Manufacturing is shifting from rigid mass production to highly adaptable workflows. Flexible Manufacturing System (FMS) allows companies to handle varying levels of production and custom configurations without stopping the line. This adaptability is crucial for modern industries facing fluctuating market demands.

According to a market report by BCC Research, the global market for flexible manufacturing systems was valued at over $14.2 billion in 2024, driven by the need for automation and efficiency. This surge highlights how critical adaptable infrastructure is becoming for competitive production.

So, this article will discuss the flexible manufacturing system definition, its core components, and real-world examples from automotive to aerospace. We will also explore how implementing an FMS improves productivity and how solutions like ScaleOcean optimize these complex systems.

- Flexible Manufacturing System (FMS) enables manufacturers to adapt quickly to product changes, volume shifts, and customization demands with minimal downtime and improved operational flexibility.

- The types of Flexible Manufacturing Systems, such as sequential, random, dedicated, and modular, are designed to match different production volume and product variety requirements.

- Flexible manufacturing improves productivity by reducing setup time, increasing equipment utilization, minimizing errors, and supporting consistent quality in high-mix production environments.

- ScaleOcean supports flexible manufacturing by integrating production, inventory, and financial data into one unified platform for better visibility, coordination, and operational control.

What Is a Flexible Manufacturing System (FMS)?

A Flexible Manufacturing System (FMS) is an automated production method designed to rapidly adapt to changes in product type, mix, and volume without requiring significant downtime or manual reconfiguration.

It bridges the gap between high-volume, inflexible lines and low-volume, manual machines, utilizing interconnected CNC machinery, robots, and automated guided vehicles (AGVs) controlled by a central computer. FMS improves efficiency, reduces lead times, lowers inventory, and enables high-quality, customized production.

Its main goal is to let manufacturers change quickly between different products or variants without long changeovers or heavy manual adjustments. This makes FMS ideal for companies that need both efficiency and flexibility.

How a Flexible Manufacturing System Works?

An FMS starts working when a production order is received. The central computer interprets the order, selects the needed machines and tools, and sets the operation sequence. It loads the correct programs at each workstation and tracks every part using barcodes or RFID tags.

Material movement is automated through equipment like Automated Guided Vehicles (AGVs), conveyors, or rail-guided carts. The system instructs this equipment when and where to pick up and deliver parts. If a machine is busy or down, the FMS dynamically reroutes parts based on real-time machine availability.

At each workstation, CNC machines and robots perform tasks such as cutting, drilling, assembly, and sometimes in‑process inspection. Tool changes and quality checks are largely automated, while the central computer monitors status and data in real time. This coordination keeps production efficient, flexible, and consistent in quality.

Who Invented the FMS?

Jerome H. Lemelson (1923–1997), an American industrial engineer and inventor, is recognized for pioneering the concept of flexible manufacturing. His original design included a robot-based system capable of welding, riveting, conveying, and inspecting manufactured products.

Systems inspired by his design started appearing on factory floors in the US and Europe during the late 1960s and gained widespread popularity throughout the 1970s.

Later, in 1965, Theo Williamson patented a specific type of system involving numerically controlled machines, further refining the technology. Their innovations transitioned manufacturing from manual oversight to computer-integrated automated control.

What Are the Different Types of Flexible Manufacturing Systems?

Flexible Manufacturing Systems come in various configurations, each designed to meet specific production needs. Depending on factors like production volume, product variety, and operational complexity, different types of FMS offer unique advantages to optimize manufacturing efficiency and flexibility.

Understanding these types can help businesses select the best system for their specific manufacturing goals. There are several types of FMS configurations, each suited for different production volumes and variety requirements.

Sequential FMS

In a Sequential FMS, parts move through a fixed sequence of workstations. This setup is similar to a traditional transfer line but offers slightly more flexibility. It is best suited for producing a specific family of parts with a defined workflow.

Random FMS

A Random FMS is capable of handling a significant variety of part configurations in any order. The system effectively manages random production schedules. It requires highly sophisticated computer control software to route parts dynamically to available machines.

Dedicated FMS

This system is designed to produce a limited variety of parts for a long period. A Dedicated FMS maximizes throughput for a specific product family. It is less flexible than a random system but faster and more efficient for defined batches.

Random Order/Engineered FMS

This type creates a specific sequence for different parts but allows for random variations within that sequence. It balances the structure of a sequential system with the versatility of a random one. It is often used when there is a known mix of products that frequently repeats.

Modular FMS

A Modular FMS allows manufacturers to expand their system by adding new modules as needed. This approach is cost-effective for growing smart factory companies. It lets businesses start small and scale up their flexible manufacturing capabilities over time.

What is a Flexible Manufacturing Cell?

A flexible manufacturing cell (FMC) typically includes two or three machines with processing stations and parts handling capabilities. Although simpler and less advanced than an FMS, an FMC still offers flexibility, such as rerouting products between machines if one fails and adjusting to higher production volumes.

In contrast, a flexible manufacturing system (FMS) is larger, consisting of four or more machines along with additional support components like wash stations for parts and pallets, plus storage areas. It’s equipped with a more sophisticated computer system that offers enhanced functions like monitoring and diagnostics.

When choosing a flexible manufacturing solution for your business, consider both FMC and FMS based on your size, resources, and available space. While an FMS provides greater flexibility, it requires more space, involves a steeper learning curve due to its complexity, and typically demands a higher investment and stronger commitment from senior management.

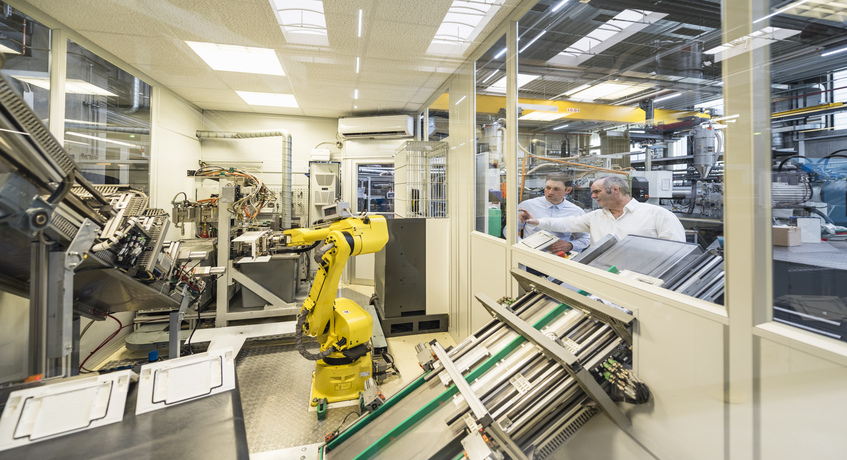

Flexible Manufacturing System (FMS) Components

A Flexible Manufacturing System is composed of several critical subsystems that work together seamlessly to enable efficient and adaptable production processes. These components coordinate to manage everything from material handling to machine operations and system control.

Understanding the main parts of an FMS is essential to grasping how the system achieves its flexibility and productivity. An FMS relies on four primary subsystems working in unison. The table below details these key components.

| Components | Functions |

|---|---|

| Workstations | These are the physical production sites, such as CNC machining centers and assembly stations. They perform the primary value-added operations like cutting, welding, or inspection to transform raw materials into finished parts. |

| Material Handling & Storage Systems | This includes automated guided vehicles (AGVs), conveyors, and robots. They act as the system’s circulatory network, moving parts and tools between workstations and storage areas to ensure a continuous production flow. |

| Computer Systems | The central nervous system of the FMS. It coordinates all activities, schedules production tasks, manages machine traffic, and tracks real-time data to ensure the system operates efficiently and without collisions. |

| Managers & Operators | Human oversight remains critical for system success. Skilled personnel are needed to program the machines, perform maintenance, make strategic production decisions, and intervene when the automated systems encounter complex issues. |

Flexible Manufacturing Examples

Various industries adopt flexible manufacturing systems to address their specific production challenges and demands. By implementing these adaptable solutions, businesses can efficiently handle changes in product design, volume, and variety while maintaining high quality and reducing downtime.

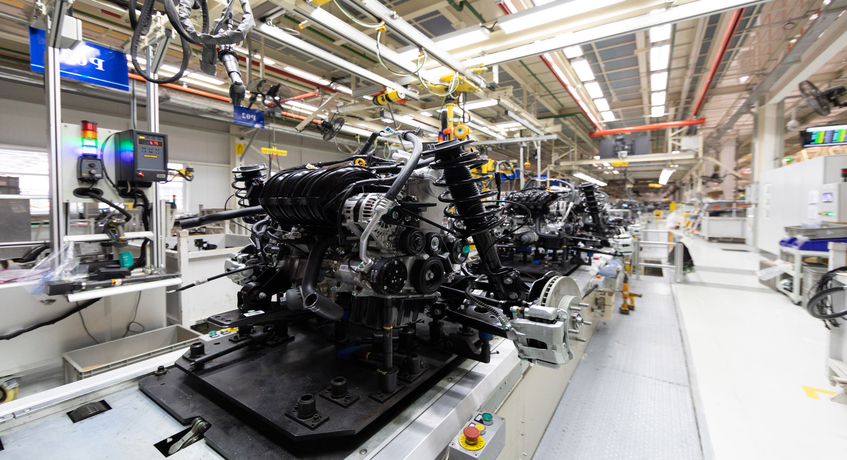

A clear flexible manufacturing system example can be seen in the automotive industry, where multiple vehicle models are produced on the same line. From automotive to electronics and aerospace, flexible manufacturing enables companies to stay competitive and responsive in dynamic markets.

FMS in the Automotive Industry

Car manufacturers use FMS to produce different vehicle models on the same assembly line. Robots can quickly switch welding tools to accommodate different chassis designs. This reduces the downtime previously needed to retool for a new car model.

FMS in Aerospace Manufacturing

Another flexible manufacturing system example is found in aerospace manufacturing, where precision parts require frequent reprogramming. The aerospace sector uses flexible manufacturing to machine complex titanium and aluminum parts.

Precision is critical, and production volumes are often lower than in automotive. FMS allows aerospace companies to switch between different aircraft components efficiently.

FMS in Electronics Production

Electronics manufacturers face short product lifecycles and high demand for customization. FMS allows them to assemble various circuit board configurations rapidly. It helps companies like Canon respond quickly to competitor moves and new technology trends.

FMS in Medical Device Manufacturing

Medical devices, such as ventilators or surgical tools, often require strict quality control and variable batch sizes. FMS enables manufacturers to ramp up production of specific devices during emergencies. Companies like Medtronic utilize flexible cells to adapt to surgical device variations.

FMS in Consumer Goods

Consumer goods are one of a flexible manufacturing system example. Companies in this industry use flexible manufacturing to handle seasonal demand and packaging variations. For example, a food processor might use the same line for different product recipes. This flexibility is vital for maintaining low inventory while meeting diverse customer tastes.

FMS in Heavy Equipment

Heavy machinery manufacturers, such as those making tractors or excavators, use FMS for machining large engine blocks. These parts are heavy and expensive to move manually. Automation ensures precision and safety while handling these massive components.

FMS in Chemical Processing

In chemical processing, flexibility allows plants to switch formulations safely and quickly. Automated control systems adjust temperature and mixture ratios for different products. This reduces waste and ensures compliance with safety regulations for various chemicals.

Companies That Use FMS

Many leading global corporations have integrated flexible manufacturing solutions into their operations to improve adaptability and efficiency. According to a market report by Market Growth Reports, Asia-Pacific is the leader of the top region, with 35% of installed Flexible Manufacturing System capacity.

These companies benefit from the ability to quickly adjust production processes, handle product variations, and meet changing market demands without compromising quality. They have mastered the true definition of what is flexible manufacturing system.

By embracing flexible manufacturing, they stay competitive and responsive in dynamic industries. Here are some notable examples of companies successfully using these systems in their production workflows.

- Ford Motor Company: Uses flexible robotic welding in body shops to quickly shift production volumes and switch between vehicle models.

- Bosch: Uses FMS in their compressor and motor assembly lines, enabling fast switching between product variants.

- Intel: Leverages FMS for producing precision metal parts used in chip fabrication equipment, ensuring extremely tight tolerances.

- Boeing: Employs FMS for the production of diverse aircraft components made from titanium and aluminum, requiring precise CNC machining.

- John Deere: Implements flexible manufacturing for drive systems and chassis components to manage seasonal demand.

- Siemens: Utilizes FMS to manufacture Simatic controllers, allowing quick adjustments in circuit board assembly configurations.

As seen across different industry examples, flexibility is critical to maintaining efficiency and consistency in modern production. ScaleOcean manufacturing ERP software supports this need with flexible manufacturing software and modular system solutions that can be tailored to your specific processes and workflows.

So, explore how ScaleOcean can fit your manufacturing operations and request a free demo today.

Pros and Cons of an FMS

Adopting a flexible manufacturing system offers numerous advantages but also involves certain trade-offs that businesses need to consider. Ultimately, answering what is flexible manufacturing system is comes down to its ability to increase adaptability while maintaining consistent output.

However, it also requires substantial investment, space, and skilled personnel to manage its complexity. So understanding both the benefits and potential challenges is crucial for making an informed decision about integrating FMS into your manufacturing operations.

| Pros | Cons |

|---|---|

| High Efficiency: Increases machine utilization up to 80% compared to traditional systems. | High Cost: Requires significant initial capital investment for equipment and software. |

| Flexibility: Adapts to changes in volume and product mix instantly. | Complexity: Difficult to plan and implement correctly without expert guidance. |

| Lower Labor Cost: Reduces direct manual labor requirements and human error. | Skill Gap: Requires highly trained technicians to operate and maintain systems. |

| Reduced Inventory: Minimizes work-in-progress and storage needs, freeing up cash. | Maintenance: System downtime can be expensive to fix if not managed well. |

Comparing the Flexible Manufacturing System with Other Production Methods

Choosing the right production strategy requires more than looking at output speed or automation level. Manufacturers must evaluate demand variability, product complexity, capital investment, scalability, and long-term adaptability.

A system that performs exceptionally well in stable, high-volume environments may struggle when product variations increase or market conditions shift.

A Flexible Manufacturing System (FMS) is positioned between traditional mass production and highly specialized rigid automation. It balances efficiency with adaptability, making it particularly suitable for industries where product lifecycles are shorter and customization is common.

Understanding how flexible manufacturing compares with other production methods clarifies when it is the right strategic investment.

FMS vs. Traditional Manufacturing

Traditional manufacturing, often called mass production, is ideal for high volumes of a single product. However, it lacks the ability to change products quickly. Flexible manufacturing sacrifices some raw speed for the ability to handle a high mix of products.

FMS vs. Rigid Automation

Rigid automation is fixed and efficient, but cannot adapt. If a product design changes, rigid systems often need to be scrapped or heavily rebuilt. An FMS is designed to evolve, allowing software updates to handle new physical tasks.

FMS vs. Lean Manufacturing

Lean manufacturing focuses on eliminating waste, while flexible manufacturing focuses on adaptability. These two often work together. An FMS supports lean goals by reducing waiting times and overproduction, as the system only produces what is needed.

How is the Flexible Manufacturing System Set Up? An Implementation Guide

A Flexible Manufacturing System is set up through several structured phases to align production goals and system design. It integrates computer-controlled machines, automated material handling, and centralized software to produce multiple products with minimal downtime.

Companies typically adopt FMS when traditional production lines become too rigid. If demand fluctuates, product designs change frequently, or customers expect shorter lead times, fixed manufacturing layouts start to struggle.

Flexible manufacturing addresses this by combining automation with adaptability. It allows manufacturers to switch between product variants, adjust batch sizes, and optimize workflows without rebuilding the entire production line.

Step 1: Identifying Production Requirements Goals

The first step is to assess your current production bottlenecks and operational constraints. Clarify whether your primary objective is higher volume, greater product variety, faster lead times, or a combination of these factors. This evaluation determines the appropriate Flexible Manufacturing System configuration, capacity level, and degree of automation required.

Step 2: Planning the FMS Configuration and Workflow

Next, engineers design the layout of workstations and material paths. This phase involves simulation software to predict workflow efficiency. You must decide between a sequential, random, or modular configuration.

Step 3: Choosing and Integrating System Components

Select the specific CNC machines, robots, and conveyors that fit your plan. Integration is key, so the software must communicate flawlessly with the hardware. This is often the most technical phase of the setup.

Step 4: Workforce Training and Skill Development

Flexible manufacturing replaces manual labor with skilled monitoring. Workers need training to operate the central computer and maintain robots. Investing in your team is as important as investing in the machinery.

Step 5: System Testing, Refinement, and Performance Optimization

Before full-scale operation, the system undergoes rigorous testing. Engineers tweak the software to eliminate lags or routing errors. Continuous monitoring ensures the system reaches its peak flexible manufacturing potential.

Does Flexible Manufacturing Improve Productivity?

Yes, flexible manufacturing significantly improves productivity for high-mix production environments. By eliminating setup time between batches, machines spend more time working and less time waiting. This leads to higher OEE (overall equipment effectiveness).

Furthermore, flexible manufacturing reduces errors caused by human fatigue. Automated inspection stations ensure that quality remains consistent, reducing the time and cost associated with rework.

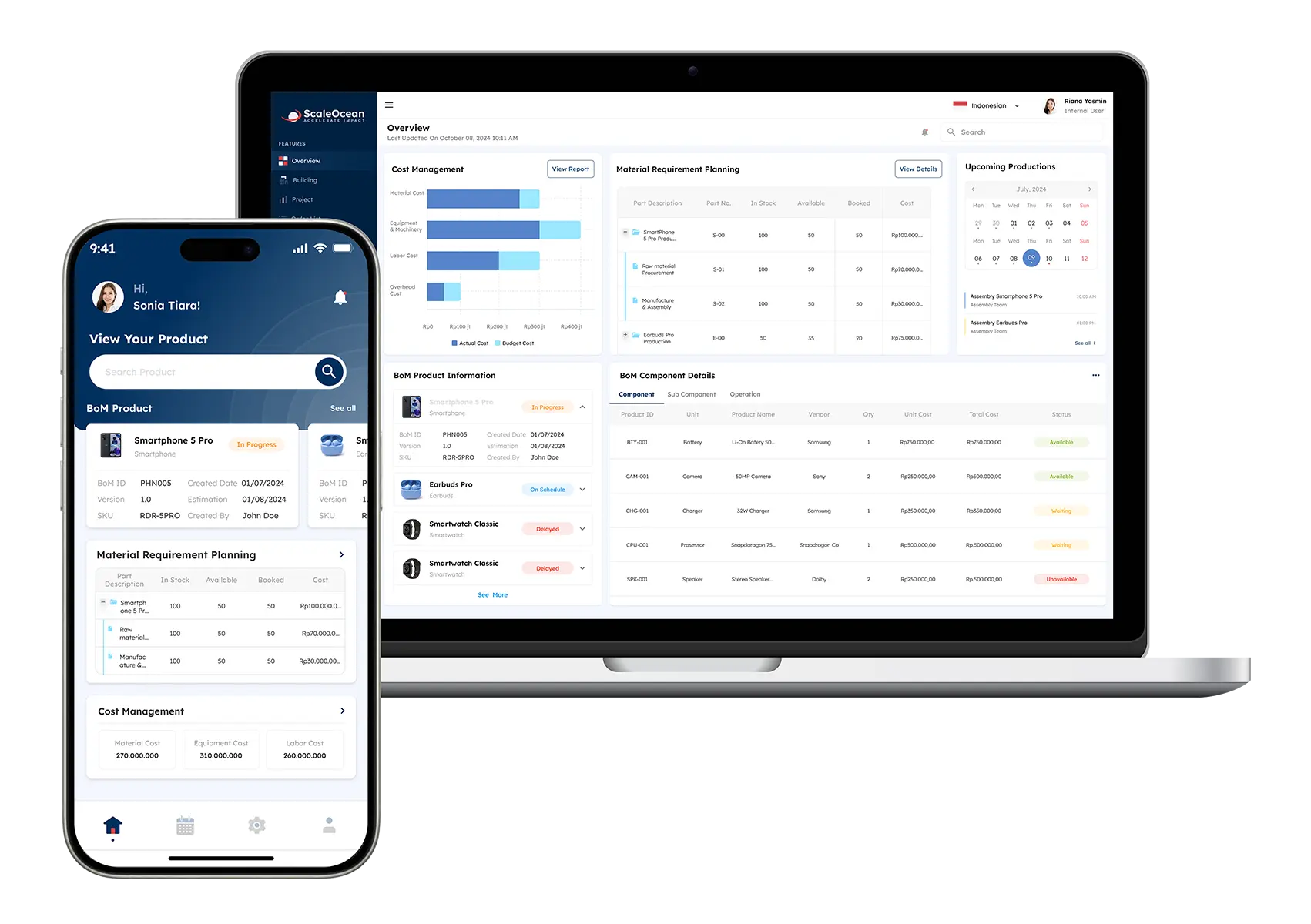

While flexible manufacturing already enhances productivity, its impact becomes even greater when supported by an integrated digital system. Connecting machines, planning, inventory, and financial data ensures that every operational improvement is aligned and measurable across the business.

This is where software like ScaleOcean plays a crucial role. By providing a unified platform to manage and synchronize manufacturing processes, companies can extend the productivity gains of flexible manufacturing beyond the shop floor and translate them into stronger overall business performance.

Optimize Flexible Manufacturing Implementation with ScaleOcean

ScaleOcean’s manufacturing ERP system delivers a comprehensive solution to optimize the implementation of a Flexible Manufacturing System. It provides a true 360° view of manufacturing operations.

Having end-to-end IIoT integration, it enables real-time machine connectivity, full data visibility, and seamless integration with existing enterprise platforms already used across the company.

As an all-in-one solution, ScaleOcean centralizes every production process within a single system, one database, and one unified dashboard. From planning and procurement to execution and financial tracking, flexible manufacturing operations run cohesively without fragmented tools or disconnected data.

The system is fully customizable to match each company’s workflow, production processes, and operations. It offers customizable dashboards, advanced smart configuration for each division, unlimited user access, and an intuitive interface designed for ease of use across departments.

In addition, ScaleOcean aligns with the requirements of the Company Training Committee (CTC) Grant, making it eligible for funding support and helping reduce the financial burden of digital transformation initiatives.

Key features of ScaleOcean manufacturing software:

- AI Smart MRP: ScaleOcean’s manufacturing software uses AI-enhanced MRP to analyze historical data and real-time production information to predict material needs and optimize planning. This reduces unexpected stockouts, accelerates line changeovers, and prevents costly production delays.

- Advanced Production Planning & Scheduling (APS): Automatically adjusts production schedules to accommodate urgent orders or priority shifts. It instantly responds to machine availability constraints and resource conflicts, ensuring continuous workflow and optimal utilization of equipment.

- IoT and IIoT Integration: Connects directly to CNC machines and PLC controllers to capture real-time production data. It monitors machine status, tracks performance metrics, and manages automated tool changes. This provides full shop floor visibility and enables data-driven decision-making.

- Multi-Level Inventory Management & Traceability: Ensures raw materials, sub-assemblies, and finished goods are consistently available across all production levels. Provides end-to-end traceability for compliance with ISO standards and medical manufacturing regulations, which is essential for quality assurance and regulatory audits.

- Predictive Quality Management System: Analyzes production flow and operational data to detect defects at an early stage. Supports achieving OEE (Overall Equipment Effectiveness) targets by minimizing waste, reducing rework, and preventing quality-related downtime.

By combining flexible system design with practical implementation support, ScaleOcean helps manufacturers streamline the setup and optimization of flexible manufacturing environments. Its user-friendly platform adapts to various types of production across Singapore’s manufacturing sector.

In addition, ScaleOcean makes it easier to manage your workflows, improve your visibility, and maintain your operational control. See how ScaleOcean can support your manufacturing transformation and request a consultation today.

Conclusion

Flexible manufacturing is becoming essential for companies facing fluctuating demand and increasing product variety. A Flexible Manufacturing System (FMS) combines automation with adaptability, enabling faster changeovers, consistent quality, and stronger overall equipment effectiveness.

To maximize these benefits, manufacturers need an integrated digital backbone. Like ScaleOcean, which connects IIoT data, production planning, inventory management, and financial control within a single system, database, and dashboard, ensuring full visibility and seamless coordination across operations.

If you are planning to implement or optimize flexible manufacturing, consider exploring how ScaleOcean can support your transformation. Request a free demo to see how the platform aligns with your operational goals and drives measurable efficiency.

FAQ:

1. What is a downside of flexible manufacturing?

One major drawback of a Flexible Manufacturing System is the high initial investment required for equipment, software, and integration. In addition, designing and configuring the system specifications can take considerable time and expertise before full implementation.

2. What is the main purpose of FMS?

The main purpose of a Flexible Manufacturing System is to enable efficient production while adapting quickly to changes in product type, mix, or volume. It allows manufacturers to maintain productivity and quality without extensive downtime for reconfiguration.

3. What equipment is used in a flexible manufacturing system?

An FMS typically includes industrial robots, CNC machines, automated tool changers, inspection stations, assembly units, and material handling systems. Each workstation performs specific operations that transform raw materials into finished products.

4. How is a flexible manufacturing system used today?

Today, Flexible Manufacturing Systems are widely used in industries that require high customization, precision, and operational control. Sectors such as automotive, aerospace, defense, food processing, and electronics rely on FMS to manage complex production demands efficiently.

PTE LTD..png)

.png)

.png)

.png)

.png)