A well-designed warehouse layout is crucial in today’s fast-moving logistics world. The way you organize your warehouse can have a big impact on how efficiently things run, cutting costs and boosting productivity. A poor layout can lead to wasted space, slower operations, and even increased risks.

According to Singapore Business Review, with supply in 2027 projected to stay high at around 5 million square feet, there are concerns about oversupply and rising vacancy rates. This makes it even more important to design a warehouse layout that maximizes space and improves efficiency, helping businesses stay competitive.

So, in this article, we’ll explore what warehouse layout is, what makes a great warehouse design and layout, what is the best warehouse layout, how to plan a warehouse layout, and why warehouse layout is important in making a huge difference for modern businesses.

- A warehouse layout is the strategic arrangement of a space to store and move products and equipment.

- The types of warehouse layout design include U-shaped (U-flow), I-shaped (I-flow), L-shaped (L-flow), and modular (zoned).

- Understanding the components of warehouse layout, like receiving, storage, and shipping areas, helps design a flow that matches operational needs.

- ScaleOcean’s AI-powered WMS offers a flexible design that can be customized to improve product flow, eliminate inefficiencies, and boost your warehouse’s overall performance.

What Is a Warehouse Layout?

A warehouse layout is the strategic arrangement of a space to store and move products and equipment. By thoughtfully arranging storage areas, equipment, and workflows, businesses can make the most of their space and ensure that products move smoothly from receiving all the way to shipping.

The main aim of a good warehouse layout is to improve productivity by reducing unnecessary movement and making things easier to access. With a well-planned layout, goods flow faster, delays are minimized, and operations run much more efficiently overall.

Why Warehouse Layout Is Important

A poor warehouse design and layout can lead to wasted time and effort as teams struggle to navigate the space, causing unnecessary delays and inefficiencies. A well-thought-out layout plan helps streamline processes, cut down on wasted effort, and reduce long-term operational costs.

According to Nexdigm, as of 2024, the Singapore warehousing market is valued at USD ~ billion, with a growing CAGR of 10.4% from 2024 to 2030. With the rapid growth in demand, businesses must invest in smart warehouse layouts to keep pace with increasing operational needs.

In the long run, a clear and efficient layout not only improves workflow but also reduces errors and enhances safety. This is especially important as businesses expand, ensuring that the warehouse remains functional and ready for growth.

Components of Warehouse for Layouting

Here are the key components of a warehouse layout:

- Receiving area: This is usually the first stop for incoming goods, where items are checked and sorted before anything else happens. It makes the most sense to place it close to the main entry point, so it doesn’t interfere too much with the rest of the flow inside the warehouse.

- Storage area: This is where inventory sits before it gets picked and moved on. How you lay it out really depends on the types of products you’re storing, like bulk goods, pallets, or smaller bins, so that everything stays easy to reach and doesn’t waste space.

- Packing area: After picking, items are brought here to be sorted, packed, and labeled. It helps to keep materials and equipment nearby, since efficiency drops fast if workers need to walk too far just to grab tape or boxes.

- Shipping area: This section handles the final handoff, where packed orders get queued up and sent out. Ideally, it’s set up to handle multiple carriers without bottlenecks, especially during busy shipping windows.

- Service area: These are the less obvious but still important parts, things like maintenance, break rooms, or office space. Even if they’re not directly tied to operations, where they’re located affects overall layout flow in a way that’s easy to overlook but definitely matters.

Warehouse Layout Considerations

When planning a warehouse layout, there are many important factors to consider that go beyond just the space itself. From operations and product types to safety and staffing, each element plays a role in how well your warehouse functions. Careful consideration ensures smoother workflows and better efficiency.

Here are some key considerations for warehouse layout:

- Types of operation: The way your warehouse runs, whether it’s for B2B, B2C, manufacturing, or cold storage, really changes how the space should be laid out. Every type of operation brings its own set of layout needs, so there’s no one-size-fits-all approach here.

- Products being stored: What you’re storing makes a difference. Size, how fast it moves, and whether it spoils all factor into how much space you’ll need and how that space should function day to day.

- Warehouse space needed: It’s not just about square footage. Things like ceiling height and column spacing can totally affect how you stack, store, and move goods around.

- Equipment requirements: If you’re using forklifts, conveyor belts, or specific shelving systems, that’s going to shape your layout too. Each piece of equipment needs space and a clear flow, or it can slow everything down.

- Workflow implementation: There should be a clear path from receiving to picking to shipping. The layout should support that whole movement in a way that feels natural, not like you’re backtracking or zigzagging all the time.

- Safety regulations: You can’t ignore safety, which includes fire exits, weight limits, and aisle spacing, which aren’t just rules because they’re essential. A well-designed layout builds those safety elements in from the start.

- Budget and cost efficiency: It’s easy to over-engineer a layout that looks impressive but drains resources. Sometimes simpler layouts are more effective and definitely easier to maintain over time.

- Staffing requirements: You’ll want to factor in who’s working the floor and what they’re actually doing. Layouts that ignore team size or task flow often end up causing more confusion than efficiency.

4 Warehouse Layout Design Types

When designing a warehouse layout, it’s essential to choose a design that best fits your operations and space constraints. Different warehouse layout types cater to various needs, from high-volume operations to more flexible and specialized workflows. The right design improves efficiency and reduces operational costs.

Here are four common best warehouse layout designs:

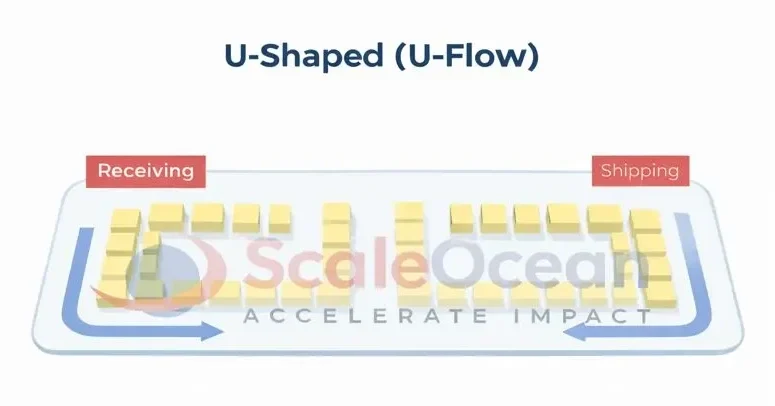

U-Shaped (U-Flow)

U-shaped warehouse layouts are pretty common, mainly because they’re practical for keeping things compact. With both receiving and shipping areas on the same side, it helps to cut down unnecessary movement and keep operations fairly centralized.

It usually works well if you’re dealing with limited floor space, but there’s a catch. If you’re not careful with how the flow is organized, it can get a bit messy with traffic crossing over.

Here are the examples of U-shaped layout design:

I-Shaped (I-Flow)

In this layout, everything flows in a straight line which goods coming in one end and going out the other. It’s a setup that tends to fit better for high-volume operations that need consistent, uninterrupted flow.

Processes stay neatly separated, which helps avoid bottlenecks. That said, it does need a longer building or more space overall to really work well.

Here are the examples of an I-shaped layout design:

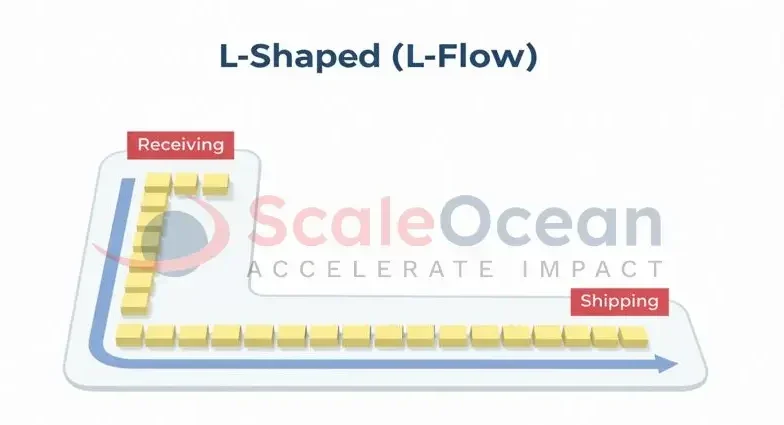

L-Shaped (L-Flow)

The L-shape puts receiving and shipping at a right angle, which can be handy when a space isn’t exactly square or symmetrical. It’s a more adaptable option if the layout has to work around existing walls or other departments.

This setup can sometimes lead to a less direct movement path, though. So while it’s flexible, it might not always be the most efficient in terms of travel time.

Here are the examples of L-shaped layout design:

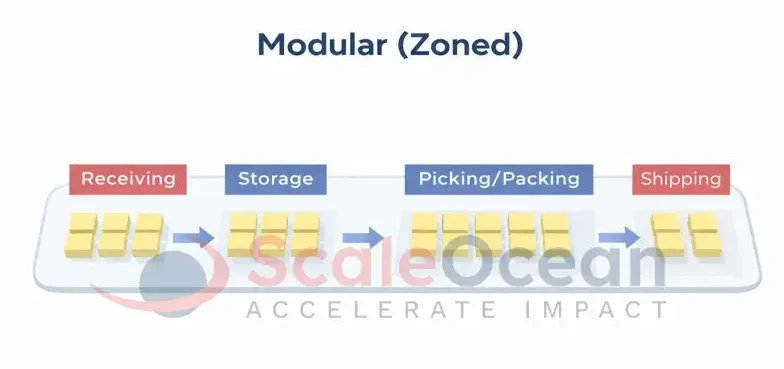

Modular (Zoned)

A modular layout breaks things into separate zones, each with its own purpose, like storage, picking, or packing. It’s a good way to build specialization into the workflow, especially in busier or more complex operations.

It does take a bit more effort to manage day-to-day, especially as product types or priorities shift. But for businesses with seasonal spikes or changing inventory, it can offer some real flexibility.

Here are the examples of modular layout design:

7 Steps of Warehouse Layout Plan

When designing a warehouse layout, it’s crucial to follow a systematic approach. From understanding its main purpose to executing the final plan, each step ensures efficiency and smooth operations. A well-planned layout helps you maximize space and optimize workflows throughout the facility.

Here are the seven steps for creating an effective warehouse layout:

1. Establish the Primary Function of the Warehouse

First, define the main goal of the warehouse, whether it’s for storing, fulfilling orders, or light manufacturing. This focus shapes the entire layout, guiding how space will be used and ensuring all areas serve the overall purpose of the operation.

Once the primary function is clear, it becomes easier to align all processes with this goal. This clarity helps shape the design, ensuring that the space is used efficiently, with each area supporting the core warehouse function.

2. Design a Warehouse Layout and Determine the Total Storage Space

Start by drawing out the space, including any permanent fixtures like columns or doors. Consider how much storage you need now and how much might be required as your inventory grows, making sure you plan for the future while using the space efficiently.

This step provides the structure for racks, equipment, and aisles. By mapping out the space early, you set the foundation for a warehouse layout that’s organized and practical, which helps maintain a smooth flow of operations as your business evolves.

3. Assess Storage Requirements

Look closely at your products, considering size, how often they’re moved, and how frequently they’re picked. This helps you decide what type of storage system works best, such as pallet racks, shelving, or bins, ensuring you match the system to your needs.

Choosing the right storage system based on your operations’ flow helps ensure everything stays organized. This setup keeps the layout from feeling cramped or cluttered, and it makes it easier for your team to move products efficiently.

4. Analyze the Need for Material Handling Equipment

Identify what equipment you’ll need, like forklifts or tuggers, and determine how much space they need to operate safely. The size and maneuverability of the equipment will influence the amount of space required between racks and aisles.

Planning for this equipment ensures smooth movement and avoids bottlenecks. It’s important to leave enough room for the equipment to work freely, which helps the warehouse run efficiently without delays or safety concerns.

5. Plan and Maximize Space Utilization

Don’t just think about floor space. Look at using vertical space as well to avoid unused areas. The goal is to find a balance between maximizing storage capacity and keeping products easily accessible for smooth daily operations.

Optimizing space is about creativity and making the most of every inch. A smart layout keeps everything organized while ensuring workers can easily reach products, ultimately increasing efficiency and reducing clutter in the warehouse.

6. Evaluate Traffic Flow

Observe how people, products, and machines move throughout the warehouse. Pay attention to spots where paths cross or traffic builds up, as these areas can cause delays and inefficiencies in the workflow.

Ensuring smooth traffic flow reduces the chance of accidents and improves productivity. By identifying trouble spots early, you can design a layout that allows for a more seamless and safer working environment.

7. Execute the Layout Plan

Once your plan is in place, start implementing it in phases. This allows you to identify and fix issues as they arise, allowing you to make adjustments to improve the layout before it’s fully set up.

Being flexible with your layout is key. Small adjustments during implementation can lead to big improvements, ensuring that the final design works well and supports long-term operational efficiency.

By following these seven steps, you can create a well-organized and efficient warehouse layout. ScaleOcean’s warehouse management software supports each of these stages, from planning storage and equipment needs to optimizing workflows and ensuring smooth operations, helping your business run seamlessly.

10 Best Practices of Warehouse Layout Design

A well-designed warehouse layout is key to boosting productivity and efficiency. The right practices help optimize space, improve workflows, and reduce costs. By following these best practices, your warehouse will run smoothly and be ready to adapt to future needs.

Here are 10 best practices for warehouse layout design:

1. Implementing Warehouse Management System (WMS)

WMS software has become much smarter over time. It now tracks your layout in real-time and adjusts based on actual operations, not just theoretical plans. This helps you make smarter decisions based on data instead of assumptions.

With a warehouse management system, inefficiencies in high-volume operations become easier to spot. This allows you to make adjustments quickly and improve overall productivity by minimizing unnecessary steps in the process. ScaleOcean’s WMS offers real-time insights, helping you optimize workflows and enhance efficiency with ease.

2. Optimize Space Utilization

Space in your warehouse can run out quickly, so it’s smart to use vertical space with things like mezzanines or taller racks. Wider aisles are only needed if you have large equipment or specific movement patterns.

Design your warehouse to meet your current needs, but leave some flexibility for growth. A layout that can adapt over time helps you avoid costly redesigns when your business expands.

3. Plan For Future Changes

Warehouses evolve, so your layout should be flexible too. Fixed shelves or permanent walls might seem efficient now, but they could limit your options as your needs change.

Modular setups and movable workstations offer flexibility. These options make it easier to adjust your layout as your business grows, avoiding the need for major changes down the line.

4. Leverage Technology

Tools like barcode scanners or pick-to-light systems are easy to integrate and can greatly speed up your operations. These systems help reduce errors while moving to different areas of the warehouse more efficiently.

Though the initial cost may seem high, the time and efficiency savings typically pay off quickly. Implementing the right technology can transform your warehouse into a highly efficient, data-driven operation.

5. Design With Safety and Cleanliness Prioritized

Forklifts, spills, and tight spaces don’t mix well, so map out clear paths and sightlines. A layout that promotes clean, open flow makes the warehouse safer and ensures operations run more smoothly.

When everything is clean and well-organized, it boosts employee morale. A tidy and safe warehouse creates a more positive environment, helping workers stay productive and focused.

6. Warehouse Layout Planning

Rushing through the warehouse layout plan stage is where many warehouse designs go wrong. It’s important to get input from the team on the ground who understands where bottlenecks happen and what slows things down.

Involving different departments early in the planning process helps ensure the layout suits everyone’s needs. Collaboration in the design phase prevents problems later and ensures smoother operations.

7. Enhancing Picking Efficiency

Fast-moving items should be placed near the packing areas, a simple but often overlooked step. Strategies like zone picking or batch picking can save a lot of time by reducing unnecessary steps in the picking process.

It’s not just about speed. It’s also about reducing the distance workers need to travel. A well-organized picking area makes the process faster and more accurate, benefiting both your team and customers.

8. Improving Warehouse Visibility and Access

Clear labeling in the warehouse is a game-changer, especially if you use color coding. This improves visibility and helps workers find what they need quickly, speeding up their work and easing the learning process for new staff.

Better visibility means fewer questions and smoother operations. When things are easy to find, staff can get their tasks done faster, and new team members can learn the layout more quickly.

9. Simplifying the Shipping Workflow

If packing and shipping are far apart, delays and unnecessary walking can slow things down. Grouping orders by delivery window or carrier helps reduce the extra movement and speeds up the entire process.

Having the packing and shipping areas closer together streamlines the handoff. The less distance to travel, the quicker and more efficient the process becomes, making it easier to meet deadlines.

10. Testing and Gathering Feedback

Once your layout is in place, don’t assume it’s perfect right away. Walk through the warehouse and see how everything works in practice. Regular feedback from staff helps you spot issues and make changes as needed.

Continuously testing and adjusting your layout ensures it stays functional as your operations evolve. Feedback from the team helps you fine-tune the layout, keeping it effective and efficient for the long term, while supporting better inventory control throughout.

Warehouse Layout Design Challenges

One thing that often gets tricky is finding that right balance between storage space and accessibility. You can squeeze in more racks, sure, but then staff spend more time just trying to get to things, which slows everything down.

Another headache? Just not having the right data. Without clear and usable insights about your operations, the layout ends up being more guesswork than strategy.

The shift toward smart warehouse systems has definitely helped streamline parts of the process. But even then, layout planning still needs that human touch, especially when things don’t go exactly by the book.

And they often don’t expect unexpected order spikes, seasonal shifts, or even just introducing a new product line can completely throw off your current layout. That’s where staying flexible becomes more than just nice to have, so it’s pretty much necessary.

Transform Your Warehouse with the Best Layouts using Scaleocean’s AI WMS

Transforming your warehouse begins with a layout that fits your operational needs. ScaleOcean’s AI-powered WMS offers a flexible design that can be customized to improve product flow, eliminate inefficiencies, and boost your warehouse’s overall performance.

ScaleOcean’s all-in-one solution makes it easy to integrate various processes and modules into your operations. The system is fully customizable, allowing you to adjust features, modules, and dashboards to perfectly match your business processes and requirements.

What makes ScaleOcean’s WMS even better is how it meets CTC grant requirements. This makes it an ideal choice for businesses looking to enhance their warehouse operations while also taking advantage of financial support, all thanks to the system’s customizable nature.

Here are the unique features of the ScaleOcean WMS software:

- Dynamic Layout Planning with AI: Flexible layout planning that adapts to operational changes using advanced AI-driven design for efficiency.

- Optimized Picking Routes: Dynamic picking routes and multi-order picking to ensure faster, more efficient product retrieval.

- Virtual Layout Testing: An AI-powered system to simulate and test warehouse layouts, ensuring optimal design before implementation.

- Putaway Optimization: Machine learning algorithms determine the best storage location for each item based on size, weight, and category.

- AI-Driven Layout Recommendations: AI analyzes historical data to identify patterns and suggest layout improvements for future growth.

In addition to the main features discussed above, ScaleOcean offers a variety of specialized tools that help address the unique challenges your business faces. To give you a hands-on experience, ScaleOcean also provides a free demo so you can see the system’s benefits for yourself before making a commitment.

Conclusion

Getting the warehouse layout right isn’t just about fitting things in. It’s about setting your operations up for long-term success. A smart layout saves time, cuts costs, and makes life easier for everyone working inside those walls. But planning it can get tricky when you’re juggling space limits, equipment needs, and fluctuating inventory.

That’s where tools like ScaleOcean’s WMS really shine. It’s a strategy partner that helps you make better layout decisions faster, so it’s not just software. If you’re serious about optimizing your warehouse, now’s the time to rethink how it’s designed. So, try the ScaleOcean free demo first, so that you can experience the features firsthand.

FAQ:

1. What is the ideal warehouse layout?

The perfect warehouse layout maximizes space efficiency, streamlines workflows from receiving to shipping, reduces travel distances, and ensures easy access to goods and workers. It balances storage, movement, and safety, optimizing both productivity and cost-efficiency.

2. What are the 7 principles of layout design?

1. Set clear objectives for the facility

2. Create a smooth flow of products and materials

3. Make the most of space both vertically and horizontally

4. Minimize distances for travel and handling

5. Use efficient storage and retrieval systems

6. Prioritize safety and easy access

7. Design with flexibility to accommodate future changes

3. What are common layout mistakes?

Common mistakes in warehouse layouts include poor planning of traffic flow, ineffective use of space, unclear division of tasks, improper aisle design, and neglecting safety or equipment needs, all of which lead to inefficiencies and increased costs.

4. What are the 5 KPIs for a warehouse?

Inventory KPIs focus on tracking the products stored in the warehouse, helping monitor stock movement. Key inventory KPIs include inventory accuracy, shrinkage, inventory carrying cost, inventory turnover, and inventory to sales ratio, providing insights into inventory management.

PTE LTD..png)

.png)

.png)

.png)

.png)