To stay ahead today, businesses need to be fast and agile. Old-school warehouses often struggle with slow speeds, human mistakes, and wasted space. These hurdles usually lead to annoying delays, messy inventory tracking, and much higher costs that eat into your profits.

According to Open Government, as AI reshapes logistics, Mohit Sagar notes the sector’s AI market is set to jump from US$2.11 billion in 2024 to US$6.51 billion by 2031. This massive growth shows how tech is reinventing warehousing, making it vital to adopt smarter, faster solutions to keep up with the world.

So, for all that risk and problem, this article will dive into what a smart warehouse really is, smart warehouse technology, and why it’s a game-changer for your business. We will explore how automation, IoT, and AI are transforming daily operations, helping you work better, faster, and much more efficiently than ever before.

- Smart warehousing is a transformative approach to using advanced technology and data-driven strategies to make storage and order handling a lot more efficient than the old-school way.

- The tools and technologies of smart warehousing, like WMS, IoT, and robotics, form the core of smarter, faster warehouse operations.

- Emerging market trends of smart warehousing, like 5G and blockchain, will significantly reshape logistics by 2026.

- ScaleOcean’s WMS software makes smart warehousing achievable with real-time control, automation, and scalable features tailored to modern needs.

What is Smart Warehousing?

Smart warehousing is a transformative approach to using advanced technology and data-driven strategies to make storage and order handling a lot more efficient than the old-school way. Things like automation and data tracking help companies gain real-time visibility into what’s happening across their supply chain.

The goal here isn’t just speed. Though that’s a big part of it, it also involves cutting down on mistakes and wasted effort. Over time, these connected operations tend to react better to demand shifts, which is something traditional setups usually struggle with.

The Role of a Smart Warehouse in Business

In today’s warehouse setup, staying ahead often comes down to how well you can manage speed and accuracy, and that’s really where a smart warehouse pulls its weight. It helps with improving throughput, accuracy, and traceability, which may not sound flashy, but it makes a real difference when things start scaling.

In today’s warehouse setup, staying ahead comes down to speed and accuracy. Smart warehouses improve throughput, accuracy, and traceability. According to the Paul Hype Page, with over 37 million TEUs managed annually by Singapore, automation and real-time data help businesses stay responsive and agile in a fast-paced logistics environment.

Smart Warehouse Technologies and Tools

Technology is really at the center of how smart warehouses work today. There’s a mix of systems and machines that come together to streamline decisions and everyday tasks in a way that didn’t exist before.

Let’s take a closer look at the tools and tech that are actually making a difference on the ground:

Warehouse Management Systems (WMS)

Think of WMS like the warehouse’s central control tower. It controls inventory, tracks goods, and helps teams make better use of space and time, which can be controlled from one place.

If you’re exploring options, the best Warehouse Management System (WMS) tends to handle automation without adding complexity, while keeping visibility clear for everyone involved.

Advanced Robotics and Automation

Today, many warehouses rely on robots to handle repetitive tasks, lifting the physical and mental load from human workers. This allows employees to focus on more complex, decision-based tasks that require human judgment.

Automation not only boosts efficiency but also improves accuracy and safety. Let’s explore how various types of advanced robotics and automation are transforming warehouse operations:

- Automated Storage and Retrieval Systems: These systems are designed to streamline the movement of goods in and out of the warehouse, eliminating the need for manual handling. They really shine when it comes to maximizing space, especially in vertical or compact warehouse setups, where every inch counts.

- Autonomous Mobile Robots (AMRs) & Automated Guided Vehicles (AGVs): These robots work independently, transporting items across the warehouse floor with ease. They navigate around obstacles, avoiding traffic jams and optimizing transport time, ensuring smooth and efficient movement throughout busy areas.

- Cobots (Collaborative Robots): Cobots are built to work side by side with humans, not replace them. They’re safe and flexible, making them ideal for tasks like sorting and picking, especially in fast-paced environments. By collaborating with humans, they help boost efficiency without compromising safety.

Internet of Things (IoT)

IoT connects all the devices in the warehouse, allowing them to communicate and share real-time data. Sensors track key details like movement, temperature, and item location, giving managers immediate insight into what’s happening and helping them stay on top of operations.

With IoT, managers can make quick decisions in response to issues as they arise. Whether it’s adjusting inventory placement or ensuring correct temperature control, real-time visibility allows for proactive decision-making, keeping the warehouse running smoothly.

Artificial Intelligence (AI) and Machine Learning

AI can predict stock shortages and suggest the most efficient delivery routes. Over time, machine learning gets smarter by continuously refining predictions based on past data, ensuring that the warehouse always stays ahead of demand and is ready to act swiftly.

This is where smart warehousing truly stands out. With AI and machine learning, systems can analyze data trends, optimize decisions, and even automate actions, allowing warehouse teams to streamline operations and reduce human error, making the entire process more efficient.

Wearable Technology

Wearable devices, such as smart glasses and voice-pick systems, enable workers to remain hands-free while staying focused on their tasks. These tools improve both speed and accuracy, helping employees complete tasks faster while reducing the chances of making mistakes during operations.

Integrating wearables into the workflow boosts productivity and reduces human error. They allow employees to carry out their tasks more efficiently without disrupting the natural flow of operations, making it easier to keep things running smoothly in fast-paced environments.

Augmented Reality (AR) and Virtual Reality (VR)

Augmented reality (AR) overlays real-time data and directions on physical items, making tasks like picking and sorting easier. Workers get visual instructions directly on the item, improving both speed and precision, which makes operations more efficient and less prone to mistakes.

Virtual reality (VR) is mainly used for training, allowing employees to practice in a virtual environment. This helps them gain experience and sharpen skills without affecting live inventory, ultimately leading to fewer errors and a better-prepared team ready to handle real-world tasks.

Automated Inventory Control

Automated inventory control systems update stock levels in real time, triggering automatic reorders when inventory hits preset levels. This eliminates manual checks, ensuring that stock is always up to date, and it saves employees from constantly reviewing and updating spreadsheets.

By automating warehouse inventory control, warehouses can maintain more consistent and reliable stock levels. The system makes sure that orders are placed when necessary, reducing the chance of stockouts or excess inventory, and providing a smoother, more predictable operation overall.

Radio-Frequency Identification (RFID)

RFID technology allows for fast and efficient tracking of items without the need for direct line-of-sight. Unlike traditional barcodes, RFID lets you scan items even when they’re out of view, helping to quickly track inventory as it moves throughout the warehouse, making processes more seamless.

With RFID, warehouses gain full visibility into inventory movement across various stages of the supply chain. This technology helps ensure better tracking and accuracy, allowing teams to easily monitor goods as they’re stored, transported, or loaded, giving them confidence in their inventory data.

Cloud Computing

Cloud computing makes warehouse data accessible from anywhere, eliminating the need to be on-site. It allows for seamless collaboration between remote teams and ensures everyone has access to up-to-date information, regardless of location, making operations more agile and efficient.

For growing warehouses, cloud computing is a game-changer. The cloud scales effortlessly to accommodate the increasing demands of larger operations, ensuring that systems and data can grow with the business without the hassle of constantly upgrading infrastructure.

Big Data Analysis

Big data tools analyze the vast amount of information generated in a warehouse, helping teams spot trends and identify areas for improvement. By making sense of all this data, businesses can optimize operations, improve efficiency, and address issues before they escalate into larger problems.

Using big data in the warehouse enables teams to gain valuable insights into inventory management, staffing, and more. With this data, they can make smarter decisions, streamline operations, and predict future demand, ensuring the warehouse runs as smoothly as possible with minimal waste.

Drones

Drones are now used in warehouses to perform tasks like checking inventory or performing shelf scans. Especially helpful for hard-to-reach areas, drones save time by eliminating the need for workers to climb ladders, ensuring that inventory checks are done quickly and safely.

By using drones for inventory tracking, warehouses not only increase speed but also improve safety. These flying robots reduce the need for risky manual tasks, like climbing tall shelves, allowing teams to focus on more strategic tasks while keeping inventory management accurate and efficient.

Market Trends of Smart Warehousing for 2026

The smart warehousing space has been moving pretty quickly, and by the time we hit 2026, we’ll likely be looking at a setup that feels very different from just a few years ago. What used to be experimental tech is now showing up in regular operations, no longer just buzzwords.

Here are a few shifts that seem to be leading the way:

Widespread Adoption with 5G Connectivity

With 5G rolling out more consistently, warehouses are starting to see real-time communication between machines, systems, and software actually work, not just on paper. That means fewer slowdowns and fewer gaps in data transfer.

The warehouses that are already running with it tend to see higher efficiency in day-to-day coordination, especially across busy shifts.

Digital Twin

The idea of building a virtual version of your warehouse might’ve seemed over-the-top a few years ago, but now it’s becoming a practical planning tool. You can run simulations, test new layouts, or even stress-test your workflows without touching the real floor.

This has made it easier to predict disruptions before they happen, which is something a lot of teams are finding useful when scaling up.

Blockchain

Blockchain might still sound like something out of fintech, but in smart warehousing, it’s quietly becoming a helpful tool for keeping records straight. Every inventory move, every supplier handoff, is logged in a secure, unchangeable way.

That layer of verification adds trust and transparency, especially when working across multiple vendors or tight compliance guidelines.

Benefits of Smart Warehouse

Smart warehouses aren’t just about using flashy tech. They actually solve a lot of day-to-day problems. Whether it’s cutting down on wasted time or speeding up how fast orders get out the door, the benefits are pretty easy to spot.

Let’s break down some of the main ones:

Efficiency & Accuracy

One of the more noticeable changes is how automation helps reduce small but costly errors during picking and packing. Over time, this leads to higher-order accuracy and fewer complaints from customers.

And since fewer mistakes are being made, the whole process starts to feel smoother, not perfect, but definitely more reliable than manual tracking.

Space Optimization

Smart warehouse solutions, like AS/RS systems, make the most out of vertical space, helping businesses use every square meter more efficiently. This is especially beneficial in high-rent areas, where saving space means saving money, maximizing the warehouse’s potential.

It’s not just about squeezing more in. It’s about creating an organized space where everything flows smoothly. With a thoughtful layout, inventory moves faster, and the space feels less chaotic, leading to better productivity and less time spent searching for items.

Cost Savings

Automation takes care of repetitive tasks, which helps companies cut down on labor costs without sacrificing efficiency. This allows businesses to focus on growth while ensuring that operations remain smooth and streamlined, reducing human errors and boosting productivity.

With automation, businesses can also predict when maintenance is due, preventing unexpected downtime. While the savings are gradual, over time, they become substantial, leading to lower operational costs and more reliable, efficient warehouse operations.

Enhanced Safety

When sensors and robotics take over the riskier parts of warehouse work, fewer people end up in harm’s way. It’s a simple but effective shift that leads to better safety outcomes and a team that feels more supported.

Plus, tools like AR can walk workers through tricky tasks, which helps reduce accidents and boost overall confidence on the floor.

The perks of smart warehouses, like better efficiency and safety, are easy to see. ScaleOcean’s ERP system brings these technologies together, smoothing out your work, cutting down on mistakes, and making the best use of your space for more productivity and long-term savings.

Potential Challenges for Smart Warehouses in 2026

Like with most big shifts, moving toward smart warehousing comes with its own set of bumps in the road. Some of which are more technical, others feel more like long-game strategy issues. Spotting these early can help keep things from going sideways later.

So here are the potential challenges for smart warehouses:

High Upfront Costs

Installing robotics, sensors, or a new Warehouse Management System (WMS) can come with a hefty price tag. These initial costs may not be easy to fit into a budget, especially for small businesses trying to keep their finances balanced while embracing new technology.

Over time, though, the return on investment becomes clear. As operations run more smoothly, with fewer delays and less manual labor, the upfront investment pays off in the form of long-term savings and improved efficiency across the warehouse.

Integration Complexity

Integrating new smart technologies into older systems can sometimes feel a bit clunky. Data syncing issues and devices failing to communicate with one another can cause headaches, slowing down the process of implementing a smart warehouse system and creating frustration for teams.

ScaleOcean’s software simplifies this process by offering seamless integration across various systems. Its compatibility with finance, inventory, and other platforms ensures smooth data flow and helps minimize integration complexities, making the transition to a smart warehouse smoother and more efficient for your team.

Cybersecurity Risks

As more devices and systems connect in a smart warehouse, the risk of cyber threats increases. Each new device or system creates an additional vulnerability, which could lead to data breaches or other security issues that disrupt operations and cost the business.

To address this, it’s essential to invest in strong cybersecurity measures. Businesses should ensure their digital systems are secure, conduct regular security audits, and stay updated on the latest threats to protect both data and infrastructure in a connected environment.

Skill Gaps

When implementing smart technologies, not everyone is immediately equipped to use them. Employees may face a learning curve, slowing down the adoption of new systems and potentially affecting overall productivity in the warehouse during the transition phase.

The solution lies in consistent and ongoing training. Investing in regular training sessions and hands-on experience with new technologies allows employees to feel confident in using the systems, helping the business adopt smart solutions faster and more effectively.

What is the Strategy to Achieve a Successful Smart Warehouse?

Smart warehousing doesn’t really flip on like a switch. It’s more like layering bricks over time. You need some planning, a bit of patience, and honestly, the ability to adjust when things don’t go exactly how you expected.

Here are a few way to go about it that tends to work well:

Strategic Planning Foundation

Before diving into smart warehousing technologies, take a step back to identify high-impact pain points and set measurable 2026 KPIs. This ensures that upgrades are aligned with business goals, helping you achieve a clear ROI and avoid spending on unnecessary solutions.

By tying your tech upgrades directly to your bigger business goals, you’re more likely to see a clear return on investment and avoid spending on things that don’t really move the needle.

Operational Continuity & Resilience

Things don’t always go according to plan, such as when systems go down, demand spikes, and weather happens. That’s why your setup needs to be flexible enough to bounce back fast, with backups in place before you need them.

At the end of the day, a smart warehouse needs to be built to withstand sudden disruptions without everything grinding to a halt.

Implementation Roadmap

Trying to change everything at once usually backfires, so it’s more practical to break things down into phases and build on what works. Start small, like implementing a smart warehouse example in one section, learn from it, then expand as you refine the process.

That kind of phased approach makes it easier to train staff and work out any issues while keeping day-to-day operations running.

How does ScaleOcean Provide Smart Warehousing Solutions?

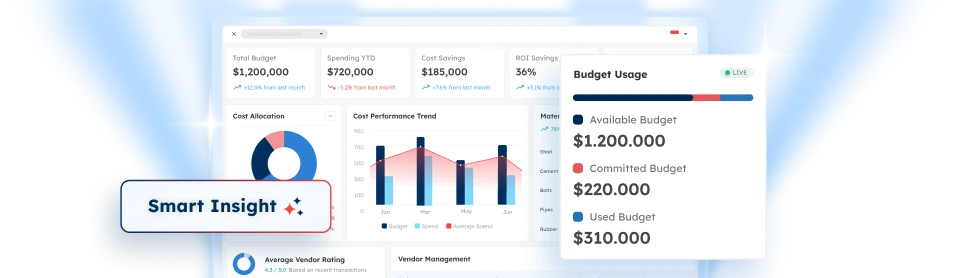

ScaleOcean WMS connects easily with various smart warehouse tools through its open and flexible system. By letting you link up with your existing platforms, this platform helps your business move smoothly toward a much smarter and more efficient warehouse operation without the usual hassle.

Also, this software is highly customizable, making it simple to sync with third-party ERPs and other tech. Whether it’s a new tool or something you already use, ScaleOcean ensures a smooth link, helping you get more out of your current setup while boosting your overall efficiency.

ScaleOcean is also eligible for the CTC grant, which supports your digital growth. This government initiative helps cover your costs when starting with our ERP system, covering up to 70% of expenses, making it much easier for you to adopt advanced, high-tech solutions.

And here are the unique features of the ScaleOcean warehouse management system:

- Advanced Smart Configuration: Personalizes workflows and dashboards based on key smart device metrics to enhance warehouse operations.

- Stock Optimizer per Warehouse: Optimizes storage by evaluating warehouse occupancy and maximizing space while minimizing waste.

- Pick Pack Delivery 3-Step Route Warehousing: Streamlines picking, packing, and delivery by optimizing item handling for faster, more efficient operations.

- Inventory Forecasting: Predicts future inventory needs using past sales data, helping avoid overstocking and stockouts with accurate planning.

- Asset Management Integration: Integrates asset tracking to manage inventory and operational assets efficiently, ensuring proper maintenance.

On top of the key features we’ve shared, ScaleOcean also provides extra tools to simplify your warehouse tasks and sharpen your operations. These complete solutions help you boost efficiency and improve your workflow. So try the free demo to see how it all works firsthand!

Conclusion

Smart warehousing uses tech like robotics and AI to boost accuracy and safety while saving on space and costs. The real trick, however, is making sure these new systems play nicely with the tools you already have in place, a challenge many businesses face today.

So with that in mind, ScaleOcean’s WMS makes switching to a smart warehouse easy with smooth integration and live tracking. To see how these benefits work for you, ScaleOcean also offers a free demo, giving you the chance to explore every feature and feel confident before making any big commitments.

FAQ:

1. What is the difference between a smart warehouse and a traditional warehouse?

A smart warehouse leverages automation, IoT, AI, and robotics to enhance inventory management, optimize order processing, and enable real-time decision-making, while traditional warehouses rely more on manual labor and paper-based tracking systems.

2. What are the three types of warehousing?

1. Public warehousing: Shared storage space available for multiple users.

2. Private warehousing: Exclusive facilities managed by a single organization.

3. Contract warehousing: Customized third-party warehouses dedicated to specific clients.

3. What is the key feature of a smart warehouse?

1. Automation: Robotics and systems replace manual labor.

2. Real-time tracking: Sensors and IoT offer instant stock visibility.

3. Advanced analytics: AI and data tools optimize decision-making and forecasting.

4. Can AI replace warehouse workers?

While AI enhances warehouse efficiency by automating repetitive tasks, it cannot entirely replace human workers. Instead, it assists in streamlining operations, allowing humans to focus on tasks that need decision-making, oversight, and problem-solving skills.

PTE LTD..png)

.png)

.png)

.png)

.png)