Despite the rapid growth of the food and beverage industry, many F&B manufacturing businesses face recurring operational issues. These include inconsistent raw material quality, the risk of expired products, and difficulties tracking production batches and costs per product.

These issues could easily be addressed if companies implemented the right ERP system. If left unchecked, these issues can reduce efficiency, erode margins, and even increase the risk of failing regulatory audits. This is where ERP software becomes increasingly important for the food and beverage industry.

ERP systems help unify production, warehouse, distribution, purchasing, and sales data into a single, integrated platform. Their use enables F&B businesses to operate more structured, minimize waste, and better prepare for fluctuations in demand.

More than just a record-keeping system, ERP software serves as the foundation for optimizing the entire food and beverage business process, from manufacturing to distribution within the food and beverage industry.

Here, we’ll discuss this in detail, including the problems and solutions offered by ERP systems, what makes them the best, and 15 recommended ERP software specifically for manufacturing and distribution processes in the food and beverage industry. Learn more here.

- Food Industry ERP centralizes inventory, production workflows, and quality control, ensuring high-speed output while maintaining safety and compliance with standards like FDA and HACCP.

- Challenges in the Food Industry include regulatory compliance, fluctuating raw material prices, changing consumer demands, and a limited skilled workforce.

- The recommended best food industry ERP software are ScaleOcean, FoodBusiness, Syspro, Datacor, Infor M3, JustFood, Deacom, Delmiaworks, and more

- ScaleOcean is the best software for the food industry because it is AI-driven, offering automation and advanced forecasting to optimize operations.

What is Food Industry ERP Software?

Food and beverage ERP software transforms manufacturing by centralizing inventory management, production workflows, and rigorous quality checks within a single platform.

By consolidating these essential functions alongside strict regulatory requirements, such as FDA and HACCP standards, these systems ensure that businesses can maintain high-speed output without compromising on safety or compliance.

Challenges in the Food Industry

The Singapore food industry faces numerous challenges that impact business efficiency and sustainability. Regulatory challenges and compliance with stringent food safety standards, such as HACCP and the FDA, require companies to consistently maintain product quality and safety.

Furthermore, fluctuating raw material prices can be influenced by external factors such as extreme weather or global supply disruptions. Furthermore, changing consumer demands, which increasingly prioritize healthier and more environmentally friendly products, force companies to adapt quickly.

This is further complicated by the limited skilled workforce in the food manufacturing sector. To address these challenges, companies must adopt technological solutions that can improve operational efficiency and enable them to remain competitive in a highly dynamic market.

How ERP Can Solve These Challenges in the Food Industry

Expert insights from Food Engineering suggest that food and beverage producers can achieve substantial financial gains by replacing disconnected legacy tools with integrated technology.

A specialized ERP system acts as a unified, scalable hub, bringing together essential data for inventory, manufacturing, and regulatory compliance to drive efficiency.

With a connected system like food manufacturing ERP software, every process in food manufacturing and distribution becomes more transparent and efficient, facilitating faster and more accurate decision-making. Here are some ways ERP software addresses issues in the food industry, including:

- Regulatory Compliance: ERP helps companies monitor and record every step of the production process according to regulatory standards, such as HACCP or FDA, ensuring consistent compliance.

- Accurate Inventory Management: ERP systems provide real-time visibility into raw material and finished product inventory, reducing waste and ensuring timely stock rotation, including expiration tracking.

- Distribution Optimization: ERP enables real-time monitoring of shipments and the status of goods, reducing delays and ensuring a smooth supply chain.

- Efficient Financial Management: ERP simplifies production cost recording, budget monitoring, and profit margin calculations, providing a clearer picture of a company’s financial health.

- Consistent Quality Control: By integrating quality processes, ERP streamlines production monitoring, ensuring products meet quality standards and minimize defects. This is especially crucial in medical manufacturing, where precision, compliance, and traceability are vital, making ERP for medical device manufacturers essential to reduce errors and costly recalls.

Top 15 Food Industry ERP Software Singapore

Every food manufacturing and distribution needs a proper supply chain and inventory management to maintain the best quality of food. Therefore, choosing the right food distribution ERP software in Singapore ensures efficiency, compliance, and scalability. Here are the top 15 food manufacturing ERP software:

1. ScaleOcean ERP Software

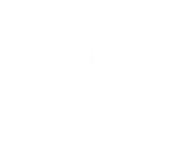

ScaleOcean Food Industry ERP Software is a cloud-based enterprise resource planning (ERP) solution designed specifically for businesses in the food distribution sector. It integrates essential business operations such as inventory management, supply chain tracking, financial management, sales, and logistics into a single platform.

With real-time data analytics, automation, and AI-driven insights, ScaleOcean enhances efficiency, reduces waste, and ensures compliance with food safety regulations. For Singaporean food manufacturing and distribution, managing perishable goods while optimizing supply chains is a complex challenge.

ScaleOcean stands out due to its end-to-end automation, real-time tracking, and customizable modules tailored to food distribution needs. Additionally, businesses can explore funding opportunities like the CTC Business Grant to ease the financial burden of digital transformation and enhance operational efficiency.

To experience its full capabilities, businesses can explore a free demo, allowing them to assess how the system streamlines operations before committing.

Key features:

- Real-time inventory tracking: Avoid shortages & excess stock.

- Automated order processing: Faster, error-free transactions.

- Food safety & compliance tools: HACCP & FSMA integration.

- Dynamic pricing & demand forecasting: AI-driven market analysis.

- Seamless third-party logistics integration: Effortless delivery tracking.

| Pros | Cons |

|---|---|

|

|

2. Food Business ERP

Food Business ERP for the food industry was developed on the Sage X3 platform. This software enables food manufacturing and distribution companies to enhance their growth and profitability by streamlining operations, improving decision-making, optimizing the supply chain, and ensuring adherence to food safety standards.

It also offers tools for managing inventory, sales, and logistics, helping businesses reduce waste and respond quickly to market demands.

Key features:

- Route Optimization

- Real-Time Tracking

- Automated Scheduling

- Integration Capabilities

| Pros | Cons |

|---|---|

|

|

3. SYSPRO

SYSPRO is designed to reduce operational risks while optimizing inventory management, quality control, improving supplier relationships, purchasing processes, and ensuring compliance with food safety standards.

It also enhances visibility across the entire supply chain, enabling the food distribution and manufacturing industries to make informed decisions and reduce waste through better forecasting and tracking.

Key features:

- Real-Time Data Analytics

- Comprehensive Inventory Management

- Production Planning

- Supply Chain Management

| Pros | Cons |

|---|---|

|

|

4. Datacor

Datacor is an ERP software for the food manufacturing industry to streamline production, inventory management, quality control, and integrates various business and also ensuring regulatory compliance.

Datacor is integrated with business functions such as procurement, sales, and distribution, providing real-time insights and improving collaboration across departments. This comprehensive solution helps manufacturers enhance operational efficiency, reduce costs, and meet the rigorous standards of the food industry.

Key features:

- Real-Time Inventory Management

- Production Scheduling

- Order Management

- Integration Capabilities

| Pros | Cons |

|---|---|

|

|

5. Food Decision Software

Food Decision Software is an all-encompassing ERP solution for food manufacturers and distributors, emphasizing procurement, inventory management, production planning, and distribution processes.

It integrates seamlessly with QuickBooks, offering features such as inventory tracking, order management, and business analytics to enhance operational efficiency.

Key features:

- Real-Time Inventory Tracking

- Order Management

- Business Analytics

- QuickBooks Integration

| Pros | Cons |

|---|---|

|

|

6. Entree Food ERP

Entree is a comprehensive ERP software for food distribution, focusing on processes like inventory management, warehouse control, and a streamlined distribution process.

Also known as NECS, it is also designed to meet the needs of those wholesale food distributors, offering key functionalities like inventory management, order processing, and regulatory compliance.

Key features:

- Catch Weight Management

- Lot Control and Traceability

- Truck Routing

- Sales Management

| Pros | Cons |

|---|---|

|

|

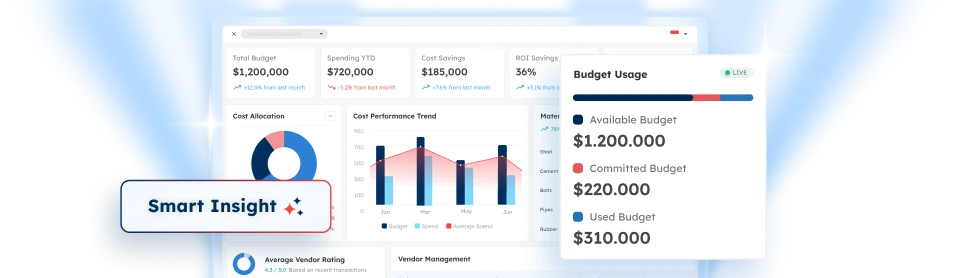

7. Infor M3

Infor M3 is a robust cloud-based ERP solution that delivers SaaS in 32 languages and 71 countries, designed to support multiple industries, including food distribution. Infor M3 streamlines manufacturing, distribution, planning, and scheduling, helping businesses navigate global challenges while optimizing operations for the food and beverage sector.

Key features:

- Advanced AI-Powered Traceability

- Real-Time Data Integration

- Comprehensive Inventory Management

- Production Planning

| Pros | Cons |

|---|---|

|

|

8. JustFood ERP

JustFood ERP for food and beverage industry offers a specialized software environment designed for the unique needs of the food manufacturing industry. By merging production, stock management, and safety protocols into one interface, it removes operational bottlenecks and automates the path to full regulatory compliance.

Key features:

- Case Management

- Reporting Tools

- Collaboration Platform

- Secure Data Storage

| Pros | Cons |

|---|---|

|

|

9. NetSuite

NetSuite’s Food Distribution ERP Software is a cloud-based solution designed to streamline and integrate various business processes within the food distribution sector.

It offers modules for inventory management, order processing, financials, and customer relationship management (CRM), enabling businesses to operate more efficiently and maintain real-time visibility across operations.

Key features:

- Real-time Inventory Tracking

- Order Management

- Financial Management

- CRM Integration

| Pros | Cons |

|---|---|

|

|

10. Deacom ERP

Deacom ERP provides a cloud-native platform engineered for the complexities of batch and process manufacturing. By housing production schedules, inventory tracking, and quality metrics under one roof, it simplifies the manufacturing lifecycle for food and beverage brands while ensuring they remain fully compliant with industry mandates.

Key features:

- Direct Store Delivery (DSD)

- Lot Traceability

- Formulation Management

| Pros | Cons |

|---|---|

|

|

11. Inecta Food ERP

iNECTA Food ERP provides a specialized cloud ecosystem built for the entire food supply chain, from manufacturers to global traders. By unifying production and recipe management, logistics, and quality assurance, the platform simplifies complex operations and ensures that every stage of the business meets rigorous industry benchmarks.

Key features:

- Recipe Configuration

- Warehouse Management

- Financial Management

| Pros | Cons |

|---|---|

|

|

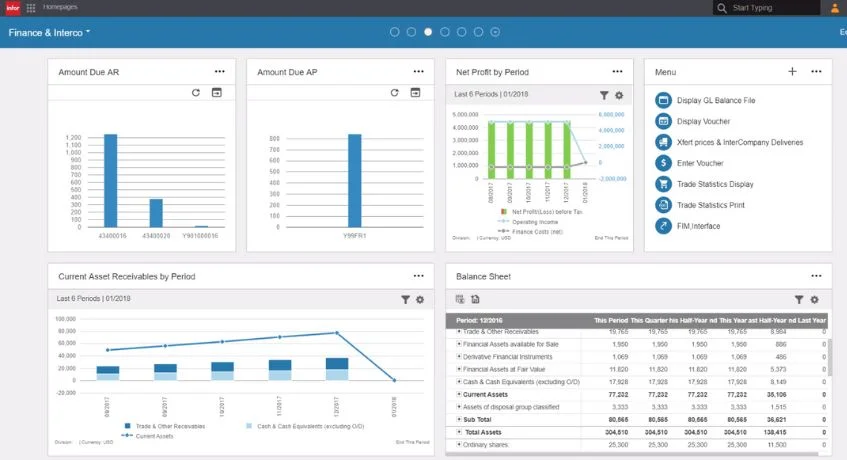

12. DELMIAWorks (IQMS) Food ERP

DELMIAWorks or IQMS provides a specialized solution that merges ERP and Manufacturing Execution System (MES) capabilities for the food industry. By unifying shop-floor production with supply chain and quality management, it offers a single point of truth that maximizes operational speed and ensures strict adherence to safety regulations.

Key features:

- Real-Time Data Access

- Integrated ERP and MES

- Quality Management System (QMS)

- Supplier Management

| Pros | Cons |

|---|---|

|

|

13. Sage X3 Food ERP

Sage X3 designed a comprehensive ERP for the food industry, built to unify the core operations of mid-market food manufacturers and distributors. By housing financials, sales, and production management in one place, it delivers the real-time visibility needed to sharpen decision-making and maintain high-level compliance across the supply chain.

Key features:

- Inventory Management

- Manufacturing Management

- Sales and Purchasing

- Accounting Integration

| Pros | Cons |

|---|---|

|

|

14. Fishbowl

Fishbowl is a comprehensive solution designed to enhance inventory and manufacturing management for food distribution businesses. Fishbowl’s powerful software streamlines operations, improving accuracy, efficiency, and visibility across the supply chain. This helps businesses optimize inventory, reduce costs, and boost overall performance.

Key features:

- Multi-Location Inventory Tracking

- Manufacturing Management

- Order Management

- Barcoding and RFID

| Pros | Cons |

|---|---|

|

|

15. Enterprise 21 Food Manufacturing ERP

Enterprise 21 is a specialized ERP for the food and beverage industry suite designed to meet the needs of small to mid-market food manufacturers and distributors.

By consolidating everything from CRM and sales to materials and production management, it provides a unified digital foundation that simplifies daily operations and automates compliance with industry safety standards.

Key features:

- Procurement Management

- Inventory Tracking

- Recipe Costing

- Menu Planning

| Pros | Cons |

|---|---|

|

|

Why Food Manufacturing Demands Specialized ERP Software

The food manufacturing industry operates in a fast-paced, highly regulated environment where efficiency, quality control, and compliance are paramount. As consumer demands evolve and regulatory requirements become more stringent, food manufacturers need a specialized ERP software solution that integrates all aspects of their operations.

This is where specialized best manufacturing ERP software features for the food industry become a critical tool for success in the food manufacturing and distribution industries, including:

Recipe Management

This feature allows companies to manage recipes more efficiently, from raw material formulation to automatic production quantity calculations. This helps maintain product consistency, reduce raw material waste, and ensure consistent quality every time a product is produced.

Quality Control

Effective quality control is crucial to ensuring that products meet high food safety and quality standards. An ERP with quality control features enables oversight at every stage of production, including raw material inspection, semi-finished product testing, and finished product testing, helping to detect problems early and reduce the risk of defects.

Sustainability and ESG Compliance

With increasing pressure to adopt environmentally friendly practices, ERP for the food manufacturing industry helps companies meet sustainability standards and ESG (Environmental, Social, and Governance) regulations.

This feature enables monitoring of emissions, waste, energy use, and supply chain sustainability, enabling companies to operate more efficiently and sustainably. Beyond the food industry, this feature is also crucial in other industries, such as chemical manufacturing. Beyond the food industry, this feature is also crucial in chemical manufacturing.

Using specialized ERP software for chemical manufacturers, precise monitoring of emissions, waste, energy use, and supply chain sustainability enables related companies to operate more efficiently and responsibly.

Lot Traceability

Traceability is crucial for monitoring the movement of each raw material and finished product in the supply chain. In this regard, ERP helps companies track the origin of raw materials, the production process, and product distribution to the end consumer. This is especially useful for product recalls or quickly resolving quality issues.

Regulatory Compliance

The food industry relies heavily on compliance with strict regulations, such as those set by local and international food authorities (e.g., the FDA, AVA).

ERP for the food industry provides features to ensure that the entire production and distribution process complies with food safety standards, halal certification, and other requirements, reducing the risk of sanctions or product recalls.

Supply Chain Management

Efficient supply chain management is crucial to ensure smooth raw material procurement, production, and distribution. This feature helps companies monitor and optimize the flow of goods from suppliers to customers, reducing waste and improving responsiveness to changing market demand.

How to Choose Suitable Food Distribution ERP Software?

Choosing the right Food Distribution ERP software streamlines operations, ensures compliance, and boosts efficiency. With rising demand and strict regulations, businesses need a system that optimizes supply chains, enhances traceability, and maintains quality.

The right type of ERP software improves visibility, minimizes waste, and drives sustainable growth.

Assess Your Business Needs

Begin by identifying your company’s specific requirements, such as lot tracking, inventory management, and compliance with food safety standards. Understanding these requirements ensures that the ERP system you select corresponds with your operational objectives.

Consider issues such as order fulfillment speed, warehouse efficiency, and supplier collaboration to ensure that the software covers all essential company operations.

Evaluate Scalability and Customization

Choose an ERP solution that can expand with your company and provide customization to solve specific difficulties. This adaptability is important for responding to market fluctuations and expanding operations.

A scalable system accommodates increasing transaction volumes, multiple locations, and advanced reporting requirements, ensuring that the software remains relevant as your business grows.

Consider Integration Capabilities

Ensure the ERP software integrates seamlessly with existing systems such as accounting software, CRM, and e-commerce platforms. This integration facilitates data consistency and streamlines workflows across departments.

A connected ecosystem eliminates data silos, improves decision-making, and enhances customer service by providing accurate, real-time information across the supply chain.

Prioritize User-Friendliness and Support

Select software with an intuitive interface to reduce training time and increase user acceptance. Reliable customer service is essential for quickly resolving technical issues and maintaining uninterrupted operations.

Look for vendors who provide training programs, ongoing support, and user-friendly dashboards to help employees maximize the system’s potential with minimal disruption.

Assess Total Cost of Ownership

Evaluate all costs associated with the ERP system, including implementation, training, maintenance, and potential upgrades. A comprehensive cost analysis helps in budgeting and prevents unforeseen expenses.

Beyond the upfront investment, factor in long-term costs like cloud hosting fees, software updates, and future scalability to ensure the ERP for the food distribution industry remains cost-effective in the long run.

Conclusion

Choosing a suitable Food Industry ERP Software is important for Singaporean businesses to streamline operations, ensure compliance, and enhance efficiency. As the industry grows, companies need solutions that optimize supply chains, improve visibility, and integrate seamlessly with existing systems.

The ERP options in this article offer tailored features, from inventory management to logistics optimization, helping businesses stay competitive and drive growth. Experience the benefits firsthand with ScaleOcean’s free demo, showcasing automation, real-time tracking, and AI-driven insights.

With multi-location warehouse management, seamless logistics integration, and unlimited user access, ScaleOcean Food Manufacturing ERP software ensures scalability and compliance with food safety standards. Request a free demo to choose the perfect match features for your food manufacturing industry.

FAQ:

1. What is the ERP system in the food industry?

In the food sector, an Enterprise Resource Planning (ERP) system serves as the central digital hub for business management. It allows food companies to coordinate and refine every aspect of their operation—integrating everything from raw material procurement and financial reporting to manufacturing schedules and final delivery.

2. What is an ERP system in distribution?

An ERP system in distribution simplifies production, quality control, and supply chain management by centralizing data across the organization. It helps distributors meet industry demands, improve efficiency, and streamline operations for better decision-making.

3. What are the 4 types of food production systems?

There are four distinct categories of food production systems, each with unique trade-offs. This section reviews the Conventional, Ready-Prepared (Cook-Chill), Commissary (Centralized Kitchen), and Assembly/Serve (Tray Line) approaches to help determine which best suits a specific operation.

4. What is ERP software in the supply chain?

ERP software streamlines supply chain management (SCM) processes like procurement, inventory, and logistics by integrating them with finance, HR, and sales. Software SCM provides a unified view of operations, ensuring efficiency, accuracy, and a single source of truth.

PTE LTD..png)

.png)

.png)

.png)

.png)