Effective inventory management is a crucial element in maintaining smooth business operations. Without the right system, poorly managed stock can hinder your business growth.

According to CSA: The Business of Retail, retail company IHL Group once faced losses of approximately USD 1.73 trillion per year due to global inventory distortions (including out-of-stocks and overstocks).

Therefore, to avoid these problems, companies must optimize their overall inventory strategy. In this article, we will discuss in detail what inventory is, its types, and how to manage it effectively. Learn more here!

- Inventory refers to the goods and materials a company holds for sale or use in production, such as raw materials, work-in-progress, and finished products.

- Types of inventory are raw materials, Work in Progress (WIP), finished goods, and Maintenance, Repair, and Operations (MRO). Also including cycle inventory, safety stock, decoupling, transit inventory, and many other

- Effective inventory management strategies include: demand forecasting, JIT inventory, ABC analysis, FIFO, safety stock management, and EOQ

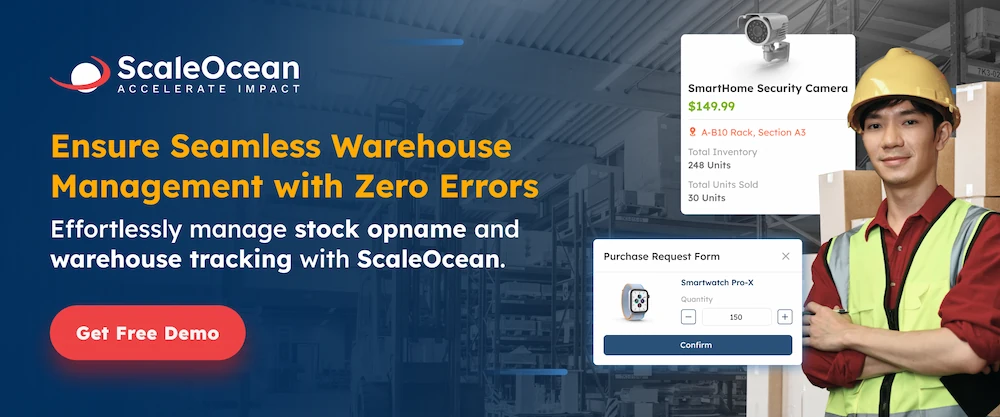

- ScaleOcean’s Inventory Software streamlines inventory with real-time insights, automating tasks, and reducing errors.

What is Inventory?

Inventory refers to the goods and materials a company holds for sale or use in production, such as raw materials, work-in-progress, and finished products. It is an essential asset for a business, representing stock available for sale or components required for manufacturing.

Additionally, inventory can encompass the process of physically counting and cataloging these items. Well-managed inventory acts as a buffer, ensuring smooth operations despite supply or demand fluctuations.

It helps fulfill orders promptly, manage production, and gain competitive advantages, with an understanding of what are the four types of inventory being key to the process.

Meaning of Inventory: How to Define

According to the Cambridge Dictionary, inventory has several definitions, including:

- An asset, either tangible or intangible,

- An asset that can be converted into revenue or holds exchangeable value, or

- An asset is currently in progress but intended for sale in the market.

Why Is Inventory Important?

Inventory plays a vital role in ensuring business operations run smoothly and efficiently. Proper management and tracking of stocks are essential for maintaining production schedules, meeting customer demand, and supporting financial planning. Here’s why inventory is so important for businesses:

1. Meeting Demand

Efficient processes ensure that a business can meet customer demand consistently. By maintaining an optimal stock level, businesses can avoid stockouts or overstocking, ensuring products are available when needed, enhancing customer satisfaction, and driving sales.

2. Asset on the Balance Sheet

Inventory is considered a current asset on the balance sheet, reflecting its value to the business. It represents a potential revenue source, and its management directly impacts cash flow, profitability, and financial health, making it a key indicator for investors and stakeholders.

3. Production Continuity

For manufacturing businesses, it ensures that production lines run smoothly without interruptions. A steady supply of raw materials and components is crucial to maintain consistent production, preventing delays, reducing downtime, and avoiding costly disruptions in the production process.

4. Strategic Planning

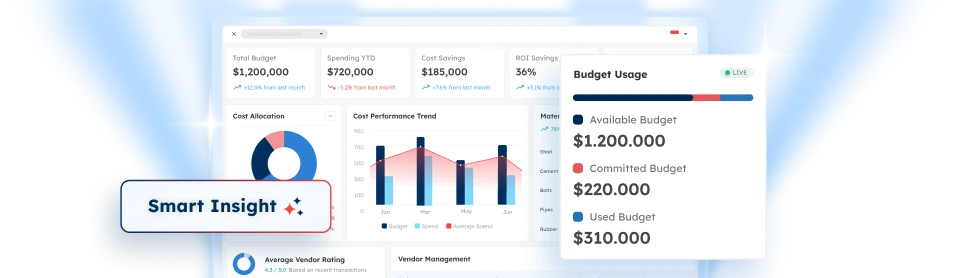

It supports strategic planning by providing insights into sales trends, production needs, and supply chain performance. Accurate inventory data helps businesses forecast demand, adjust procurement strategies, and plan for future growth, making it a valuable tool for long-term decision-making.

Types of Inventory and Examples

Inventory kinds are vital for understanding a company’s operating assets. The inventory generally has different categories, such as raw material, work-in-progress, finished goods, also maintenance, repair, and operations (MRO) goods.

These categories depict an item’s path through production and sales, providing firms with a clear picture of their stocks. If you’re wondering how many types of inventory exist, every firm, regardless of industry, needs to handle them efficiently.

Its kinds are interrelated, demonstrating how value moves through the business from purchase to sale. Poor management in any one category can disrupt the entire supply chain, resulting in significant consequences. Here are the 4 types of inventory that require a comprehensive approach to ensure seamless operations.

1. Raw Materials

Raw materials are the necessary inputs for starting production operations. They provide the foundation for completed things. For example, a furniture builder requires wood and screws, whereas a baker requires wheat and eggs. Proper management is critical to guaranteeing seamless production.

Efficient raw material management necessitates balancing supply and demand. Too much stock increases storage expenses, whereas too little can create manufacturing delays. Achieving this equilibrium is critical for organizations to run smoothly and economically.

2. Work-in-Progress (WIP)

Work-in-Progress (WIP) refers to goods that have entered production but have not yet been completed. It contains partially processed raw materials, labor, and overhead expenditures. This stage complicates appraisal because it is between a fundamental component and a finished product.

High volumes of WIP frequently imply inefficiencies or bottlenecks in the manufacturing process. If commodities remain in this stage for an extended period of time, capital becomes constrained, and revenue is not generated.

3. Finished Goods

Finished goods are final products that are ready for sale after the manufacturing process is completed. Customers see these things on store shelves or in online catalogs, and they have a direct impact on sales and consumer happiness.

Managing finished products’ inventories necessitates precise demand forecasts. Overestimating demand creates surplus goods, storage expenses, and probable obsolescence, whilst underestimating it results in stockouts, missed sales, and disgruntled consumers.

4. Maintenance, Repair, and Operations (MRO)

MRO contains goods that are required for operations but not part of the finished product, such as cleaning supplies, office equipment, replacement parts, and safety equipment. MRO, while often underestimated, is critical for operational continuity and avoiding downtime.

A scarcity of MRO supplies, such as missing spare parts, can cause production to stop just as rapidly as a lack of raw materials. Effective MRO management ensures that these components are constantly available, avoiding costly disruptions and maintaining operational efficiency.

Exploring 13 Different Types of Inventory

Understanding the different types of inventory is crucial for businesses to optimize their operations and improve efficiency. Each type plays a distinct role in the supply chain, from raw materials to finished goods. By categorizing inventory effectively, businesses can better manage stock levels, reduce costs, and streamline processes.

Here are some other types of inventory that are important to understand and manage effectively, including:

1. Cycle Inventory

Cycle inventory, sometimes called lot-size, is essentially the stock a business keeps on hand to handle its normal demand between new orders. For instance, if you order a batch of 1,000 units to cover a month, that’s your cycle stock, and how much you hold is a direct result of purchasing policies.

The trick here is balancing ordering costs against holding costs; ordering big batches less often might cut down on order fees but racks up storage expenses, while frequent small orders do the opposite, making its optimization a key financial consideration for sure.

2. Safety Stock (Buffer Stock)

Safety stock, or buffer stock as some call it, is that extra bit of stock kept aside specifically to guard against the unexpected bumps in supply and demand. Think of it as a crucial insurance policy against stockouts, not for everyday use, but to ensure business continuity during volatile periods.

Figuring out just the right amount is a real puzzle, because too much stock ties up cash needlessly, but too little means it can’t do its job, leaving you exposed; that’s why a proper safety stock calculation becomes an essential part of modern inventory strategies for many.

3. Decoupling Inventory

Decoupling is a specialized kind of buffer stock, strategically placed between different steps in a production process. Its main goal is to let each stage work on its own for a bit, stopping a hiccup in one spot from immediately bringing the whole line to a halt and making the overall system more resilient and flexible.

Imagine a machine needing a quick fix mid-assembly; stages before it can keep making parts, building up this inventory, while stages after can keep going by using what’s already there, which is super helpful in complex setups to minimize the impact of minor disruptions.

4. Transit Inventory (Pipeline Stock)

Transit inventory, or pipeline stock, refers to goods in transit, like raw materials or finished products. Even if not in the warehouse, it stays on the balance sheet. According to My Careers Future, sustainable tech at Tuas Port, set to be the world’s largest by 2040, will enhance types of inventory

Shipping times and demand speed determine the amount of transit inventory required. Reduced lead times and improved logistics efficiency can help global organizations with complicated supply chains save stock and free up capital.

5. Anticipation Inventory (Seasonal Stock)

Anticipation inventory, also known as seasonal stock, is the practice of stockpiling ahead of an expected demand rise. It is typical in seasonal sectors, such as holiday shops or air conditioning makers, to plan for peak times to minimize last-minute, costly manufacturing.

While effective, this method entails hazards. If demand does not meet expectations, excess inventory may result, resulting in discounts and potential losses. Accurate forecasting is required to create a balance between supply levels and demand predictions.

6. Excess Inventory

Excess inventory is stock that a company owns but does not intend to sell in the near future, typically owing to erroneous demand forecasting, over-ordering, or shifting consumer preferences. While still sellable, it becomes a problem when current demand surpasses supply.

Excess inventory ties up working capital and incurs storage, insurance, and obsolescence fees. Businesses should use techniques such as sales promotions or liquidation to quickly turn excess inventory into cash and manage cash flow properly.

7. Dead Stock

Dead stock, also known as obsolete inventory, refers to things that have lost their whole market worth because they are outdated, expired, damaged, or replaced by newer ones. This type cannot be sold through traditional channels, even at a discount, and it becomes a problem for the company.

Companies must take prompt action to dispose of dead stock, such as donating it for a tax write-off, selling it to liquidators for a fraction of its value, or writing it off entirely. Removing dead stock improves financial reporting accuracy and makes room for valuable products.

8. Consignment Inventory

Consignment inventory is an arrangement in which a supplier (consignor) installs things in a retailer’s (consignee) store while maintaining ownership until the items are sold. The retailer pays for sold items, transferring the risk of unsold inventory to the supplier, which benefits the merchant.

Consignment inventory allows suppliers to have access to retail shelf space without the inconvenience of making wholesale purchases. However, it ties up cash in unsold merchandise, necessitating trust and effective tracking technologies to precisely manage inventory, resulting in a partnership-based approach.

9. Dropshipping Inventory

Dropshipping is an e-commerce approach in which the retailer does not store inventory. Instead, they acquire the product from a third party after placing an order, and the supplier distributes it straight to the consumer, eliminating the need for warehousing and inventory.

The primary benefit of dropshipping is the low barrier to entry, as no upfront funding for goods is necessary. However, it comes with lower business margins, dependency on suppliers for product quality and shipping speed, and customer service issues. Therefore, dependable suppliers are essential.

10. Packing and Packaging Materials

Packing and packaging materials are crucial for protecting products during transportation and ensuring they reach customers in good condition. These materials are typically considered part of inventory and need to be tracked to avoid shortages that could delay shipping and increase costs.

11. Service Inventory

Service inventory refers to the stock of resources required to deliver services to customers, such as equipment, spare parts, or even human resources. Unlike physical products, it is often intangible and plays a critical role in ensuring smooth service delivery and customer satisfaction.

12. Theoretical Inventory

Theoretical inventory is an estimate of the stock that a business should have at any given time based on production schedules, demand forecasts, and sales targets. It helps companies assess if actual stock levels align with ideal conditions for operations and customer fulfillment.

13. Book Inventory

Book inventory refers to the recorded quantity of stock in a company’s financial or inventory management system. It reflects the theoretical stock on hand but may differ from actual physical inventory due to factors like stock discrepancies, shrinkage, or errors in data entry, requiring regular reconciliation.

Effective Inventory Management Strategies

Effective inventory management is essential for optimizing operations, reducing costs, and ensuring customer satisfaction. By implementing the right strategies, businesses can streamline their supply chain, avoid stockouts or overstocking, and improve overall efficiency. Here are some key strategies for success:

1. Demand Forecasting

Demand forecasting helps businesses predict future inventory needs by analyzing historical sales data, market trends, and seasonal patterns. This strategy allows companies to adjust inventory levels accordingly, minimizing excess stock while ensuring sufficient supply to meet customer demand.

2. Just-In-Time Inventory

Just-In-Time (JIT) focuses on minimizing stock levels by ordering products or materials only when needed. This strategy reduces holding costs and waste, allowing businesses to operate more efficiently. However, it requires precise coordination with suppliers to prevent delays in production or sales.

3. ABC Analysis

ABC Analysis categorizes stock into three groups based on value and importance. ‘A’ items are high-value and require close monitoring, while ‘B’ and ‘C’ items have lower values. This strategy helps businesses prioritize stock management efforts, focusing resources on high-priority items to optimize operations.

4. Safety Stock Management

Safety stock acts as a buffer to prevent stockouts during unexpected demand spikes or supply chain disruptions. By maintaining an optimal level of safety stock, businesses can ensure smooth operations while minimizing the risk of lost sales and dissatisfied customers due to inventory shortages.

5. Economic Order Quantity (EOQ) Model

The Economic Order Quantity (EOQ) model helps businesses determine the ideal order quantity to minimize total costs, including ordering, holding, and stockout costs. By calculating the EOQ, companies can optimize inventory replenishment, reducing overstocking and understocking issues.

6. First-In, First-Out (FIFO)

The FIFO method ensures that the oldest inventory is used or sold first. This strategy is particularly useful for perishable goods or items with expiration dates, reducing the risk of stock becoming obsolete or wasted. FIFO helps businesses maintain product freshness and compliance with regulations.

How to Manage Inventory

Managing inventory effectively is key to maintaining smooth operations and ensuring business profitability. By implementing efficient strategies, businesses can reduce costs, improve stock accuracy, and meet customer demands. Here are some practical steps for better inventory management:

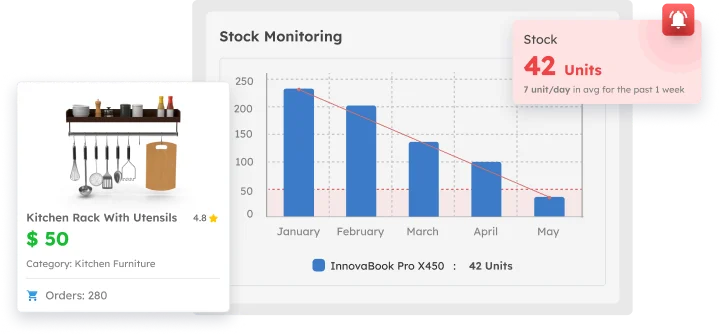

1. Automate Inventory Management

Automating inventory management systems streamlines processes such as stock tracking, order processing, and replenishment. By using software solutions, businesses can reduce human error, improve data accuracy, and gain real-time insights into stock levels, leading to better decision-making and efficiency.

Companies can use an ERP system with an inventory module to centralize all inventory data, allowing for seamless integration with other business functions such as sales, procurement, and finance.

With ScaleOcean inventory management, you can customize modules and systems to suit your business needs. Furthermore, with the multi-warehouse module, you can manage all inventory across your multiple warehouses within a single system. Take a free demo now!

2. Conduct Regular Audits and Cycle Counting

Regular audits and cycle counting help ensure stock accuracy by systematically checking stock levels and identifying discrepancies. By implementing this process, businesses can catch errors early, maintain precise records, and minimize the risk of stockouts or overstocking, improving overall management and control.

3. Optimize Warehouse Layout

An optimized warehouse layout improves inventory flow and accessibility, reducing the time needed to locate items and increasing operational efficiency. Proper shelving, clear labeling, and organized storage areas help minimize handling errors, speed up order fulfillment, and reduce the risk of inventory damage.

4. Manage Supplier Relationships

Effective supplier management ensures timely and reliable deliveries, helping maintain inventory levels and avoid disruptions. By establishing strong relationships, negotiating favorable terms, and monitoring supplier performance, businesses can improve supply chain efficiency and ensure they always have the right stock on hand.

5. Clear Obsolete Stock

Clearing obsolete or slow-moving stock helps businesses free up valuable space and resources. Regularly reviewing stocks to identify unsellable items allows companies to discount, liquidate, or dispose of old stock, ensuring that only relevant products are taking up space and reducing storage costs.

6. Set KPIs

Setting Key Performance Indicators (KPIs) helps businesses track performance and identify areas for improvement. Metrics such as inventory turnover, stockouts, and carrying costs provide valuable insights into efficiency, enabling data-driven decisions that optimize stock levels and reduce waste.

For easier management, consider using the best inventory management system, such as ScaleOcean, which can automatically and in real-time monitor inventory across multiple locations. You can customize the features and dashboard to suit your needs to optimize your company’s inventory operations.

To learn more about this solution, contact us to schedule a free demo.

What Can Inventory Tell You About a Business

Inventory is a crucial indicator of a company’s operational efficiency, financial health, and customer demand management. By analyzing inventory levels, businesses can assess their ability to meet customer demand without overstocking or experiencing stockouts.

High inventory turnover can indicate strong sales and effective stock management, while low turnover might suggest overstocking or declining demand. Additionally, inventory data can reveal supply chain issues, inefficiencies in the ordering process, or areas where production or procurement processes need improvement.

Ultimately, inventory management provides valuable insights into a business’s overall performance, helping leaders make informed decisions about pricing, sales strategies, and resource allocation.

Understanding Inventory Turnover and Its Impact on Profitability

Inventory turnover is a key metric that measures how often a company sells and replaces its inventory within a given period. A high turnover rate indicates efficient inventory management, as products are sold quickly, reducing holding costs and the risk of obsolescence.

On the other hand, low turnover suggests that managing stock is not selling as expected, potentially leading to overstocking, increased storage costs, and cash flow issues.

By maintaining an optimal inventory turnover rate, businesses can improve profitability by ensuring that they are investing in products that move quickly, minimizing excess stock, and freeing up capital for reinvestment in higher-demand items.

Efficient inventory turnover also leads to better cash flow management, as the company is able to recover investment in inventory more rapidly, enabling it to invest in other growth opportunities.

Is Inventory an Asset or a Liability?

Inventory is considered an asset on a company’s balance sheet. As a current asset, it represents goods that are held for sale or use in production, and its value can be converted into cash through sales.

However, while inventory is an asset, it can also become a liability if not managed effectively. If inventory levels are too high or not selling fast enough, it can tie up cash flow, incur storage costs, and risk obsolescence.

In such cases, inventory may result in a financial burden, leading to wasted resources. Therefore, while inventory is classified as an asset, it requires proper management to maintain its value and prevent it from becoming a liability that hampers profitability.

Manage Inventory Integrated and Real-Time with Scaleocean Inventory System

ScaleOcean’s inventory system provides a comprehensive automation solution for comprehensive inventory management. This ERP-based inventory software can automate the entire inventory process, from stock management and warehouse management to reporting for each type of inventory.

Furthermore, ScaleOcean offers seamless integration with various business functions, from finance and production to sales and purchasing. This integrated data management ensures inventory data is always updated with every movement in various business processes.

You can also customize the system to suit your specific business needs, workflows, and the specific industry you manage. To experience this system customization, request a free demo and consult with ScaleOcean’s professional team now!

With the CTC grant, ScaleOcean’s adaptability becomes a valuable tool for any inventory system, accelerating expansion. ScaleOcean also offers several special features to optimize inventory management in your business, including:

- Real-time inventory management easily determines the exact number of items available, out-of-stock items, and items that need to be reordered, thus avoiding stockouts and overstocking.

- Monitoring of inventory movement, from incoming to outgoing items, ensures that every transaction is accurately recorded.

- Multi-location warehouse management can integrate and synchronize inventory management across multiple inventory locations, with stock monitoring and management conducted in a single, centralized system.

- Barcode and QR code technologies leverage this technology to increase inventory speed and accuracy, allowing for real-time and automatic data collection.

- Inventory reporting and analysis automatically generate reports on inventory performance, including inventory rotation rates, warehouse stay times, and inventory demand analysis.

- Flexibility in grouping items into various categories and subcategories according to business needs and operations, simplifying inventory searches and reporting.

With this solution, ScaleOcean provides a complete solution for more efficient, transparent, and automated inventory management, allowing companies to focus more on increasing productivity and business development.

Conclusion

Effective inventory management is essential for optimizing business operations, enhancing profitability, and maintaining customer satisfaction. By understanding the importance of inventory turnover, implementing the right strategies, and utilizing advanced tools, businesses can streamline their processes and reduce costs.

For those looking to take their inventory management to the next level, ScaleOcean’s inventory system offers a comprehensive solution. With real-time tracking, seamless integration across departments, and advanced features like multi-warehouse support, ScaleOcean ensures that your inventory is always under control, helping you make data-driven decisions that drive growth and efficiency.

Take a free demo to get this solution for your business.

FAQ:

1. What is the main purpose of inventory?

The role of inventory is to act as a buffer between production and sales, ensuring a smooth flow of goods and product availability when customers place orders. To accomplish this, businesses must carefully manage their inventory levels and invest in the right system when needed.

2. What are the two main tasks of inventory?

Handling involves tracking the arrival of items or materials, including their quantity and type. Storing requires that products or materials be kept in a secure, yet easily accessible location, such as a warehouse on-site.

3. What is the golden rule for inventory?

The key principle of inventory management is straightforward: “Keep inventory levels optimal.” This means having enough stock to satisfy customer demand without overstocking or wasting resources. Achieving this balance helps reduce holding costs and maximize profitability.

4. How often should inventory be checked?

Typically, larger businesses with higher inventory volumes conduct checks on a monthly basis, while smaller businesses may opt for weekly checks due to having fewer items in stock. Monthly checks provide a thorough overview of inventory, while weekly checks help identify errors and discrepancies more promptly.

PTE LTD..png)

.png)

.png)

.png)

.png)