In Singapore’s fast-paced logistics industry, efficiency is essential, and manual procedures can no longer compete. A warehouse barcode system is critical for streamlining inventory management, allowing organizations to function more quickly and correctly in order to stay competitive.

According to WSG, Industry 4.0 will cause considerable employment displacement or redesign in the logistics sector, affecting around 20 job roles totaling 11 positions. This demonstrates the industry’s increased demand for automation and digital solutions.

This article explains what a warehouse barcode system is, why it’s necessary for growth, and how to use it successfully. It covers everything from fundamental components to complex technologies, providing organizations with a clear path for developing their inventory management systems.

- A warehouse barcode system employs barcodes to identify and track merchandise, which automates data collection.

- Types of warehouse barcode can be used by 1D (linear) barcodes, and 2D (matrix barcode), including QR codes, data matrix, PDF417, and aztec.

- Implementing a warehouse barcode system can be done by planning for proper barcode label placement, ensuring system integration, training staff effectively, regularly testing and maintaining the system, and choosing the right barcode types

- Barcoding technologies for warehouses are handheld scanners, fixed scanners, cloud connectivity, mobile computers, and RFID

- ScaleOcean’s WMS integrates barcode scanner data, providing real-time visibility, ensuring inventory accuracy, and reducing human error in warehouse operations.

What is Warehouse Barcode System?

A warehouse barcode system employs barcodes to identify and track merchandise, which automates data collection. Workers scan barcodes instead of writing down item numbers, transferring detailed information to a central database.

This reduces human error and speeds up operations, resulting in improved efficiency. The system can track not only products, but also locations, pallets, containers, and even employees.

It delivers full visibility and responsibility by establishing a thorough audit trail, assuring accurate, real-time inventory tracking, and making effective warehouse operations management easy.

There is a crucial component to implementing warehouse barcode effectively, and you have to consider a three-legged stool. If a single component is missing or faulty, the entire warehouse scanning system may fail, resulting in operational disruptions. So, we’ll dive right into what each of these important parts actually does.

- Barcode Labels. It is crucial for identifying products, pallets, or storage locations within the warehouse, especially for warehouses that often use 2D barcodes or QR codes. These labels contain scannable codes that hold key product information, such as SKU numbers, batch codes, and manufacturing dates. The labels must be durable enough to withstand warehouse conditions, such as exposure to moisture, temperature variations, and physical wear and tear.

- Barcode Scanner/Hardware Requirement. The hardware in a warehouse barcode system includes barcode scanners, printers, and mobile devices. Barcode scanners, either handheld or fixed, read the codes printed on items or labels, sending the data to the system. Printers generate high-quality, durable labels for products or storage locations. Mobile devices, such as tablets or smartphones, help employees access real-time information, allowing for seamless inventory tracking.

- Warehouse Management System. Warehouse barcode systems require software to manage and interpret the data collected by the scanners. The software integrates with the WMS to provide real-time inventory updates, track movement, and generate reports. Integration with enterprise resource planning (ERP) systems ensures that barcode data flows seamlessly across all business functions, such as procurement, sales, and accounting.

Type of Warehouse Barcodes

Not all barcodes are the same, and selecting the correct one might affect how much data you store and use regularly. Barcodes are classified into two types: 1D (linear) and 2D (matrix). Understanding these distinctions is critical for choosing the best solution for your operations.

Your scanning requirements will dictate your decision. A one-dimensional barcode is suitable for simple product identification. For comprehensive information, such as batch numbers or supplier links, a 2D barcode is preferred. Each of these categories has distinct advantages for various applications within your facility.

1D (Linear) Barcodes

1D barcodes are the black and white parallel lines that are most commonly associated with barcodes. These simple barcodes store little data, usually a product identifier such as a UPC or EAN code, and are often employed in warehouse barcoding systems to facilitate scanning.

Commonly found on retail items or in logistics with Code 128, 1D barcodes are linked to a central database. When scanned, they retrieve detailed product information from the system, enabling more effective inventory management and tracking.

2D (Matrix) Barcodes

These barcodes store information in both horizontal and vertical dimensions, allowing them to hold more data. They are increasingly used for complex tracking in modern warehouse systems.

This two-dimensional architecture allows them to hold significantly more information than one-dimensional barcodes, making them perfect for current warehouse systems that require complicated data tracking.

Their adaptability makes them valuable in warehouses when tracking more than simply SKUs is required. Furthermore, they stay readable even when slightly damaged, which is a significant advantage. The examples of 2D barcode for the warehouse are:

- QR Codes: Quick Response codes are highly popular due to their ability to store large amounts of data in a small space. These codes can be scanned using smartphones, making them ideal for fast-paced warehouse environments.

- Data Matrix: These barcodes are compact and robust, commonly used for small items due to their ability to store a lot of data in a tiny space, making them ideal for labeling small products in warehouses.

- PDF417: This is a two-dimensional barcode that can store a significant amount of data, including text, images, and numbers. It is often used in logistics for shipping labels and inventory management.

- Aztec: A type of 2D barcode that is highly efficient and can store more data in a smaller space. Aztec codes are used in situations where there are space constraints or where quick, error-free scanning is required.

Why Use Warehouse Barcode System?

In Singapore’s competitive economy, efficiency and precision are critical. A warehouse barcode system has become critical for organizations to succeed, tackling common issues including order errors, stagnant inventory, and excessive labor expenses that impede development and scalability.

Implementing a barcode system enables firms to satisfy increasing customer needs for quick, precise delivery. Without it, businesses must rely on time-consuming manual checks, which increases the likelihood of errors. This technology enables Singaporean enterprises to remain globally competitive while also ensuring operational efficiency.

Increased Accuracy and Reduced Human Error

Human mistake is a serious problem in warehouses, wasting time, money, and resources. A small error, such as entering the incorrect product code or miscounting stock, can result in shipping issues, inventory discrepancies, and dissatisfied customers, reducing profit margins.

A warehouse barcode system decreases errors by automating data entry, resulting in more dependable operations. With scan accuracy rates as high as one in several million, this system matches physical inventory to data, eliminating stockouts and overstocking for smoother operations.

Drastically Improved Efficiency and Speed

Time is money, especially in a warehouse where every second matters. Manual operations, such as checking off things during pick-up or receiving shipments, are slow. A barcode system streamlines these operations, allowing personnel to handle more items in less time.

For example, barcodes make receiving shipments faster because workers can simply scan pallets or objects to rapidly update inventory. Similarly, order picking is more efficient since scanners direct workers to the correct goods, enhancing productivity without adding staff.

Real-Time Inventory Visibility and Control

Accurate inventory tracking is practically impossible without a barcode system. Manual counts are inefficient and out of date, making it difficult to manage stock levels, respond to consumer inquiries, or make educated purchase decisions.

Every movement is recorded in real time using barcode scanning, providing you with an up-to-date inventory view. This visibility helps just-in-time (JIT) inventory strategies and prevents stockouts, which is one of the reasons why it is regarded as the best WMS in Singapore for control.

Significant Operational Cost Reduction

While the initial cost of a barcode system may appear exorbitant, the long-term benefits are significant. Reducing errors reduces the expenses of returns, reshipping, and customer complaints, resulting in fewer mistakes and happier, more loyal customers.

Increased efficiency enables your current crew to handle bigger volumes of work, lowering labor expenses as your organization grows. Optimising inventory levels eliminates excess stock, freeing up cash, and these savings generate a significant return on investment.

Enhanced Scalability for Business Growth

In Singapore, as a worldwide logistics and transshipment hub, managing large amounts of commodities efficiently is critical. As organizations grow, manual methods become a bottleneck, particularly as inventory and orders increase. A barcode system is scalable, allowing firms to operate smoothly as they grow.

This approach aids in managing increased complexity, such as new product lines or increasing order volumes. It provides consistent and efficient procedures, which are critical in a competitive logistics landscape where good labor cost management is essential for long-term growth.

How a Warehouse Barcode System Works

A warehouse barcode system starts by assigning each item a unique digital identification. As products arrive at the receiving dock, the system monitors their progress throughout the process, ensuring that each step is checked and recorded.

This constant tracking results in an unbroken chain of data, which gives significant insights for operational control and thorough analysis. It increases workflow efficiency while maintaining accuracy and accountability at all stages of the process, so let’s walk through the typical five-stage process of how this system really works.

Item Assignment

The first step is to establish a unique identity for each product, which is often done through your WMS or inventory management software. Each SKU is assigned a barcode number, which serves as the foundation for all subsequent tracking, allowing the barcode system to function properly.

This approach prevents misunderstanding by assigning each variable, such as size or color, its own unique barcode. This level of granularity is essential for accurate inventory control, acting as a digital birth certificate for each product in your operations.

Receiving and Labeling

When a fresh shipment arrives, the reception process begins. If the items already have barcodes, your team can scan them into the WMS, which will automatically match the shipment to your purchase order. This helps identify differences early on, preventing larger problems.

If your items lack barcodes or you prefer internal numbering, now is the time to attach custom labels. Once scanned, the WMS updates the status to ‘in stock’ and suggests the optimal storage location, ensuring inventory is accounted for. The stock-keeping unit’s purpose is to streamline this process by ensuring correct placement.

Tracking and Locating

Barcodes are vital for tracking products once they have been placed in the warehouse. When staff move things, they scan the item’s barcode and the new shelf placement, which updates the WMS in real-time. This guarantees that you know exactly where everything is.

This continuous tracking makes inventory and cycle counting significantly faster and less disruptive. Instead of interrupting operations for a thorough physical count, you may conduct smaller, more frequent checks by scanning a few places, ensuring correct inventory data without affecting production.

Picking, Packing, and Verification

When a customer order arrives, the WMS creates a pick list optimized for the most efficient route. Using a mobile scanner, the worker scans the shelf and product to ensure that the correct item and quantity are picked, considerably reducing picking errors.

After choosing, the items are sent to a packing station, where another scan checks accuracy before the order is sealed. This final check ensures that consumers receive exactly what they purchased, which increases operational efficiency and customer happiness.

Shipping and Manifest Creation

The last step in the process is shipping. When the packed order is complete, the shipping label containing a barcode is scanned, and the order status is updated to’shipped.’ This often results in an automatic confirmation email to the customer, which includes tracking information.

The scan also enters the package into the carrier’s system and creates a shipping manifest that lists all packages being sent out. This automates the fulfillment process, resulting in accurate records and a traceable transfer from the warehouse to the shipping carrier.

To optimize the way the barcode warehouse works, you can use easy, integrated WMS software such as Scaleocean. The system leverages barcode scanning for tracking stock in real-time.

ScaleOcean’s WMS software allows for seamless updates and management of inventory, ensuring that every movement of goods, from receipt to dispatch, is recorded and traceable. You can request a free demo to get this solution for your warehouse optimization.

Implementing Warehouse Barcode System: The Complete Guide

Implementing a warehouse barcode system can drastically improve inventory accuracy, reduce errors, and streamline operations. However, successful implementation requires careful planning and adherence to best practices. Below are some best practices that will help you maximize the benefits of a barcode system.

Step 1. Plan for Proper Barcode Label Placement

Barcode labels should be placed in consistent and easily accessible locations on products, pallets, or storage shelves. The placement should ensure that barcodes are always visible and scannable, even when items are stacked or stored in bins.

Careful planning of label placement also minimizes the risk of errors during scanning and improves workflow efficiency.

Step 2. Ensure System Integration Software Platforms

A warehouse barcode system should seamlessly integrate with existing systems like warehouse management software (WMS) and enterprise resource planning (ERP) software.

Integration ensures that data flows smoothly between systems, providing real-time updates on stock levels, order processing, and shipments. This reduces data discrepancies and enables better decision-making.

Step 3. Train Your Staff Effectively

Proper training is critical for the successful implementation of a barcode system. Staff should be familiar with the system’s operation, from scanning barcodes to managing the software and hardware components.

Ongoing training and support should also be provided to address any changes or upgrades to the system, ensuring that employees can efficiently use the technology.

Step 4. Choose the Right Barcode Type

Selecting the right type of barcode for your specific needs is vital. Different barcodes (1D, 2D, QR, etc.) offer varying levels of data storage and scanning capabilities.

Choose a barcode type that aligns with your warehouse’s inventory complexity, storage requirements, and scanning equipment. This ensures efficiency and scalability as your operations grow.

Step 5. Design Barcode Labels

Designing barcode labels involves choosing a format that suits your inventory needs. Typically, labels include product details like SKU, product name, and a unique barcode. The label design must ensure readability by barcode scanners and be durable enough to withstand warehouse conditions.

Step 6. Regularly Test and Maintain the System

Regular testing and maintenance of the barcode system are essential to ensure its ongoing effectiveness. Routine checks should be conducted to verify scanner functionality, barcode label quality, and software performance.

Maintenance tasks like updating software and replacing damaged barcode labels help prevent system failures and reduce downtime, keeping warehouse operations smooth.

Step 7. Establish Barcode Inventory Process

To establish the barcode inventory process, first, assign unique barcodes to all inventory items. Train staff to scan items during receiving, storage, and shipping. Integrate barcode scanners with the WMS for real-time updates, ensuring accurate tracking of inventory at each stage of the workflow.

Common Barcoding Technologies Used in the Warehouse

Barcodes are only the beginning. The technology that reads and processes them drives the warehouse system. The hardware and connectivity solutions you select are critical because they determine the efficiency and flexibility of your warehouse operations.

Every piece of technology, from handheld devices to the network that connects everything, plays an important role. The key goal is to create a fast, dependable infrastructure for data capture and communication, ensuring that the warehouse system evolves alongside your organization.

Handheld Scanners

Handheld scanners are required for most warehouse barcode systems. These portable gadgets enable personnel to scan things around the warehouse floor. They can be wired (directly connected to a computer) or wireless (real-time data transmission via Bluetooth or Wi-Fi).

Wireless portable scanners are ideal for duties such as picking, putting away, and cycle counting. Ergonomically constructed and sturdy, they include rugged casings that can withstand drops and warehouse hazards, making them an essential tool for any warehouse workforce.

Fixed Scanners

Fixed scanners, also known as stationary scanners, are installed in a specific location and automatically scan items that pass by. They are commonly used in conveyor systems and read barcodes without the need for human involvement as packages pass within their range of view.

This automation is best suited for high-volume processes such as big sorting facilities or distribution centers. Fixed scanning systems can read barcodes at fast speeds and from a variety of angles, allowing them to handle thousands of items per hour while decreasing the need for manual labor.

Cloud Connectivity

Modern warehouse barcode systems incorporate cloud connectivity for flexibility and scalability, providing access from anywhere. This enables efficient tracking and management, ensuring smooth operations across different locations and enhancing the overall workflow.

According to the Building and Construction Authority, the new JTC Logistics Hub (JLH) is Singapore’s first high-rise logistics facility, combining container depots, warehouses, and a heavy vehicle park in one development. This innovative approach optimizes land usage and boosts logistics efficiency and competitiveness.

Cloud-based WMS removes the need to maintain server hardware, as software upgrades are frequently handled automatically. It also streamlines connectivity with other cloud-based business tools, allowing for real-time insight throughout the whole supply chain, not just the warehouse.

Mobile Computers

Mobile computers are a huge improvement over basic portable scanners. These ruggedized devices, comparable to smartphones, include built-in barcode scanning, a touchscreen interface, and run operating systems such as Android, making them a complete mobile workstation.

Workers can utilize these mobile laptops for more than just scanning documents. They can see pick lists, enter quantities, access product information, and communicate directly with the WMS. This technology is an important part of a warehouse execution system since it increases productivity on the floor.

RFID

RFID (Radio-Frequency Identification) uses radio waves to identify objects. An RFID tag, which contains a microchip and an antenna, is attached to an item, allowing an RFID reader to collect the tag’s data without requiring a direct line of sight, unlike traditional barcode systems.

RFID allows entire pallets to be scanned simultaneously, saving significant time over scanning individual boxes. Although more expensive than barcodes, RFID has advantages in terms of speed and efficiency, signifying a significant advancement in automated inventory tracking for some applications.

Troubleshooting Common Issues in Warehouse Barcode System

Even with meticulous planning, warehouse barcode systems may encounter frequent difficulties. Most issues concern scanning, label quality, or system connectivity. Recognizing these issues early can save time and frustration, resulting in seamless operations.

Managing these difficulties is critical to keeping a warehouse’s barcode system working efficiently. A straightforward strategy to swiftly identify and resolve problems increases productivity and reduces downtime, resulting in more efficient operations. Let’s look at common difficulties and solutions.

Scanners Not Reading Barcodes

It’s a rather common issue: your scanner simply won’t read the barcode. Often, the first thing to examine is the scanner itself. Perhaps its window is dirty or damaged, which can interfere with its ability to pick up the code properly.

If the scanner is clean, the issue could be the barcode itself. It may be crumpled, damaged, or poorly printed, making it difficult to scan. Additionally, environmental factors such as illumination and altering the scanning angle can increase scanner performance.

Poor Label Quality or Durability

Barcode labels can become illegible with time, particularly in harsh conditions such as cold storage or dusty, damp places. Standard paper labels are frequently insufficiently durable, causing challenges with the warehouse barcode scanning process and reducing operating efficiency.

The solution is to select the appropriate label material and printing procedure. Polyester or polypropylene synthetic labels withstand ripping, dampness, and strong chemicals better than other materials. Using a thermal transfer printer also improves label durability and extends its lifespan.

Connectivity and System Integration Problems

It’s frustrating when the scanner works, but the data doesn’t make it to your WMS, which is frequently due to network issues. Wireless scanners may encounter Wi-Fi dead spots in your warehouse, which can be resolved by doing a thorough Wi-Fi site inspection and installing more access points.

System integration challenges are common when your WMS does not sync with other software. If this occurs, your vendor’s technical support may be required, particularly if a warehouse control system integration is involved, to ensure smooth data flow and stable connectivity.

Choosing the Right Barcode System for Your Warehouse

Selecting the right barcode system for your warehouse is a crucial decision that can directly impact efficiency, accuracy, and scalability. The ideal system should align with your operational needs, technology infrastructure, and long-term goals.

Below are the best practices to help you choose the most suitable barcode system for your warehouse.

Assess Your Warehouse Needs

The first step in choosing the right barcode system is to assess your warehouse’s specific needs. Consider factors like inventory volume, complexity, and the types of products being handled.

If your warehouse deals with a large variety of products or requires real-time tracking, a 2D barcode system might be more suitable. Understanding your operational requirements ensures that the barcode system you choose will meet your day-to-day demands.

Consider System Compatibility and Integration

Ensure that the barcode system you choose integrates seamlessly with your existing warehouse management software (WMS), enterprise resource planning (ERP) system, and other relevant software platforms.

Compatibility ensures smooth data flow, real-time inventory updates, and better decision-making. Choose a system that offers easy integration to avoid additional costs and operational disruptions.

Evaluate Hardware and Scanning Options

Barcode systems require appropriate hardware for scanning and printing labels. Evaluate the hardware options, such as handheld barcode scanners, mobile devices, and label printers.

Consider the types of barcodes you will be using and the environment in which the system will operate. Choose scanners that can read your selected barcode type (e.g., 1D, 2D, QR) and are durable enough to withstand warehouse conditions.

Prioritize Scalability and Future Growth

As your warehouse operations grow, so will your barcode system’s requirements. Choose a barcode system that is scalable and can handle increased data volume, more users, and additional warehouses if needed.

Investing in a system that allows for expansion ensures that you won’t need to replace your infrastructure as your business grows, saving both time and money in the long run.

Ensure User-Friendliness and Training

The barcode system you choose should be user-friendly for your staff. A complex system may lead to errors, decreased productivity, and longer training times. Look for a solution with intuitive interfaces and easy-to-navigate features.

Additionally, ensure that comprehensive training resources are available for your team, so they can quickly adapt to the new system and make the most of its capabilities.

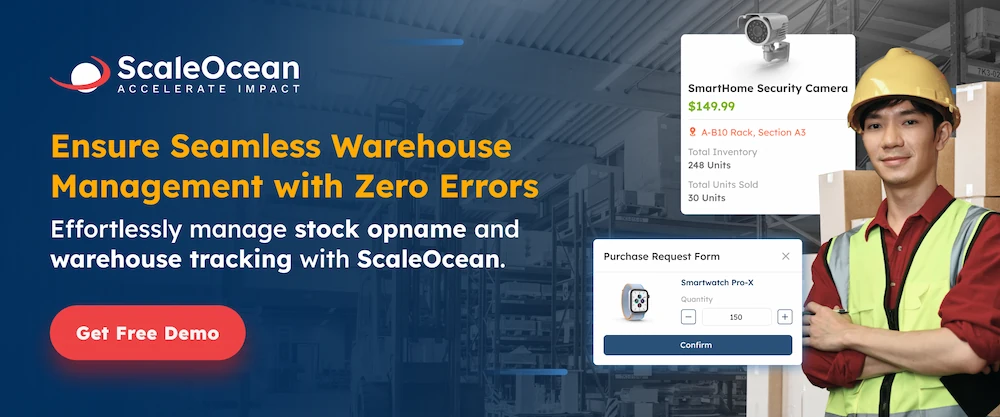

Efficiently Integrate Your Warehouse Barcode System with ScaleOcean WMS

ScaleOcean’s WMS serves as the brain of your barcode system, integrating scanner data to provide real-time visibility and control. It assures inventory accuracy through scan verification, minimizing human error from receipt to packing.

ScaleOcean’s WMS improves efficiency through automation and real-time dashboards that enable quick decisions. Its cloud design supports operations and qualifies for both PSG and CTC grants, allowing businesses to automate and streamline. Below is a list of ScaleOcean software features:

- Seamless Integration with Barcode Systems: ScaleOcean’s WMS integrates scanner data for real-time visibility, improving inventory accuracy and reducing errors from receiving to packing.

- Automation for Improved Efficiency: ScaleOcean’s WMS automates processes, eliminating manual steps and optimizing workflows to enhance operational efficiency and reduce human error.

- Real-Time Dashboards for Quick Decision Making: ScaleOcean provides real-time dashboards for instant insights, enabling fast, data-driven decisions that improve productivity and minimize delays.

- Cloud-Based Architecture for Scalability and Flexibility: ScaleOcean’s cloud-based solution allows seamless scaling across multiple locations, ensuring flexibility, reducing overhead, and simplifying expansion.

- End-to-End Visibility for Complete Control: ScaleOcean’s WMS offers full visibility of warehouse operations, reducing errors and maintaining optimal stock levels to streamline the supply chain.

Conclusion

A warehouse barcode system is more than a tool. It is a game-changing technology for Singapore enterprises. It overcomes problems such as human error, inefficient processes, and insufficient inventory visibility, creating the groundwork for a more accurate, efficient, and scalable operation.

The genuine value comes from the combination of labels, scanners, and a sophisticated WMS like ScaleOcean. Effective implementation, from strategy to training, ensures success. ScaleOcean’s WMS improves warehouse operations while also making the company more competitive and future-ready.

FAQ:

1. How to set up a barcode system for the warehouse?

To implement a barcode system in a warehouse, begin by choosing the right barcode scanners and software. Label each product with a unique barcode, set up the system to integrate with your Warehouse Management System (WMS), and train employees to scan products during various processes like receiving and dispatching.

2. What type of barcode is used in warehouses?

In warehouses, Code 128 and Code 39 barcodes are commonly used because of their reliability and compact design. Additionally, QR codes are gaining popularity for tracking and managing complex or large inventories, offering more data storage capacity.

3. How does a barcode inventory system work?

A barcode inventory system functions by scanning barcodes on products at various stages, such as receiving, storing, picking, and shipping. The scanned data is sent directly to the WMS, ensuring real-time updates on stock levels, product locations, and inventory status.

4. What are the advantages of the barcode system in a warehouse?

A barcode system enhances operational efficiency by reducing human errors, speeding up processes, and providing real-time data on inventory. It improves accuracy, reduces labor costs, enhances tracking, and allows for scalable inventory management across large warehouses.

PTE LTD..png)

.png)

.png)

.png)

.png)