Singapore’s global logistics reputation extends beyond its ports to the sophisticated network that facilitates the movement of products. Warehouse logistics is an important component of this network, since it helps manage inventories, fulfill orders, and ensure effective operations.

According to EDB Singapore, foreign investors are increasingly supporting logistics facilities in Singapore as shippers restructure supply chains to deal with trade tensions and geopolitical threats, emphasizing the city’s important role in global trade and efficient warehouse operations.

In this post, we will look in depth at warehouse logistics and how important it is for Singapore firms. We’ll talk about how efficient warehouse management affects supply chain operations and why mastering logistics is critical for growth and staying competitive in the market.

- Warehouse logistics manages product flow from arrival to shipping, focusing on efficiency, which is key to supply chain performance, especially in fast-paced markets like Singapore.

- Key processes like receiving, put-away, picking, packing, shipping, and inventory control must be synchronized, as delays in one area affect the whole system.

- Different types of Singapore’s warehouses, including distribution, fulfillment, automated, cold storage, and bonded, cater to diverse business needs.

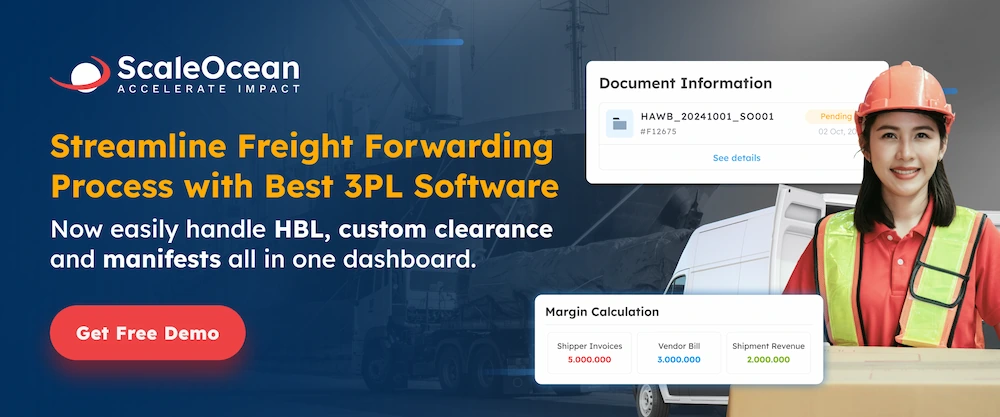

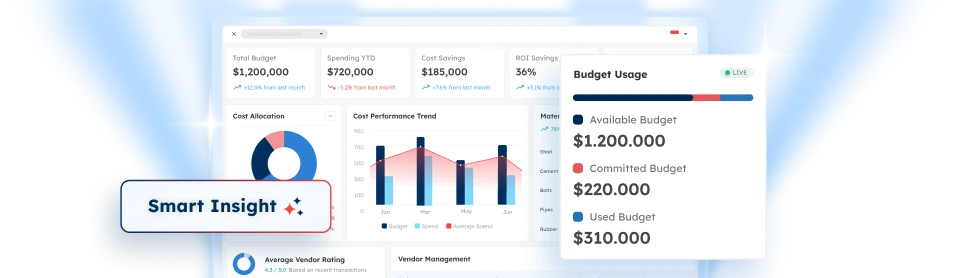

- ScaleOcean’s logistics software improves warehouse management by providing visibility, control, and automation, boosting efficiency and addressing challenges like cost accuracy.

What is Warehouse Logistics?

Warehouse logistics entails managing the flow of products within a facility, from arrival to shipping. It’s not only about space. It’s also about getting items moving efficiently, which is critical to the overall performance of supply chain operations, especially in fast-paced markets like Singapore.

Understanding the various types of logistics clarifies how warehousing fits into the whole supply chain. Warehouse logistics connects inbound and outbound commodities, affecting customer happiness, operational expenses, and business success, making it a valuable strategic asset for any organization.

The Strategic Importance of Warehousing in Singapore’s Supply Chain

For global hubs like Singapore, efficient warehousing ensures smooth goods movement, promotes trade, and keeps the country competitive. Warehouses play a crucial role in meeting demand and managing inventory within global supply chains.

Warehousing minimizes disruptions and provides flexibility during supply and demand swings. Warehouses maintain product continuity and availability by allowing for strategic inventory storage, which supports corporate growth and fosters market trust even in unpredictable times.

1. Central Hub for Goods Consolidation and Deconsolidation

Warehouses in Singapore act as crucial centers for goods aggregation, combining products from multiple vendors into larger shipments. This technique enables enterprises to obtain full container load (FCL) rates, thereby expediting exports and reducing freight expenses for global markets.

Deconsolidation, the process of breaking down huge inbound shipments into smaller quantities for distribution, is also critical. This function reinforces Singapore’s role as a regional hub, allowing international corporations to efficiently serve Southeast Asia from a strategic location.

2. Enables Efficient Inventory Management

Effective warehousing is critical to inventory management. It guarantees that products are precisely tracked, allowing firms to prevent running out of inventory or overstocking. This visibility allows for smarter purchasing and manufacturing decisions, maximizing capital usage and lowering wasteful inventory expenses.

Warehouse logistics also enables advanced inventory methods such as Just-In-Time (JIT) and First-In, First-Out (FIFO). These strategies reduce waste, particularly for perishable commodities, and cut costs such as storage fees, insurance, and obsolescence, resulting in a more lucrative company.

3. Crucial for Fast and Accurate Order Fulfillment

In today’s e-commerce landscape, speed and accuracy are critical. Efficient warehouse operations, picking, packing, and shipping have a direct impact on customer satisfaction. Streamlining these processes allows firms to stand out by providing quick, error-free order fulfillment.

In Singapore’s urban landscape, speedy delivery is the norm. Efficient warehouse location and internal operations are critical for satisfying same-day or next-day delivery expectations. Any breakdown in operations results in delayed orders and disgruntled customers, which harms a brand’s reputation.

4. Adds Value Through Services

Modern warehouses are no longer static. They instead include value-added services (VAS) such as product assembly, kitting, bespoke packaging, and labeling. These services enable product customization closer to the point of sale, resulting in greater flexibility and response to market demands.

By offering these services, warehouses transition from cost centers to value providers. This method, known as postponement, decreases the risk of storing superfluous finished goods while increasing supply chain agility, allowing businesses greater flexibility in meeting consumer needs.

5. Reduces Overall Transportation Costs

Consolidating supplies at strategically located warehouses helps to cut transportation expenses. Businesses realize economies of scale for both inbound and outbound commodities by improving delivery routes and making the entire process more efficient and cost-effective.

Warehouses cut transportation expenses by using sea freight for vast distances and speedier vehicles for last-mile delivery. This hub-and-spoke approach is more economical than direct shipping. According to the URA, Singapore’s 1991 decentralization policy boosted the business ecosystem by establishing job nodes across the island.

Core Processes and Components of Warehouse Logistics

Understanding warehouse logistics entails coordinating everyday activities that ensure seamless operations. Each phase is interconnected, and delays in one area can spread throughout the system, hurting efficiency, accuracy, and overall business performance.

Core processes function like gears in a machine, requiring precise timing to operate. Every activity, from receiving goods to dispatching, is part of a carefully organized sequence that maximizes speed, precision, and smooth flow across the warehouse.

1. Receiving

Receiving is the first and most important phase in warehouse logistics. It entails unloading products, examining for accuracy and damage, and comparing them to the purchase order. This initial check lays the groundwork for quality control and proper data entry.

At this point, the products are entered into the warehouse management system (WMS), which provides real-time inventory updates. Any irregularities, such as wrong numbers or damage, should be notified immediately. A mistake here can lead to serious inventory concerns later on.

2. Put-away and Storage

Once products have been received and validated, they are transferred to their allocated storage locations. The put-away process is based on a strategic storage strategy that takes into account item velocity, size, and weight, ensuring that items are efficiently placed for simple access and retrieval.

Efficient storage makes the best use of warehouse space while allowing for easy selection. This includes implementing racking systems or categorizing products in order to reduce staff travel time and optimize the warehouse architecture for speedier retrieval.

3. Picking and Packing

Picking is the process of picking things from storage locations to fulfill client orders. It is frequently the most labor-intensive and expensive warehouse activity. Different methods, such as single-order, batch, or zone picking, provide distinct benefits based on your operation.

Once selected, items are delivered to the packing station for a final inspection, secure packaging, and proper labeling. Proper packing uses the appropriate box sizes and dunnage to avoid damage while lowering shipping costs and maintaining product safety during transit.

4. Shipping

Shipping is the final warehouse procedure in which packed orders are sorted by carrier and destination before loading onto outbound vehicles. This process necessitates close cooperation to ensure timely dispatch with appropriate documents, such as packing lists and bills of lading.

Efficient shipping requires clear communication with carriers and freight forwarders. A well-managed process contributes to meeting delivery promises and maintaining a good reputation. Some organizations utilize freight forwarding software to streamline cargo and ensure smooth transitions to the transportation network.

5. Inventory Control and Management

Inventory control is a continuous process that includes monitoring stock levels, doing frequent cycle counts, and analyzing data to estimate demand. It is the foundation of warehouse operations, ensuring accurate records and contributing to efficient warehouse management in logistics.

Effective inventory management ensures that the appropriate stock is available to fulfill demand while reducing surplus inventory. It aids in the identification of slow-moving or obsolete commodities, lowers storage costs, and improves order fulfillment rates, resulting in a cost-effective solution.

Types of Warehouses in Singapore

Warehouses exist in a variety of shapes and sizes, each designed for a unique function within the supply chain. Businesses in Singapore’s fast-paced logistics sector can select between huge distribution hubs and customized storage units based on their requirements.

The sort of warehouse a firm utilizes is determined by its business model, product types, and target market. E-commerce enterprises, for example, have different requirements than those that import perishable items. Understanding these distinctions enables businesses to select the best warehouse in Singapore.

1. Types of Warehouses By Function

Warehouses are classified based on their primary role in the supply chain, with functions driving operations. It’s about more than simply the structure. Specific activities, layout, processes, and technology all contribute to the warehouse’s efficiency in accomplishing company objectives.

A mismatch between warehouse function and business requirements might result in inefficiencies. Distribution centers and fulfillment centers are the two primary functional kinds, with each providing a particular purpose in ensuring smooth operations and supporting broader strategic goals.

a. Distribution Centres

A distribution center (DC) focuses on distributing things swiftly rather than holding them for an extended period. It accepts huge quantities from numerous sources and gets them to merchants quickly. Cross-docking allows things to flow straight from one vehicle to another, resulting in efficient B2B logistics and supply chains.

b. Fulfilment Centres

Fulfillment centers are designed to process a large number of small orders quickly and accurately. They also manage responsibilities like as returns processing (reverse logistics), which is critical in e-commerce by ensuring that online retailers receive orders in a timely and efficient manner.

2. Types of Warehouses By Technology Level

A warehouse’s technology and automation level have a significant impact on its efficiency and capacities. As technology progresses, Singapore warehouses transition from basic manual operations to advanced, smart warehouses that leverage automation to boost performance and efficiency.

This whole tech gap often lines up pretty well with how old a facility is and how much the operators have actually invested in it. Newer places, you’ll notice, are usually designed with automation as a core idea from the start. Let’s check out the main technology categories we see.

a. Traditional Warehouses

Traditional warehouses rely on physical labor and simple equipment, such as forklifts. Manual processes, such as inventory management and record-keeping, are inefficient and prone to errors. While initially less expensive, they have difficulty scaling and meeting high-volume demands.

b. Automated Warehouses

Due to limited land, Singapore is a leader in automated, multi-story warehouses. These transfer products use technology like as conveyors and AS/RS, which reduces the need for physical labor. This increases productivity, accuracy, and speed, allowing firms to expand operations while reducing errors.

c. Smart Warehouses

Smart warehouses combine automation with AI, IoT, and advanced analytics to create a self-optimizing environment. Technologies such as autonomous mobile robots (AMRs), AI software, and IoT sensors improve efficiency and accuracy, establishing these warehouses as the future of logistics.

3. Types of Warehouses By Specialization

Certain warehouses are intended for unique products that require specific storage or handling. These facilities are critical to Singapore’s industries, which frequently require permits and tight regulatory compliance. They ensure the secure and compliant storage of commodities that cannot be accommodated in regular warehouses.

Cold storage and bonded warehouses are essential for industries such as food, medicines, and re-export trade. They ensure that products are correctly stored and meet regulatory requirements, hence assisting Singapore’s various and important businesses.

a. Cold Storage

Cold storage warehouses store temperature-sensitive commodities such as food and medications, maintaining product safety through controlled temperature and humidity. While they are expensive to operate due to energy requirements, they are critical to Singapore’s food security and biomedical sectors by preserving cold chain integrity.

b. Bonded Warehouses (Customs Warehouse)

Bonded warehouses in Singapore’s Free Trade Zones, near ports and airports, are crucial for transshipment. The bonded warehouse benefit includes tax deferral on customs-approved goods until they are sold or enter the domestic market, enhancing cash flow while ensuring compliance.

Strategies to Optimize Warehouse Logistics

Warehouse logistics optimization entails optimizing procedures to make them faster, more accurate, and cost-effective. This includes smart layout design, incorporating new technologies, and constantly refining procedures to create smoother, more efficient workflows.

In the competitive Singapore market, even minor improvements can have a huge impact on the bottom line. The goal is to build a lean, agile, and responsive warehouse operation that can react to changing customer needs and market conditions, ensuring business success. So, we’ve got six critical strategies to assist you in making that happen.

1. Optimize Your Warehouse Layout

Your warehouse’s layout has a significant impact on its efficiency. Poor design can cause traffic congestion, wasted time, and accidents. A smooth, logical flow of goods from receipt to shipment is critical. Strategic layout planning ensures that the warehouse runs smoothly, safely, and productively.

Slotting, or placing fast-moving objects near shipping terminals, is a technique for optimizing layout. Ensure that the aisles are wide enough for equipment to move safely. To increase warehouse management and efficiency, modify the layout regularly as inventory changes.

2. Implement a Warehouse Management System (WMS)

A Warehouse Management System (WMS) enables real-time visibility and control over inventory and warehouse operations. It serves as the core brain, controlling and tracking all actions, which is critical for better warehouse management in logistics.

A strong WMS increases inventory accuracy, streamlines picking paths, and improves labor management. Investing in robust logistics software enables organizations to make data-driven choices and increase warehouse efficiency, making it an essential tool for modern operations.

3. Adopt Automation and Technology

Automation increases warehouse productivity and helps to alleviate manpower shortages in Singapore, which is a major concern for warehouse logistics. Even simple equipment like as barcode scanners, conveyor belts, and automated sorting systems can provide considerable returns while increasing efficiency.

Advanced technologies such as autonomous mobile robots (AMRs) and automated storage and retrieval systems (AS/RS) improve picking speed and storage capacity. Businesses may enhance warehouse management and maximize the value of their investments by automating repetitive processes.

4. Focus on Data-Driven Inventory Management

To improve warehouse logistics, focus on knowing your inventory by studying sales data and inventory trends. This data-driven strategy enables organizations to make better judgments about what to store, how much to maintain, and where it should be located.

Using methodologies like ABC analysis prioritizes high-value, high-frequency items, ensuring that they are always available. This technique lowers carrying costs and increases cash flow, making it critical for effective warehouse management, particularly in Singapore’s fast-paced market.

5. Invest in Staff Training and Development

Staff training is critical to warehouse success. Employees who have been properly taught and motivated are essential for effectively implementing new systems and equipment. Regular training promotes safety, precision, and seamless operations, which are essential for effective warehouse management in logistics.

Investing in employee development enhances morale, lowers attrition, and promotes a productive workplace. A skilled workforce leads to higher quality, more productivity, and a deeper dedication to optimization, making staff training critical for long-term business success.

6. Implement Cross-Docking Where Possible

Cross-docking is a logistics approach in which items are transferred directly from one truck to another, reducing storage time. This reduces the need for warehousing and order picking, reducing handling time and costs. It is especially useful for warehouse logistics in Singapore.

While cross-docking is ideal for high-volume, fast-moving commodities, it necessitates precise coordination between incoming and leaving vehicles. When handled properly, it accelerates the supply chain and delivers a significant competitive advantage, particularly in distribution environments.

Key Challenges of Warehousing in the Singapore Context

Singapore has a world-class logistics infrastructure, but running a warehouse here has unique obstacles. These difficulties arise from the country’s economic backdrop, geographical limits, and high market expectations, forcing enterprises to adapt and discover effective solutions.

Navigating these hurdles is critical to effective warehousing in Singapore. Businesses must strike a balance between cost control and consumer needs, pushing for smarter, faster, and more efficient processes to remain competitive. Let’s look at the major difficulties confronting the Singapore warehouse logistics sector.

1. High Land and Rental Costs

Singapore’s small, highly populated island results in limited land availability and high warehouse rental rates. This puts enormous pressure on logistics organizations to maximize every square meter, making efficient space usage critical to operational success.

To address this issue, warehouses are increasingly using high-rise, multi-story designs to maximize storage. Efficient space usage and inventory management are critical for maximizing throughput by ensuring that no space is wasted on slow-moving or obsolete products.

2. Tight Labour Market and Rising Manpower Costs

Singapore’s tight labor market, with low unemployment and reluctance for physically demanding professions, has resulted in a manpower shortage in logistics. Government measures to lessen reliance on foreign labor have increased wages, making it difficult to locate and keep skilled workers.

This labor shortage is causing businesses to adopt automation and invest in technology. Robotics and systems increase production, while staff training and better working conditions help recruit and keep qualified workers, making workforce management a strategic focus.

3. Increasing Customer Expectations for Speed

The advent of e-commerce and on-demand services has raised expectations about speed. Customers increasingly expect faster, more frequent, and consistent delivery, putting additional pressure on warehouses to handle orders swiftly and efficiently to achieve this new standard.

To achieve these expectations, warehouses must be strategically placed and outfitted with efficient operations and cutting-edge technology. Meeting the demand for same-day or two-hour delivery has become critical, and processing orders rapidly is now a firm survival need.

4. Need for High-Tech Integration and Cybersecurity

As warehouses adopt modern technologies, flawless integration of systems such as WMS, TMS, robotic controls, and IoT sensors is critical. A single integration failure can interrupt the entire operation, demonstrating the vulnerability of modern smart warehouses.

Increased connection also creates cybersecurity vulnerabilities. A cyberattack on a WMS could disrupt operations, create data breaches, and result in financial and reputational harm. Investing in robust IT infrastructure and cybersecurity policies is critical to safeguarding warehouse operations.

5. Pressure for Sustainable and Green Operations

The logistics industry is under increasing pressure to embrace sustainable methods as the world’s attention on environmental sustainability grows. Warehouses, particularly those with cold storage, require significant energy, prompting calls from customers and authorities for greener operations.

To address these demands, businesses are turning to solutions such as solar panels, energy-efficient lighting, and better transportation routes. While these procedures may involve an initial expenditure, they provide long-term cost benefits and boost a company’s sustainable image.

The Future of Warehousing: Automation and Sustainability

In Singapore, automation, such as AMR robots and ASRS systems, directly solves the constraints of high labor costs and limited space. These technologies optimize warehouse operations, lowering the need for manual labor and increasing productivity, making businesses more competitive.

Smart warehouses will utilize AI and IoT to optimize inventory and workforce scheduling. Sustainability, which includes solar panels and energy management systems, is becoming increasingly important. This is consistent with the Singapore Green Plan 2030, ensuring revenue while promoting environmental aims.

Manage and Automate Your Warehouse with ScaleOcean’s Logistics Software

Navigating modern warehouse logistics in Singapore involves more than just hard work. It also necessitates sophisticated technology. ScaleOcean’s logistics software delivers visibility, control, and automation to address costs, speed pressures, and accuracy, thereby streamlining workflows and increasing performance.

ScaleOcean’s logistics software is eligible for CTC grant funding to decrease adoption costs. It enables firms to streamline supply chain operations, manage inventory efficiently, and increase overall efficiency. The following are the primary features of ScaleOcean’s software:

- Integrated Warehouse Management: Optimizes inventory and automates warehouse workflows for efficiency and accuracy.

- Transportation Management System: Enhances route planning and provides real-time shipment tracking for cost-effective deliveries.

- End-to-End Visibility: Offers complete transparency from warehouse to customer delivery, crucial for complex logistics in Singapore.

- Seamless Integration: Easily integrates with other business systems, improving coordination and decision-making.

- Automation and Cost Reduction: Automates logistics processes to improve efficiency, reduce costs, and minimize errors.

Conclusion

Warehouse logistics in Singapore is more than just storage. It’s the engine of the supply chain, directly impacting profitability, customer satisfaction, and competitiveness. Every element, from inventory placement to picking, packing, and shipping, plays a crucial role.

The future of warehouse logistics lies in automation and sustainability. By embracing technology as a core strategy, businesses can build smarter, faster operations. ScaleOcean’s logistics software supports this transformation, optimizing operations and ensuring long-term success in a competitive market.

FAQ:

1. What is warehouse logistics?

Warehouse logistics involves the systematic management of goods within a warehouse. This includes overseeing inventory, coordinating order fulfillment, managing storage, and optimizing internal processes to ensure the efficient movement of products throughout the facility.

2. What is the role of a warehouse in logistics?

A warehouse serves a critical function in logistics by storing goods and ensuring they’re readily available for distribution. It also facilitates order processing, consolidates shipments, and supports efficient inventory management, all vital for smooth supply chain operations.

3. Are warehousing and logistics the same?

No, warehousing and logistics are closely related but not identical. Warehousing refers to the storage of goods, whereas logistics involves the broader supply chain process, including transportation, inventory management, and the overall movement of goods.

4. What is an example of logistics in a warehouse?

An example of logistics in a warehouse is managing stock rotation. This involves organizing goods to ensure that products are accessible for picking, efficiently packed, and shipped according to customer demand, helping streamline order fulfillment and reduce delays.

PTE LTD..png)

.png)

.png)

.png)

.png)