Inventory control is an important technique for organizations to guarantee that they have the proper amount of goods to satisfy demand without overstocking or understocking.

Efficient inventory control reduces unnecessary expenditures, optimizes storage, and enhances overall operational efficiency. However, businesses frequently encounter issues such as inaccurate tracking, stockouts, and inefficiencies, which can disrupt operations and compromise customer satisfaction.

As firms develop and market demands fluctuate, good inventory control becomes increasingly important. Businesses can reduce losses, eliminate stockouts, and ensure the seamless operation of their supply chain by implementing effective tactics.

This article will discuss the complete guide to inventory control, from definition, how to improve with the best practices methods, and also the examples. Learn more here!

- Inventory control is the practice of overseeing how goods are purchased, stored, and used to keep stock at ideal levels.

- The importance of inventory control is to reduce overstocks and stockouts, improve cash flow, enhance customer satisfaction, optimize storage costs, and streamline operations

- Inventory control Techniques are JIT, EOQ, ABC analysis, FIFO, LIFO, VMI, Barcode inventory, RFID, QR code inventory, JIC, Dropshipping, inventory optimization, and stocktaking

- Best practices of inventory control are implementing inventory tracking, optimizing stock rotation, streamlining supplier relationships, automating with an inventory management system, and more

- ScaleOcean’s WMS provides an integrated solution to enhance efficiency, minimize human error, optimize stock levels, and improve overall inventory control in a warehouse.

What Is Inventory Control?

Inventory control is the practice of overseeing how goods are purchased, stored, and used to keep stock at ideal levels. The goal is to meet customer demand without creating excess costs or waste. It includes monitoring stock movement, managing purchase orders, and using tools like barcodes to keep data accurate and operations efficient.

It is an important aspect of business management since it ensures that organizations always have the right amount of merchandise on hand. These entail managing inventory in such a way that it satisfies demand without overstocking, which can result in increased prices.

Proper inventory control enables firms to avoid stockouts, decrease waste, and increase cash flow. The process involves a variety of tactics and technologies for tracking inventory movements, forecasting demand, and maintaining an effective supply chain.

Businesses that manage inventory correctly can assure smooth operations, increase customer happiness, and lower operating expenses.

The Importance of Inventory Control

Inventory control is vital for firms to run efficiently and profitably. Businesses can avoid production or sales delays by keeping proper stock levels, as well as stockouts and surplus inventory. Proper inventory management optimizes the supply chain, lowers costs, and increases profitability.

In today’s competitive industry, inventory management is critical to consumer happiness. Keeping popular products in stock builds customer trust and loyalty. Without it, firms risk experiencing delays, missing orders, and revenue losses. Here are the importance and advantages of inventory control, including:

1. Reduces Overstocking and Stockouts

Effective inventory control allows businesses to balance stock levels by preventing overstocking and stockouts. Overstocking incurs additional storage costs and potential waste, whilst stockouts result in lost revenue and consumer discontent.

Businesses that effectively estimate demand and monitor stock levels can maintain an appropriate inventory balance that fulfills consumer expectations without incurring high costs.

Furthermore, good demand forecasting enables businesses to change their stock in response to market trends, ensuring they avoid the traps of both excess and shortfall. This balance boosts profitability by reducing waste and increasing sales opportunities.

2. Improves Cash Flow

Effective inventory control increases cash flow by preventing capital from being locked up in unsold goods. Businesses that manage stock levels efficiently might free up resources for other operational purposes.

This method allows organizations to invest in areas such as marketing, innovation, and expansion, increasing overall flexibility. Well-managed inventory can also make businesses more appealing for business grants to fund future growth.

Businesses use tactics such as just-in-time inventory to maintain only the stock they need, minimizing unnecessary storage expenditures. This strategy decreases the danger of overinvestment in low-demand items, hence improving cash flow.

Furthermore, effective inventory management improves resource allocation, boosting the chances of qualifying for business funding.

3. Enhances Customer Satisfaction

Inventory control ensures that businesses have the right products available at the right time, which is crucial for meeting customer demand. Businesses that maintain proper stock levels can reduce lead times and fulfill orders more quickly, thereby improving the customer experience.

This leads to enhanced customer satisfaction, loyalty, and repeat business. Furthermore, constantly meeting client demands strengthens a company’s dependability and reputation. Customers are more inclined to return if they believe things will always be available when they need them, which increases brand loyalty and satisfaction.

According to Forbes, organizations that prioritize inventory management and keeping stock levels in line with consumer demand are better positioned to develop long-term client loyalty and satisfaction.

4. Optimizes Storage Costs

Proper inventory control enables firms to manage storage expenses by keeping inventory levels in line with demand. Overstocking increases storage prices, but understocking might create delays or operational problems. Businesses can save money on storage by tracking stock levels and modifying them to meet actual demand.

Efficient inventory control also guarantees that enterprises do not have surplus stock that will go unsold, eliminating the need for larger storage facilities. This simplifies the entire supply chain and eliminates superfluous operational expenses, resulting in better cost management.

5. Streamlines Operations

A well-organized inventory system improves business operations by minimizing supply chain delays and inefficiencies. Businesses that check their stock levels accurately can respond promptly to demand swings and maintain smooth production cycles.

This reduces bottlenecks and ensures that resources are directed to where they are most needed. Furthermore, an effective inventory system delivers real-time stock status updates, allowing firms to make more educated purchase and distribution decisions.

This eliminates operational friction, increases communication, and speeds up the movement of commodities from suppliers to customers, resulting in overall increased efficiency.

Common Inventory Control Processes

Inventory control is critical for ensuring optimal stock levels and avoiding disruptions. It entails meticulously tracking inventory to ensure that businesses can satisfy demand without overstocking.

Effective inventory control reduces costs, increases productivity, and prevents lost sales. A simplified approach ensures that firms have the correct products on hand at the appropriate time. The following are the essential processes in the inventory control process that most firms adopt.

1. Stock Replenishment

Stock replenishment involves determining the right time to reorder items based on current inventory levels. Companies use demand forecasting to predict stock needs and reorder points, ensuring that customer demand is met without overstocking.

This balance is crucial for maintaining efficiency while avoiding stockouts. By aligning stock replenishment with the product life cycle stages, businesses can streamline the process and minimize disruptions.

Automated systems and real-time data tracking help ensure timely orders, while strong supplier relationships and accurate tracking are essential for effective restocking and smooth operations.

2. Stock Auditing and Monitoring

Stock auditing is the process of evaluating inventory levels and resolving irregularities. Regular audits help organizations keep correct records, prevent theft, and detect inefficiencies.

Businesses that continuously monitor stock can detect movement and avert concerns such as overstocking or stockouts. This guarantees that inventory data reflects actual stock levels.

By incorporating both manual and computerized stock checks, firms can increase accuracy and transparency. Automated inventory management solutions improve efficiency by offering real-time data and insights.

Auditing allows organizations to make more educated decisions, which improves overall inventory control. It also helps to make better decisions about future stock replenishment and sales methods.

3. Order Processing and Fulfillment

Order processing is an important phase in inventory control that includes receiving and managing customer orders. Efficient order fulfillment ensures that the appropriate products are picked, packed, and dispatched on time.

The process begins when a consumer submits an order, and inventory is reviewed to ensure product availability. If the items are in stock, they are processed and shipped; otherwise, reordering occurs. Accurate inventory tracking and flawless departmental communication are required during the order fulfillment process.

By integrating inventory management systems with sales platforms, organizations may ensure real-time updates and avoid order processing problems. A flawless fulfillment procedure improves client happiness and retention. As a result, it increases the company’s reputation and boosts sales.

4. Demand Forecasting

Demand forecasting is the art of estimating future product demand using past sales data, industry trends, and seasonal swings. Accurate forecasting allows organizations to predict inventory demands and minimize stockouts.

Understanding patterns in customer behavior allows businesses to better align their supply levels with predicted demand. Effective demand forecasting uses data-driven insights and advanced analytics to predict changes in purchase behavior. Businesses must also consider external factors such as economic fluctuations, promotions, and rival moves.

With the correct tools, demand forecasting improves purchasing decisions and guarantees that organizations have enough stock without overcommitting resources. This leads to improved inventory management and lower holding costs.

5. Inventory Storage and Organization

Proper inventory storage and management are critical for ease of access, accurate tracking, and minimizing product damage. Businesses should categorize products depending on size, shelf life, and frequency of usage.

This arrangement makes it easier to manage inventory and streamline picking procedures during order fulfillment. A well-organized warehouse allows for speedy product retrieval while also maintaining inventory accuracy.

Shelving units, barcode systems, and RFID technology can all help optimize the storage process. Businesses can reduce error rates and enhance overall operational efficiency by optimizing storage and organizing. Proper organization also helps to reduce handling expenses and the danger of product damage.

13 Inventory Control Techniques and Methods

Effective inventory control systems are essential for firms to run smoothly and meet client demand. These tactics aid in inventory tracking, waste minimization, and storage space optimization, resulting in lower operational expenses and more customer satisfaction.

The best technique varies according to the business type and supply chain complexity. With technological developments, inventory control has expanded to encompass automated systems and real-time tracking technologies.

These solutions simplify operations and enable data-driven decisions to improve inventory management. The following are eight regularly utilized approaches for helping firms improve their inventory control.

1. Just-in-Time (JIT) Inventory

The Just-in-Time (JIT) inventory system lowers inventories by ordering things just as they are required for manufacturing or sale. Close supplier coordination is required for timely delivery that adheres to production schedules.

This reduces stockpiles, saves storage space, and lowers inventory expenses. JIT is suitable for businesses with variable demand, such as fashion and technology, according to Investopedia.

JIT lowers inventory holding costs, releasing capital that would otherwise be locked up in surplus goods. It helps to reduce the danger of product obsolescence and waste, particularly in fast-moving sectors.

The method increases cash flow and operational efficiency. JIT preserves a competitive advantage by encouraging lean operations and supporting good stock management.

2. Economic Order Quantity (EOQ)

Economic Order Quantity (EOQ) is a technique for determining the best order quantity while minimizing overall inventory expenses. It balances ordering and holding costs by calculating the optimal stock level using mathematical calculations.

This strategy prevents overstocking and ensures that businesses have just enough inventory to meet demand. By maintaining the proper balance, EOQ assists businesses in avoiding excess stock and costly storage. EOQ facilitates cost-effective purchasing decisions by eliminating the requirement for excess inventory.

It also lowers storage expenses by maximizing warehouse space. As a result, businesses can run smoothly without experiencing frequent stockouts or carrying surplus inventory. This technique promotes a more streamlined and effective inventory management process.

3. ABC Analysis

ABC analysis divides inventory into three value categories: A (high-value), B (moderate-value), and C (low-value). It directs management attention toward high-value issues that have a major impact on profitability.

Businesses can ensure that their core items are constantly in stock by focusing resources on them. This strategy aids in the efficient allocation of resources, preventing overstocking and understocking. Implementing ABC analysis improves resource utilization by focusing on valuable stock.

It lowers inefficiencies and prioritizes high-value products in inventory management. This strategy enhances overall stock control by emphasizing the most profitable items. It enables organizations to streamline operations while preserving profitability.

4. First-In, First-Out (FIFO)

FIFO guarantees that older inventory is used or sold first, which is critical for reducing waste and spoilage, particularly with perishable commodities. This approach is commonly used in industries such as food and pharmaceuticals, where product shelf life is important.

By prioritizing older stock, FIFO protects product quality and decreases the risk of obsolete items. It also helps organizations meet safety regulations by ensuring inventory is used on time.

This strategy reduces waste and avoids loss due to expired supplies. FIFO also improves inventory control by shifting older stock first. It ensures that clients receive fresh, high-quality products, which increases their pleasure.

5. Last-In, First-Out (LIFO)

LIFO assumes that the most recently received inventory is sold first, which helps to manage costs in volatile markets. This strategy is effective in businesses where product prices are constantly changing, such as raw materials.

It enables organizations to successfully manage expenses during inflation by prioritizing newer stock. LIFO can aid in accurately reflecting current market conditions in financial reports.

LIFO minimizes taxable revenue as inventory prices rise, which benefits firms financially. It also ensures that older inventory is available for long-term use. This strategy is particularly useful for controlling costs during periods of price volatility. However, it may not be appropriate for every industry.

6. Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory (VMI) enables suppliers to directly monitor and manage inventory levels, assuring a consistent supply based on predetermined parameters. This decreases the operational burden for organizations by automating stock replenishment.

VMI improves collaboration with suppliers and optimizes supply chain procedures, reducing stockouts. Businesses gain from a more efficient system when the duty for inventory management is transferred to suppliers.

This method reduces manual stock monitoring and optimizes stock levels, preventing shortages. VMI enhances inventory accuracy, resulting in timely product replacement.

It improves supplier connections and creates a more dependable supply chain. As a result, organizations may concentrate on core tasks while leaving inventory management to the supplier.

7. Barcode Scanning Inventory Control

Barcode scanning tracks inventory by scanning unique codes on objects, which are then automatically updated in real time. This method improves efficiency by maintaining accurate and up-to-date inventory information.

It reduces manual errors and assures accurate tracking of stock movement. Barcode scanning increases inventory visibility and streamlines stock management operations. This strategy saves time by automating data entry and increasing accuracy.

It enables firms to better manage stock levels and make educated decisions. Barcode scanning lowers the danger of overstocking or understocking. Businesses can improve inventory management and operational efficiency by implementing real-time updates.

8. Radio Frequency Identification (RFID)

RFID tracks inventories using electromagnetic fields and tags that offer real-time data updates. It automates inventory tracking, which increases accuracy and visibility throughout the supply chain.

RFID improves inventory management by providing detailed information on product movement and location. This technology lowers manual errors while increasing operational efficiency.

RFID enables organizations to monitor stock levels and track things across numerous locations. It improves security by giving a more reliable tracking system than barcodes.

It also delivers real-time data, allowing organizations to respond quickly to inventory needs. This method enables more accurate, efficient, and cost-effective inventory management.

9. QR Code Inventory Control

QR code inventory control works similarly to barcodes but uses two-dimensional codes, which can hold more data. These codes can be scanned using smartphones or scanners, making them a cost-effective solution.

This technique provides real-time data and is ideal for businesses seeking a more flexible and versatile tracking method with added storage capacity.

10. Just in Case (JIC)

Just in Case (JIC) is a more conservative approach where businesses keep extra stock on hand to ensure they don’t run out of products, even during unexpected demand spikes or supply chain disruptions.

While it reduces the risk of stockouts, it can lead to higher inventory costs and waste. This method is often used by industries that face uncertainty or long lead times.

11. Dropshipping

Dropshipping is a retail fulfillment method where businesses don’t keep inventory in stock. Instead, when a customer places an order, the product is directly shipped from the supplier.

This technique eliminates storage and handling costs but may result in longer shipping times and less control over inventory management, making it ideal for businesses with limited capital.

12. Inventory Optimisation

Inventory optimization involves strategically managing stock levels to ensure products are available without excessive inventory. It focuses on accurate forecasting, data analysis, and adjusting stock based on demand patterns.

This technique helps businesses minimize holding costs, reduce waste, and improve cash flow by keeping inventory levels as efficient as possible.

13. Stocktaking

Stocktaking is the process of physically counting inventory to verify the quantities recorded in the system. It helps identify discrepancies between physical stock and system records, ensuring accuracy in financial reporting and replenishment planning. Regular stocktaking is essential for maintaining data integrity and avoiding issues like stockouts or overstocking.

Types of Inventory Control Systems

Effective inventory control is essential for businesses to maintain a balance between supply and demand while minimizing waste. Various inventory control systems help businesses track and manage their stock levels.

The right system depends on factors such as the size of the business, the volume of products, and operational needs. Below are the common types of inventory control systems:

1. Periodic Inventory Control System

The periodic inventory control system involves physically counting stock at regular intervals, such as monthly or yearly. This system does not provide real-time updates, and businesses must wait until the next inventory count to assess stock levels.

While it’s a simpler and more cost-effective method for smaller businesses, it may lead to inaccuracies in real-time stock monitoring.

2. Perpetual Inventory Control System

The perpetual inventory control system provides real-time tracking of inventory levels by automatically updating records with each transaction, such as sales or purchases.

This method ensures accurate, up-to-date data and is ideal for businesses with large volumes or complex inventory needs. It requires investment in technology but offers better control and minimizes stockouts or overstocking risks.

3. Achieve Operational Excellence

Achieving operational excellence in inventory management involves using the right mix of strategies, processes, and technologies to optimize inventory control.

It focuses on continuous improvement, efficient resource use, reducing waste, and ensuring product availability. Businesses can leverage technology, staff training, and accurate data analysis to enhance overall inventory performance and streamline operations.

Inventory Control Policies and Processes

Inventory control policies and processes are essential guidelines that businesses follow to manage their stock effectively. These policies define the procedures for ordering, storing, and tracking inventory, aiming to ensure stock levels meet demand without incurring excess costs.

Clear inventory control processes help businesses maintain operational efficiency by minimizing stockouts, preventing overstocking, and optimizing storage costs. Additionally, they ensure consistency in inventory handling, improve data accuracy, and align with overall business objectives, enabling better decision-making and smoother operations.

Key Performance Indicators in Inventory Control

Key Performance Indicators (KPIs) in inventory control are vital metrics used to evaluate the effectiveness of inventory management practices. These indicators help businesses measure and track performance in areas such as stock levels, order accuracy, and turnover rates.

By monitoring KPIs, businesses can identify inefficiencies, make data-driven decisions, and optimize inventory management processes.

1. Inventory Turnover Rate

The inventory turnover rate measures how often inventory is sold and replaced within a given period. A higher turnover indicates efficient inventory management, meaning products are moving quickly and reducing holding costs.

It helps businesses assess demand forecasting accuracy, determine slow-moving stock, and optimize purchasing decisions to avoid overstocking.

2. Stockout Rate

The stockout rate tracks the frequency at which items are out of stock. A high stockout rate indicates poor inventory planning and forecasting, leading to lost sales and customer dissatisfaction.

By monitoring this KPI, businesses can adjust reorder points, improve demand forecasting, and ensure product availability to meet customer expectations.

3. Carrying Cost of Inventory

Carrying cost refers to the expenses associated with storing unsold goods, such as warehousing, insurance, and taxes. This KPI helps businesses evaluate the cost-effectiveness of their inventory management practices.

A high carrying cost suggests overstocking, prompting businesses to adjust order quantities, improve stock rotation, or adopt just-in-time (JIT) strategies to reduce unnecessary costs.

4. Order Accuracy

Order accuracy measures the percentage of orders fulfilled correctly without errors. This KPI is crucial for customer satisfaction and operational efficiency.

High-order accuracy reflects well-managed inventory systems and ensures that the correct items are shipped to customers on time. Monitoring this KPI helps businesses identify areas for improvement in picking, packing, and shipping processes.

5. Lead Time

Lead time refers to the amount of time it takes to replenish inventory from the moment an order is placed to when the product is available for sale.

Shortening lead time improves responsiveness to market demand, reduces the risk of stockouts, and enhances customer satisfaction. Tracking lead time helps businesses identify bottlenecks in their supply chain and optimize procurement processes.

6. Inventory Accuracy

Inventory accuracy measures how closely actual stock levels match recorded inventory data. This KPI is essential for preventing stock discrepancies, improving order fulfillment, and maintaining financial accuracy.

High inventory accuracy ensures reliable decision-making, while discrepancies indicate the need for better stock tracking systems, such as barcode or RFID technologies.

Challenges in Inventory Control and Their Solutions

Effective inventory control is critical to ensuring corporate operations run smoothly and profitably. However, organizations regularly face a number of issues that interrupt inventory management, resulting in inefficiencies and financial losses.

Poor inventory control can have an impact on everything from cash flow to customer happiness, and without adequate management, issues like stockouts, overstocking, and inaccurate tracking can occur.

As firms expand and supply networks get more complicated, addressing these concerns becomes increasingly important. The following are some of the most typical inventory control issues that firms confront, as well as effective solutions to them.

1. Overstocking and Understocking

Overstocking ties up important capital while also increasing storage costs and the risk of goods becoming obsolete, whereas understocking results in missed sales opportunities and consumer unhappiness.

The balance between having enough stock to meet demand and not committing to surplus inventory is critical. One of the most successful approaches to addressing this issue is to deploy Just-in-Time (JIT) inventory systems.

JIT focuses on keeping only the necessary stock levels, allowing firms to order what they need when they need it. Demand forecasting technologies can also assist organizations in predicting future sales and managing stock levels accordingly, avoiding both overstocking and understocking.

2. Poor Inventory Tracking

Manual inventory monitoring can lead to errors and anomalies, making it difficult for firms to keep correct data. Incorrect stock counts can cause misunderstanding, overordering, or stockouts, all of which have a negative influence on both sales and customer happiness.

The solution to this challenge is to use automated inventory tracking technologies like barcode scanning or Radio Frequency Identification (RFID). It provides businesses with real-time inventory visibility, cutting down on manual data entry and ensuring that their stock information is always reliable.

Accurate tracking allows organizations to increase order fulfillment, optimize storage, and obtain better visibility into inventory turnover.

3. Inefficient Stock Rotation

In industries such as food, medicines, and electronics, incorrect stock rotation can cause obsolete inventory, outdated or outmoded products to go unsold, resulting in waste and financial losses. An ineffective stock rotation method can also diminish inventory turnover and profitability.

To avoid this, organizations should use inventory management strategies such as FIFO (First In, First Out) or LIFO (Last In, First Out), depending on the products they manage.

FIFO ensures that the oldest inventory is used first, decreasing waste and increasing stock turnover. These inventory rotation tactics assist organizations in staying organized and maintaining fresh supplies, particularly for time-sensitive products.

4. Inadequate Supplier Relationships

An inconsistent supply chain can cause delivery delays and inventory shortages, disrupting sales and manufacturing plans. Without solid supplier ties, organizations may face unexpected lead times and stockouts, limiting their ability to satisfy client demand.

Strengthening supplier relationships through open communication and explicit agreements is critical to guaranteeing timely deliveries and better inventory replenishment.

Businesses should also consider diversifying their supplier base to minimize reliance on a single source, which lowers the risk of stock outages and improves supply chain resilience.

5. Lack of Real-Time Data

Access to real-time data is critical for making informed inventory management decisions. Without precise and up-to-date information, organizations may experience stock imbalances, ordering inefficiencies, and missed sales opportunities.

Implementing real-time inventory tracking software or combining inventory management systems with advanced analytics can provide firms with useful information about stock levels, sales trends, and overall inventory performance.

Businesses can use these technologies to better alter their inventory plans, ensuring they fulfill client demand while reducing waste and overstocking. Real-time data allows for more accurate forecasting, better stock control, and faster decision-making, all of which improve corporate efficiency.

How to Improve Inventory: Best Practices Methods

Effective inventory control is critical for organizations to meet consumer requests while eliminating surplus inventory. A well-organized system saves money and increases productivity, but maintaining inventory may be difficult, especially as firms develop.

Businesses may improve inventory control, avoid stockouts, and overstocking by implementing the correct tactics and technologies. Continuous monitoring, accurate forecasting, and cutting-edge technology are all required for effective inventory management.

Here are some tips and best practices methods to help firms streamline and improve inventory control operations in business, including:

1. Implement Real-Time Inventory Tracking

Real-time inventory tracking is an essential method for efficient inventory management. Using tools like barcode scanners or RFID, companies can track their stock and products in real time, cutting down on manual mistakes.

This ensures that inventory data is always up to date, making it easier to manage stock levels and eliminate discrepancies. Furthermore, real-time tracking enables firms to respond swiftly to changes in demand and supply chain interruptions.

If a product is running low or there is an unexpected increase in client demand, businesses can change their ordering and stock levels accordingly. This agility is essential in today’s fast-paced market, where delays can lead to lost sales and strained client relationships.

2. Utilize Inventory Forecasting Tools

Accurate forecasting is required for effective supply and demand management. Inventory forecasting technologies, along with smart warehousing technology, use past sales data, trends, and other factors to forecast future demand.

Businesses can use these tools to minimize overstocking and understocking, as well as make smarter buying selections. Forecasting allows organizations to plan for demand swings during seasonal peaks or promotional times.

This guarantees that the proper amount of stock is available at the appropriate moment, lowering excess inventory and the danger of stockouts. Forecasting tools help increase cash flow by preventing excess money from being locked up in unsold inventory.

3. Optimize Stock Rotation

Proper stock rotation is critical to keeping products from becoming outmoded or expired, particularly in industries such as food and pharmaceuticals. Implementing inventory management techniques such as FIFO (First In, First Out) or LIFO (Last In, First Out) can assist in ensuring that older material is used first.

This reduces waste and maximizes stock turnover. Stock rotation not only reduces waste but it also increases warehouse efficiency. Staff can swiftly access and disperse the oldest inventory, preventing stagnant inventories and enhancing product flow. This also helps to cut storage expenses by keeping stock fresh and in demand.

4. Streamline Supplier Relationships

Building solid, dependable connections with suppliers is critical for efficient inventory management. Poor supplier communication and inconsistent deliveries can cause delays and stockouts.

Businesses may ensure timely and regular inventory replenishment by communicating clearly and negotiating favorable terms. Furthermore, having numerous sources or a backup plan in place might help to mitigate the risks associated with relying solely on one source.

A diverse supplier base contributes to a consistent flow of goods and eliminates disruptions caused by supplier issues such as production delays or transportation problems.

5. Automate Inventory Management Systems

Automating inventory control systems can significantly increase efficiency and accuracy. With automated inventory tracking, businesses can say goodbye to manual data entry and reduce the risk of costly errors, leading to better inventory management and increased profitability.

This results in more accurate records and fewer discrepancies in inventory reporting. Automation also allows employees to devote more time to strategic tasks, such as evaluating inventory trends or identifying cost-cutting opportunities.

Automation may greatly improve inventory management by decreasing manual processes, resulting in cost savings and more efficient operations.

6. Regularly Audit Inventory

Conducting regular inventory audits is critical for detecting inconsistencies between recorded and real inventory levels. Periodic audits can discover errors early, allowing organizations to address problems before they worsen. This also helps organizations keep accurate financial records and reduces the possibility of inventory shrinkage.

There are numerous ways to conduct inventory audits, including cycle counting and annual stocktakes. Regardless of the method, regular audits ensure the company understands its inventory situation and can make informed decisions about restocking and purchasing.

7. Improve Warehouse Organization

Your warehouse’s organization is critical to improving inventory control. Properly labeled shelves, optimal storage layouts, and quick access to commonly sold items can all help to speed up order fulfillment and inventory checks.

A well-organized warehouse saves time locating products and eliminates the possibility of errors during stocktaking. Furthermore, employing a well-planned warehouse layout design can boost safety and productivity, ensuring efficient storage and quicker access to items when needed.

A clutter-free, logically organized environment ensures that inventory is stored most effectively, allowing employees to easily discover items and save time searching for products.

8. Monitor Inventory KPIs (Key Performance Indicators)

Tracking inventory KPIs such as turnover rates, order correctness, and stockout frequency is critical for determining the success of your inventory control procedures. Businesses that frequently analyze these data can find areas for improvement and alter their strategies as needed.

For example, if stockouts occur frequently, it may highlight the need for better forecasting or more dependable suppliers.

Monitoring KPIs also helps organizations evaluate the financial success of their inventories. By tracking variables such as inventory carrying costs, firms may make data-driven decisions about how much stock to keep on hand and how to optimize inventory turnover for maximum profit.

9. Set PAR Levels

PAR levels are predefined minimum stock quantities for each product that trigger reorder actions. By setting appropriate PAR levels, businesses can ensure they maintain enough stock to meet demand without overstocking.

Regularly reviewing and adjusting PAR levels based on demand trends and sales patterns helps prevent stockouts and minimize holding costs.

10. Correctly Classify Products

Proper product classification ensures that inventory is organized in a way that maximizes storage and facilitates easy tracking. Categorizing products based on factors like demand frequency, size, or usage helps streamline inventory management processes.

This classification allows businesses to apply the right inventory control techniques to different product categories, improving overall efficiency. To easily enhance inventory control, utilize the best warehouse management software that fits your workflow.

ScaleOcean’s warehouse software provides integrated solutions to optimize inventory control, offering real-time stock tracking and ensuring accurate inventory levels while minimizing discrepancies.

It also enhances efficiency across multiple locations by managing stock transfers between warehouses based on real-time needs, ultimately reducing the risks of overstocking or understocking and improving operational accuracy. Request a free demo to get this solution for your inventory management.

Differences Between Inventory Control and Inventory Management

Inventory control and inventory management are sometimes used interchangeably. However, they refer to different aspects of supply chain management.

Inventory control is keeping adequate stock levels, monitoring inventory, and conducting audits to avoid stockouts or overstocking. Its purpose is to successfully balance stocks to satisfy demand without oversupply or scarcity.

In contrast, inventory management is a more comprehensive strategy that encompasses procurement, storage, distribution, and inventory control. It encompasses the entire inventory lifecycle, from sourcing to delivery, to ensure efficient product flow throughout the firm.

Charts of Inventory Control

Inventory control charts are powerful tools that help businesses visualize and track stock levels to ensure optimal inventory management. These charts provide insights into when to order, how much to order, and how much safety buffer is needed to avoid disruptions in operations. Understanding the key elements of these charts is essential for efficient stock control and minimizing excess inventory.

1. Min Stock

The minimum stock level is the lowest quantity of a product that a business should keep on hand. It serves as a trigger point for reordering stock to prevent stockouts.

By setting the right minimum stock levels, businesses can avoid running out of critical items, ensuring continuous operations without overstocking and tying up excess capital in inventory.

2. Max Stock

The maximum stock level represents the highest amount of inventory that should be maintained for a product. This figure prevents overstocking, which can lead to unnecessary storage costs and waste.

It ensures that businesses do not over-invest in stock, while also helping to keep inventory turnover at optimal levels to meet demand without exceeding capacity.

3. Safety Stock

Safety stock is the additional quantity of inventory kept on hand as a buffer against unforeseen demand spikes or supply chain delays. By maintaining safety stock, businesses can minimize the risk of stockouts during lead time variability.

It helps to balance between too little and excessive inventory, ensuring customer demand is met while preventing waste.

4. Lead Times

Lead time refers to the time it takes from placing an order with a supplier until the inventory is available for sale or use. Understanding lead times is crucial for accurately determining reorder points and maintaining optimal stock levels.

By factoring in lead times, businesses can avoid stockouts and ensure they have enough time to replenish inventory without unnecessary delays.

5. Rate of Sale or Use/Rate of Consumption

The rate of sale or use measures how quickly a product is consumed or sold over a specific period. By tracking this rate, businesses can predict demand patterns and adjust inventory levels accordingly.

Understanding the rate of sale helps improve demand forecasting, ensure efficient inventory rotation, and prevent overstocking or stockouts of fast-moving items.

6. Reorder Points

Reorder points represent the inventory levels at which a new order is triggered to replenish stock before it runs out. They are calculated by considering lead time and rate of consumption, ensuring that new stock arrives before existing stock is depleted.

Setting accurate reorder points prevents stockouts and optimizes inventory management by ensuring timely restocking.

Examples of Inventory Control

Inventory control is a vital part of operations for businesses to efficiently manage stock levels, reduce waste, and meet customer demand. Various methods can be applied depending on the business size, industry, and specific needs.

Below are examples of inventory control systems, each with distinct benefits for different operational scenarios, including:

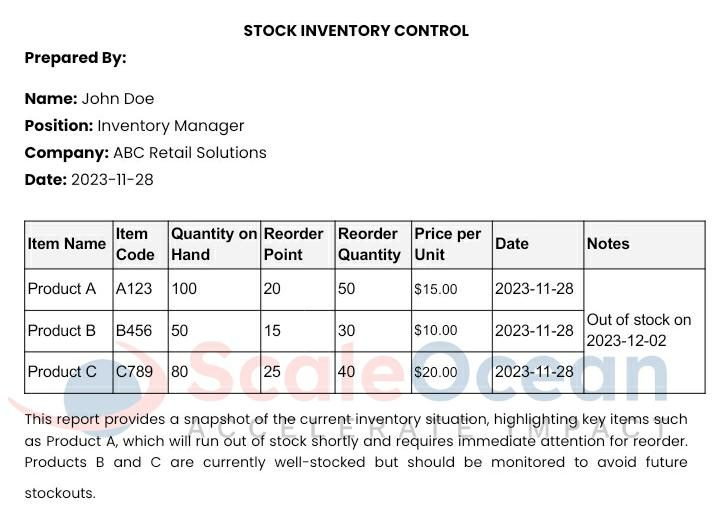

1. Manual Inventory Control System

Manual inventory control involves manually counting, recording, and tracking stock levels using paper-based logs or spreadsheets. This method is low-cost but prone to human errors, inefficiencies, and time-consuming processes.

It’s suitable for small businesses with limited inventory, but as the business grows, it may become less reliable and harder to manage effectively. This method can also involve templates like the following:

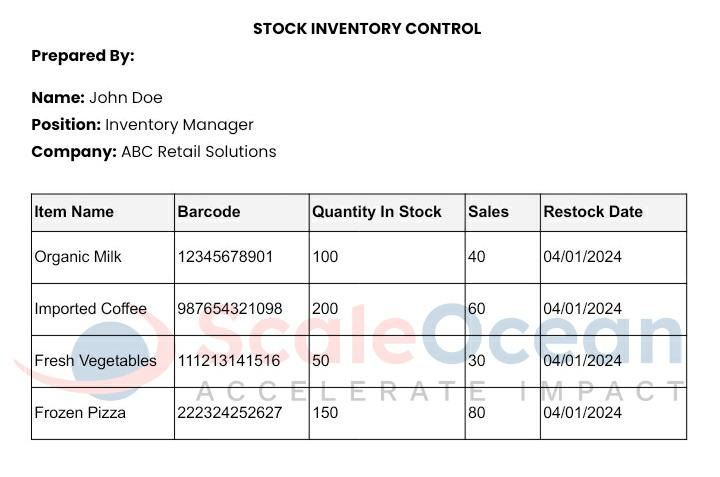

2. Barcode-Based Inventory Control System

Barcode-based inventory control uses barcodes and barcode scanners to track inventory. Items are tagged with unique barcodes that can be scanned to instantly update stock levels in the system.

This method improves accuracy, speeds up the inventory process, and reduces human error. It is widely used in retail and warehouses for quick, real-time inventory tracking. Here’s an example of a barcode inventory tracking template:

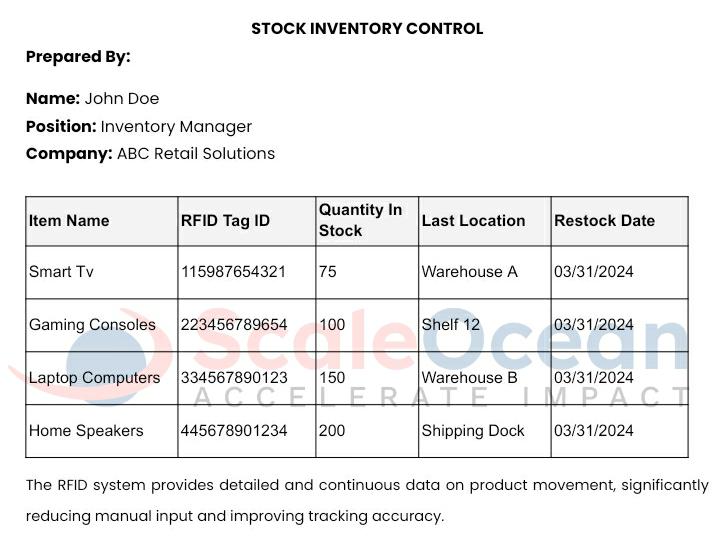

3. Radio Frequency Identification (RFID) System

RFID system inventory control uses radio frequency waves to track inventory. Each item is tagged with an RFID chip, and an RFID reader scans these chips to automatically update stock levels in real-time.

This method offers higher efficiency and accuracy than barcode systems, as it doesn’t require a direct line of sight to read tags, making it ideal for large or high-value inventories. Here is an RFID inventory template:

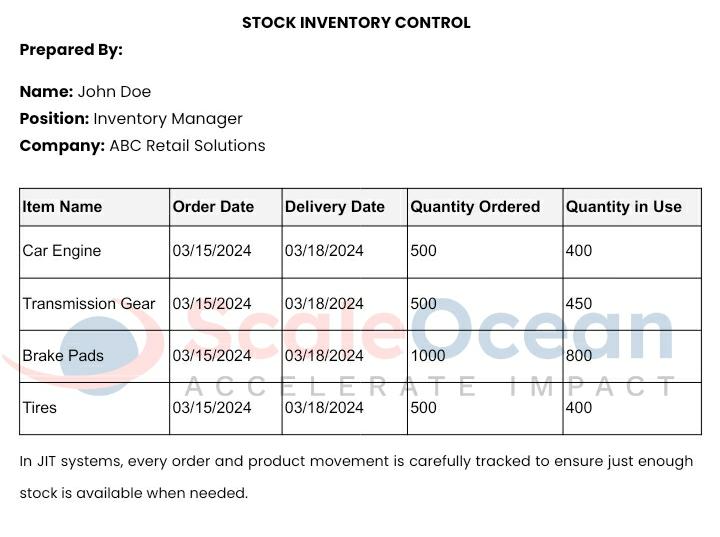

4. Just-in-Time (JIT) Inventory System

Just-in-Time (JIT) inventory control aims to minimize stock levels by ordering and receiving goods only when they are needed in the production process or to meet customer demand.

JIT reduces storage costs, minimizes waste, and ensures efficient use of resources. However, it requires precise demand forecasting and reliable suppliers to avoid stockouts or delays. Here’s an example template for tracking JIT:

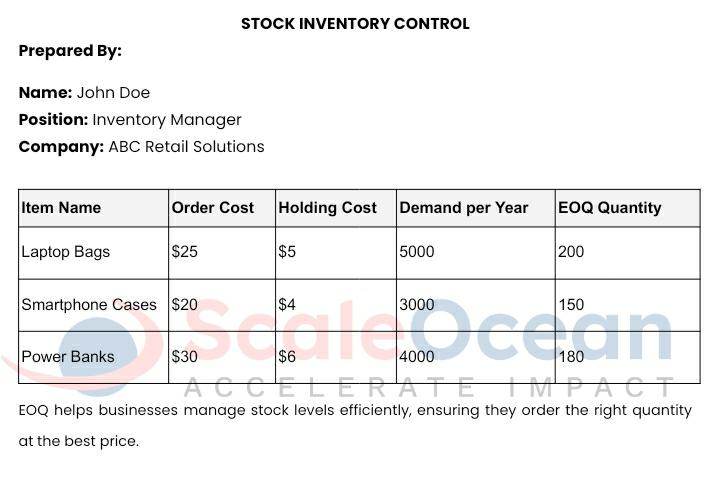

5. Economic Order Quantity (EOQ) System

Economic Order Quantity (EOQ) is a formula used to determine the optimal order quantity that minimizes the combined costs of ordering and holding inventory. By calculating the EOQ, businesses can ensure they are ordering the right amount of stock at the right time, reducing overstocking and understocking.

This method is commonly used for products with consistent demand patterns and predictable ordering costs. The EOQ formula frequently incorporates data from inventory templates to predict optimal order quantities:

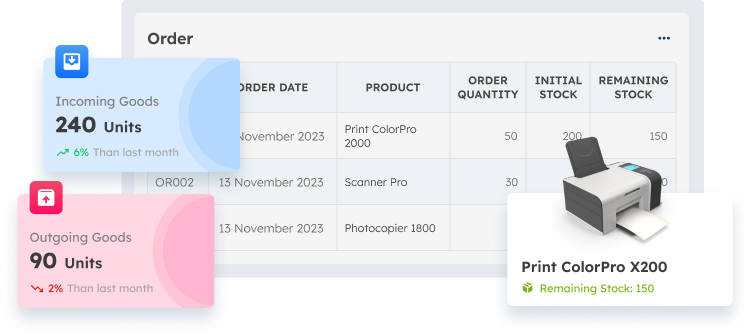

Monitor Inventory Control in Real-Time and Integrated with ScaleOcean WMS Software

Efficient inventory management is a key difficulty for many firms, particularly when product volumes rise and the flow of items gets more complex. To overcome this, a trustworthy Warehouse Management System (WMS) is required.

ScaleOcean offers a WMS solution that allows organizations to track stock status in real time, providing complete visibility of goods movement from warehouse to customer.

Businesses that use ScaleOcean’s WMS may prevent common concerns such as overstocking or understocking, which can have an impact on profitability and customer satisfaction.

With ScaleOcean’s WMS, you can simply manage stock and provide more accurate data, allowing you to make smarter business decisions. The ScaleOcean WMS system has several major features, which are listed below.

- Real-Time Stock Monitoring: ScaleOcean provides businesses with complete visibility into inventory, helping to balance supply and demand while preventing stockouts and overstocking.

- Automated Stock Recording: WMS ScaleOcean automates stock updates as goods are received or transported, eliminating manual tracking errors. This increases accuracy, speeds up inventory audits, and reduces the risk of mistakes.

- Low Stock Alerts: ScaleOcean WMS’s low stock alert feature automatically notifies businesses when inventory is low, allowing for quick reorders and preventing stockouts. This ensures smooth operations, avoids missed sales, and maintains product availability for customers.

- Multi-location Inventory Management: WMS ScaleOcean enables businesses to manage inventory across multiple locations on a single platform, providing a unified view of their stock. This centralized control helps optimize stock distribution, reduce shortages, and prevent excess inventory at different sites.

- Comprehensive Stock Reporting and Analytics: ScaleOcean provides detailed stock reporting and analytics, helping businesses track inventory levels, turnover rates, and stock movements for better decision-making.

Using ScaleOcean’s WMS Software with these features can help businesses improve efficiency, reduce human error, optimize stock levels, and enhance the overall control of inventory in a warehouse. Request a free demo today to get this system.

Conclusion

Effective inventory control is essential for businesses to maintain the right balance between supply and demand while minimizing costs. Whether through manual tracking, barcode scanning, RFID systems, or just-in-time strategies, choosing the right method depends on the business’s size, industry, and operational needs.

By implementing the right inventory control practices, businesses can improve efficiency, reduce waste, and enhance customer satisfaction, ultimately leading to better financial performance and smoother operations.

ScaleOcean’s Warehouse Management System (WMS) provides the best solution for achieving this by offering real-time tracking, automated replenishment, barcode scanning, and seamless integration with other business systems. Take a free demo to get a system that fits your business and inventory workflow.

FAQ:

1. What is the role of an inventory controller?

An Inventory Controller is a specialist tasked with overseeing inventory levels, ensuring precise tracking of stock, and streamlining inventory management procedures to reduce costs and enhance operational efficiency.

2. What is the golden rule for inventory?

The golden rule of inventory management is straightforward: “Keep inventory levels optimized.” This means having enough stock to fulfill customer needs without overstocking or creating waste. Achieving this balance helps reduce holding costs and boost profitability.

3. Is ERP used for inventory?

Process: ERP systems consolidate inventory data, offering real-time visibility into stock levels, order management, and supply chain activities.

Benefit: This ensures consistent and accurate information is accessible throughout the organization, enhancing decision-making and improving coordination.

4. How many steps are there for controlling inventory?

5 key steps. A well-organized inventory management process includes: planning and forecasting, purchasing and ordering, receiving, storing, and packing, inventory tracking, and finally, order fulfillment.

PTE LTD..png)

.png)

.png)

.png)

.png)