keep your operations organized and efficient.

Procurement Life Cycle Flowchart

A procurement life cycle diagram or flowchart is a visual representation that outlines the steps in the procurement process. It breaks down each task into easy-to-follow steps, making it clear where each phase begins and ends, and helping everyone involved stay on the same page. Here is the flowchart for the procurement life cycle:

Using this flowchart can greatly improve transparency. It helps businesses track progress through the entire process, ensuring each part of procurement is completed without missing important steps, leading to better outcomes and fewer mistakes. Here is a list of the procurement lifecycle’s main stages:

- Determining procurement needs and requirements

- Submitting bids to suppliers (tendering process)

- Selecting suitable suppliers and vendors

- Managing contracts and procurement results effectively

- Evaluating and continuously improving procurement processes

20 Steps in the Procurement Life Cycle

The procurement life cycle is made up of a series of steps that ensure all needs are met efficiently and effectively. From identifying what’s needed to evaluating suppliers, these steps keep everything on track and within budget, aligning with the overall procurement plan for the business. Let’s walk through these steps one by one:

1. Identify Procurement Need

The first step is to recognize a need for goods or services. This involves understanding what the business requires, the quantity, and how it fits into larger goals. Pinpointing the need early ensures that only necessary purchases are made, reducing unnecessary costs.

Once the need is identified, stakeholders clarify the specifics of the purchase. This includes figuring out exactly what’s needed, which helps avoid over-purchasing and ensures that procurement decisions align with the organization’s objectives.

2. Perform a Market Analysis

Market analysis helps businesses understand the landscape before making a purchase. It involves looking at available suppliers, current market trends, and any potential risks. This step ensures that organizations can make informed decisions when sourcing products or services.

A thorough market analysis helps identify the best suppliers by evaluating their offerings, pricing strategies, and reliability. By understanding the market, businesses can secure the best deals and build strong relationships with trustworthy suppliers.

3. Conduct Needs Assessment

A needs assessment involves taking a deeper dive into the specific requirements of the business. This ensures that the procurement is focused on the essential goods or services, preventing waste and optimizing resources for the most crucial needs.

Involving all relevant departments in the needs assessment helps align everyone on the specifications. When all perspectives are considered, businesses make sure they purchase the right items, meeting both immediate and long-term goals efficiently.

4. Create a Supplier Strategy

Developing a supplier strategy is key to ensuring that businesses partner with the best vendors. This strategy outlines the criteria for supplier selection, like quality, price, and delivery times, to make sure the right suppliers are chosen to meet the organization’s goals.

By selecting suppliers that align with business goals, companies can build long-term, reliable partnerships. A solid supplier strategy focuses on quality and consistency, ensuring smooth procurement processes and dependable supply chains.

5. Perform Pre-Procurement

Pre-procurement involves gathering the necessary information and resources before formal procurement steps begin. This includes ensuring that policies, compliance issues, and legal requirements are addressed. Proper preparation here avoids delays later in the process.

Making sure all internal approvals are in place before starting the procurement process ensures smoother execution. This helps mitigate risks and ensures that everything is in line with both legal and organizational standards, speeding up procurement.

6. Determine Budget and Funding

Determining the budget for procurement is crucial to ensuring that there are enough funds to meet purchasing needs. This includes accounting for all related costs, like shipping, taxes, and other incidental expenses. Proper budgeting helps avoid overspending and financial issues.

A well-defined budget ensures that businesses make purchases within their financial capabilities. It prevents unexpected costs and encourages smarter decision-making during the procurement process, which helps meet goals without exceeding financial constraints.

7. Develop Procurement Strategy

Creating a procurement strategy outlines how the procurement process will unfold. It sets guidelines for selecting suppliers, negotiating terms, and establishing timelines, ensuring that all procurement activities are aligned with the company’s overarching goals.

A strong procurement strategy helps prioritize tasks and set realistic deadlines. It provides a clear roadmap for achieving procurement objectives, ensuring that everything stays on track and within budget for optimal results.

8. Market Testing

Market testing is used to gauge the availability of the required goods or services in the market. It involves collecting feedback from potential suppliers through informal discussions or requests for information (RFIs). Market testing ensures that suppliers can meet expectations.

Through market testing, businesses gather valuable insights that help refine their procurement strategy. This feedback ensures that procurement specifications are realistic, helping identify the right suppliers and setting the stage for smoother future procurement activities.

9. Identify Potential Suppliers in Tender

Identifying potential suppliers during the tendering process is crucial to ensuring that businesses have access to the best possible options. This involves evaluating suppliers based on key criteria such as price, reliability, and overall quality.

By identifying the right suppliers early on, companies can conduct a thorough and competitive evaluation process. This increases the chances of finding a vendor who meets requirements and offers the best value for money, leading to stronger procurement outcomes.

10. Conduct an RFI

An RFI (Request for Information) is an essential part of the procurement cycle that gathers additional information from suppliers. It helps businesses understand a supplier’s capabilities and how well they align with the company’s needs before moving to formal bidding processes.

Issuing an RFI helps streamline the procurement process by providing critical information about suppliers. This step ensures that companies only move forward with suppliers who meet their specifications, reducing the likelihood of errors later in the cycle.

11. Issue Request for Proposal/Quotation

An RFP (Request for Proposal) or RFQ (Request for Quotation) is issued to suppliers to receive formal offers. This step clarifies what is required and invites vendors to submit detailed proposals or quotations that meet specific terms and conditions.

This stage allows businesses to review a variety of options, making it easier to compare costs, terms, and services. Inviting multiple suppliers to submit proposals ensures that the organization can choose the best offer available, minimizing procurement risks.

12. Issue Tender Documentation (RFQ or ITT)

Tender documentation, including RFQs or ITTs (Invitations to Tender), provides suppliers with the full scope of procurement needs. This documentation ensures that all suppliers are clear about the expectations, requirements, and terms before submitting their bids.

The documentation clarifies the criteria and sets expectations, reducing misunderstandings and ensuring a transparent process. Clear tender documentation fosters competition and helps businesses choose the right suppliers who can meet the outlined needs.

13. Evaluate Bids

Bid evaluation involves reviewing and comparing the bids received from suppliers. It’s essential to consider pricing, quality, and delivery times to ensure that the selected bid offers the best value. This step is critical to making informed procurement decisions.

Evaluating bids allows businesses to assess each supplier’s ability to meet the required specifications. Clear evaluation criteria ensure that decisions are based on facts, reducing risks and selecting the supplier best suited to the needs of the business.

14. Receive and Evaluate Supplier Responses

Once suppliers submit their responses, they must be carefully evaluated. This includes checking compliance with the terms of the RFP or RFQ, assessing product quality, and ensuring pricing aligns with the company’s budget. A thorough evaluation helps identify the best suppliers.

By evaluating responses properly, businesses ensure they only move forward with the most qualified suppliers. This careful process helps avoid unnecessary procurement delays, ensuring smooth supplier engagement and cost-effective purchasing.

15. Select Preferred Supplier(s)

Once the evaluation is complete, the preferred suppliers are selected. This choice is based on how well their proposals meet the business’s needs. It’s important to select suppliers who can consistently deliver on quality, cost, and service expectations.

Selecting the right supplier is crucial for building long-term relationships. It ensures that procurement cycles are smooth and future engagements are mutually beneficial, enhancing overall operational efficiency and supplier performance.

16. Negotiation and Contracting Agreement

Negotiating terms with the selected supplier ensures both parties are on the same page regarding pricing, delivery, and other terms. Finalizing the contract creates a solid foundation for cooperation, ensuring clarity and accountability from both sides.

Strong contract negotiation ensures that there are no surprises down the line. By clearly outlining obligations, payment terms, and delivery schedules, both parties are aligned, contributing to successful procurement and long-term partnerships.

17. Procurement Receiving & Inspection

Once the goods or services are delivered, the receiving and inspection phase begins. This ensures that the quality and quantity of the goods match what was agreed upon in the contract. Proper inspection prevents costly errors or disputes later in the process.

A thorough inspection ensures discrepancies are addressed before acceptance, preventing returns and improving inventory management. According to CBRE, with a 4.4% increase in inventory over the past year, across Singapore, Hong Kong, Tokyo, and Sydney, efficient inspection is vital to managing higher stock volumes.

18. Three-Way Matching & Payment

Three-way matching compares the purchase order, receipt of goods, and supplier invoice to ensure everything aligns. This verification process ensures that only legitimate invoices are paid, reducing the risk of overpayment or fraud in the procurement cycle.

By using three-way matching, businesses ensure that payments are made only for the goods and services received. For an efficient and accurate process, using the best purchase order software can significantly enhance financial accuracy and promote trust between buyers and suppliers.

19. Supplier Relationship Management and Performance

Supplier relationship management ensures that businesses maintain effective and positive relationships with their suppliers. Regular performance evaluations and communication help ensure that suppliers meet expectations consistently and deliver quality products.

Building strong relationships with suppliers improves overall procurement performance. By maintaining transparency and open communication, businesses foster loyalty, reliability, and a more effective procurement cycle in the long run.

20. Record Keeping & Evaluation

Proper record-keeping ensures that all procurement documentation, contracts, and invoices are securely stored. Evaluation of the procurement process helps identify areas for improvement, allowing businesses to refine strategies and streamline procurement for future cycles.

Tracking your progress is easy when you have detailed records to look back on. ScaleOcean ERP makes this a breeze with its smart and various types of procurement report features, giving you real-time insights that help your business constantly level up its procurement game.

What is the Importance of an Optimized Procurement Life Cycle?

Optimizing the procurement life cycle is crucial for improving efficiency, reducing costs, and maintaining supplier relationships. A well-optimized process ensures that resources are used effectively, and procurement cycles are completed smoothly and on time.

An optimized procurement life cycle also minimizes errors and delays. By streamlining each stage, businesses can improve supplier management, reduce risks, and achieve better purchasing outcomes, ensuring that procurement supports the overall goals of the organization.

What Should be Considered in the Planning Stage of the Procurement Life Cycle?

Getting the planning stage right is the secret to a smooth procurement journey. It’s all about spotting needs early, weighing up risks, and setting a solid strategy. Good planning really builds the foundation for everything that follows. Here’s what to keep in mind:

1. Strategic Sourcing

Strategic sourcing is about finding the right suppliers who can meet quality standards while providing competitive pricing. This process helps ensure that suppliers offer the best value for the organization, contributing to long-term success.

By carefully evaluating suppliers based on their capabilities and alignment with business goals, businesses ensure they partner with vendors who can deliver on time, meet quality requirements, and reduce procurement risks.

2. Technology Integration

Integrating technology into procurement allows businesses to automate tasks and improve communication. Technology helps businesses streamline procurement workflows, ensuring faster execution, fewer errors, and better visibility into procurement activities.

Integrating tech gives you real-time data to make smarter choices. It cuts out boring manual work, so your team can focus on strategy and suppliers. Using the best e-procurement software in Singapore makes this even easier by fitting perfectly with your current systems.

3. Sustainability & Ethics

Focusing on sustainability and ethical sourcing helps businesses make procurement decisions that align with social responsibility. By partnering with suppliers who adhere to environmental and ethical standards, organizations contribute to a positive reputation and long-term success.

Ethical sourcing ensures that procurement practices align with corporate social responsibility (CSR) goals. It also helps mitigate risks associated with unethical practices, building trust and improving relationships with both suppliers and customers.

How to Manage the Procurement Life Cycle?

Managing the procurement life cycle involves overseeing each stage to ensure that procurement activities meet organizational goals. Effective management includes monitoring suppliers, assessing risks, and managing contracts to ensure smooth operations throughout the procurement process. Key tasks include:

1. Strategic Planning and Needs Assessment

Getting your strategic planning and needs assessment right is the best way to make sure your buying activities actually match your business goals. It’s all about making sure every move you make counts.

This stage is where you figure out exactly what you need, why you need it, and where it’s coming from. By doing this, you ensure your procurement efforts are focused, effective, and don’t waste any time or resources.

2. Supplier Sourcing and Risk Management

Finding the right partners is about more than just a good price, but it’s also about picking reliable suppliers while keeping an eye out for potential risks. This balance is key to a smooth, worry-free process.

It’s all about picking suppliers carefully to avoid headaches like market shifts or delays. Having a solid procurement risk management plan helps you spot and handle trouble early, making sure your procurement stays as safe and steady as possible for your business.

3. Contract and Order Execution

This is where your agreements finally turn into action. It’s the stage that makes sure everything you’ve discussed and signed on paper actually starts moving forward in the procurement process.

In this phase, you’ll finalize contracts and make sure orders are processed and delivered correctly. It’s all about ensuring that everything, from the actual delivery to the final invoice, follows the terms you’ve already agreed upon.

4. Performance and Relationship Management

Building strong ties with your suppliers and keeping an eye on how they perform ensures everything stays aligned with your goals. It’s all about creating a partnership that actually works for your business.

Checking in regularly and evaluating performance helps you catch any hiccups early. Clear communication ensures your suppliers know exactly what you need, making it much easier for them to meet your expectations every single time.

Does the Procurement Life Cycle Vary Across Different Businesses?

Yes, the procurement cycle definitely changes based on a business’s size and industry. For instance, manufacturing often needs very specific material details and longer lead times, while retail or service sectors might have a much faster process.

In fields like construction or healthcare, you’ll often find extra steps for regulations and safety. Matching the procurement cycle to your specific industry is the best way to keep things running efficiently and stay within your budget.

Challenges in the Procurement Life Cycle

Managing supplier risks and avoiding delays can be a real juggle in procurement. On top of that, shifting market trends and changing customer needs often make decisions even tougher, which can lead to frustrating inefficiencies if you aren’t careful.

To beat these hurdles, it helps to lean on smart tech and better supplier strategies. Staying flexible and planning allows your team to handle risks easily and adapt to changes, making the whole procurement journey much smoother for everyone.

Tools and Technologies for Efficient Procurement Life Cycle

Using the right tech can really give your procurement a boost. With tools like AI and blockchain, you can simplify your workflow, make smarter calls, and save money. These innovations help you work faster and manage suppliers better. Check out these top tech picks:

1. AI and Machine Learning

AI and machine learning are like having a crystal ball for your data. They help you spot market trends and grade supplier performance instantly. This means you can make smarter, data-backed choices instead of just relying on your gut feeling.

By letting AI handle boring tasks like data entry, your team is free to focus on the big picture. This not only cuts down on operational costs but also makes your whole procurement process much faster and more efficient.

2. Blockchain

Blockchain brings a whole new level of trust and security to procurement. By creating records that can’t be changed, it helps keep suppliers accountable and naturally cuts down on the chances of errors or fraud happening behind the scenes.

This tech gives everyone a secure and clear way to track every transaction. It makes working with suppliers much easier by providing one “source of truth” that everyone trusts, which keeps everyone on the same page and helps prevent any messy disputes.

3. Integrated Platform with ScaleOcean’s Procurement Software

An all-in-one tool like ScaleOcean e-procurement connects with your accounting management, vendor management, and inventory, making data flow easily. You get better visibility across the board and can even customize the features to fit your team’s specific way of working.

ScaleOcean’s platform, eligible for the CTC grant, makes managing procurement a breeze while keeping you in total control. By offering solutions tailored to you, it helps your business stay on track with both your project goals and your budget.

Here are the Main Features of ScaleOcean’s procurement software:

- Procurement Process Automation: One key feature is automated RFQ and PO creation, speeding up procurement and reducing errors by replacing manual processes.

- Vendor Selection Based on Objective Data: ScaleOcean’s automated vendor evaluation system selects suppliers based on objective criteria like price, punctuality, and service quality.

- Real-Time Stock and Procurement Notifications: Low-stock notifications alert businesses when inventory reaches a minimum, ensuring timely procurement and avoiding operational disruptions.

- Long-Term Procurement Management: Blanket Order Management enables long-term agreements with vendors, ensuring ongoing orders and optimized inventory for sustained supply.

- Flexible Customization: The platform offers customizable features, from system integration to dashboard layout, allowing adaptation to various industries and business needs.

Conclusion

The procurement life cycle is a smart way to get what your business needs without overspending. By lining up your buying habits with your goals, you can lower risks, build better supplier bonds, and keep your whole operation running like a well-oiled machine.

ScaleOcean’s e-procurement software makes procurement easy by automating the boring stuff. From quick RFQs to real-time stock alerts, it helps you make better, data-driven calls. Plus, you can try ScaleOcean’s free demo to see exactly how it can boost your team’s efficiency!

FAQ:

1. What is full cycle procurement?

Full cycle procurement involves the complete process of obtaining goods or services, starting from identifying needs, evaluating suppliers, and negotiating contracts to purchasing, receiving, paying, and keeping records. It ensures smooth and cost-effective operations throughout.

2. What are the 4 types of procurement methods?

1. Direct procurement

2. Indirect procurement

3. Services procurement

4. Capital procurement

3. What are the 5 pillars of procurement?

1. Cost

2. Availability

3. Compliance

4. Quality

5. Timeliness

4. What are the 5 P’s of procurement?

The 5 P’s of procurement include Proposal, Planning, Pricing, People, and Project Management. These elements help guide procurement efforts from supplier engagement through delivery, ensuring alignment with company goals and requirements.

PTE LTD..png)

.png)

.png)

.png)

.png)