The chemical manufacturing industry is increasingly relying on ERP (Enterprise Resource Planning) systems to streamline operations, enhance efficiency, and ensure regulatory compliance.

Singapore, a vital hub for chemical production in Southeast Asia, requires enterprises to manage complicated production processes while maintaining high quality and optimizing resources.

According to GBR Singapore Chemicals, industry bodies such as ASPRI are pushing for the adoption of Industry 4.0 principles to assist chemical producers with their digital transformation.

Choosing the correct ERP system is critical for maintaining competitiveness and driving long-term growth. This article reviews the top ERP solutions for chemical manufacturers, highlighting their features, benefits, and potential drawbacks.

It emphasizes how these systems support critical activities such as production management, inventory control, and compliance, emphasizing the need to select an ERP system that is adapted to a company’s specific requirements. Learn more here!

- ERP systems for chemical manufacturers play a crucial role in optimizing operations, ensuring regulatory compliance, and boosting efficiency.

- Key benefits of ERP for chemical manufacturers include: real-time data, automation, and seamless integration, enabling manufacturers to enhance production workflows, track inventory in real-time, and optimize supply chain management.

- Top ERPs for the chemical manufacturers industry include ScaleOcean, SAP S/4HANA, Microsoft Dynamics 365, and Oracle NetSuite, each offering unique features tailored to specific business needs.

- ScaleOcean is the best option with customization, integration, and all-in-one solutions for the chemical manufacturing industries

What is ERP for Chemical Manufacturers?

ERP for chemical manufacturers is a tailored software solution that streamlines essential business functions like production, inventory, and quality control, while addressing unique industry needs such as formula management, lot traceability, and adherence to regulatory standards.

ERP systems allow chemical firms to optimize processes, minimize manual chores, and limit the possibility of errors by centralizing these operations. As a result, firms can increase efficiency and collaboration between divisions.

ERP for chemical manufacturing improves operational efficiency while also ensuring regulatory compliance. It includes capabilities for tracking inventory levels, managing raw materials, and adhering to safety guidelines.

What Makes a Great ERP for the Chemical Manufacturing Industry

A great ERP system for the chemical manufacturing industry is one that seamlessly integrates key processes such as formula management, production, inventory control, and compliance tracking.

It should offer specialized features like batch and lot traceability, quality assurance, and regulatory compliance management, ensuring that every aspect of the operation is streamlined and efficient.

Additionally, the system should be customizable to meet the unique needs of chemical manufacturers, offering flexibility in handling complex production formulas, managing hazardous materials, and ensuring full visibility across the supply chain.

An intuitive user interface, real-time data access, and robust reporting capabilities are also essential for empowering employees to make informed decisions and enhance operational efficiency. Ultimately, a great Singapore manufacturing ERP system for the chemical industry drives improved productivity, safety, compliance, and cost savings.

Here are the must-have features of ERP that the chemical manufacturing industry should expect, including:

- Formula and Recipe Management. Formula and recipe management is a critical feature of ERP systems for chemical manufacturers. These systems enable precise control over the creation, modification, and standardization of product formulas. By storing detailed recipe data, ERP systems ensure consistency in production, minimize errors, and allow for seamless scaling of production across different batches and facilities.

- Batch and Lot Traceability. Batch and lot traceability is essential for ensuring product quality and safety in the chemical industry. ERP systems track the origin, production processes, and distribution of each batch or lot, providing full visibility of the supply chain. This feature is crucial for compliance, quality control, and quick identification of any issues that may arise with specific products, enabling rapid corrective actions.

- Regulatory Compliance. Chemical manufacturers face strict regulatory requirements, and ERP systems for chemical companies are designed to help ensure compliance with industry regulations. By automating the tracking and reporting of required certifications, safety standards, and environmental regulations, ERP systems reduce the risk of non-compliance. These systems also generate accurate reports for audits and inspections, streamlining the compliance process.

- Quality Assurance. Quality assurance is a critical aspect of the chemical manufacturing process, and ERP systems integrate quality control measures at every stage of production. These systems automate testing procedures, track quality metrics, and ensure that products meet predefined standards. Real-time monitoring allows for immediate corrective action if any quality issues arise, ensuring consistent product quality and customer satisfaction.

- Inventory Management. Efficient inventory management is vital for chemical manufacturers to maintain production flow and minimize waste. ERP systems optimize inventory levels by automating stock tracking, demand forecasting, and order processing. This ensures that raw materials and finished products are available when needed, reducing the risk of overstocking or stockouts and improving the overall supply chain efficiency.

- Hazardous Material Handling. For chemical manufacturers, handling hazardous materials safely is paramount. ERP systems include features that ensure the proper storage, labeling, and tracking of hazardous substances. These systems manage safety data sheets (SDS), monitor regulatory compliance, and help prevent accidents by alerting employees to potential hazards. By ensuring safe handling, ERP systems protect both employees and the environment.

- Compliance and Customization. ERP systems help chemical companies maintain compliance with industry regulations and standards by automating the tracking and reporting of compliance requirements. The system can be customized to meet specific industry needs, including managing safety, environmental regulations, and quality standards. Customizable workflows ensure the ERP system adapts to the company’s unique processes, ensuring better compliance and flexibility.

- Operational Excellence. A key function of ERP in chemical companies is streamlining operational business, such as supply chain logistics and optimizing manufacturing processes. By automating inventory management, order processing, and production schedules, ERP systems improve efficiency across the entire supply chain. This leads to smoother operations, quicker response times, reduced lead times, and the ability to meet customer demands on time.

- Financial Control. ERP systems provide robust financial control by integrating accounting, procurement, and sales processes. These systems ensure accurate financial reporting, monitor cash flow, and support budgeting and forecasting. By having real-time access to financial data, chemical companies can make informed decisions, maintain profitability, and reduce the risk of financial discrepancies or errors.

- Asset Management. For chemical companies, managing physical assets such as machinery, equipment, and facilities is crucial to maintaining productivity and minimizing downtime. ERP systems help track asset performance, schedule maintenance, and ensure that all equipment is functioning optimally. This proactive approach to asset management helps extend the life of valuable assets and reduce maintenance costs.

- Data and User Experience. ERP systems provide centralized access to real-time data across departments, improving decision-making and operational insights. These systems also offer an intuitive user experience, ensuring ease of use for employees at all levels. With features like customizable dashboards and detailed reporting, ERP systems empower users to analyze data effectively and take quick action to optimize performance.

The chemical manufacturing business confronts unique obstacles, such as managing complicated production processes, adhering to rigorous standards, and ensuring excellent product quality.

To tackle these issues, many factories rely on customized ERP systems that streamline operations, increase productivity, and maintain compliance. Similarly, industries like medical manufacturing also benefit from specialized ERP for medical device manufacturers, which offer tailored features to address specific regulatory requirements.

Top 10 ERP Systems for the Chemical Manufacturing Industry

The appropriate ERP solution may help the chemical manufacturing industry streamline its whole supply chain, enhance inventory management, and automate essential activities to increase productivity.

The following are the top 10 ERP solutions for chemical manufacturing industries, such as ScaleOcean, SAP S/4 HANA, Microsoft Dynamics 365, and many more, each with a set of features tailored to solve industry-specific needs and promote success in this highly competitive field. Here is the complete explanation:

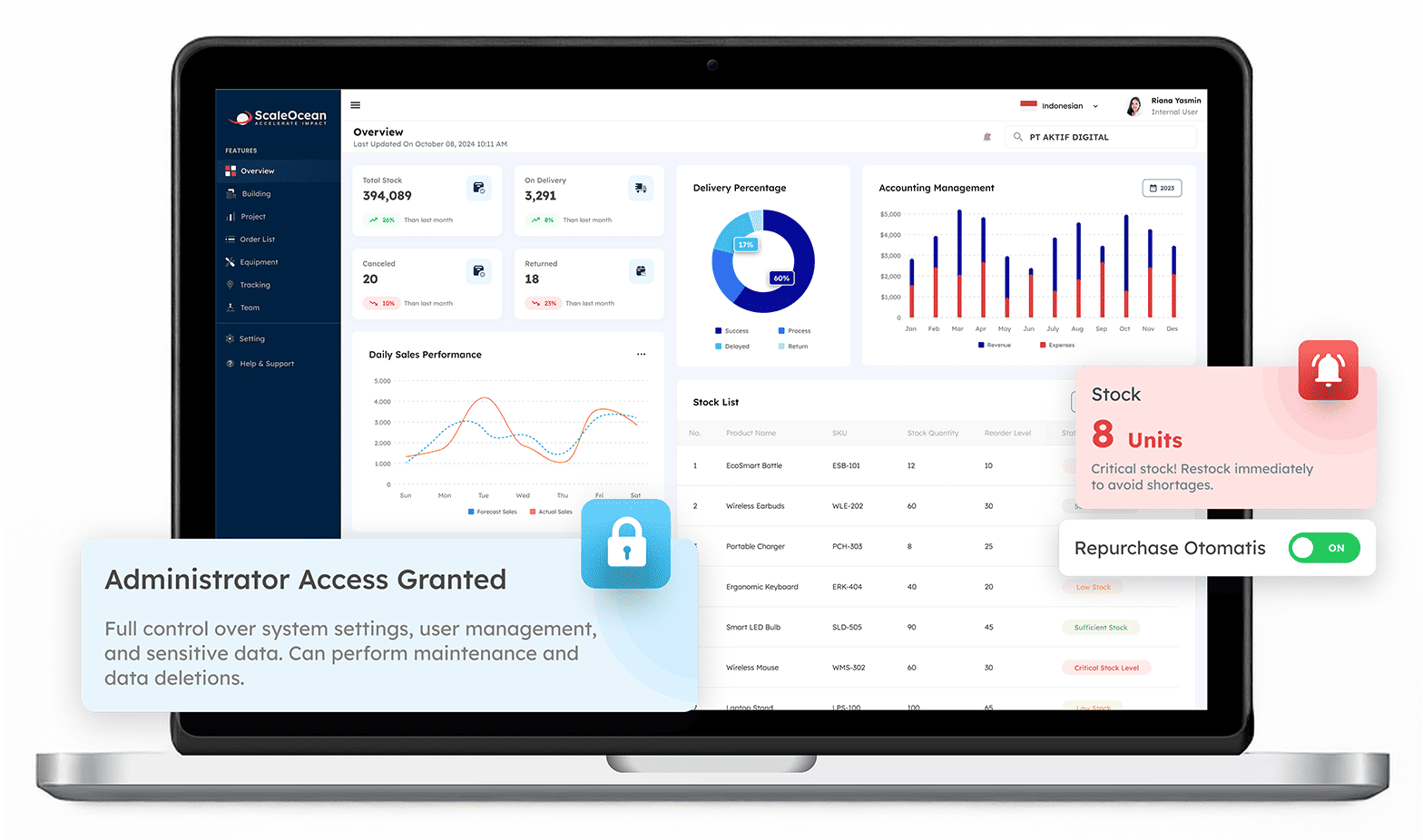

1. ScaleOcean ERP System

ScaleOcean ERP manufacturing is a scalable, cloud-based solution for medium to large chemical businesses. With customizable dashboards and advanced analytics, it helps optimize production management and ensure seamless process integration.

The system provides real-time data to enhance productivity and ensure regulatory compliance. Its modular design allows businesses to tailor the solution to their specific needs, making it ideal for boosting productivity and streamlining operations.

ScaleOcean ERP is a great option for businesses wishing to optimize their operations. With a free demo accessible, producers may see firsthand how the software can improve operational efficiency and compliance.

ScaleOcean is also qualified for the CTC (Cost-to-Company) grant, which provides additional funding for enterprises that engage in technological solutions to increase productivity. This enables manufacturers to get the most out of their investment while also boosting corporate growth with a comprehensive ERP system.

Key Features

- Robust Regulatory Compliance Tools: ScaleOcean ERP includes solutions to ensure compliance with demanding industrial norms.

- Comprehensive Quality Control and Traceability: The technology provides complete visibility into the manufacturing process, allowing firms to meet high-quality standards.

- Efficient Inventory and Resource Management: ScaleOcean ERP assists chemical firms in optimizing inventory levels by offering real-time visibility into stock availability and demand predictions.

- Strong Supply Chain Management Capabilities: ScaleOcean’s comprehensive supply chain management tools help manufacturers streamline their whole supply chain operation.

Recommended for: ScaleOcean is suitable for medium to large-scale companies in various industries, especially the chemical manufacturing industry, that need a system that can be customized to specific needs and integrated smoothly.

| Pros | Cons |

|---|---|

|

|

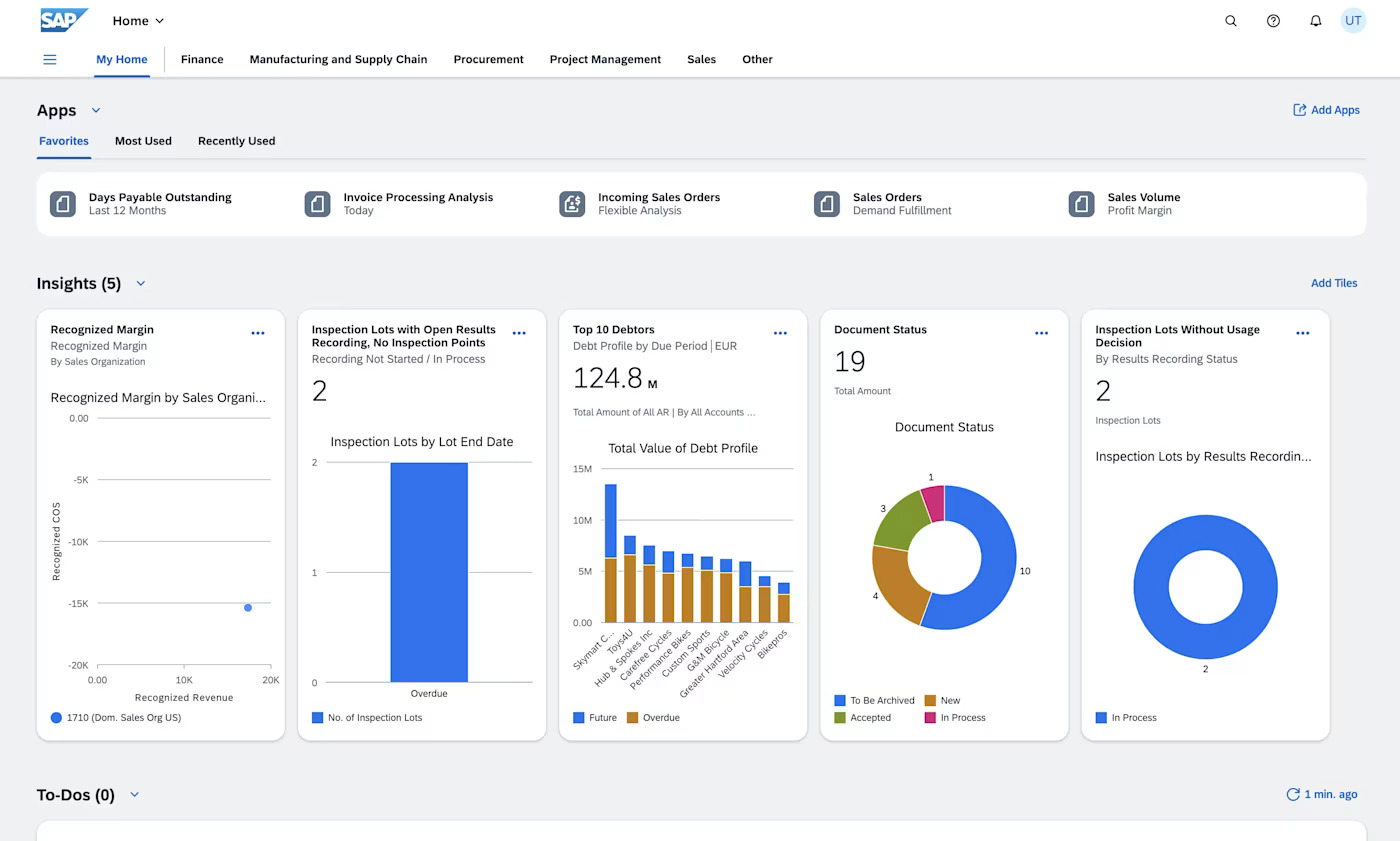

2. SAP S/4HANA

SAP S/4HANA is designed for large chemical companies, which offer strong features to handle intricate, international operations. It is perfect for global chemical makers because it provides capabilities to assist regulatory compliance, AI-driven insights, and advanced analytics.

Businesses can increase operational efficiency across several departments and streamline their procedures with the help of this technology.

Key Features

- Advanced analytics provide data-driven insights.

- AI-driven insights enhance decision-making.

- Industry-specific tools streamline chemical industry operations.

Recommended For: SAP S/4HANA is best for large-scale global chemical enterprises that need global compliance management, and have a supply chain complexity.

| Pros | Cons |

|---|---|

|

|

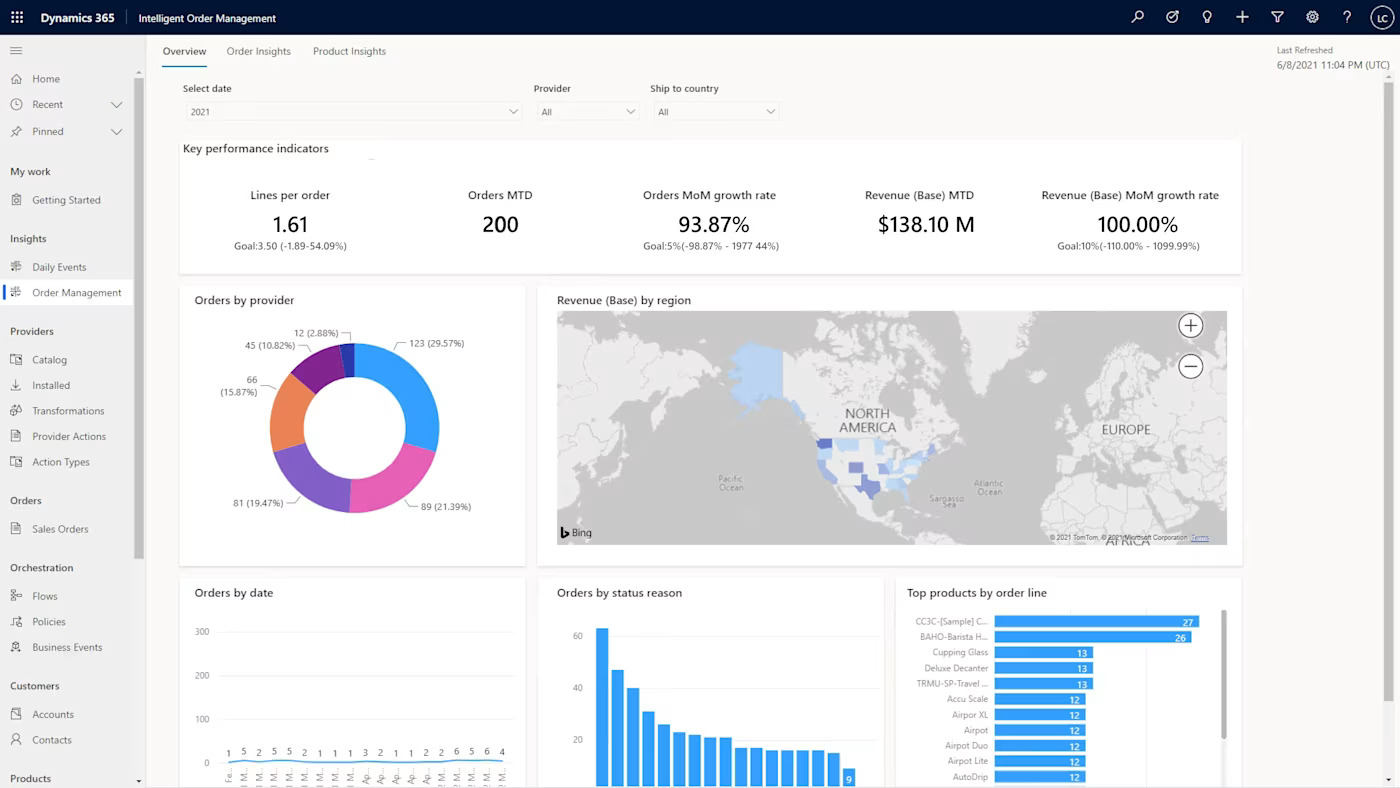

3. Microsoft Dynamics 365

Microsoft Dynamics 365 is a cloud-based solution that provides deployment, financial management, and supply chain features.

This solution increases operational efficiency, especially in finance and operations management, while assisting businesses in scaling. Real-time analytics and smooth interaction with other corporate operations improve decision-making.

Key Features

- Cloud deployment offers flexibility and scalability.

- Financial management tools ensure accurate budgeting and forecasting.

- Supply chain management optimizes inventory and distribution.’

Recommended For: Microsoft Dynamics 365 suites for mid-to-large enterprises that need to integrate seamlessly with the broader Microsoft technology stack.

| Pros | Cons |

|---|---|

|

|

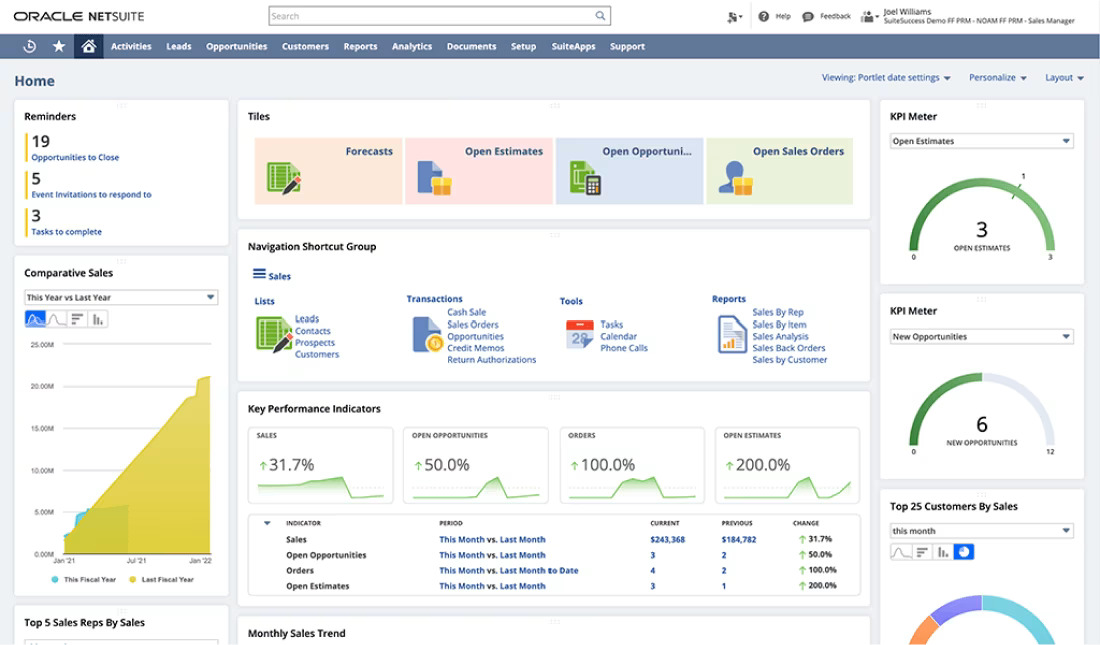

4. Oracle NetSuite

Oracle NetSuite is a cloud-based system designed to support the expansion of the chemical manufacturing industry by assisting companies in streamlining their financial and operational procedures, including managing manufacturing overhead. Because of its scalability, companies may readily grow and change to meet changing needs.

Key Features

- Financial management simplifies accounting and reporting.

- Order processing helps track and manage orders efficiently.

- CRM integration enhances customer relationship management.

Recommended For: Oracle NetSuite is a suite for mid-sized chemical companies or industries that focus on financial management and international expansion.

| Pros | Cons |

|---|---|

|

|

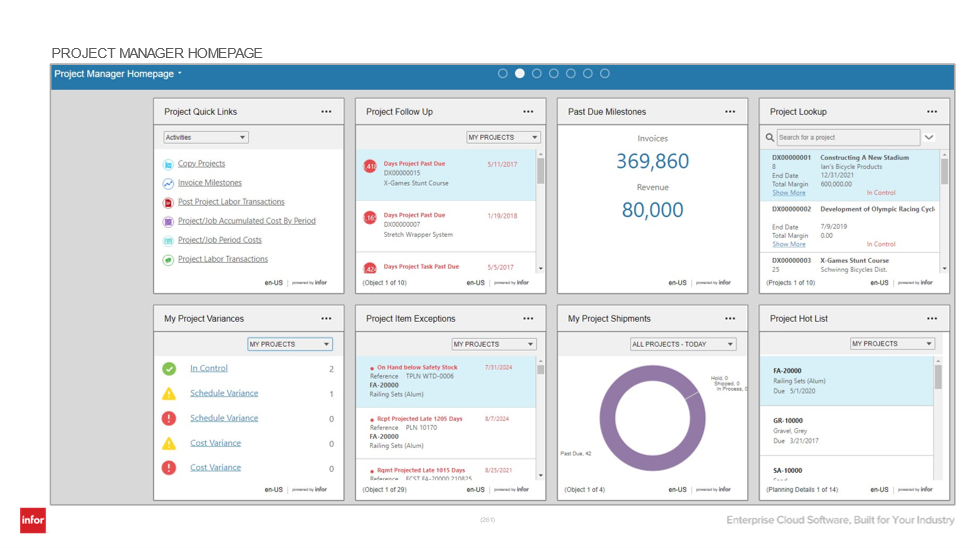

5. Infor CloudSuite

Infor CloudSuite is a system with intricate processes and an option for companies with complex production processes and particular demands because it comes with forecasting tools, compliance tracking, and batch management. It was also increased by the system’s smooth integration across all business units.

Key Features

- Built for the chemical industry with specialized tools.

- Batch management allows for efficient production tracking.

- Compliance tracking ensures adherence to regulations.

Recommended For: Infor is suited for companies in the medium market to large chemical manufacturing companies.

| Pros | Cons |

|---|---|

|

|

6. Acumatica

Acumatica is a cloud-based ERP solution for mid-sized chemical firms seeking a flexible. With capabilities like financial tools, production management, and inventory control, it enables companies to grow and smoothly combine many operational facets. It is simple to use and implement across departments thanks to its intuitive design.

Key Features

- Financial management helps maintain financial health.

- Inventory control ensures optimal stock levels.

- Production management optimizes manufacturing workflows.

Recommended For: Acumatica suites for small-to-medium enterprises (SMEs) that need a modern cloud-ERP, mobile access, and also a modern user interface.

| Pros | Cons |

|---|---|

|

|

7. Odoo

Odoo is a flexible ERP solution for small to medium-sized chemical businesses. It provides a cost-effective and user-friendly solution for organizations looking to grow by offering flexibility in sales, inventory, accounting, and production. Businesses can add features as they develop and expand because of the system’s versatility.

Key Features

- Modular ERP allows customization for specific business needs.

- Sales applications streamline sales processes and order management.

- Inventory management ensures real-time stock control.

Recommended For: Odoo is suited for startup companies, small chemical manufacturing, and companies that have an unlimited budget.

| Pros | Cons |

|---|---|

|

|

8. Sage ERP

Sage ERP offers industry-specific accounting, reporting, and inventory management tools for small to mid-sized chemical businesses. It ensures compliance and improves resource management while streamlining financial and operational procedures.

Its seamless adoption and usage within the company are guaranteed by its simple connection with current systems.

Key Features

- Inventory management helps track raw materials and finished goods.

- Accounting features streamline financial processes.

- Reporting tools provide detailed insights into operations.

Recommended For: Sage ERP or Sage X3 is suited for mid-sized chemical manufacturers that need a stable system and also have a process-specific solution.

| Pros | Cons |

|---|---|

|

|

9. Genius ERP Software for Chemical Manufacturing

Genius ERP’s integrated CRM, inventory management, and production planning features make it ideal for mid-sized chemical firms.

It is perfect for companies looking for more integration because it emphasizes production efficiency and provides customizable choices. Its user-friendly interface streamlines procedures and boosts departmental productivity.

Key Features

- Built-in CRM improves customer management and communication.

- Inventory management helps track material usage and stock levels.

- Production planning optimizes manufacturing workflows.

Recommended For: Genius ERP suites for niche markets of chemical manufacturing that produce custom-engineered equipment as part of their operations.

| Pros | Cons |

|---|---|

|

|

10. Ramco

Ramco is an option for large chemical businesses seeking capabilities for manufacturing, supply chain, finance, and human resources. It unifies all corporate operations into a single platform, guaranteeing operational effectiveness and real-time decision-making. Because it is cloud-based, data is easily accessible, and team collaboration is enhanced.

Key Features

- Cloud-based ERP offers flexibility and scalability.

- Finance features ensure accurate financial tracking and reporting.

- HR management streamlines employee and payroll administration.

Recommended For: Ramco fits for large chemical manufacturing companies with heavy infrastructure needs, and also has complex operations functions.

| Pros | Cons |

|---|---|

|

|

Key Benefits and Functions of Using an ERP for Chemical Manufacturing Specific

Chemical producers benefit from the implementation of an ERP system in a variety of ways, including improved operational efficiency and optimization. ERP systems are critical for guaranteeing the seamless operation of day-to-day activities, from improved resource management to increased compliance.

According to WIPO Magazine, with manufacturing, including chemicals, accounting for nearly 20% of Singapore’s GDP, the chemical industry plays a key role in the nation’s Smart Nation initiative.

The adoption of ERP systems, along with Industrial IoT (IIoT), can significantly enhance productivity, safety, and competitiveness within the sector. Here are the primary advantages of implementing ERP in the chemical production industry:

- Increased Efficiency. Chemical-specific ERPs streamline operations by automating key processes such as procurement, production, and delivery. This integration eliminates manual tasks, reduces the risk of errors, and improves coordination between departments. By optimizing workflows, manufacturers can increase productivity, shorten lead times, and ensure timely delivery, ultimately enhancing their operational efficiency.

- Improved Quality. These systems ensure that products meet rigorous quality standards by integrating quality control measures into every stage of production. With real-time monitoring and automated testing, chemical manufacturers can detect defects early, minimize production delays, and maintain consistent product quality. This improves customer satisfaction and ensures compliance with industry standards.

- Enhanced Visibility. By providing real-time data across the entire supply chain, chemical-specific ERP systems enhance visibility into inventory levels, production progress, and order status.. This transparency allows managers to make informed decisions, predict demand more accurately, and optimize resource allocation. It also enables quicker responses to disruptions and improves overall supply chain efficiency.

- Reduced Costs. Chemical-specific ERPs help minimize waste by optimizing inventory levels and production processes. These systems track raw materials and finished products in real-time, ensuring that resources are used efficiently and minimizing the chances of overproduction or stockouts. Additionally, by improving production workflows and reducing downtime, manufacturers can lower operating costs and boost profitability.

- Better Compliance. Adhering to regulatory standards is critical in the chemical industry. Chemical-specific ERPs simplify compliance by automating the tracking of regulations, ensuring all processes meet legal requirements. The system can automatically generate necessary reports, track safety standards, and keep records up-to-date, making it easier for companies to comply with evolving regulations and industry standards.

- Improved Production Efficiency. An ERP system for chemical producers optimizes production workflows, improving resource management and scheduling. By automating operations like material tracking and batch processing, manufacturers may reduce downtime, increase production productivity, and avoid costly errors. This leads to smoother operations and increased production productivity.

- Better Inventory Management. Effective inventory management is critical in the chemical sector, as raw materials, chemicals, and finished commodities must be precisely tracked. It enables real-time inventory management, eliminating stockouts and lowering surplus inventory, resulting in cost savings and improved cash flow. This real-time control also contributes to maintaining ideal stock levels for continuous manufacturing.

- Real-Time Analytics and Reporting. ERP systems for chemical manufacturing give real-time data and analytics, allowing company leaders to make more informed decisions. These insights, whether used to estimate demand, analyze production performance, or optimize the supply chain, promote efficiency and profitability. The capacity to act on these insights keeps producers ahead of market trends.

- Seamless Integration. Chemical factories frequently use various software packages for distinct roles. An ERP system combines all of these functions into a single platform, assuring data consistency and lowering the risk of errors caused by interacting with various systems. This integration promotes greater collaboration and information flow across departments.

How to Choose the Right ERP for Chemical Manufacturing

Choosing the right ERP for chemical manufacturing is a crucial decision that can greatly impact operational efficiency, compliance, and overall business performance.

With so many ERP options available, it’s essential to consider the specific needs of the chemical industry, such as formula management, regulatory compliance, and batch traceability. Here are the key factors to consider when selecting the right ERP system for your chemical manufacturer.

- Industry-Specific Features. When selecting an ERP for chemical manufacturing, it’s important to ensure the system offers industry-specific features, such as formula and recipe management, batch and lot traceability, and regulatory compliance tracking. These features are crucial for managing production complexity, maintaining product consistency, and ensuring adherence to safety and environmental regulations, which are common in the chemical sector.

- Customization and Flexibility. A great ERP for chemical manufacturing should offer high levels of customization to adapt to the unique processes of your business. Look for systems that allow you to tailor workflows, reporting, and dashboards to match your production methods and regulatory requirements. Flexibility is key for a system that can grow with your business and accommodate changing needs as regulations and processes evolve.

- Integration Capabilities. The ability to integrate with systems like supply chain management, inventory control, and financial platforms is vital when selecting an ERP. Singapore’s food manufacturing ERP systems, for example, offer seamless integration with existing tools, improving data flow and eliminating silos. This enables better collaboration, real-time visibility, and informed decision-making across departments, enhancing overall operational efficiency.

- User Experience and Training. Ease of use is essential for the adoption and success of an ERP system. A user-friendly interface ensures that employees can quickly navigate the system without extensive training. Additionally, the ERP provider should offer robust training resources, ongoing support, and a responsive helpdesk to assist your team in using the system effectively. The simpler the interface, the faster your team can adapt to the new system.

- Scalability and Future-Proofing. As your chemical manufacturing business grows, your ERP system should be able to scale with you. Look for an ERP that can handle increasing production volumes, more complex formulas, and additional regulatory requirements as your business expands. Future-proofing your ERP ensures that it can support long-term growth and adapt to new technologies or industry changes, preventing costly upgrades down the line.

- Cost and ROI. While cost is an important consideration, it should not be the sole factor when selecting an ERP for chemical manufacturing. Focus on the overall value the system brings, including its ability to reduce waste, optimize production, and improve compliance. A great ERP should deliver a clear return on investment by streamlining operations, reducing costs, and increasing productivity in the long run.

Conclusion

Chemical firms rely on ERP to optimize operations, save costs, and ensure compliance with industry requirements. With so many ERP systems available, organizations must choose the best option for their specific requirements.

The appropriate system can streamline operations, increase efficiency, and boost overall production, which is critical for remaining competitive in a continually changing industry.

ScaleOcean ERP stands out as a top choice because it provides a flexible and scalable solution that helps chemical industries grow and improve their operational efficiency. ScaleOcean’s versatility allows it to adapt to your business’s specific needs.

ScaleOcean offers a free demo to assist you in making an informed decision, allowing you to see for yourself how it can streamline your operations and contribute to your business’s success.

FAQ:

1. Which software is used in the chemical industry?

Enterprise Resource Planning (ERP) Systems. ERP for the chemical industry is an all-in-one software solution that integrates and automates key business processes, including production planning, inventory management, quality control, and regulatory compliance.

2. What are the 7 types of chemical industries?

1. Petrochemical industry

2. Agrochemical industry

3. Pharmaceutical industry

4. Specialty chemicals industry

5. Basic chemicals industry

6. Consumer chemicals industry

7. Advanced materials industry

3. What is SCADA in the chemical industry?

The three primary types of manufacturing costs are direct materials, direct labor, and manufacturing overhead.

4. What are the four segments of the chemical industry?

The chemical industry is divided into four key segments: basic chemicals, specialty chemicals, consumer products, and life sciences. Each segment has distinct characteristics and plays a vital role in the overall success of the industry.

PTE LTD..png)

.png)

.png)

.png)

.png)