The medical device industry is experiencing rapid growth along with technological advancements and the increasing demand for more advanced healthcare. This is evident in Marketsandmarkets projections for the medical device industry, which show a market value of $671 billion by 2027 and contract manufacturing reaching $149.4 billion by 2029.

Medical device manufacturing companies that don’t utilize advanced technology like ERP often face numerous issues that can hinder efficiency and growth. These include inefficient inventory management, difficulty complying with regulations and quality standards, uncoordinated manufacturing processes, and a lack of data and reporting transparency.

Therefore, to avoid these issues, it’s crucial to adopt the best ERP software for companies that can easily improve operational efficiency, data transparency, and comply with strict regulations in Singapore.

To choose the best ERP software, consider the following 15 recommendations for medical device ERP software, such as ScaleOcean, SAP, Sage X3, Oracle, and more, to find the solution that best suits your business needs. Learn more here

- ERP for medical device manufacturers is essential for streamlining operations, ensuring compliance, improving traceability, and enhancing efficiency in production.

- The best ERP for medical device manufacturers in Singapore, such as ScaleOcean ERP system, SAP, Oracle, and Acumatica, with each offering industry-specific functions.

- Must-have features in ERP for medical device manufacturers include MRP, inventory control, PDM, RoHS compliance, and serial/lot tracking.

- ScaleOcean can be the best ERP solution for medical device manufacturers, offering industry-specific capabilities, real-time data visibility, and IIoT integration.

What is ERP for Medical Device Manufacturers?

ERP for medical device manufacturers integrates various business functions to streamline operations, ensure compliance, and support quality control and traceability.

This ERP system can help manufacturers manage inventory, production schedules, regulatory requirements, and financials in one unified platform.

Automating the process reduces manual errors, enhances efficiency, and improves decision-making. ERP for manufacturing companies in the medical device industry is necessary for businesses that want to remain competitive while adhering to strict industry standards, regulatory guidelines, and maintaining product quality throughout the supply chain.

How ERP of Healthcare and Medical Devices Simplifies Compliance

ERP systems designed for healthcare and medical device companies play a crucial role in simplifying compliance with regulatory requirements. These systems automate and streamline key processes, such as tracking product documentation, maintaining audit trails, and ensuring traceability of medical devices from production to distribution.

These systems automate processes like tracking product documentation, maintaining audit trails, and ensuring traceability throughout the product lifecycle. For example, the U.S. Food and Drug Administration (FDA) 21 CFR 820 QMS requirements are designed to ensure the safety and efficacy of medical devices.

Medical device manufacturers must adhere to relevant sections of FDA Part 820 to comply with good manufacturing practices. As a result, an effective ERP system becomes a critical component of the overall quality management system for medical devices, one that needs to be validated by regulatory agencies.

By integrating modules for quality control, inventory management, and real-time reporting, ERP systems help businesses meet regulations such as FDA, CE Marking, and ISO standards, ensuring compliance and reducing the risk of non-compliance.

Benefits of ERP for Medical Device Manufacturers

Implementing an ERP for medical device manufacturers can transform operations in the highly regulated and complex world of medical device manufacturing. ERP solutions provide significant benefits that align with industry demands and compliance requirements, ranging from increased visibility to faster workflows.

1. Comprehensive Process Visibility and Control

An ERP system provides end-to-end visibility across all manufacturing stages, from procurement to production and distribution. This ensures better decision-making, improved resource allocation, and adherence to strict regulatory standards, fostering operational efficiency and compliance.

2. Instant Access to Business Insights

Real-time data analytics enables medical device manufacturers to monitor key performance indicators (KPIs) and make informed decisions quickly. The characteristics of ERP also include the capability to improve agility, reduce downtime, and facilitate proactive problem-solving in a fast-paced industry.

3. Streamlined Operational Workflows

ERP systems simplify intricate processes by automating repetitive tasks and integrating disparate systems. This reduces manual errors, speeds up production cycles, and ensures better coordination between departments, ultimately increasing productivity.

4. Advanced Tracking and Traceability

Robust tracking tools in an ERP allow for precise monitoring of materials, components, and finished products. This is critical for complying with regulations such as FDA 21 CFR Part 820 and ensuring timely identification of issues, thereby reducing risks.

5. Financial Integration for Accountability

Integrated financial modules provide a unified view of costs, revenues, and profitability. This ERP also has a feature specifically for a manufacturing accounting system to ensure transparency, ensuring accurate budgeting, cost control, and compliance with financial reporting standards, enhancing overall fiscal responsibility.

6. Enhanced Cash Flow and Banking Control

ERP systems offer tools to manage banking transactions, monitor cash flow, and optimize working capital. This ensures financial stability, reduces liquidity risks, and supports strategic investments in growth and innovation.

What are the Main ERP Needs of a Medical Device Company?

In the highly regulated and competitive medical device industry, companies must ensure their operations are efficient, compliant, and able to meet strict quality standards. To ensure your Medical Device ERP meets all requirements, you must first define what those requirements are.

Here are 10 things to look for when you are choosing an ERP for medical devices and health manufacturing, including:

- Compliance with quality standards like TS13485 and ISO 9001. The ERP should ensure that your company adheres to industry-recognized quality standards for general quality management. These certifications help guarantee that your products are safe, effective, and produced under strict quality guidelines.

- Fulfillment of FDA software validation requirements, ensuring that the software operates in compliance with FDA regulations for medical device manufacturers. This is essential for gaining approval from regulatory bodies and maintaining market access.

- Secure electronic signature and document control for 21 CFR Part 11 compliance. The ERP must include secure electronic signatures and robust document control. This ensures that all electronic records and signatures are legally binding, reducing the risk of fraud or non-compliance.

- Full visibility, control, and audit trail of manufacturing processes, offering full control over production workflows and a comprehensive audit trail. This helps ensure that every step of the process is documented, making it easier to identify and rectify any issues that may arise.

- Integrated Corrective Action/Preventive Action (CAPA) functionality, which helps identify and resolve quality issues. This feature is vital for maintaining product quality and ensuring compliance with industry regulations, while also preventing future occurrences of the same issues.

- Lot and serial tracking with traceability. The ERP system must allow for lot and serial tracking, ensuring that each product can be traced throughout its lifecycle. This feature is vital for both regulatory compliance and managing product recalls, should they be necessary.

- Warranty and service tracking capabilities enable tracking of warranty information and service records for medical devices. This ensures that customers receive the appropriate support, helps manage warranty claims, and allows businesses to track device service history for better maintenance planning.

- Assurance of regulatory compliance. A medical device ERP must ensure continuous compliance with all relevant regulatory bodies, such as the FDA, CE, and other international standards. The system should be regularly updated to reflect changes in regulations, making it easier for companies to maintain compliance.

- Supplier management and approved vendor settings. It allows businesses to track approved vendors and maintain quality control over incoming materials. This ensures that only certified suppliers provide materials, which is critical for maintaining compliance and ensuring the quality of medical devices.

- Elimination of time-consuming, paper-based tracking systems. The ERP should replace outdated paper-based systems with digital tracking solutions. This not only saves time and reduces human error but also ensures that data is stored securely and is easily accessible for audits and regulatory reporting.

Features Must-Have in ERP for Medical Device Manufacturers

An ERP system in the tightly regulated medical device manufacturing sector must include specialized functionalities to ensure efficiency, compliance, and quality. These critical features optimize workflows, improve traceability, and ensure strict industry compliance.

1. Material Requirement Planning (MRP)

MRP (Material Requirement Planning) tools optimize the procurement and allocation of raw materials, ensuring timely availability for production. This minimizes waste, reduces costs, and prevents delays, enabling manufacturers to meet demand while maintaining efficient resource utilization.

2. Inventory Control

Effective inventory management ensures optimal stock levels, reducing overstocking or shortages. Real-time tracking of materials and components enhances accuracy, minimizes waste, and supports just-in-time manufacturing, crucial for cost-efficiency and operational smoothness.

3. Product Data Management (PDM)

PDM consolidates product-related data such as designs, specifications, and revisions, ensuring uniformity, enhancing teamwork, and speeding up market entry while adhering to regulatory and quality standards.

4. RoHS Compliance

An ERP for medical device manufacturers with RoHS compliance features ensures that materials and components comply with the Restriction of Hazardous Substances (RoHS) directive. This is critical for global market access, environmental responsibility, and compliance with safety regulations.

5. Serial, Lot Tracking, and Traceability

Robust tracking tools enable precise monitoring of serial and lot numbers throughout the supply chain. This ensures accountability, simplifies recalls, and supports compliance with FDA and ISO standards, enhancing product safety and quality assurance.

15 Best ERPs for the Medical Device Industry in Singapore

Choosing the right ERP system is essential for medical device manufacturers to streamline production, ensure compliance, and enhance efficiency. Here is the 15 best ERP software for medical device manufacturers list that is tailored for industry-specific needs in Singapore Companies, including:

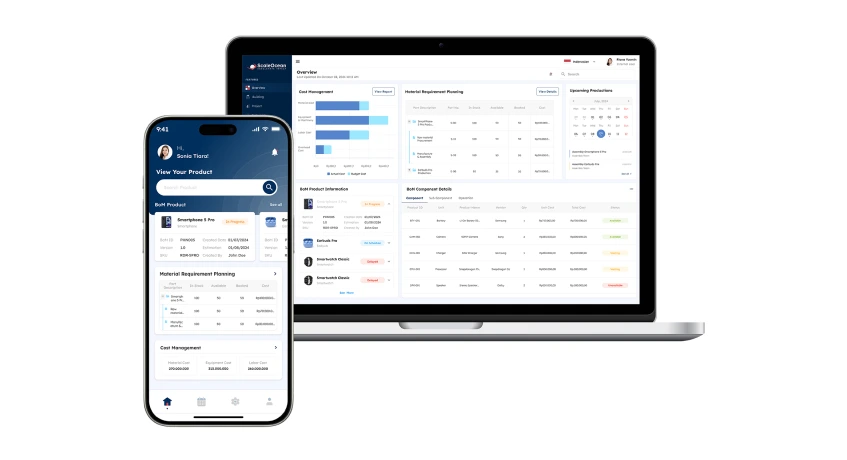

1. ScaleOcean ERP

ScaleOcean Medical Device Manufacturing ERP is an integrated enterprise resource planning (ERP) solution tailored specifically for medical device manufacturers. This software streamlines critical business processes such as production planning, inventory control, regulatory compliance, quality assurance, and financial management into a centralized platform.

Ensuring real-time data visibility across departments, it enhances operational efficiency, automates workflow processes, and maintains compliance with stringent medical device industry regulations, such as FDA and ISO 13485. For medical device manufacturers, maintaining high precision and regulatory compliance is non-negotiable.

ScaleOcean ERP stands out because of its deep industry-specific capabilities, flexible modular structure, and cost-effective pricing. Unlike other ERP systems, ScaleOcean offers built-in quality management, traceability, and seamless IIoT integration, ensuring full control over the production lifecycle.

Designed for compliance and efficiency, ScaleOcean is an ideal choice for Singaporean manufacturers seeking a future-proof ERP solution. Request a free demo to see how it can transform your operations.

Key Features

- Regulatory Compliance Management: FDA & ISO 13485 compliance tracking.

- End-to-End Traceability: Full product lifecycle monitoring system.

- Automated Quality Control: Smart defect detection and reporting.

- IIoT Integration: Real-time machine and production monitoring.

- Multi-Location Inventory: Centralized stock control across facilities.

| Pros | Cons |

|---|---|

|

|

2. SAP Business ByDesign

SAP Business ByDesign is a cloud-based enterprise resource planning (ERP) solution suited for small and medium-sized businesses.

It consolidates numerous company operations, such as financial management, customer relationship management, supply chain management, and project management, onto a single platform to increase operational efficiency and decision-making.

Key Features:

- Financial Management

- CRM 360 View

- Project Management

| Pros | Cons |

|---|---|

|

|

3. Sage X3

Sage X3 is an Enterprise Resource Planning (ERP) solution designed to streamline and optimize business processes across various industries. It also allows for increased operational efficiency, real-time data insights, and adherence to strict regulatory standards

This software provides specialized functionality for medical device manufacturers, integrating financial administration, supply chain operations, manufacturing processes, and compliance management into a single solution.

Key Features:

- Advanced Financial Management

- Robust Supply Chain Management

- Manufacturing Process Optimization

| Pros | Cons |

|---|---|

|

|

4. Oracle Cloud

Oracle Cloud ERP is a cloud-based Enterprise Resource Planning application that automates and integrates multiple business operations.

It provides specialized functions for medical device makers, including financial management, supply chain operations, production planning, and compliance tracking, to ensure industry compliance and improve operational efficiency.

Key Features:

- Compliance Tracking

- Manufacturing Operations

- Financial Management

| Pros | Cons |

|---|---|

|

|

5. Acumatica

Acumatica is a cloud-based Enterprise Resource Planning (ERP) solution that automates financial administration, supply chain logistics, and customer relationship management (CRM).

For medical device manufacturers, Acumatica offers specialized functionalities that ensure compliance with industry regulations, enhance operational efficiency, and provide real-time data insights.

Key Features:

- Compliance Management

- Integrated CRM

- Real-Time Data Access

| Pros | Cons |

|---|---|

|

|

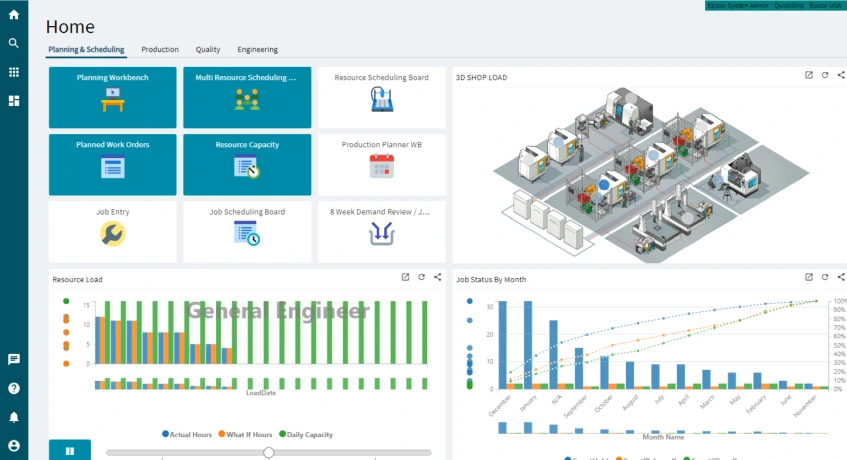

6. Epicor Kinetic

Epicor Kinetic is an ERP solution designed to handle the complex demands of manufacturing industries, including medical device production.

It streamlines key operations like production planning, supply chain management, financial processes, and compliance tracking within a single platform. This integration enhances efficiency and ensures manufacturers meet strict industry regulations effectively.

Key Features:

- Advanced Manufacturing Execution

- Integrated Financial Operations

- Comprehensive Compliance Management

| Pros | Cons |

|---|---|

|

|

7. Microsoft Dynamics 365

Microsoft Dynamics 365 is a cloud-based Enterprise Resource Planning (ERP) solution that integrates many business activities such as finance, supply chain management, manufacturing, and customer relationship management.

It provides specialized functions to medical device manufacturers to maintain regulatory compliance, streamline operations, and improve overall efficiency.

Key Features:

- Advanced Analytics and AI

- Unified ERP and CRM

- Cloud-Based Solution

| Pros | Cons |

|---|---|

|

|

8. Infor Cloudsuite

Infor Cloudsuite Industrial (formerly SyteLine) is an ERP solution designed to integrate business proc++esses within manufacturing industries. It provides specialized functions for medical device manufacturers and is also one of the food industry’s manufacturing ERP software, ensuring compliance and efficiency.

Key Features

- Quality Control Modules

- Supply Chain Management

- Regulatory Compliance Tools

| Pros | Cons |

|---|---|

|

|

9. SAP S/4 HANA

SAP S/4HANA is an Enterprise Resource Planning (ERP) system that integrates various business processes into a unified platform. It provides specialized functionalities for medical device manufacturers, including finance, procurement, quality management, production, and compliance, to ensure conformity to tight industry requirements.

Key Features:

- Advanced Supply Chain Management

- Real-Time Analytics

- Comprehensive Financial Management

| Pros | Cons |

|---|---|

|

|

10. QAD Systems

QAD Adaptive ERP is a cloud-based Enterprise Resource Planning system designed to streamline and integrate various business processes within manufacturing industries.

For medical device manufacturers, it offers specialized functionalities that encompass production planning, supply chain management, quality control, and regulatory compliance, ensuring adherence to stringent industry standards

Key Features:

- Regulatory Compliance Tools

- Supply Chain Management

- Quality Control Modules

| Pros | Cons |

|---|---|

|

|

11. Deacom ERP

Deacom ERP, developed by ECI Software Solutions, is a Enterprise Resource Planning system tailored for batch and process medical device manufacturers. It also guarantees that operations are streamlined, data is available in real time, and high industry requirements are met

It integrates various business processes such as production planning, quality control, regulatory compliance, inventory management, and customer relationship management into a single, unified platform.

Key Features:

- Integrated Quality Control

- Advanced Inventory Management

- Comprehensive CRM Functionality

| Pros | Cons |

|---|---|

|

|

12. Priority ERP

Priority Software offers an Enterprise Resource Planning (ERP) solution tailored for medical device industry.

This system integrates critical business processes, including material requirements planning, inventory control, product data management, and quality assurance. By providing end-to-end manufacturing capabilities, it ensures compliance with industry standards and streamlines operations.

Key Features

- Serial and Lot Tracking:

- Product Data Management (PDM)

- Material Requirements Planning (MRP)

| Pros | Cons |

|---|---|

|

|

13. SYSPRO

SYSPRO ERP is an Enterprise Resource Planning solution tailored for manufacturing and distribution companies, including those in the medical device sector.

It integrates various business processes such as manufacturing operations management, inventory optimization, procurement, and quality control into a unified system, ensuring compliance with industry regulations and enhancing production efficiency.

Key Features:

- Traceability

- Inventory Optimization

- Manufacturing Operations Management

| Pros | Cons |

|---|---|

|

|

14. Rootstock

Rootstock ERP is a cloud-based Enterprise Resource Planning system designed to streamline and integrate various business processes within the manufacturing sector, specifically tailored for medical device manufacturers.

It integrates inventory management, production scheduling, quality control, and compliance tracking into a single platform, improving operating efficiency and assuring adherence to strict industry rules.

Key Features:

- Salesforce Integration

- Inventory Management

- Production Scheduling

| Pros | Cons |

|---|---|

|

|

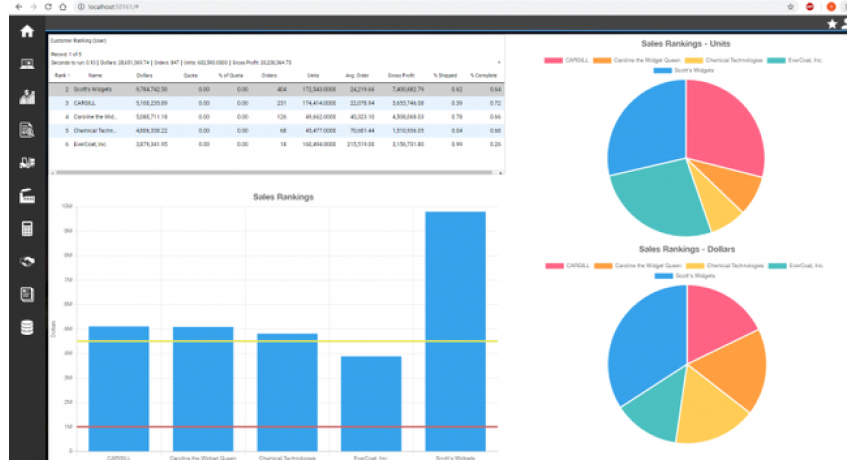

15. DELMIAWorks

DELMIAWorks, originally known as IQMS, is an Enterprise Resource Planning (ERP) system designed for the manufacturing industry, specifically for the medical device industry.

It unifies numerous business operations such as production planning, quality management, inventory control, and regulatory compliance into a single platform, improving operational efficiency and assuring adherence to strict industry standards.

Key Features

- Planning and Scheduling

- CRM and Sales Analytics

- Quality Management System

| Pros | Cons |

|---|---|

|

|

How to Choose a Medical Device Manufacturer in Singapore

Choosing the appropriate ERP manufacturing software for Singapore companies in the medical device industry is essential for maintaining operational efficiency and meeting regulatory standards.

An effective ERP optimizes workflows, enhances traceability, and accommodates industry-specific needs, highlighting the importance of carefully assessing key factors during the selection process.

1. Assess Industry-Specific Needs

Identify unique requirements such as FDA compliance, traceability, and quality management. Choose an ERP tailored to medical device manufacturing to ensure it meets regulatory standards and supports specialized workflows, reducing implementation risks.

2. Evaluate Scalability and Flexibility

Choose a scalable ERP that can grow with your company. Ensure that it adapts to changing regulations, production volumes, and technological advancements, delivering long-term value while minimizing the need for costly upgrades.

3. Prioritize Integration Capabilities

Select an ERP that works seamlessly with existing systems like CRM, PLM, and MES. Smooth data flow across platforms improves efficiency, reduces errors, and creates a unified operational ecosystem, such as ERP software for chemical manufacturers in Singapore.

4. Verify Compliance and Security Features

Ensure the ERP complies with industry regulations like FDA 21 CFR Part 820 and ISO 13485. Robust security features, including data encryption and access controls, are essential to protect sensitive information and maintain compliance.

5. Consider Vendor Expertise and Support

Choose a vendor with proven experience in medical device manufacturing. Reliable customer support, training, and regular updates are crucial for smooth implementation, ongoing optimization, and addressing industry-specific challenges.

6. Flexible and Affordable Deployment options

The manufacturer should offer flexible ERP deployment options, such as cloud-based systems, providing access from anywhere. Mobile access through devices like iPads, iPhones, and Android phones enhances real-time decision-making and ensures efficient, on-the-go management.

7. Device and Batch History Reports and support for FDA Audits/Recalls

The manufacturer should provide detailed device and batch history reports, which are essential for tracking production data. This capability supports FDA audits, recalls, and ensures traceability in case of product safety concerns or regulatory investigations.

Conclusion

As the medical device industry expands, reaching a projected $671 billion by 2027, manufacturers must adapt to increasing complexity and regulatory demands. A well-implemented ERP system is no longer an option, but rather a requirement for streamlining workflows, ensuring compliance, and preserving operational efficiency.

Businesses that use systems designed for medical device manufacturing can improve traceability, automate quality control, and seamlessly integrate financial management, allowing them to remain competitive in a shifting market.

For Singaporean manufacturers looking for a future-proof solution, ScaleOcean Manufacturing ERP delivers industry-specific capabilities, real-time data visibility, and seamless IIoT integration. Its modular structure and unlimited user model provide cost-effective scalability, ensuring long-term growth and compliance. Request a free demo today and experience how ScaleOcean can streamline your operations and drive efficiency.

FAQ:

1. What is the best ERP for healthcare?

The best ERP systems for healthcare include:

1. ScaleOcean ERP: A comprehensive, all-in-one solution for healthcare operations, including patient management, financials, and inventory.

2. Oracle NetSuite

3. Sage Intacct

4. QuickBooks Online

5. Microsoft Dynamics 365

6. Acumatica

7. SAP ERP

8. Xero

9. Odoo

These systems streamline healthcare operations, improving efficiency and compliance.

2. What is the ERP system for manufacturing?

Enterprise Resource Planning (ERP) is a software system that integrates core business functions, such as finance, HR, manufacturing, supply chain, sales, and procurement, into one unified platform. ERP systems for manufacturing industry, like ScaleOcean ERP software, SAP ERP, Oracle, and Acumatica, enhance operational efficiency by providing a single source of truth and streamlining processes across production and supply chains.

3. What is ERP system in pharmaceutical industry?

Pharmaceutical industry ERP software centralizes and integrates data from various business functions such as manufacturing, vendor cost management, accounting, supply chain, and raw materials. Solutions like ScaleOcean ERP software, Oracle NetSuite, and Microsoft Dynamics 365 help streamline these processes, ensuring compliance and providing real-time insights for better decision-making.

4. What are ERP systems in healthcare?

Healthcare ERP solutions are integrated software systems that manage various processes and resources within healthcare organizations. These best ERP for Singapore companies can help track inventory, manage billing, schedule staff, handle appointments, and order supplies, improving efficiency and ensuring compliance in healthcare management.

PTE LTD..png)

.png)

.png)

.png)

.png)