Singapore’s dynamic corporate landscape is characterized by rapid technical breakthroughs and shifting consumer behaviors. According to DBS SME Banking, the country is projected to achieve an economic growth rate of 2.8% in 2025, in line with the estimated medium-term growth of 2-3%. To remain competitive, firms must adapt to changing conditions and anticipate client wants. Demand forecasting has become an important approach for businesses to stay agile and efficient in this evolving environment.

This article discusses the relevance of demand forecasting, including methodology and industry-specific applications. It also demonstrates how integrating CRM systems can improve forecasting accuracy, hence enhancing business performance and assisting firms in making better decisions.

- Demand forecasting predicts future customer demand using historical data and market trends, enabling businesses to make informed decisions and plan effectively.

- There are several types of demand forecasting, including short-term, long-term, passive, active, and causal, allowing businesses to choose the best method based on their needs.

- Demand forecasting methods, such as qualitative techniques and quantitative methods like time series analysis and machine learning models, improve accuracy in predicting future demand.

- Integrating ScaleOcean’s CRM Software with inventory management enhances forecasting by using customer data, helping businesses adjust inventory levels and respond to demand changes more effectively.

What Is Demand Forecasting?

Demand forecasting is the practice of projecting future customer demand for a product or service using historical data, market trends, and other pertinent information. Businesses can make more informed judgments by studying previous sales data and current market conditions.

The primary purpose of demand forecasting is to assist businesses in properly planning their inventory, production, and resource allocation. This enables them to satisfy consumer demand without overstocking or understocking, resulting in more efficient operations and a lower risk of both excess inventory and stockouts. WMS System can play a critical role in inventory control, ensuring that products are stocked according to demand forecasts.

The Importance of Demand Forecasting for Businesses

Effective demand forecasting is critical for businesses to remain competitive. It enables businesses to better manage resources and match operations with future market trends. Accurate projections enable firms to achieve operational success and improve overall performance. Let’s look at the key advantages of demand forecasting in business:

1. Operational Efficiency

Accurate demand forecasting enables organizations to optimize inventory levels, reducing storage costs and stockouts. This leads to more efficient operations because products are readily available when needed. Better planning can also help businesses avoid the inefficiencies of overstocking, which wastes resources and contributes to obsolete inventory. As a result, businesses may focus on more efficient operations that increase productivity.

2. Financial Planning

Demand forecasting is critical for anticipating future sales and revenue, which affects a company’s financial planning. Businesses can use these insights to create more accurate budgets and set achievable financial goals. Companies that anticipate demand can better deploy resources, lowering the likelihood of unanticipated expenses. This proactive approach ensures a company’s financial stability over time.

3. Strategic Decision-Making

Businesses that rely on precise demand estimates are able to make better strategic decisions about procurement, production, and marketing. Forecasting helps organizations foresee prospective trends and consumer behavior, allowing them to alter their strategies accordingly. This ensures that businesses are prepared for market changes, such as increases or decreases in demand. As a result, it promotes long-term success by matching company practices with consumer requirements.

4. Customer Satisfaction

One of the most significant advantages of demand forecasting is the direct impact on customer satisfaction. Businesses can establish strong client loyalty by making sure their items are available when they are needed. Accurate forecasting helps to maintain consistent product availability and avoid stockouts, thereby improving the overall customer experience. Satisfied clients are more likely to return, resulting in long-term commercial ties.

Advantages of Accurate Demand Forecasting

Effective demand forecasting provides numerous benefits to businesses, including increased operational efficiency and better decision-making. Understanding future demand allows businesses to better manage resources, inventory, and production. Various factors, such as historical data, market trends, and external events, influence the accuracy of forecasts and, in turn, contribute to the benefits of demand forecasting. The following are the main advantages of demand forecasting:

1. Efficient Inventory Control

Accurate demand estimates enable organizations to maintain optimal stock levels. This guarantees that businesses do neither overstock, which can lead to additional expenditures, or understock, which can result in lost sales. Proper inventory management balances expenses while maintaining product availability for customers. Material requirement planning (MRP) systems can help ensure that the correct materials are available in line with demand forecasts.

2. Enhanced Production Scheduling

Reliable demand forecasts enable businesses to plan their production more efficiently. Companies that align manufacturing with anticipated demand can reduce delays, optimize resource use, and reduce waste. This leads to a more efficient production process and smoother operations. Product life cycle management can also contribute to more accurate forecasting by tracking products from introduction to decline.

3. Cost Reduction

Accurate forecasting helps organizations reduce wasteful expenses by preventing unnecessary inventory costs, optimizing supply chain management, and eliminating rush orders. Seasonal fluctuations and external factors, such as economic shifts or market disruptions, should be considered, as they can affect supply chain performance and demand patterns.

4. Improved Cash Flow Forecasting

Knowing future demand allows organizations to better plan their financial flows. Companies can forecast sales to predict when cash inflows and outflows will occur, allowing them to manage their finances more efficiently and avoid liquidity concerns. Changes in consumer behavior and preferences, often influenced by external factors like holidays or economic conditions, must be taken into account to ensure accurate cash flow projections.

5. Increased Customer Satisfaction

Demand forecasting is critical for meeting customers’ needs on schedule. Businesses can improve the customer experience and loyalty by having products available when demand is high. Understanding seasonality and competitor activity enables companies to adjust their marketing and inventory strategies, ensuring products are readily available during peak demand periods, leading to higher customer satisfaction.

6. Data-Driven Decision Making

Demand forecasting provides useful information for strategic decision-making. Whether it’s pricing, marketing, or supply chain management, knowing what to expect allows firms to align their actions with market conditions and consumer preferences. External factors and supply chain limitations should be factored into forecasting models to enhance the precision of decision-making and help businesses stay competitive.

7. Avoidance of Stockouts

Stockouts can result in lost sales, consumer unhappiness, and a tarnished reputation. By accurately estimating demand, firms can reduce the risk of stockouts and ensure product availability even during peak demand periods. Market trends and seasonal demand should be considered to anticipate changes and prevent stockouts, especially in industries with fluctuating demand due to weather or holidays.

8. Gaining a Competitive Edge

Companies that excel in demand forecasting can stay ahead of competitors by responding quickly to market changes. They can adjust inventory and production plans ahead of time, ensuring they meet customer expectations more efficiently. According to BusinessTimes, despite stronger-than-expected first-quarter growth, Singapore’s MTI kept its 2025 growth forecast at 0 to 2 percent, highlighting the need for businesses to adapt to economic changes and adjust strategies accordingly.

How to Predict Demand Accurately

Demand forecasting is a critical process for businesses seeking to improve their operations. Predicting future demand enables businesses to manage their inventories, production, and resources more efficiently. The following are the primary methods and stages for accurately forecasting demand:

1. Collect Historical Data

Begin by collecting prior sales data to better understand demand patterns. Historical data can provide valuable insights into trends and consumer behavior. Analyzing this data allows us to estimate future demand based on repeating patterns. This foundation is critical for developing accurate forecasts.

2. Analyze Market Trends

Understand how market development might affect product demand. Consumer preferences, emerging technology, and economic factors all have a significant impact. With this monitor, businesses can adjust to changing market conditions. Understanding the trend helped to improve forecast accuracy.

3. Consider Seasonality

Seasonal differences, such as holidays or weather, might have an impact on product demand. Identifying seasonal patterns allows for more effective inventory and production planning. It ensures that firms are ready for variations during peak periods. Recognizing seasonality reduces overstocking and stockouts.

4. Use Forecasting Methods

Use technologies such as time series analysis or machine learning to examine historical data. These strategies use historical trends and current market conditions to make accurate predictions. The correct forecasting approaches increase prediction accuracy. Using advanced techniques provides better insight into future demand.

5. Refine and Adjust Regularly

Update and alter forecasts in response to new data and market movements. Continuous refinement helps to keep forecasts relevant and accurate. Regular review ensures that forecasts reflect current trends and situations. Making timely modifications makes predictions relevant to current business reality.

Types of Demand Forecasting

Demand forecasting can be divided into several forms, each providing a distinct function based on periods and data analysis. Depending on their needs, businesses can use these methods to better plan their operations and meet customer expectations. The following types of demand forecasting are frequently utilized to satisfy specific forecasting needs:

1. Short-Term Forecasting

Short-term forecasting focuses on estimating demand for a specific time period, usually up to a year. This method is especially useful for businesses that experience seasonal fluctuations in demand, allowing them to adjust their inventory and production plans accordingly.

2. Long-Term Forecasting

Long-term forecasting predicts demand over a longer time period, assisting firms with strategic planning. It is critical for businesses looking to increase capacity, align production schedules, and prepare for future market changes and growth opportunities.

3. Passive Forecasting

Passive forecasting is primarily reliant on historical data, presuming that previous demand patterns will persist into the future. This strategy is beneficial when demand is relatively stable over time, but it may fail to catch unexpected market changes or variations in consumer behavior.

4. Active Forecasting

Active forecasting uses current market data and external factors to adjust predictions in real time. This strategy improves forecast accuracy by accounting for changes in consumer preferences, new trends, and economic adjustments.

5. Causal Forecasting

Causal forecasting seeks to understand the cause-and-effect relationships between variables such as marketing campaigns, promotions, and economic conditions. By studying these factors, firms may better foresee demand fluctuations and plan their operations.

Key Methods of Demand Forecasting and Their Examples

Demand forecasting is based on a variety of methods, each with their own set of strengths. These strategies allow firms to more correctly estimate future demand, resulting in better inventory management and production planning. The following are some of the primary approaches used in demand forecasting:

1. Qualitative Methods

Short-term forecasting focuses on predicting demand for a brief period, typically up to a year. This method is especially beneficial for businesses that experience seasonal fluctuations, such as clothing retailers during the holiday season or foodservice industries during major holidays. For example, a retailer may forecast higher demand for winter jackets in the colder months, allowing them to adjust their inventory and production plans accordingly.

2. Quantitative Methods

Quantitative methods use statistical data and historical performance to predict future demand, enabling data-driven decisions. For example, a clothing retailer analyzes past sales data to forecast seasonal demand and adjust stock levels. The following are key quantitative methods used in demand forecasting:

a. Time Series Analysis

Time series analysis is examining historical data to detect trends and seasonal patterns. This strategy is beneficial for forecasting future demand based on historical trends. For example, a holiday décor company might utilize time series analysis to estimate revenue increases over big holidays like Christmas.

b. Regression Analysis

Regression analysis looks at the relationship between several variables to forecast how changes in one factor will affect demand. For example, a fast-food business may employ regression analysis to better understand how advertising spending influences customer visitation, allowing them to estimate demand during promotional periods.

c. Machine Learning Models

Machine learning models employ algorithms to examine complicated data and learn from trends, increasing the accuracy of demand estimates. For example, an e-commerce company may utilize machine learning to monitor customer browsing activity and forecast which products would be in great demand in the coming months.

Understanding Demand Forecasting Models

Demand forecasting models are mathematical tools that anticipate future demand based on past data and trends. These models can take many different forms, including as spreadsheets, equations, or specialist software, and are suited to each business’s specific data, situation, and assumptions. These models enable businesses to make informed decisions about inventory, production, and resource allocation.

Consider a corporation with 50 retail stores, each of which generates $15,000 in monthly sales. The company is opening new locations at a rate of one per month. At time = 0, the company’s total monthly revenues are $750,000 ($15,000 × 50 locations). To forecast future sales, we choose a basic linear trend model. Using the ordinary least squares (OLS) regression method, the sales prediction model can be written as follows:

Sales Forecast = $15,000 × (Months since start) + $750,000

Using this model, we can anticipate that in 12 months, the company’s monthly sales will be $780,000 ($15,000 * 12 + $750,000), representing a $30,000 increase due to the addition of new stores. This example shows how a linear regression model can help firms anticipate future sales using historical data and present patterns, providing significant insights into expected growth over time.

Industry-Specific Applications of Demand Forecasting

Demand forecasting is important in many industries because it allows businesses to better anticipate and manage customer demand. Companies can use accurate estimates to improve operations, decrease inefficiencies, and exceed customer expectations. Here are some important uses in several sectors:

1. Logistics and Supply Chain

Demand forecasting helps logistics and supply chain management by predicting cargo quantities, optimizing warehouse operations, and reducing lead times. It enables businesses to handle fluctuating demand and optimize transportation, ensuring better resource deployment and fewer stockouts. Supply chain optimization software further streamlines processes and improves forecast accuracy.

2. Manufacturing

For manufacturers, reliable demand forecasting is critical for matching production schedules to market demand. Demand forecasting helps organizations plan production volumes, schedule maintenance, and manage supply chains more effectively. This guarantees that raw supplies are acquired on time, waste is reduced, and the manufacturing process runs smoothly and efficiently.

3. Retail and E-commerce

Demand forecasting assists retailers and e-commerce businesses in maintaining an optimal balance of stock levels and customer demand. Demand forecasting allows firms to establish optimal reorder points, safety stock levels, and inventory turnover rates. This technique prevents stockouts or overstocking, which can result in missed sales or higher holding costs.

4. Fashion and Luxury Goods

AI-driven demand forecasting helps the fashion and luxury goods industries handle changes in customer demand. Adopting AI-driven forecasting models improves inventory management, eliminates waste, and enables firms to optimize stock levels. This leads to increased profitability and customer satisfaction, ensuring that fashion businesses stay ahead of trends while reducing excess inventory.

Challenges in Demand Forecasting

Demand forecasting is not without obstacles. Businesses face numerous challenges that can compromise the accuracy and reliability of their predictions. Understanding these problems is critical for firms who want to enhance their demand forecasting systems. Key issues include:

1. Data Quality and Availability

Reliable forecasting requires high-quality, accurate data. Without access to comprehensive and consistent data, predictions can easily be inaccurate, resulting in poor decision-making. Inaccurate or outdated data can distort demand forecasts, affecting inventory and resource planning.

2. Market Volatility

Sudden market changes, such as economic shifts or unexpected global occurrences, might impair demand forecasting accuracy. Businesses may fail to revise their forecasts quickly enough to reflect these changes, resulting in overstocking or stockouts. Managing these unanticipated events requires agility and flexibility.

It also important to focusing on customer retention strategies can help stabilize demand by maintaining strong relationships with existing customers, ensuring more predictable sales, and reducing the impact of market fluctuations.

3. Integration Issues

Integrating demand forecasting tools into existing ERP and CRM systems can be difficult and lead to erroneous estimates. If the systems are not properly aligned, data conflicts can occur, reducing the overall quality of the projections. Seamless integration is critical for producing reliable and actionable insights.

4. Resource Constraints

Some firms may have limited access to advanced forecasting technologies or the expertise required to use them effectively. Small businesses, in particular, may lack the resources to invest in advanced forecasting technologies, making it difficult to improve forecasting accuracy. Proper training and resource allocation are critical for overcoming this obstacle.

Demand Forecasting Trends

As firms expand, demand forecasting trends change to reflect technological advancements. Forecasts are becoming more accurate and flexible because of new tools and methodologies. To remain competitive, firms are adopting innovative technologies to address changing market conditions. Let’s look at some of the major trends in demand forecasting:

1. AI and Machine Learning Integration

AI and machine learning are transforming demand forecasting by allowing for the examination of huge datasets. These technologies aid in the discovery of patterns and trends, ultimately enhancing forecast accuracy. Machine learning algorithms let organizations estimate demand more accurately. This improves decision-making and helps to optimize operations in real time.

2. Real-Time Data Utilization

Real-time data allows firms to quickly change forecasts depending on developing trends. Companies use data from sources such as social media and customer behavior to keep ahead of demand shifts. This helps prevent overstocking and stockouts. Real-time data enables more agile inventory and supply chain management.

3. Collaborative Forecasting

Businesses collaborate with suppliers and partners to improve prediction accuracy. Sharing data and insights improves production scheduling while lowering inventory risks. This strategy improves supply chain relationships. It also helps organizations better align their operations with actual demand.

4. Industry-Specific Forecasting Models

Tailored forecasting models are increasingly important for sectors facing specific issues. Fashion and logistics industries benefit from tailored ways to better estimate demand. These models contribute to better resource allocation and production scheduling. Industry-specific forecasting ensures that organizations fulfill market expectations successfully.

How to Choose the Right Demand Forecasting Software For Your Business

Understanding your company’s requirements is the first step in selecting the appropriate demand forecasting software. Consider which aspects are critical, such as processing historical data, real-time projections, and seasonal adjustments. Evaluate whether the software can scale with your business and integrate seamlessly with existing tools like CRM software systems. Whether your business is small or huge, the software should be appropriate for its complexity.

Another important consideration is ease of use and client support. Choose user-friendly software to enable speedy adoption by your workforce. Look for effective customer service and training resources to help with adoption. The software should also give continuing maintenance and updates to ensure that it remains effective as your organization expands.

Best Practices for Demand Forecasting

Demand forecasting enables organizations to predict future demand accurately and streamline operations. Best practices can help businesses improve inventory, production, and customer satisfaction. Here are some important best practices for good demand forecasting:

1. Use Historical Data

Analyze past sales data to uncover patterns and trends that will serve as the foundation for future estimates. Historical data enables businesses to understand market cycles and seasonal fluctuations, ensuring that forecasts reflect actual demand. This data-driven strategy lowers ambiguity and improves decision-making.

2. Update Forecasts Regularly

Forecasts should be constantly refined in response to new data and market changes. Regular updates enable organizations to respond to changing client behavior, economic upheavals, and external influences. Companies can avoid overstocking and stockouts by modifying predictions on a regular basis, allowing operations to better line with demand.

3. Integrate Cross-Functional Data

Combine insights from many areas, such as sales, marketing, and production, to create a more comprehensive prediction. Each department contributes unique insights, which improve the accuracy of demand predictions. This integrated method promotes greater supply-demand alignment, which improves operational efficiency.

4. Implement Technology and Automation

Use forecasting software and automation techniques to improve accuracy while reducing human error. These tools analyze massive databases quickly, identifying trends and providing real-time insights. Automation accelerates the forecasting process, allowing organizations to respond more quickly to changes in demand.

Embracing Advanced Technology for Optimized Demand Forecasting

As demand forecasting advances, organizations are relying on innovative technologies to improve accuracy and efficiency. Companies that integrate innovative tools and platforms may make more informed decisions, resulting in easier operations and lower risks. Here are some significant technologies that transform demand forecasting:

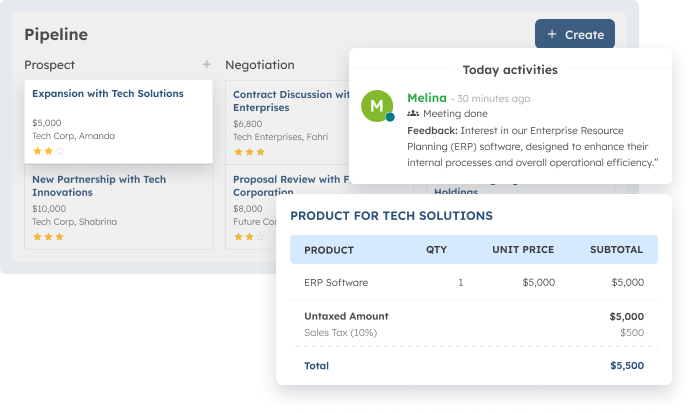

1. CRM Software Integration with Inventory Management Systems

Integrating CRM systems with ScaleOcean’s inventory management software improves forecasting accuracy by leveraging customer data. This link delivers deeper insights into customer preferences, allowing firms to estimate demand more accurately. Companies that use ScaleOcean’s CRM analytics may make better decisions, adjust inventory levels more effectively, and respond faster to demand swings.

Integrating CRM with ScaleOcean’s inventory management platform enhances forecasting and streamlines operations. ScaleOcean offers a free demo to show how the system can optimize your processes. Additionally, ScaleOcean qualifies for the CTC (Cost to Company) grant, offering financial support for businesses adopting this powerful software. ScaleOcean’s software includes the following key features:

- Seamless Module Integration, ScaleOcean ERP offers smooth integration between CRM, Sales, and Inventory Management, ensuring real-time stock tracking and quick customer demand response.

- Business Process Automation & Efficiency, Automates processes like inventory management and demand forecasting, reducing human errors and improving workflow efficiency.

- Real-Time Reporting and Analytics, Provides real-time reporting and interactive dashboards, offering valuable insights for quick, data-driven decision-making.

- Flexibility and Customization, ScaleOcean is highly flexible and customizable, allowing gradual integration of modules tailored to specific business needs, suitable for both small and large companies.

- Support for Growth and Expansion, With a user license model that incurs no extra charges, ScaleOcean supports company growth without additional user fees, making it ideal for scaling teams.

2. Automation

Automated tools simplify the forecasting process and reduce human error. These solutions support real-time data processing and can change forecasts depending on fresh information, ensuring that firms remain nimble. Automation allows firms to retain a high degree of accuracy while reducing the amount of manual effort required.

3. Cloud-Based Solutions

Cloud platforms provide scalable and accessible forecasting solutions. Businesses can use the cloud to store massive volumes of data and use forecasting tools from anywhere, increasing flexibility and collaboration across teams. Cloud-based solutions also allow firms to expand their forecasting capabilities as they grow.

4. Predictive Analytics

Predictive analytics assists firms in forecasting future demand trends by studying previous data and detecting patterns. This enables businesses to alter their strategy in advance, ensuring that they remain ahead of market developments. Businesses can use predictive analytics to better align their plans with changing consumer behavior.

Conclusion

Demand forecasting is critical for firms to remain efficient and competitive. Companies that effectively forecast future demand can manage inventories, improve financial planning, and make strategic decisions that promote performance. Using the correct forecasting methodologies is critical for success in today’s fast-paced economy.

ScaleOcean’s best CRM system offers solutions for demand forecasting, which seamlessly integrates with forecasting systems. This software enables businesses to manage customer relationships in real time, providing valuable insights into customer behavior and preferences. Aligning CRM data with forecasted demand helps improve resource allocation and enhances overall operational efficiency.

FAQ:

1. What is meant by demand forecasting?

Demand forecasting is the practice of predicting future customer needs for products or services by analyzing past data, market patterns, and statistical techniques. It assists businesses in planning their operations, controlling inventory, and efficiently allocating resources.

2. What are the three types of demand forecasting?

The three main types of demand forecasting are:

1. Qualitative Forecasting – Relies on expert opinions, market research, and subjective judgments.

2. Quantitative Forecasting – Utilizes historical data and statistical tools to predict future demand.

3. Causal Forecasting – Focuses on understanding relationships between demand and influencing factors, such as economic conditions or promotions.

3. What are the 7 steps in a forecasting system?

The seven essential steps in a forecasting system are:

1. Establish objectives – Identify the purpose and scope of the forecast.

2. Collect historical data – Gather past data relevant to the forecast.

3. Choose a forecasting method – Select the most suitable method (qualitative, quantitative, etc.).

4. Examine the data – Analyze the data to identify trends or patterns.

5. Generate the forecast – Apply the selected method to produce the forecast.

6. Validate the forecast – Compare the forecast with actual outcomes and adjust if necessary.

7. Review and update – Continuously track the forecast’s accuracy and make improvements over time.

4. What are the four steps in demand forecasting?

The four key steps in demand forecasting are:

1. Data Collection – Obtain historical data and relevant market insights.

2. Data Analysis – Process and analyze the data to spot patterns and trends.

3. Forecasting – Apply appropriate methods to predict future demand.

4. Implementation – Use the forecast in business operations and adjust strategies accordingly.

PTE LTD..png)

.png)

.png)

.png)

.png)