Supply chain optimization software assists companies in overseeing and enhancing their supply chains by providing resources for demand forecasting, inventory control, logistics, and other functions, which in turn boosts efficiency and lowers expenses. Automating tasks, analyzing data, and optimizing processes enables smoother coordination and more informed decision-making.

In Singapore, recognized as a global logistics center, the demand for efficient supply chain management has reached unprecedented levels. According to OpenGov, Singapore’s logistics sector is expected to grow by SG$6.9 billion by 2025, further emphasizing the urgency of adopting technology like supply chain optimization tools for staying competitive.

These factors highlight the importance for businesses in Singapore to adopt supply chain optimization software, helping them streamline operations and meet global demand with accuracy and agility. However, choosing the right supply chain inventory optimization software is not a decision to be made lightly.

With numerous options available, each offering unique features, strengths, and limitations, businesses need a system that aligns with their specific goals and operational needs. This article aims to provide valuable insights into the best supply chain optimization tools options based on their features, advantages, and drawbacks, helping businesses make informed decisions. Some popular platforms include ScaleOcean, Logility, Blue Yonder, Kinaxis, Anaplan, and more.

- Supply chain optimization software is a system to boost efficiency by analyzing and streamlining the flow of goods, data, and finances from sourcing to delivery.

- Benefits of supply chain optimization include better visibility, forecasting, cost reduction, improved inventory management, and enhanced customer service.

- Top recommendations for supply chain optimization software include ScaleOcean, Logility, Anaplan, Netstock, Oracle SCM, and more.

- ScaleOcean is a top solution for optimizing supply chain processes, integrating AI technology to automate tasks, predict demand, and improve efficiency across operations.

What is Supply Chain Optimization Software?

Supply chain optimization software is a system to boost efficiency by analyzing and streamlining the flow of goods, data, and finances from sourcing to delivery. It offers powerful tools to oversee and refine processes, enabling companies to lower costs, enhance customer satisfaction, and improve overall operational effectiveness.

This software aids in predicting the future performance of suppliers and customers, enhances collaboration with trading partners, and ultimately contributes to increased revenue and profitability.

According to the Economic Development Board, Singapore’s success as a logistics hub is fueled by its capability to manage the complexities of international supply chains with exceptional efficiency. The country ranks first in the World Bank’s 2023 Logistics Performance Index, excelling in areas such as customs clearance and the quality of logistics services.

For companies operating in Singapore, the implementation of supply chain optimization software is crucial for maintaining competitiveness in a rapidly evolving global marketplace. Given Singapore’s strategic role as a key center for trade and logistics, organizations can leverage real-time data and predictive analytics to improve their supply chain operations.

The integration of this software allows businesses to streamline inventory management, reduce operational costs, and improve delivery efficiency. These capabilities are crucial for maintaining a competitive edge in Singapore’s dynamic, fast-paced, and technology-driven economy.

Key Benefits of Supply Chain Optimization Software

Supply chain network optimization tools provide numerous benefits that help businesses improve efficiency, reduce costs, and enhance overall performance. In this section, we’ll explore the key advantages of using this software to streamline supply chain operations and drive business success.

1. Enhanced Visibility

Supply chain network optimization tools improve visibility by delivering real-time insights into all components of the supply chain, from raw materials to final products. This level of transparency enables businesses to closely oversee their operations, detect potential problems at an early stage, and make well-informed decisions. Enhanced visibility allows companies to coordinate more effectively with suppliers, manage inventory efficiently, and facilitate smoother overall operations.

2. Improved Forecasting and Planning

Utilizing historical data alongside predictive analytics, supply chain optimization software greatly enhances the precision of forecasting and planning. Companies can better predict variations in demand, modify production timelines, and fine-tune inventory levels as needed. This forward-thinking strategy minimizes the likelihood of stock shortages or surplus inventory.

3. Supply Chain Planning

Supply chain optimization tools help businesses design, execute, and monitor end-to-end supply chain strategies. By integrating various functions like manufacturing ERP Singapore, procurement, and logistics, it ensures a cohesive and efficient workflow. This planning capability allows companies to identify bottlenecks, improve resource allocation, and streamline processes, leading to better overall supply chain performance.

4. Cost Reduction

A significant advantage of supply chain network optimization tools is their capacity to decrease costs via automation and effective resource management. By refining inventory levels, optimizing transportation routes, and improving procurement processes, organizations can reduce operational costs. These reductions directly enhance profitability while ensuring the maintenance of high-quality service standards.

5. Inventory Optimization

Inventory optimization is crucial for balancing product availability with minimal carrying costs. Supply chain inventory optimization software uses real-time data to track stock levels and predict demand, ensuring that businesses maintain just the right amount of inventory. This helps reduce excess stock, minimize storage costs, and ensure timely order fulfillment, enhancing operational efficiency.

6. Data Analytics

Data analytics is a core benefit of supply chain optimization software, enabling businesses to make data-driven decisions. By analyzing trends, patterns, and operational performance, companies can identify areas for improvement and implement strategies to enhance efficiency. This analytical approach leads to more informed decision-making, helping businesses stay competitive in a dynamic market.

7. Risk Management

Risk management is a vital benefit of supply chain optimization tools, allowing businesses to identify, assess, and mitigate potential risks. By monitoring supply chain activities and external factors in real-time, companies can anticipate disruptions, such as supplier delays or market fluctuations. This proactive approach enables businesses to implement contingency plans and minimize the impact of unforeseen events on operations.

8. Improved Customer Service

Optimized supply chains directly lead to improved customer service by ensuring that products are delivered on time and in the right quantities. With better demand forecasting, efficient order fulfillment, and enhanced inventory management, businesses can meet customer expectations consistently. As a result, companies can improve customer satisfaction, foster loyalty, and enhance their reputation in the market.

Key Features and Capabilities of Supply Chain Optimization Software

Supply chain network optimization tools play a critical role in enhancing operational efficiency by streamlining processes, reducing costs, and improving decision-making across the supply chain. Understanding SCM is essential for leveraging these tools effectively to achieve better outcomes.

Below are the key features that drive performance and support business growth:

1. Demand Planning and Forecasting

This module can forecast and predict future demand to ensure adequate inventory levels. Accurate demand planning and forecasting are essential for businesses in Singapore to maintain the right inventory levels while avoiding overstocking or stockouts. By leveraging AI and machine learning, businesses can predict demand patterns in real time. Value chain forecasting aligns sourcing to distribution with demand predictions, minimizing costs and maximizing efficiency.

Here are the key capabilities of inventory management:

- Predicting Future Demand: Uses historical data and market trends to accurately forecast demand.

- Real-Time Forecasting: Utilizes AI and machine learning to adjust forecasts based on live data.

- Automated Stock Adjustments: Automatically updates inventory levels based on demand predictions, reducing manual interventions.

2. Inventory Management

Inventory management can optimize inventory levels, reduce storage costs, and minimize stockouts. Managing inventory is important for keeping a smooth supply chain, making sure that products are accessible without having too much in stock. Real-time monitoring enables companies to track the flow of products between different sites, providing clarity at every phase.

Here are the key capabilities of inventory management:

- Real-time Tracking: Enhances visibility across the supply chain and ensures accurate stock levels.

- Inventory Optimization: Utilizes data analytics to maintain optimal inventory levels and reduce wastage.

- Warehouse Management: Improves productivity by streamlining warehouse processes, reducing errors, and maximizing space.

3. Logistics and Transportation

Logistics and transportation involve managing transportation routes, optimizing freight costs, and ensuring timely deliveries. This includes managing transportation routes to minimize delays and costs, optimizing freight expenses through strategic planning and partnerships, and ensuring timely deliveries to meet customer expectations.

Here are the key capabilities of logistics and transportation:

- Route Optimization: Efficiently planning the best transportation routes to reduce time and cost.

- Freight Cost Management: Analyzing and optimizing shipping costs through negotiation and strategic partnerships.

- Delivery Scheduling: Ensuring on-time delivery through careful planning and communication with suppliers and customers.

4. Supply Chain Visibility

Supply chain visibility provides real-time the entire supply chain, from suppliers to customers. It enables businesses to gain end-to-end visibility into their operations, helping them make informed decisions about inventory, production, and logistics. By identifying bottlenecks and delays, companies can take proactive measures to address inefficiencies before they escalate, ensuring a smoother and more responsive supply chain.

Here are the key capabilities of supply chain planning:

- End-to-End Visibility: Provides a comprehensive overview of supply chain processes, from raw materials to customer delivery.

- Bottleneck Identification: Detects and addresses potential bottlenecks or delays in the supply chain.

- Scenario Planning: Simulates different supply chain scenarios to anticipate challenges and plan accordingly.

5. Order Management

Order management in supply chain optimization tools helps businesses efficiently process and track orders from purchase through fulfillment, minimizing delays and errors. By streamlining the order processing workflow, you can ensure quick delivery and maintain strong customer satisfaction.

Here are the key capabilities of order management:

- Streamlined Order Processing: Automates order handling, inventory management, and fulfillment for faster processing.

- Omnichannel Capabilities: Manages orders from multiple sales channels, providing flexibility and convenience.

- Real-Time Order Tracking: Offers visibility into order status and shipment progress to both businesses and customers.

6. Collaboration

Collaboration can facilitate collaboration among different stakeholders in the supply chain, including suppliers, manufacturers, and distributors. It involves fostering effective communication and teamwork among various stakeholders, such as suppliers, manufacturers, and distributors.

Key capabilities of supply chain collaboration include:

- Information Sharing: Providing real-time data and insights across stakeholders to improve decision-making.

- Joint Planning: Coordinating schedules, forecasts, and production plans to align operations and meet demand.

- Performance Monitoring: Tracking and evaluating partner performance to ensure goals are met efficiently.

7. Risk Management

Risk management in the supply chain network optimization tools is essential for identifying, assessing, and mitigating potential disruptions that could impact business operations. By leveraging predictive analytics and real-time monitoring, businesses can proactively manage risks related to suppliers, logistics, and market fluctuations.

Here are the key capabilities of risk management:

- Risk Identification and Assessment: Uses data and analytics to identify potential risks in the supply chain and evaluate their potential impact.

- Supplier Risk Evaluation: Assesses the reliability and stability of suppliers, helping businesses avoid disruptions caused by external factors.

- Contingency Planning: Develop contingency strategies and backup plans to mitigate the effects of identified risks.

8. Analytics and Reporting

Data analytics in supply chain optimization software plays a crucial role in driving business decisions by uncovering trends and patterns that may not be immediately visible. With powerful analytics and reporting tools, companies can monitor performance metrics and track supply chain efficiency.

Here are the key capabilities of analytics and reporting:

- Data-Driven Decision-Making: Utilizes historical and real-time data to guide business strategies and operational improvements.

- Performance Monitoring: Tracks key performance indicators (KPIs) to assess supply chain efficiency and performance.

- Customizable Reporting: Allows businesses to generate tailored reports that highlight specific areas of focus or concern.

Top 10 Recommendations of Supply Chain Optimization Software

When it comes to enhancing the efficiency of your supply chain, choosing the right software is crucial. In this section, we’ve compiled the top 10 recommendations of supply chain optimization software that can help streamline your operations, reduce costs, and improve overall performance.

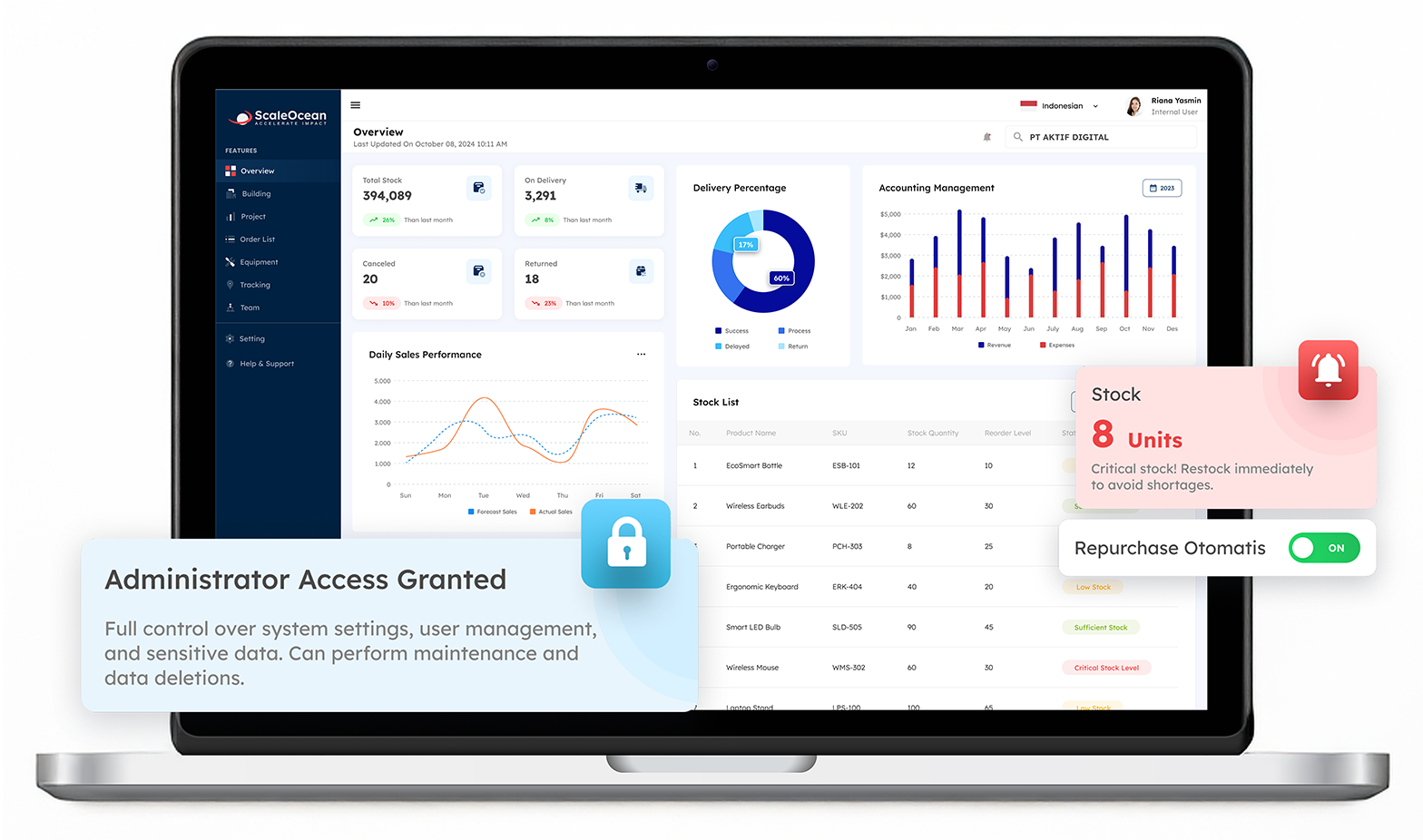

1. ScaleOcean Software

ScaleOcean ERP is a powerful AI-driven software for supply chain optimization. It helps businesses streamline their operations while reducing risks and improving overall efficiency. With its advanced features such as automation and predictive analytics, ScaleOcean allows you to make smarter decisions by predicting demand, minimizing the chances of stockouts, and optimizing procurement processes.

ScaleOcean ERP’s advanced analytics also provide real-time insights, allowing you to identify potential bottlenecks before they affect operations. Companies can also optimize procurement processes, ensuring that the right materials are sourced at the right time, without delays. The result is reduced operational costs, faster delivery times, and better service quality for your customers.

ScaleOcean also offers a free demo to give you a comprehensive understanding of how the system works, allowing you to see firsthand how it can benefit your operations. Additionally, ScaleOcean is aligned with the CTC grant in Singapore, which helps businesses invest in digital solutions to enhance their operations and boost productivity.

Key features of ScaleOcean ERP are:

- Real-Time Inventory Management: Provides real-time tracking and updates of inventory levels, ensuring stock is always optimized and reducing the risk of overstocking or stockouts.

- Automated Procurement: Streamlines purchasing processes by automating order creation and vendor management, ensuring timely replenishment of materials.

- Sales Order Management: Optimizes sales order processing, enhancing order fulfillment accuracy and improving customer satisfaction by reducing delays.

- Supply Chain Analytics: Delivers comprehensive analytics and reporting, allowing businesses to identify inefficiencies, track performance, and make data-driven decisions.

- Demand Forecasting: Utilizes predictive analytics to forecast demand, helping businesses plan procurement and production schedules with greater accuracy.

- Customizable Workflow Automation: Automates repetitive tasks and approvals based on custom business rules, improving efficiency and reducing manual effort.

| Pros | Cons |

|---|---|

|

|

2. Logility

Logility is supply chain optimization software that focuses on helping businesses improve demand forecasting analytics, inventory management, and overall supply chain operations. The solution is particularly useful for companies looking to enhance supply chain efficiencies and manage inventory with better insight.

Features:

- Advanced demand forecasting

- Inventory management tools

- Supply chain visibility and optimization

| Pros | Cons |

|---|---|

|

|

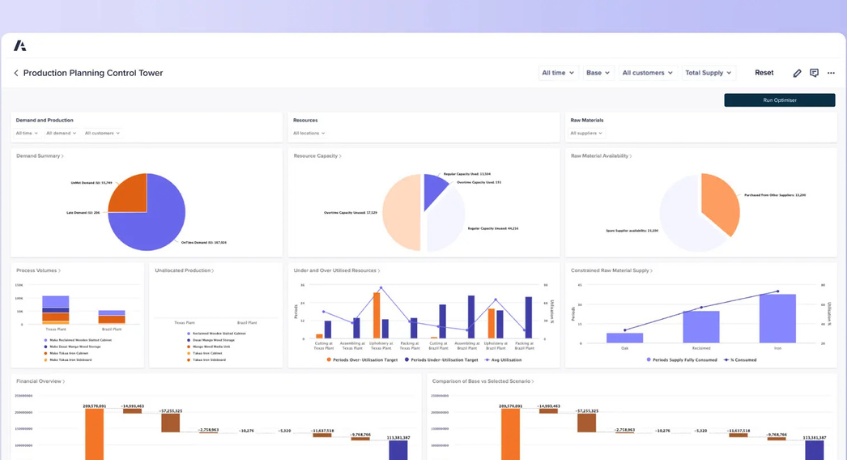

3. Anaplan

Anaplan provides a versatile platform for business planning, performance management, and decision-making across finance, sales, HR, and supply chain. It enables agile, real-time planning, helping businesses respond quickly to changes. The platform’s flexibility makes it suitable for companies that require a comprehensive, scalable solution.

Features:

- Agile business planning and performance management

- Integrates across multiple functions (finance, sales, HR, supply chain)

- Real-time decision-making capabilities

| Pros | Cons |

|---|---|

|

|

4. Netstock

Netstock is a supply chain inventory optimization software that focuses on inventory management, providing advanced analytics to help businesses maintain optimal stock levels. It minimizes carrying costs while ensuring product availability. This solution is ideal for businesses aiming to enhance operational efficiency and improve their stock management practices.

Features:

- Inventory optimization tools

- Advanced analytics for stock level management

- Cost-effective inventory solutions

| Pros | Cons |

|---|---|

|

|

5. Oracle SCM

Oracle supply chain management helps businesses automate and optimize their supply chain operations using advanced analytics. These supply chain optimization tools provide robust solutions for managing disruptions, work-in-progress production, and improving supply chain visibility. Oracle SCM is designed to offer alternatives and contingency plans for smoother operations.

Features:

- Real-time data analytics and reporting

- Order management system

- Integrated logistics and transportation management

| Pros | Cons |

|---|---|

|

|

6. Blue Yonder

Blue Yonder is an AI-powered supply chain network optimization tools that optimize inventory management and synchronizes supply and demand in real-time. The platform’s use of artificial intelligence allows for dynamic adjustments to changing supply and demand conditions, ensuring efficient operations.

Features:

- Real-time supply-demand matching

- Adaptive supply chain risk management tools

- AI-driven decision support system

| Pros | Cons |

|---|---|

|

|

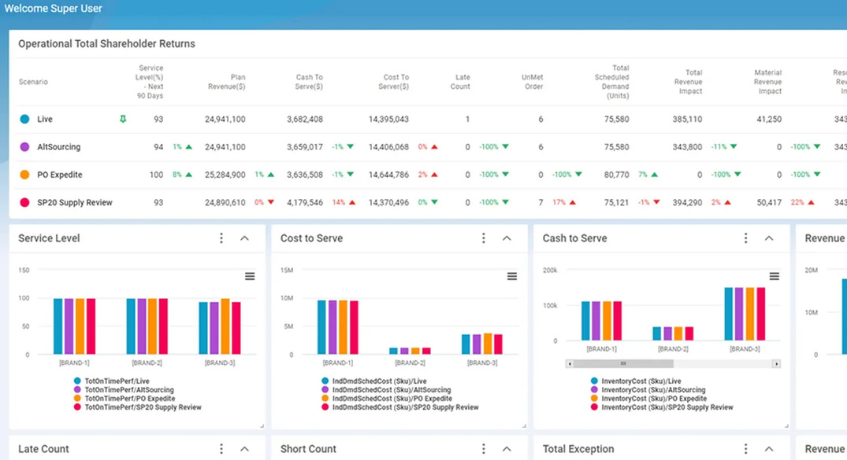

7. Kinaxis

Kinaxis is a cloud-based platform for supply chain planning and optimization. It offers a comprehensive supply chain management software solution by integrating diverse systems, enabling businesses to make faster, informed decisions. The platform excels at delivering end-to-end visibility and fostering deep collaboration across the supply chain.

Features:

- Continuous supply chain monitoring and alerts

- Supply chain modeling and simulation tools

- Cross-functional collaboration tools

| Pros | Cons |

|---|---|

|

|

8. E2open

E2open is a cloud-based supply chain optimization tool designed to help businesses optimize their supply chains. It provides a comprehensive suite of tools for improving visibility, collaboration, and execution across various business processes. The platform is suited for organizations looking to enhance their supply chain capabilities.

Features:

- Cloud-based supply chain network management

- Automated demand forecasting and supply planning

- Integrated supplier and customer collaboration tools

| Pros | Cons |

|---|---|

|

|

9. Coupa

Coupa is a comprehensive supply chain optimization software that provides a wide array of solutions, encompassing procurement, invoicing, and expense management. It assists organizations in controlling their expenditures and enhancing their procurement procedures, while also delivering analytics to facilitate improved decision-making.

Features:

- Supplier management and performance tracking

- Expense management and invoicing solutions

- Business intelligence and spend analytics

| Pros | Cons |

|---|---|

|

|

10. Freightos

Freightos delivers software-as-a-service technology designed to assist businesses in managing freight quotes, rates, and routing. It provides real-time solutions for pricing and route optimization, thereby improving the overall efficiency of logistics operations.

Features:

- Dynamic pricing optimization tools

- Shipment tracking and status updates

- Integrated route planning and optimization

| Pros | Cons |

|---|---|

|

|

What’s the role of AI in Supply Chain Optimization Software?

AI plays a transformative role in supply chain optimization software, enabling smarter decision-making and real-time data analysis. Leveraging machine learning and predictive analytics, AI enhances businesses’ ability to streamline operations, forecast demand, and optimize various supply chain functions with greater accuracy and efficiency.

Here are the key roles of AI in supply chain optimization:

1. Inventory Optimization

AI-driven solutions optimize inventory levels, balancing supply with demand to prevent overstocking and stockouts. The software analyzes historical sales data and demand trends to recommend precise order quantities. This approach reduces the cost of holding excess stock while ensuring that products are available when needed, improving overall inventory efficiency.

2. Demand Forecasting and Planning

With the power of AI, demand forecasting becomes more accurate by analyzing amounts of historical and real-time data. AI models can predict demand fluctuations based on patterns, market trends, and external factors like seasonality or economic conditions. This results in more reliable forecasting, allowing businesses to plan production and procurement strategies.

3. Supply Chain Cost Reduction and Resource Utilization

AI optimizes supply chain processes, identifying inefficiencies like delays, underutilized resources, or unnecessary stock. It dynamically adjusts routes, schedules, and inventories, cutting transportation costs, reducing waste, and maximizing resource utilization. These adjustments result in significant cost savings and a more efficient use of supply chain management resources.

4. Improved Decision Making

AI improves decision-making by delivering real-time insights and predictive analytics derived from both current and historical data. This capability enables businesses to make well-informed choices regarding inventory management, supplier selection, and logistics planning. By analyzing intricate datasets and offering actionable recommendations, AI facilitates faster and more effective decision-making, ultimately enhancing supply chain performance.

5. Risk Management and Adaptability

AI in supply chain optimization software supports risk management by identifying potential disruptions and offering proactive solutions. Through predictive analytics, businesses can anticipate risks like supply delays or market shifts and take preventive measures. This enables businesses to adapt quickly to unexpected changes, ensuring that the supply chain remains responsive and continues to function smoothly even in uncertain conditions.

Types of Supply Chain Optimization Software

There are several types of supply chain optimization tools, each designed to address specific aspects of the supply chain and improve overall efficiency. In this section, we’ll explore the different types and how they contribute to optimizing operations and driving business success.

1. Order Processing Software

Order processing software is designed to streamline and optimize the management of customer orders. It automates processes such as sales order entry, order management, and real-time tracking. This software helps businesses meet customer expectations by providing fast and accurate order fulfillment.

2. Inventory Management Software

Inventory management software provides businesses with the tools necessary to optimize stock levels and reduce carrying costs. Offering features such as real-time tracking and demand forecasting, it helps companies avoid overstocking or stockouts. This type of software is crucial for maintaining a lean and cost-effective inventory system that supports both operational efficiency and profitability.

3. Demand Forecasting Software

Demand forecasting software uses historical data and market trends to predict future demand. By leveraging advanced analytics, this software enables companies to anticipate fluctuations in demand and adjust their supply chain strategies accordingly. It empowers businesses to make informed decisions on production, inventory, and procurement.

4. Transportation Management Software

Supply chain optimization tools, including SCM software, streamline logistics by automating route planning and tracking. This improves delivery times, cuts transportation costs, and significantly enhances overall operational efficiency for businesses.

5. Collaboration Portal Software

This software allows teams to address issues such as bottlenecks, order discrepancies, or delays in real time. By fostering transparency and collaboration across departments, suppliers, and partners, supply chain network optimization tools help improve overall efficiency and reduce the likelihood of disruptions, ultimately driving better supply chain performance.

How to Implement Supply Chain Optimization Software

Implementing supply chain optimization software involves several key steps to ensure successful integration and maximize its benefits. Here’s a step-by-step approach to guide you through the process:

1. Define Clear Objectives

Start by identifying the specific goals you want to achieve with the software. Whether it’s improving inventory management, enhancing forecasting accuracy, or reducing operational costs, having clear objectives will help you choose the right supply chain optimization software and tailor it to your needs.

2. Choose the Right Software

Research and select a software solution that aligns with your business requirements and objectives. Consider factors like scalability, integration capabilities with existing systems, and user-friendliness. Consulting with vendors or experts can also help ensure the software meets your specific supply chain needs.

3. Plan and Customize the Implementation

Once the software is selected, create a detailed implementation plan. This should include timelines, resource allocation, and customization requirements. Customization may be needed to adapt the software to your unique workflows, business processes, and industry requirements.

4. Data Integration and Migration

Ensure that your data, such as inventory levels, supplier information, and order history, is integrated into the new system. Data migration can be a complex process, so it’s essential to ensure accuracy and consistency to avoid disruptions in operations. Work closely with your IT team or external specialists to facilitate this step.

5. Training and Change Management

Training employees on the new system is crucial for successful adoption. Offer comprehensive training sessions to ensure that your team can effectively navigate and utilize the software. Additionally, implement change management practices to help staff transition smoothly to the new system and overcome any resistance.

6. Test and Monitor

Before going live, conduct thorough testing to identify any issues or bottlenecks in the supply chain optimization tools. Pilot testing helps to ensure that everything works as expected. After implementation, continuously monitor the software’s performance, gather feedback, and make adjustments as needed to ensure optimal performance.

7. Continuous Improvement and Updates

Supply chain optimization is an ongoing process. Regularly assess the software’s effectiveness and make improvements based on performance data and market changes. Keep the software up to date with regular updates and ensure it evolves with your business needs.

Conclusion

Adopting supply chain optimization software is a crucial step for businesses aiming to stay competitive in today’s fast-paced and complex global market. For businesses in Singapore, where logistics plays a central role in the economy, implementing such software can help navigate the complexities of global supply chains, ensuring timely deliveries, efficient resource utilization, and a robust response to market changes.

Choosing the right supply chain optimization tools is vital to meeting your business’s unique needs and goals. Based on the recommendations and features outlined above, ScaleOcean’s software stands out as the ideal solution. ScaleOcean offers a comprehensive platform tailored to streamline your operations. To see how it can benefit your business, try our free demo today and experience firsthand how ScaleOcean can transform your supply chain operations.

FAQ:

1. What is supply chain optimization software?

Supply chain optimization software enhances supply chain performance by automating data-driven decisions and utilizing mathematical models. When selecting SCO tools, it’s important to find a balance between advanced analytical features and their ease of use.

2. What are the four major types of SCM software?

There are four primary supply chain models:

1. Continuous-flow model

2. Fast model

3. Efficient model

4. Custom-configured model

3. What are the 5 main functions of SCM?

Supply chain management involves five key functions:

1. Purchasing

2. Operations

3. Logistics

4. Resource management

5. Information flow

PTE LTD..png)

.png)

.png)

.png)

.png)