In Singapore’s fast-expanding logistics and e-commerce industries, efficient warehouse operations are vital to supply chain success. To remain competitive, firms must implement cutting-edge technologies that enable speedier order fulfillment and seamless operations.

According to Grand View Research, the warehouse robots industry in Singapore is expected to reach USD 582.3 million by 2030, expanding at a compound annual growth rate (CAGR) of 21.8% between 2024 and 2030. This growth demonstrates the increasing reliance on automation in warehouse operations.

In this tutorial, we will look at how warehouse execution systems (WES) may dramatically improve warehouse management in Singapore. WES streamlines operations by optimizing task execution, resulting in faster and more efficient performance.

Furthermore, WES improves resource allocation by ensuring that personnel, equipment, and inventories are used efficiently. These solutions also increase operational efficiency by reducing errors and downtime, resulting in smoother warehouse operations and improved overall supply chain performance.

- A warehouse execution system is a sophisticated software solution that optimizes warehouse operations in real time by coordinating many areas of warehouse management.

- The function of a Warehouse Execution System streamlines tasks such as automating task allocation, optimizing order fulfillment, improving resource allocation, and more.

- The Role of Automation in a Warehouse Execution System includes Automation that optimizes material handling, stock control, order processing, task distribution, and performance.

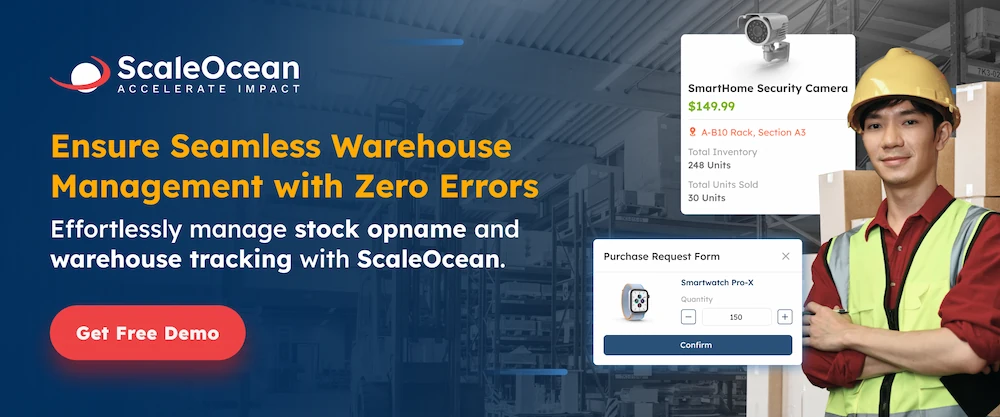

- ScaleOcean WMS provides warehouse execution software that enables enterprises to improve warehouse productivity and operational accuracy.

What is a Warehouse Execution System?

A warehouse execution system (WES) is a sophisticated software solution that optimizes warehouse operations in real time by coordinating many areas of warehouse management.

It acts as a bridge between the best warehouse management system (WMS) and a warehouse control system (WCS), guaranteeing smooth communication and coordination of critical warehouse tasks like inventory monitoring, labor scheduling, and equipment use.

A WES improves operational efficiency by dynamically managing tasks, labor, and automation, so minimizing human errors, removing bottlenecks, and enhancing order fulfillment accuracy.

It also allows warehouses to adapt to changing demand, implement automation techniques successfully, and improve overall supply chain agility. The result is a more productive, cost-effective, and responsive warehouse operation that matches changing business requirements.

Why Warehouse Execution System Important for Your Business?

A Warehouse Execution System (WES) is a game-changer for modern warehouses, blending automation with real-time tracking and smart data. It boosts efficiency, cuts down on mistakes, and keeps tasks moving smoothly.

Let’s dive into how it works and why it’s so vital for your daily operations.

- Real-Time Process Automation: WES automates warehouse processes, coordinating workers, equipment, and inventory in real time using APIs, reducing errors and improving efficiency across operations.

- Intelligent Control Center: WES acts as a control center, gathering and analyzing data to monitor and adjust warehouse operations in real time, ensuring smooth task execution and optimized workflows.

- Efficient Task Direction: WES improves task efficiency by assessing order priority, resource availability, and equipment status, ensuring jobs are allocated efficiently to prevent delays and bottlenecks.

- Increased Productivity: By automating resource allocation and task execution, WES reduces downtime and idle time, leading to faster order processing, higher throughput, and better resource utilization.

- Compliance and Inventory Management for Bonded Warehouses: WES streamlines compliance, inventory tracking, and duty deferral in bonded warehouses, ensuring smooth operations and reducing errors while maintaining regulatory compliance.

The Functionalities and Benefits of a Warehouse Execution System (WES)

A warehouse execution system (WES) provides a variety of features that help warehouses streamline operations, increase efficiency, and improve overall performance. These features enable seamless coordination of multiple warehouse processes, making operations more nimble and responsive to changing demands.

The following are the major characteristics of a WES and how they help with warehouse optimization:

1. Task Management

A WES prioritizes and allocates jobs dynamically based on resource availability, inventory location, and order urgency. Automating task distribution reduces idle time while increasing productivity.

Furthermore, it ensures that high-priority orders are completed first, while distributing the burden among available resources. This proactive approach reduces bottlenecks and increases overall warehouse productivity.

2. Order Fulfillment Optimization

A WES ensures that the picking, packing, and shipping procedures are carried out as efficiently as possible by regulating order flow and sequence. This decreases lead time and increases client satisfaction.

Furthermore, it reduces errors by guaranteeing that the product is picked and packed correctly before shipment. The technology also allows for the priority of urgent orders, ensuring that high-demand items reach clients as soon as possible, hence enhancing service levels and operational reliability.

3. Resource Allocation

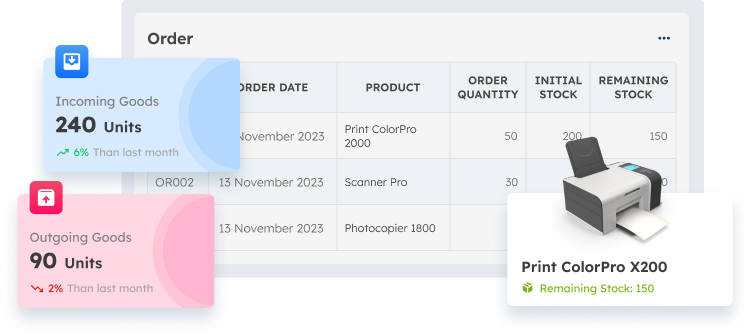

A warehouse execution system makes better use of people and machines by assigning jobs based on workload balance and demand changes. Integrating a warehouse barcoding system enhances this process by providing real-time tracking of inventory, ensuring more accurate task allocation.

It uses real-time data and predictive analytics to establish the optimal resource allocation, ensuring that all tasks are completed with minimal waste. This leads to increased production and lower operating expenses.

Furthermore, by constantly altering personnel and machine usage in response to changing needs, it improves warehouse agility, allowing firms to retain maximum performance even during peak periods.

4. Real-time Visibility

A WES provides real-time data on warehouse operations, allowing managers to track inventory levels, task progress, and potential bottlenecks. It provides real-time warnings and reporting tools to discover inefficiencies before they affect operations. This improves decision-making and enables a quick response to disturbances.

Furthermore, by employing data analytics, a WES may identify trends and recommend proactive changes to warehouse procedures, turning any work in progress into completed tasks, resulting in increased efficiency and less downtime.

5. Integration Capabilities

A warehouse execution system works smoothly with WMS, WCS, and ERP software. This link guarantees end-to-end visibility and efficient information flow between systems. Businesses that synchronize these systems can improve operational efficiency and eliminate the need for manual interventions.

Furthermore, this connectivity improves data accuracy, allowing for real-time tracking, better decision-making, and a faster response to market demands.

6. Intelligent Decision-Making

A WES uses modern algorithms and data analytics to make intelligent judgments that increase efficiency. It uses past data to estimate demand, optimize operations, and offer process changes.

Evaluating real-time operational patterns enables proactive decision-making that reduces disruptions while increasing throughput. A WES can also discover inefficiencies and provide corrective steps, ensuring that warehouse operations are continuously optimized.

7. Exception Handling

A WES ensures smooth operations by spotting and responding to exceptions like inventory shortages or equipment faults. To mitigate disturbances, it sends out alerts and suggests alternative workflows.

Furthermore, it continuously monitors warehouse conditions to anticipate possible failures, allowing for proactive problem remediation. This feature lowers downtime, improves overall efficiency, and ensures that operations continue even in the face of unforeseen obstacles.

8. Reduced Complexity

A WES simplifies warehouse operations by automating repetitive tasks, minimizing human intervention, and streamlining processes. This reduces the complexity of managing various workflows, systems, and operations, which typically require manual effort to coordinate and track.

With a WES in place, warehouses can reduce the need for separate systems, tools, and manual coordination between departments. Automation and integration make it easier to manage operations, improving efficiency while ensuring smoother processes across all warehouse functions.

9. Cost Reduction

By automating key tasks, such as inventory management and order fulfillment, a WES significantly lowers labor costs. It reduces the need for manual data entry, minimizes human errors, and improves resource allocation, directly impacting the bottom line.

Furthermore, automation leads to better productivity and reduced operational waste. As processes become more efficient and optimized, warehouses can achieve higher throughput with fewer resources, ultimately leading to substantial cost savings and better financial performance.

10. Scalability and Flexibility

A WES enables warehouse expansion by reacting to changing business requirements. It ensures long-term operational efficiency by increasing automation, managing seasonal demand surges, and integrating new technology.

With modular scalability, you can add new features whenever you need them without slowing down your current work. ScaleOcean’s warehouse software includes all the WES functionalities mentioned above, ensuring smooth integration and helping you adapt to future demands with total ease.

The Role of Automation in a Warehouse Execution System

According to Globe Newswire, the e-commerce market in Singapore is expected to reach USD 10 billion by 2026. This rapid growth calls for more efficient warehouse operations, with automation playing a critical role in meeting increasing demands and ensuring operational excellence.

To stay competitive, businesses must embrace automation across various warehouse processes. Below are key areas where automation plays a pivotal role in optimizing warehouse performance:

- Automated Material Handling: Automation speeds up material movement within the warehouse, reducing labor costs, minimizing errors, and ensuring more efficient handling of goods.

- Stock Control and Management: Automated systems track inventory in real time, improving stock accuracy and ensuring efficient management without manual intervention.

- Automated Order Processing: Automation accelerates order fulfillment by handling picking, packing, and shipping, which reduces lead time and increases order accuracy.

- Efficient Task Distribution: Automation analyzes task priority, resource availability, and equipment status, ensuring efficient allocation and completion of tasks.

- Data Sync and Insights: Automated systems integrate data from various sources, providing real-time insights and enabling data-driven decisions to optimize warehouse performance.

- Monitoring and Enhancing Performance: Automation enables continuous performance monitoring, identifying inefficiencies, and enhancing warehouse operations to increase productivity.

Also Read: What is Inventory Control? Optimizing Stock Management

Enhance Warehouse Operations with ScaleOcean Warehouse Execution Software

ScaleOcean WMS provides warehouse execution software that enables enterprises to improve warehouse productivity and operational accuracy. This solution offers faster and more accurate order processing by including advanced features like automated task management, seamless system integration, and real-time data analytics.

Companies can use ScaleOcean to optimize resource allocation, increase operational visibility, and minimize total expenses. ScaleOcean’s warehouse execution software enables you to maximize the potential of your warehouse operations. Experience a game-changing solution that improves productivity, streamlines workflows, and eliminates bottlenecks.

Take advantage of our free demo to see firsthand how ScaleOcean can streamline your operations, boost productivity, and provide real-time actionable insights targeted to your company’s needs. And Why Choose ScaleOcean Warehouse Execution Software?

- Unlimited Users Without Additional Cost: Enjoy 100% unlimited users at no extra charge, allowing you to scale your business without restrictions.

- All-in-One Solution with Complete Modules: Access 200+ industry-specific modules and over 1,000 feature options tailored to your business requirements.

- Transparent and Fixed Pricing, Benefit from a flat-rate pricing model with no hidden costs, ideal for medium to large enterprises.

- Customizable to Fit Your Business Needs: Personalize the software with dashboard customization and Advanced Smart Configuration for each department.

- Seamless Multi-Branch Integration: Connect multiple subsidiaries or business branches within a single platform, ensuring smooth operations across locations.

Conclusion

A warehouse execution system is an essential tool for modern warehouses that want to increase efficiency, accuracy, and embrace automation. A WES improves warehouse operations by optimizing job management, expediting order fulfillment, and ensuring efficient resource allocation.

Integrating it with automation and WMS systems increases its impact, making it an essential component of competitive supply chain management.

Businesses that invest in modern WES can improve operational management, lower costs, and generate long-term growth. ScaleOcean’s free demo allows you to fully explore the capabilities of a warehouse execution system.

Discover how our intelligent software can transform your warehouse operations, increase efficiency, and deliver real-time visibility into your logistics. Don’t pass up this opportunity to improve your business efficiency, so schedule your demo today!

FAQ:

1. What are the 5 warehouse processes?

Professionals focus on five essential processes, such as receiving, putaway, inventory management, picking, and shipping. These stages ensure efficient product handling, accurate stock management, and smooth order fulfillment within the warehouse.

2. What are the 7s of warehousing?

The seven key elements in warehousing are sorting, setting in order, shining, standardizing, sustaining, safety, and spirit. This methodology emphasizes organization, cleanliness, safety, and fostering a positive culture within the warehouse.

3. What is a class 3 warehouse?

A Class 3 Bonded Warehouse is a secure facility regulated by U.S. Customs and Border Protection (CBP) where imported goods can be stored without paying duties for up to five years from the import date, allowing time for customs clearance.

4. What are the 4 pillars of warehouse?

A resilient warehouse is built on four crucial pillars like People, Process, Building, and Technology. Effective management of these areas prevents operational risks and ensures long-term warehouse success, particularly when integrated into an overarching facility management strategy.

PTE LTD..png)

.png)

.png)

.png)

.png)