Procurement risk management is essential for businesses in competitive markets, where efficiency and dependability are key. Effective procurement methods reduce delays, lower costs, and ensure timely deliveries.

This article discusses common procurement hazards, how to mitigate them, and the significance of risk management plans. It provides actionable advice for business owners to improve procurement efficiency, reduce disruptions, and develop supplier relationships, allowing them to maintain a competitive advantage in their sectors.

- Procurement risk involves identifying, evaluating, and reducing risks related to the acquisition of goods and services to avoid financial and operational setbacks.

- Common procurement risks are inaccurate analysis, supply chain disruptions, price fluctuations, supplier risk, quality and performance risk, and many others

- Procurement risks can be mitigated by risk assessment, supplier relationship management, risk monitoring, establishing clear supplier criteria, creating strong contracts, and many other

- ScaleOcean’s E-Procurement Software helps businesses streamline procurement by automating tasks, monitoring supplier performance, and ensuring real-time data accuracy, reducing procurement and supply chain risks.

What Is Risk Management in Procurement?

Procurement risk involves identifying, evaluating, and reducing risks related to the acquisition of goods and services to avoid financial and operational setbacks. This includes tackling challenges from unreliable suppliers, disruptions in the supply chain, financial instability, and external events such as geopolitical changes or natural disasters.

A strong strategy incorporates measures like thorough supplier vetting, effective contract negotiations, supplier diversification, and contingency planning. These hazards have the potential to interrupt the flow of goods and services, increase expenses, and negatively affect an organization’s overall performance.

Identifying procurement risks early can help firms take preventive measures to reduce losses and keep operations running smoothly. It also includes identifying potential hazards, developing mitigation solutions, and ensuring that the procurement process stays efficient and cost-effective.

Companies that implement excellent risk management techniques for procurement processes can better protect their interests and keep the supply chain stable.

12 Common Procurement Risks

Procurement risks are an intrinsic feature of every organization. Understanding these risks is critical for businesses seeking to protect their operations and maintain seamless commercial activity.

These risks might develop at any point during the procurement and purchasing process in business, affecting cost, timeliness, and quality. Businesses should be aware of the following frequent procurement risks:

1. Inaccurate Analysis

Inaccurate analysis during the procurement life cycle process can lead to poor decision-making. Without reliable data, businesses may overestimate demand, misjudge supplier capabilities, or miss cost-saving opportunities.

This can result in overstocking, understocking, or excessive spending. To mitigate this risk, procurement teams must invest in data analysis tools and ensure accurate forecasting based on historical trends and market insights.

2. Supply Chain Disruptions

Natural catastrophes, pandemics, and political instability can all interrupt the supply chain and cause delays in deliveries. These delays can cause a domino effect on production schedules, resulting in missed deadlines and dissatisfied consumers.

Businesses must develop effective strategies for dealing with these unpredictable events. This involves diversifying suppliers and creating backup plans.

3. Price Fluctuations

Market prices for raw materials or items can fluctuate unexpectedly, resulting in increased procurement expenses. For firms with set budgets, these swings may pose unexpected financial strain. To mitigate these risks, companies can monitor market trends and implement long-term contracts or hedging strategies.

A robust purchase journal can help track these fluctuations, ensuring accurate financial reporting. A robust purchase journal, along with the best purchase order software, can help track these fluctuations, ensuring accurate financial reporting.

4. Supplier Risk

Suppliers who fail to deliver items on schedule or do not satisfy quality standards might cause serious problems. Late delivery and low-quality items not only disrupt operations but also undermine a company’s image.

To achieve dependability, firms should regularly evaluate supplier performance and maintain open communication lines. Setting clear expectations with suppliers can help prevent these problems from occurring.

5. Quality and Performance Risk

Quality and performance risks occur when suppliers fail to meet required product standards or delivery expectations. Substandard quality can lead to customer dissatisfaction, increased returns, and damage to brand reputation.

Performance risks arise when suppliers fail to deliver goods on time or as specified in contracts. Thorough vetting, regular supplier audits, and clear performance metrics help mitigate these risks, ensuring that procurement consistently meets organizational quality standards.

6. Financial Risk

Financial risks in procurement stem from the potential for price fluctuations, supplier bankruptcy, or unforeseen economic conditions that can impact procurement budgets. Exchange rate volatility, rising raw material costs, and financial instability in supplier organizations can disrupt procurement plans.

Procurement risk strategies, such as locking in prices with long-term contracts, diversifying suppliers, and regularly reviewing financial health, can help reduce financial risks in procurement.

7. Cyber Risk

As procurement increasingly relies on digital systems, cyber risks become a significant concern. Hacking, data breaches, and cyber-attacks can compromise sensitive procurement data, including pricing information and supplier contracts.

Cybersecurity measures such as encryption, regular system audits, and employee training on security protocols are essential for mitigating these risks. Protecting procurement systems from cyber threats ensures that business operations remain secure and resilient.

8. Regulatory and Compliance Risks

Noncompliance with laws, regulations, and standards can result in legal issues, fines, and reputational damage. Adherence to all applicable procurement regulations is critical to avoiding costly penalties and business disruptions.

Regular audits, staff training, and compliance checks can help to reduce this risk. Keeping up with regulatory developments is also critical for ensuring compliance.

9. Fraud and Corruption

When suppliers or procurement teams participate in dishonest activities, there is a risk of fraud or unethical activity. Fraudulent activity can result in financial losses, legal consequences, and a tarnished reputation.

To reduce this risk, companies should have robust internal controls, perform regular audits, and develop a transparent culture. Implementing secure payment systems and supplier checks can also help prevent fraud.

10. Contractual Disputes

Poorly written contracts or unclear terms can result in misunderstandings or legal disputes between the company and its suppliers. Contract disagreements can cause procurement processes to be delayed and result in significant legal expenditures.

To avoid this, firms should make sure their contracts are clear, explicit, and complete. Seeking legal counsel when drafting contracts can help reduce the likelihood of future disputes.

11. Weak Contract Management Processes

Weak contract management processes can result in miscommunication, breaches of contract, and missed opportunities for cost reductions or performance improvements.

It is essential to have clear, well-drafted contracts that define terms, penalties, and responsibilities. Regularly reviewing and updating contract terms, as well as automating contract management systems, helps mitigate these risks.

12. Insufficient Use of Automation

Failing to utilize automation in procurement can lead to inefficiencies, errors, and delays. Manual processes are time-consuming and prone to mistakes, especially when handling large volumes of transactions.

Implementing automated systems for order processing, invoice management, and supplier tracking can increase accuracy, speed, and efficiency, ultimately reducing procurement risks and improving overall productivity.

How to Mitigate Procurement Risks and The Strategies

Mitigating procurement risks is critical to ensuring smooth operations and solid supplier relationships. Businesses that identify and handle possible risks early might avoid costly disruptions and safeguard their bottom line. Here are a few techniques for reducing procurement risks:

1. Risk Assessment

Regular assessments help to detect both actual and potential hazards in the procurement process. Businesses can resolve risks before they spread throughout the supply chain by reviewing the entire process. Early detection of risks enables rapid corrective actions, reducing the impact on operations and expenditures.

2. Supplier Relationship Management

Building strong, collaborative relationships with suppliers is essential for effective procurement risk management. Transparent communication and mutual trust can help settle conflicts quickly and prevent them from escalating.

Strong supplier ties also encourage better coordination, resulting in more timely deliveries and higher quality standards. Companies also regularly monitor supply chain operations to identify disruptions early. Use real-time tracking tools to stay updated on supplier performance and inventory levels.

According to BuildMagazine SG, a transparent FM procurement process can reduce operating costs by up to 10% and boost productivity. This helps you quickly address issues, minimizing delays and stockouts.

3. Risk Monitoring

Continuous monitoring of procurement processes, suppliers, and market conditions is critical for detecting early warning signs of potential risks.

Businesses can utilize data analytics and real-time tracking to stay informed about changes in supplier performance and market volatility. This enables swift interventions, keeping procurement efforts on schedule.

4. Establish Clear Supplier Criteria

Assess suppliers based on their financial health, performance history, and ability to meet deadlines. This process helps to ensure that you are working with trustworthy partners who can consistently meet your quality and delivery standards.

Comprehensive assessments will help to avoid future interruptions caused by unreliable suppliers. Avoid depending on a single supplier. Diversifying your supplier base reduces the risks associated with supply disruptions caused by natural disasters, strikes, or political instability.

With many suppliers, companies can also ensure that their supply chain stays intact even if one provider experiences difficulties.

5. Create Strong Contracts

To protect your business in the event of a disagreement, make sure your contracts explicitly state terms, duties, and eventualities. A well-defined agreement will establish expectations for both parties and provide clear guidelines for dealing with issues like delays or quality problems.

To mitigate procurement risk, companies can also use blanket order contracts to streamline procurement by ensuring consistent delivery terms for large or long-term projects.

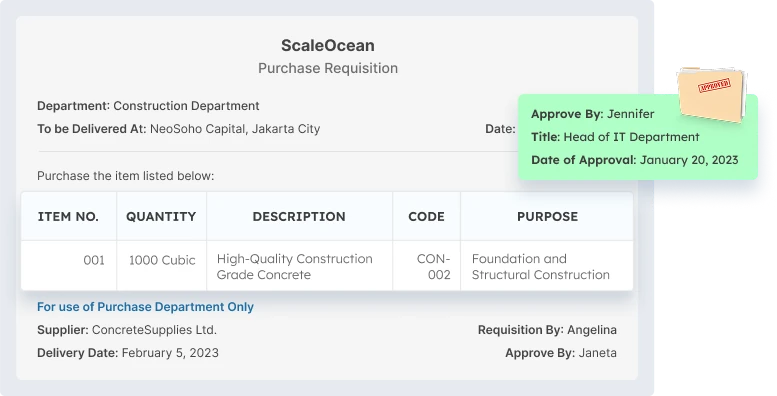

6. Implementing E-Procurement Solutions

Implementing advanced e-procurement solutions helps streamline the procurement process, reduce human error, and improve efficiency. These systems enable automation of routine tasks, such as purchase orders and invoicing, ensuring that procurement data is accurate and real-time.

With enhanced visibility into procurement activities, businesses can track supplier performance, identify potential risks, and address issues before they escalate, leading to more effective decision-making.

7. Enhance Procurement Transparency

Transparency in procurement processes is critical for reducing the risk of fraud, ensuring compliance, and building trust with suppliers. It allows businesses to better track procurement activities, monitor supplier performance, and make more informed decisions based on up-to-date data, such as procurement reports.

By maintaining clear and open communication with vendors, setting clear expectations, and providing detailed reporting, companies can foster stronger relationships with suppliers and avoid misunderstandings.

8. Continuous Spend Analysis

Regularly analyzing procurement spending helps businesses identify inefficiencies, detect potential risks, and ensure that resources are being allocated effectively.

Spend analysis involves examining purchasing patterns, supplier costs, and contract terms to uncover areas where savings can be made or processes can be improved.

By continuously reviewing procurement data, companies can optimize supplier selection, negotiate better terms, and make data-driven decisions to reduce procurement risks.

9. Implement Contingency Plans

Prepare for unforeseen circumstances by creating backup plans. This may involve alternate suppliers or emergency supply levels to ensure that your firm can continue to run properly. Planning ahead of time can help you mitigate the effects of potential disruptions to your procurement process.

10. Implement Strong Internal Controls

Strengthen your organization’s internal controls to prevent fraud and corruption. Regular audits and oversight processes ensure transparency and compliance. This helps minimize dishonest behavior and maintains integrity in procurement.

Effective controls ensure all procurement activities follow established protocols, protecting the business.

11. Establish Clear Risk Mitigation Strategies

Define and integrate specific risk-mitigation actions into your procurement risk management strategy. A clear plan allows your team to respond swiftly when risks arise. This reduces the potential impact on business operations.

Proactively addressing risks ensures that disruptions are minimized, keeping procurement methods and processes running smoothly.

12. Conduct Regular Training

Teach your procurement team about risk management principles and procedures to enhance their ability to identify and handle risks effectively. Regular training helps staff recognize potential risks early and respond appropriately.

It ensures that everyone is aligned with best practices for mitigating risks. This continuous learning process strengthens the team’s ability to manage procurement challenges efficiently.

13. Utilize Technology Integration for Risk Monitoring

Use technology to monitor supplier performance, market prices, and regulatory changes to avoid surprises. Automation tools and real-time systems help identify risks early. This enables businesses to take timely preventive actions.

By leveraging technology, firms can stay ahead and minimize disruptions in procurement. Integrating procurement software into the risk management plan automates procedures and improves operational efficiency.

Technology solutions enable firms to monitor hazards in real time, allowing them to respond quickly to any new concerns. Technology minimizes the risk of human errors while increasing total efficiency.

You can use the best e-procurement software, ScaleOcean, which can be integrated into an organization’s ERP system, so the system can play a critical role in mitigating procurement risks by automating and streamlining various procurement processes, improving efficiency, and enhancing transparency.

Request a free demo to customize the system according to your business needs!

Why Managing Procurement Risk is Important

Managing procurement risk is crucial for maintaining a business’s stability and efficiency. By effectively identifying and mitigating risks, companies can avoid issues like unreliable suppliers, missed deadlines, and resource wastage.

This not only supports the overall health of the business but also ensures smooth operations and sustainable revenue. Furthermore, proactive risk management can offer a competitive edge, allowing companies to reduce costs, strengthen their supply chain, and adapt swiftly to market changes.

Mitigate Procurement Risk Integrated with the ScaleOcean E-procurement

ScaleOcean’s e-Procurement Software is designed to streamline the procurement process by automating tasks, enhancing efficiency, and reducing risks across the entire supply chain.

By integrating procurement management with real-time data, the system allows businesses to monitor supplier performance, track inventories, and ensure timely deliveries.

The software provides a comprehensive solution that helps companies manage procurement risks, control costs, and improve decision-making, ultimately enhancing business performance.

To experience how ScaleOcean can transform your procurement processes, we offer a free demo to showcase its capabilities. Additionally, ScaleOcean is eligible for the CTC grant, making it an even more valuable investment for your business. Below are the key features of the ScaleOcean software:

- Real-Time Supplier Tracking: Monitor supplier performance in real-time to ensure timely deliveries and quality, reducing procurement risks.

- Automated Vendor Rating: Automatically rate vendors based on performance metrics, helping select the best suppliers and manage risks.

- Transparent Procurement Process: Full visibility of the procurement process ensures transparency, reduces errors, and aligns with business goals.

- Integrated Modules: E-Procurement integrates seamlessly with other ERP modules, streamlining data flow and reducing inefficiencies.

- Cost and Budget Control: Track budgets and receive alerts for low-stock items, maintaining cost control and stable supply chain operations.

Conclusion

Managing procurement and supply chain risks is critical to maintaining smooth operations and profitability. Businesses may improve procurement processes, increase reliability, and save costs by identifying risks and applying mitigation techniques.

This includes implementing effective risk management practices, leveraging technology, and cultivating supplier relationships. ScaleOcean’s e-Procurement Software is an ideal solution for reducing procurement risks.

ScaleOcean automates processes and provides real-time information to assist organizations in managing supplier relationships, maintaining inventories, and ensuring timely deliveries, reducing risks and increasing efficiency in today’s competitive market. Request a free demo and do the consultation to get this solution for your business.

FAQ:

1. What are the 4 types of risk management?

The four common approaches to managing risks are risk avoidance, risk mitigation, risk acceptance, and risk transference, which we will discuss in more detail shortly.

2. What is the biggest risk in procurement?

1. Inaccurate Needs Analysis: The procurement process starts with understanding needs, but inaccurate analysis can lead to poor decisions.

2. Inadequate Vendor Management & Sourcing: Failing to manage vendors properly or source suppliers effectively can cause disruptions.

3. Lack of Supply Chain Risk Management: Without a strategy to manage supply chain risks, businesses face potential disruptions.

4. Underdeveloped Contract Management: Weak contract processes can result in unclear terms and legal complications.

5. Absence of Automation: Manual processes increase the risk of errors and inefficiencies in procurement.

6. Poor Procurement Planning: A lack of proper planning can lead to inventory issues and unnecessary costs.

3. What are the 5 P’s of procurement?

The 5 P’s of procurement are Power, People, Processes, Planning, and Prevention. Power pertains to the authority and influence of the procurement team, while People refers to the individuals responsible for executing the procurement strategy.

4. What is a procurement risk assessment?

Procurement risks refer to the potential threats and likelihood of failure within specific procurement processes. Conducting a procurement risk assessment is essential for businesses to optimize their supply chain and reduce the chances of fraud, subpar quality, delivery problems, and budget overruns.

PTE LTD..png)

.png)

.png)

.png)

.png)