In today’s competitive business environment, effectively managing a value chain has become crucial for companies seeking to enhance their operational efficiency. A value chain involves every step a business takes, from sourcing raw materials to delivering a finished product to the customer. According to EDB Singapore, S$25 billion has been allocated for R&D through the RIE 2025 plan, with S$3 billion invested last year in advanced manufacturing, sustainability, and the digital economy.

This article goes into the concept of a value chain, discussing its significance, components, and how firms may optimize each phase for optimum value. It discusses critical subjects such as the distinctions between value chains and supply chains, the advantages of value chain analysis, and practical procedures for implementation. Business owners and decision-makers will gain vital insights that will help them streamline processes, make better decisions, and create long-term success.

- A value chain refers to the full set of activities a company performs to deliver a product or service, from sourcing materials to after-sales support, ensuring customer satisfaction throughout the process.

- The value chain includes primary activities like logistics and operations, as well as support activities such as HR and technology, all driving value creation.

- Value chain analysis helps businesses identify inefficiencies, improve operations, and increase customer value by streamlining processes.

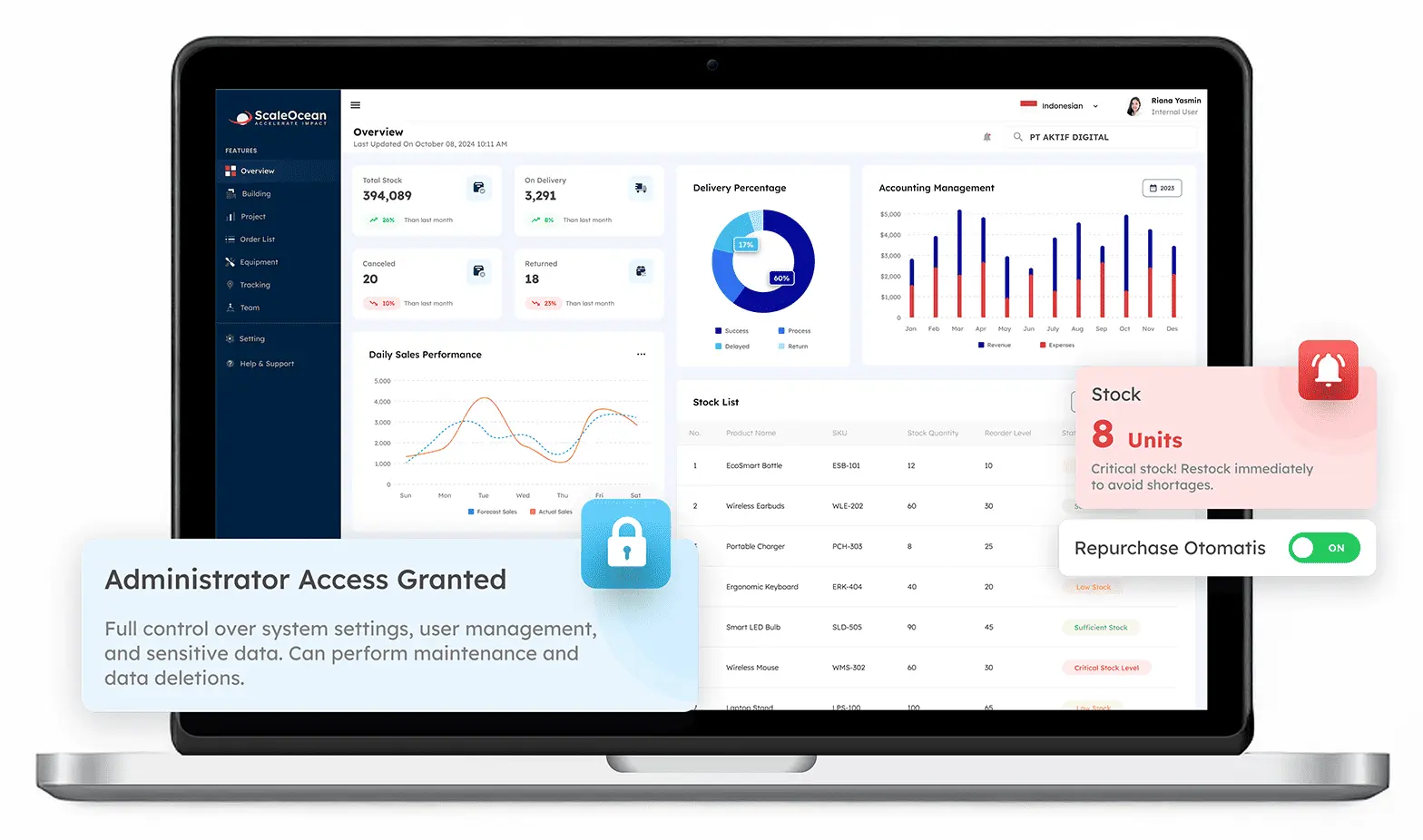

- ScaleOcean ERP integrates procurement, inventory, sales, and finance, optimizing business operations with real-time insights for better decision-making.

What Is a Value Chain?

A value chain is the whole set of activities that firms perform to convey a product or service from concept to client. This covers material procurement, manufacture, marketing, delivery, and after-sales support. Each phase is critical to ensuring that the finished product satisfies the customer’s expectations.

When properly managed, a strong value chain allows businesses to run more efficiently, minimize wasteful expenditures, and give greater value to their consumers. Optimizing each action assists firms in remaining competitive and achieving long-term growth by providing high-quality products at low cost.

Understanding Value Chains

Consider the value chain to be a sequential journey. Every stage of this process, from raw materials to ultimate delivery, adds value to the product or service. Each element, whether production, marketing, or sales, contributes to the overall quality of the offering.

Whether it’s a tiny business in Singapore or a multinational corporation, effectively managing these stages can improve performance and profitability. It also helps businesses gain a better understanding of their internal processes and how they engage with external partners, resulting in increased collaboration and efficiency.

Components of a Value Chain

A value chain is made up of many actions that contribute to the development of a product or service. These activities are separated into two categories: primary and support, with both contributing significantly to value creation. Let’s look at the many components of a value chain, starting with the fundamental activities.

1. Primary Activities

Primary activities are the fundamental procedures involved in developing and delivering a product or service to a consumer. These efforts bring tangible value to the product and are critical to maintaining consumer satisfaction. They cover everything from raw material procurement to after-sales support. The main primary activities include the following:

a. Inbound Logistics

This refers to the process of receiving, storing, and handling raw materials or goods obtained from suppliers. Efficient inbound logistics ensures that materials are available for manufacturing as needed, which has a direct impact on production timetables and prices.

b. Operations

The primary goal of operations is to convert raw materials into finished goods. This includes activities such as product assembly, packaging, and refining, which ensure that the product meets quality standards while minimizing waste and inefficiency. Understanding the product life cycle at this stage helps to assess where improvements can be made to enhance product quality and reduce environmental impact during production.

c. Outbound Logistics

This operation includes distributing finished products to clients. It comprises operations such as warehousing, inventory management, and product delivery. Effective outbound logistics provides timely delivery and precise inventory tracking to satisfy customer requests.

d. Marketing and Sales

Marketing and sales activities are in charge of recruiting clients and producing revenue. This includes market research, promotional methods, advertising, and the sales process itself, all of which contribute to increasing product recognition and demand.

e. Service

Service refers to the after-sales support provided to customers to ensure their pleasure and retention. This may include installation, maintenance, customer service, and warranty handling. A robust service procedure promotes long-term customer loyalty and repeat business.

2. Support Activities

Support activities are critical functions that enable and optimize core activities in a value chain. These efforts ensure that the firm operates smoothly and efficiently at all levels of the value chain. While they do not directly produce goods or services, they provide the necessary support to keep everything running smoothly. The major support activities are:

a. Firm Infrastructure

Planning, finance, and quality management are all critical tasks of firm infrastructure. These processes assist to build a firm basis for the company, ensuring that activities function efficiently and in accordance with legal and financial rules. Strong infrastructure facilitates decision making and resource allocation.

b. Human Resource Management

Human resource management entails hiring, training, and keeping skilled workers. It guarantees that the organization has the skills required to complete its tasks efficiently. This activity also entails managing employee benefits, performance, and creating a favorable company culture to increase employee engagement and productivity.

c. Technology Development

Technology development focuses on innovation and the application of technological instruments to improve business processes. Whether it’s automating jobs, increasing communication, or enhancing product development, technology is crucial to optimizing operations, lowering costs, and allowing firms to remain competitive.

d. Procurement

Procurement is the process of sourcing the best products, services, and equipment needed to run a firm. This action guarantees that the organization has access to high-quality, cost-effective inputs that meet its production requirements. Effective procurement helps to keep production lines running smoothly and products delivered on time.

Example of a Value Chain

Assume a coffee firm situated in Singapore wants to increase its regional reach. The value chain begins with sourcing coffee beans from Indonesia, which are then roasted locally. The company then packages the product in environmentally friendly materials, ensuring a sustainable approach from the start.

Next, the brand employs digital marketing to reach more customers in Southeast Asia, promoting the quality and sustainability of its coffee. Finally, logistical partners manage delivery, while a dedicated customer support staff responds to comments, guaranteeing a consistent experience from bean to cup.

What Is a Value Chain vs. a Supply Chain?

A value chain is frequently mistaken for a supply chain management system. A supply chain primarily focuses on the transportation of goods, ensuring that things are efficiently carried from suppliers to buyers. It involves logistics, inventory, and delivery management, all with the goal of ensuring that commodities move smoothly.

On the other hand, the value chain provides a more comprehensive perspective. It examines how value is added throughout the process, from raw materials to the finished product. While the supply chain is concerned with operations and flow, the value chain focuses on how each step contributes to business growth and increases customer satisfaction.

Why Is Value Chain Analysis Important?

A value chain analysis assists firms in determining which operations add the greatest value and which areas require improvement. Understanding these characteristics allows businesses to streamline operations, cut costs, and improve overall efficiency. This method also reveals areas where adjustments can be made to increase customer satisfaction and profitability.

Furthermore, analysis helps decision-makers identify process weaknesses and new potential for innovation. Understanding value chain performance provides a competitive advantage, whether you manage a small local business or a multinational corporation. It enables firms to maintain agility and respond rapidly to market changes.

What Are the Steps to Value Chain Analysis?

Analysis enables firms to find opportunities for development and promote growth by streamlining their internal operations. Understanding each action in the value chain allows businesses to improve productivity, cut costs, and increase customer value. Let us look at the key steps in conducting a successful value chain analysis:

1. Identify All Activities

The first stage is to make a list of all the tasks and processes, both primary and support, that help to offer your product or service. Mapping out each stage allows you to understand how your organization operates from beginning to end, ensuring that nothing crucial is neglected.

2. Evaluate Value Contribution

Next, evaluate how each operation adds value to the product or service and improves consumer happiness. This stage assists you in determining which aspects of the process are most important and which may require change to increase overall customer value.

3. Spot Inefficiencies

Look for processes that cause delays, waste, or excessive costs. This step focuses on identifying areas for improvement, such as lowering bottlenecks, minimizing waste, and eliminating needless activities. Implementing supply chain optimization software can help to streamline these processes and maximize efficiency.

4. Benchmark Against Competitors

See how your value chain stacks up against competitors in terms of performance, innovation, and cost-efficiency. Benchmarking allows you to find areas for improvement and align with best practices in your sector.

5. Make Improvements

Finally, apply the knowledge gathered in the preceding steps to modify or automate important operations, improve the customer experience, and cut costs. By adopting these changes, you may promote continual improvement and gain a competitive advantage.

Can the Value Chain Span the Globe?

In today’s global economy, a value chain can span multiple countries. For instance, a Singapore-based tech company might design products locally, manufacture in Vietnam, and sell globally. According to Gov Tech, the Singapore Government launched the Singapore Green Plan 2030 in 2021, aiming for net-zero emissions by 2050.

This focus on sustainability underscores the need to optimize value chains for reduced environmental impact. However, maintaining a global value chain adds complexity. Companies must handle issues such as carbon footprints, labor practices, and foreign rules. This makes value chain analysis even more important in ensuring long-term sustainability and operational efficiency across borders.

Manage Your Value Chain Integrally with ScaleOcean ERP Software

ScaleOcean ERP software is a comprehensive system that automates and integrates important company activities such as procurement, inventory, sales, and finance. ScaleOcean helps organizations optimize their value chain by centralizing these operations, resulting in increased efficiency and lower costs. The software ensures that every step of the process, from raw material procurement to product delivery to clients, is fully integrated, offering real-time data and important insights for better decision making.

To fully see the potential of ScaleOcean, we provide a free demo that demonstrates how the program may alter your business processes. Furthermore, ScaleOcean is eligible for the CTC grant, making it even more affordable for firms wishing to deploy a sophisticated ERP solution. ScaleOcean program has several essential characteristics, which are listed below:

- Unlimited User Access Without Additional Fees, ScaleOcean ERP offers unlimited user access without additional fees, enabling seamless collaboration across all departments in your growing value chain.

- Comprehensive All-in-One Solution, With 200+ modules, ScaleOcean ERP integrates procurement, inventory, sales, and finance, optimizing your entire value chain from start to finish.

- Flat and Reasonable Pricing Model, ScaleOcean ERP’s cost-effective flat pricing ensures all parts of your value chain are supported without hidden fees.

- Customizable to Fit Specific Business Workflows, ScaleOcean ERP’s customization options allow businesses to tailor workflows, boosting efficiency across every link in the value chain.

- Seamless Integration Across Multiple Branches, ScaleOcean ERP connects multiple branches, ensuring real-time data sharing and synchronized value chain operations.

Conclusion

Managing a value chain is critical for streamlining business operations and increasing performance. Companies that analyze each stage can save money and improve customer satisfaction. A well-integrated value chain provides a competitive advantage in today’s market.

ScaleOcean ERP software is an excellent choice for streamlining value chain activities. ScaleOcean increases coordination and efficiency by offering modules for procurement, inventory, sales, and finance. Adopting ScaleOcean’s ERP improves visibility and optimizes processes for long-term growth.

FAQ:

1. What is the meaning of value chain?

A value chain encompasses all the activities a company undertakes to produce and deliver a product or service, from sourcing raw materials to delivering the final product to the consumer. This process includes procurement, production, marketing, distribution, and customer support, all focused on adding value to the product or service.

2. What are the 5 value chains?

The five key components of a value chain typically refer to the main stages in the process of creating and delivering a product:

– Inbound Logistics: The handling and storage of incoming raw materials.

– Operations: The process of converting raw materials into a finished product.

– Outbound Logistics: The distribution of the final product to customers.

– Marketing & Sales: Efforts to advertise and sell the product.

– Service: The ongoing support provided to customers after the sale.

3. What is an example of a value chain?

A common example of a value chain is seen in the food industry. For instance, a food company may source ingredients from suppliers, process them into finished products, package the products, and distribute them to retail outlets. They also market the products to consumers and offer customer service for support post-purchase.

4. What are the 5 primary activities of a value chain?

The five primary activities that make up a value chain are:

1. Inbound Logistics: Managing the receipt and storage of raw materials.

2. Operations: Converting raw materials into the finished product.

3. Outbound Logistics: Delivering the final product to the market.

4. Marketing & Sales: Promoting and selling the product to consumers.

5. Service: Offering after-sale services and customer support.

PTE LTD..png)

.png)

.png)

.png)

.png)