A Stock Keeping Unit (SKU) is essential for businesses to manage inventories, track stock, sales, and order fulfillment. In Singapore’s competitive market, SKUs improve efficiency and reduce errors, leading to better decision-making and customer satisfaction. According to Open GOV Asia, 60% of eligible government systems now operate within the Government Commercial Cloud (GCC), highlighting the growing need for effective inventory management in the digital age.

This article will help Singapore business owners understand everything there is to know about SKUs. It discusses their significance, applications across sectors, and how to design effective SKU systems. It also answers typical questions concerning SKUs, UPCs, and inventory management, providing vital insights into optimizing your inventory system for smoother operations.

- A Stock Keeping Unit (SKU) is a unique identifier used by businesses to track and manage products in their inventory system, facilitating stock control, sales tracking, and product organization.

- SKUs are essential for various business operations, such as inventory tracking, sales monitoring, order management, and data analysis, helping businesses optimize stock management and improve overall efficiency.

- Creating SKUs requires a systematic approach based on product characteristics and business needs, ensuring consistency and clarity in the inventory system for effective management.

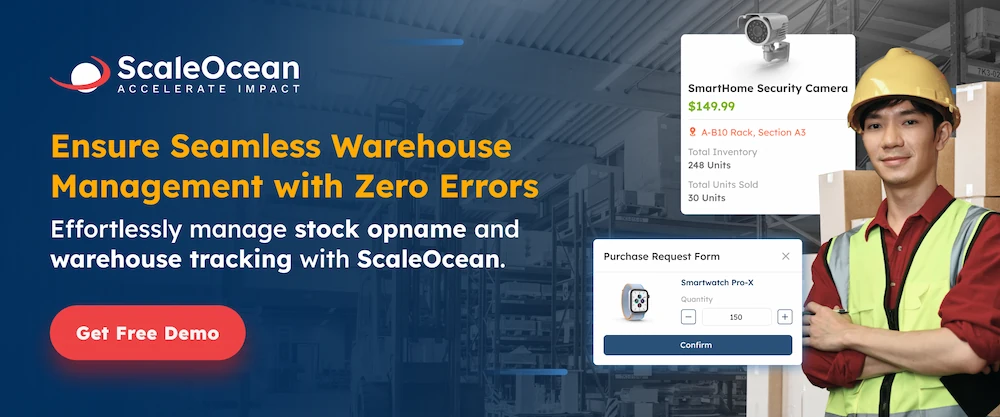

- ScaleOcean Warehouse Software automates SKU creation from product specifications, streamlining inventory management by reducing human error and improving real-time tracking of products.

What is a Stock Keeping Unit (SKU)?

A Stock Keeping Unit (SKU) is a unique identifier that firms use to track and manage their products in the inventory system. It facilitates stock control, sales tracking, and product organization by allowing businesses to differentiate between distinct things. SKUs are typically alphanumeric and may include product specifications such as size, color, brand, or model.

Retailers, wholesalers, and manufacturers rely heavily on SKUs to manage inventory. Businesses that assign a unique code to each product can better manage their inventories, monitor sales, and ensure that supplies are available when needed. This makes SKUs critical for ensuring effective operations and lowering the risk of stockouts or overstocking, which is where safety stock comes into play as an essential part of inventory planning.

What Are SKUs Used For?

SKUs are used for a variety of purposes in inventory and business operations. These unique codes help businesses organize and track products, making it easier to manage stock, monitor sales, and improve overall efficiency. Whether for tracking inventory levels or forecasting sales, SKUs offer a clear and reliable way to handle business data. Below are some of the key uses of SKUs:

1. Inventory Tracking

SKUs are essential for monitoring stock levels, guaranteeing product availability. Assigning a unique identifier to each item simplifies tracking, making it easy for businesses to know precisely when to reorder. This proactive approach prevents both stockouts and overstocking, including the risk of accumulating obsolete inventory, leading to more efficient inventory control and consistently meeting customer demand.

2. Sales Monitoring

By examining SKU data, companies can identify top sellers and slow-moving items, guiding decisions on promotions, discontinuation, and inventory flow. According to the Monetary Authority of Singapore (MAS), markets and exchanges are governed by the Securities and Futures Act 2001 (SFA) and related regulations. This ensures businesses comply with regulatory standards, leading to more efficient transactions. Analyzing sales patterns helps businesses improve demand forecasts and optimize inventory strategies.

3. Order Management

Stock Keeping Units (SKUs) are crucial for smooth order processing. When customers make a purchase, SKUs act as unique identifiers for each product, guaranteeing that the right items are picked and shipped without delay. This precision minimizes errors and boosts customer satisfaction by ensuring accurate and timely deliveries.

4. Data Analysis

SKUs are invaluable for in-depth data analysis, empowering businesses to create comprehensive reports. These reports reveal key insights into what customers like, how well products are selling, and emerging market trends. Leveraging SKU data helps companies make smarter choices regarding pricing strategies, promotional campaigns, and inventory management. By tracking individual product performance through SKUs, businesses can also refine their strategic planning and decision-making for better outcomes.

Where are SKUs Used?

Stock Keeping Units (SKUs) find their utility across a multitude of sectors, from retail to manufacturing and e-commerce. In the retail world, companies depend on SKUs to meticulously arrange their displays and storage areas. This organization ensures products are simple to locate and retrieve, cutting down on search times and enhancing the customer’s shopping journey.

For online businesses, SKUs are fundamental for overseeing product catalogs, tracking customer orders, and keeping inventory levels current in real-time. Similarly, manufacturers leverage SKUs to keep tabs on components, raw materials, and completed products throughout their production cycles, which facilitates seamless inventory control and prompt delivery of orders. Ultimately, SKUs are indispensable for operational effectiveness wherever goods are managed.

How are SKUs Created?

Creating SKUs requires a systematic strategy that takes into account the unique characteristics of the products a business sells. Businesses design their own SKU systems that align with their operational requirements and help manage inventory efficiently.

This process requires careful analysis to ensure that each SKU remains clear, useful, and consistent with the company model. For more tips on optimizing inventory systems, including choosing the right warehouse management system, check out a warehouse management guide on improving storage and tracking.

Here are the important steps in producing SKUs:

1. Design Based on Product Attributes

SKUs are produced by taking into account certain product qualities such as category, brand, size, color, and materials. These characteristics enable firms to distinguish between products and track them more efficiently in the inventory system. A well-designed SKU will make it simple to identify crucial product details at a glance, resulting in improved inventory control and organization.

2. Tailored to Business Needs

Businesses can develop their own SKU systems that meet their operating requirements. For example, a clothing business may include size and color in its SKUs, whereas a technology company may focus on model numbers and specifications. Customizing SKUs to match the business results in a more simplified procedure that meets the company’s specific needs and workflow.

3. Simple or Detailed Structure

Some firms choose basic SKUs that are straightforward to read and enter, but others may generate more complex codes that define the product in greater depth. For example, a simple SKU may only indicate the product category and size, whereas a thorough SKU may include the brand, model, size, color, and material. The choice is determined by the level of detail required for effective tracking and management.

4. Consistency is Key

It is critical to ensure that SKUs are consistent, simple to grasp, and fit the business strategy. Consistent SKU structures help to avoid errors during data entry and guarantee that everyone in the company knows the system. Whether utilizing a simple or comprehensive structure, keeping consistency in how SKUs are assigned improves inventory management and avoids confusion.

How Long Should SKUs Be?

The length of an SKU normally spans between 8 and 12 characters, depending on the complexity of the products and the company’s inventory system. For simpler product lines, a shorter SKU is frequently sufficient, offering just enough detail to effectively separate items.

However, for more complex product lines, SKUs may be lengthier in order to collect extra features such as size, color, or model information. SKUs must be easy to read, input, and remember, as long codes can cause confusion and slow down processes. When developing SKUs, always stress consistency and simplicity.

Examples of SKU Codes

Stock Keeping Units (SKUs) are critical for firms to maintain and organize their products effectively. They assist in product categorization, inventory tracking, and ensuring smooth operations across departments. An effective SKU system not only reduces confusion, but also guarantees that the correct products are easily recognizable and accessible. The following are a few examples of how SKUs might be built to represent distinct products, demonstrating how they split down crucial features like color, size, and style.

1. SH-RED-M-S

This SKU refers to a red shirt in size medium. It is designed to transmit important information about the product: “SH” specifies the category, which is a shirt, and “RED” denotes the color. The “M” represents the medium size, with a specific detail that distinguishes it from other sizes.

Finally, the “S” at the end represents the shirt’s style or design, which allows for additional customization. Businesses may simply track inventory by splitting it down into segments of the SKU, ensuring that the correct products are ordered, sold, or restocked based on the precise features.

2. BLK-105-WD-12

This SKU refers to a black wallet, model 105, in size 12. “BLK” is the color code for black, making it simple to recognize the product’s appearance at first glance. The number “105” alludes to the wallet’s distinctive style or design, making it easily distinguishable from other wallet designs in the product range.

“WD” signifies that this product is a wallet, and “12” represents its size, allowing customers and staff to distinguish between the numerous sizes offered. With this well-structured SKU, inventory management becomes more straightforward, lowering the likelihood of confusion or error.

What is the Difference Between SKU and UPC?

A Universal Product Code (UPC) is a standardized barcode that retailers use to identify products. All stores selling a given product apply this universal code. Retailers commonly use UPCs at the point of sale (POS) to scan products and process payments quickly.

In contrast, a Stock Keeping Unit (SKU) is unique to each company and is used for internal inventory control. Unlike UPCs, SKUs can differ between stores and businesses. They assist firms in tracking and managing their inventory, making it easier to monitor stock levels and product flow within the organization.

What is the Difference Between SKU and Inventory?

An SKU (Stock Keeping Unit) is a unique identification that a company allocates to a single product to track it in its inventory system. It often includes features like size, color, and style, which help firms distinguish between different products in their inventory.

An SKU (Stock Keeping Unit) is used to identify and track individual products, while inventory refers to the total stock a business has available for sale or use. The importance of inventory control lies in how SKUs help businesses manage and organize inventory levels efficiently.

Also Read: What is Inventory Control? Optimizing Stock Management

Are SKUs the Same as Model Numbers?

SKUs and model numbers are closely similar yet serve distinct purposes. The manufacturer often assigns a model number to identify a product’s specific version or design. It is usually consistent across all stores and helps customers and businesses distinguish between different varieties of a product.

On the other hand, the company selling the goods creates SKUs to aid with inventory control. While an SKU may have a model number, it usually includes extra information such as size, color, or material, which the company needs for tracking products in its inventory system.

Is a Barcode a SKU?

A barcode and an SKU are similar but serve separate purposes. A barcode is a graphic depiction of an SKU or UPC code intended for easy scanning. It speeds up transactions by making it simple to identify products at the point of sale or during shipping. Barcodes, particularly when integrated into a warehouse barcode system, are utilized in a variety of businesses, particularly retail and logistics, to simplify operations and eliminate errors.

In contrast, a business creates an SKU as an internal identifier to manage its inventory. The SKU includes information such as size, color, and style, which helps businesses maintain and arrange inventory more efficiently. While businesses rely on SKUs for inventory management, they use barcodes externally to assist with product identification and sale, making them complementary rather than interchangeable.

Automatically Create SKUs Using ScaleOcean Warehouse Software

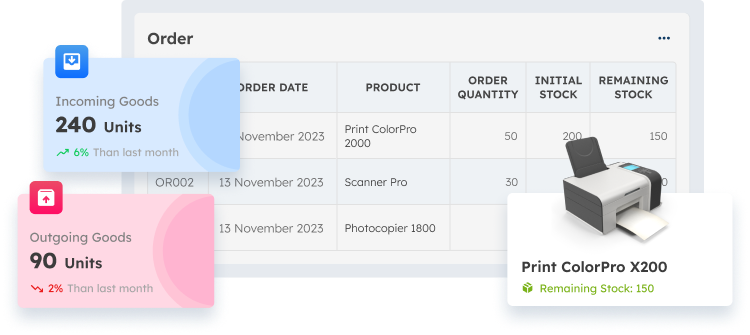

ScaleOcean Warehouse Software is a sophisticated solution that streamlines and optimizes inventory management for enterprises of all sizes. It automates critical procedures including SKU generation, barcode creation, and real-time inventory tracking. ScaleOcean ensures precise inventory monitoring by automatically establishing SKUs based on product characteristics, reducing the possibility of human error.

Businesses benefit from increased operational efficiency, improved inventory visibility, and easy connection with other ERP modules. ScaleOcean provides a free demo for companies wishing to improve their warehouse operations, and you may be eligible for a CTC grant to help fund your investment. The following are the main features of ScaleOcean software:

- Automated SKU Generation, Automatically generates SKUs from detailed product specifications, ensuring accurate and consistent SKU creation. This reduces manual entry errors and saves time.

- Real-Time Barcode Management, Full integration of barcode printing, scanning, and management, allowing seamless tracking and updating of inventory in real-time.

- Inventory Visibility and Control, Real-time stock visibility through automated updates, integrated with SKU and barcode systems.

- Seamless Integration with Other Modules, ScaleOcean Warehouse Software integrates smoothly with other ERP modules such as Sales, Purchasing, and Accounting, ensuring synchronized SKU and barcode data across the system.

- Customizable SKU and Barcode Systems, The software offers customizable fields for SKUs and barcodes, allowing businesses to tailor the system to their unique product types and operational needs.

Conclusion

ScaleOcean Warehouse Software offers firms an efficient, automated way to optimize inventory management. By automating operations such as SKU development, barcode production, and stock tracking, it ensures accurate inventory control and improves operational efficiency, all while seamlessly connecting with other ERP modules for better decision-making.

Furthermore, ScaleOcean provides robust Warehouse Management Software that streamlines inventory processes, optimizes stock levels, and improves warehouse operations. This technology, when integrated with Warehouse Software, allows organizations to increase efficiency and control over their inventory management.

FAQ:

1. What does stock keeping unit mean?

A Stock Keeping Unit (SKU) is a unique identifier assigned to products to help businesses manage and track their inventory. SKUs are used to distinguish different items based on attributes like size, color, and brand, making it easier to monitor stock levels and sales.

2. What is the difference between SKU and inventory?

An SKU is a specific code assigned to individual products for easier tracking and management, while inventory refers to the total quantity of goods a business has on hand. SKUs are used to track and manage each item, whereas inventory reflects the overall stock of products available for sale or use.

3. What is an SKU example?

For example, an SKU could be BLK-JKT-L, representing a black jacket in size large. The SKU includes important details such as product type, color, and size, helping businesses quickly identify and manage the item within their inventory system.

4. What is the difference between SKU and ISBN?

An SKU is a unique identifier created by businesses to manage product inventory, while an ISBN (International Standard Book Number) is a specific identifier used for books. The ISBN is standardized internationally and is assigned to books for sales and distribution, while an SKU is used more broadly across all product types for internal tracking.

PTE LTD..png)

.png)

.png)

.png)

.png)