In the business world, the terms procurement and purchasing are often used interchangeably to optimize the procurement process for goods and services within a company. Businesses must optimize these processes, either by employing the right strategy or utilizing advanced technology.

As quoted in RouteFifty, a Singapore-based newsletter, explains that the use of AI in procurement and purchasing can improve security and effectiveness. Furthermore, it is also important to understand the differences between procurement and purchasing so that companies can optimize their procurement processes appropriately and optimally.

This article will discuss the differences between the two processes in detail, as well as their meanings. Learn more here.

- Procurement refers to the strategic, end-to-end process of acquiring goods, services, or works required for business operations.

- Steps in procurement are identifying needs, supplier sourcing, negotiation and contracting, purchase order and delivery, payment, and performance evaluation

- Purchasing is the process of acquiring goods and services required for business operations.

- Steps in purchasing are creating a purchase requisition, approving the requisition, issuing the PO, receiving and verifying the order, conducting three-way matching, approving the invoice, and keeping reliable records.

- ScaleOcean helps companies manage procurement and purchasing efficiently, reduce manual errors, and improve control over costs and availability.

What Is Procurement?

Procurement refers to the strategic, end-to-end process of acquiring goods, services, or works required for business operations. It involves identifying needs, sourcing suppliers, managing contracts, receiving materials, and processing payments.

The procurement process also emphasizes value creation, risk mitigation, and long-term supplier relationships beyond mere purchasing activities.

The Importance of Procurement

Procurement plays a crucial role in ensuring business sustainability and competitiveness. It goes beyond acquiring goods and services—it drives cost efficiency, mitigates risks, supports strategic goals, and builds lasting supplier partnerships that contribute to long-term growth and operational excellence.

1. Cost-Effectiveness & Value Optimization

Effective procurement helps companies control spending while maximizing value across the supply chain. By negotiating favorable contracts, standardizing purchasing processes, and leveraging economies of scale, businesses can achieve significant cost savings. It also ensures that every purchase delivers measurable returns and supports financial efficiency.

2. Risk Management

Procurement safeguards companies from potential disruptions such as supplier failure, price volatility, or compliance issues. This proactive approach also ensures business continuity and stability in unpredictable markets.

By properly evaluating, diversifying, and continuously monitoring suppliers through procurement, companies can anticipate and mitigate risks before they affect operations.

3. Strategic Alignment

Procurement process aligns purchasing activities with the company’s broader goals, whether it’s sustainability, innovation, or growth.

By integrating procurement strategies into corporate planning, organizations ensure resources are allocated efficiently and that every purchasing decision supports long-term objectives, improving overall business performance and competitiveness.

4. Stronger Supplier Relationships

Building strong supplier relationships enables better collaboration, trust, and innovation. When companies maintain open communication and mutually beneficial agreements, suppliers become strategic partners rather than mere vendors.

This strengthens supply reliability, enhances product quality, and promotes continuous improvement that benefits both parties.

Key Steps in the Procurement Process

The procurement process involves a series of structured steps to ensure that every purchase is efficient, transparent, and aligned with organizational goals. Each stage—from identifying needs to managing supplier performance—plays a vital role in optimizing costs, ensuring quality, and maintaining accountability.

1. Identifying Needs

The process begins with recognizing what goods or services the company requires. Departments assess operational gaps and specify detailed requirements such as quantity, quality, and delivery timelines. Clearly defining these needs helps avoid unnecessary spending and ensures that purchases directly support business operations.

2. Supplier Sourcing

After identifying requirements, the next step is to search for and evaluate potential suppliers. Procurement teams compare vendors based on factors like price, reliability, quality, and compliance. This stage ensures the organization partners with reputable suppliers who can meet expectations consistently and deliver value over time.

3. Negotiation and Contracting

Once the right supplier is selected, the organization negotiates terms covering pricing, delivery, and service levels. Contracts are then formalized to ensure mutual understanding and accountability. This step is essential to securing cost advantages while protecting the company from legal and financial risks.

4. Purchase Order and Delivery

A purchase order (PO) is issued to confirm the agreed terms. The supplier then delivers the goods or services according to the specifications. During this stage, Procurement teams use purchase order system software to track deliveries, inspect items, and ensure compliance with order details efficiently.

5. Payment and Performance Evaluation

After successful delivery, the company processes invoices and releases payments based on contract terms. Procurement also conducts performance evaluations to measure supplier reliability, quality, and responsiveness. These insights support continuous improvement and help build a more efficient and accountable supply chain.

Types of Procurement

Procurement is a crucial function in managing a company’s supply chain, ensuring the acquisition of goods and services to meet operational needs. It can be categorized into different types based on the nature of the items or services being procured. Here are the main types of procurement:

1. Direct Procurement

Direct procurement refers to the acquisition of goods and services that are directly involved in the production of the company’s final products. This includes raw materials, components, and parts essential for manufacturing. It plays a central role in production efficiency and cost control.

2. Indirect Procurement

Indirect procurement covers goods and services that are not directly involved in production but are essential for daily operations. This can include office supplies, IT services, and maintenance. Though not directly linked to revenue generation, indirect procurement supports the organization’s overall efficiency.

3. Goods Procurement

Goods procurement involves the acquisition of physical items, such as raw materials, equipment, and finished products, necessary for operations. It focuses on sourcing the right quantities at the right price to ensure smooth operations, production timelines, and inventory management.

4. Services Procurement

Services procurement refers to acquiring non-tangible items like consulting, IT services, or marketing expertise. This type of procurement requires a focus on vendor capabilities, service level agreements, and long-term contracts. It ensures the business has the necessary skills and support to function effectively.

The Methods of Procurement

Procurement methods determine how goods, services, or works are acquired based on the project’s objectives, urgency, and value. Choosing the right method ensures transparency, efficiency, and cost-effectiveness while aligning with both organizational goals and regulatory requirements.

1. Competitive Methods

Competitive methods promote fairness by inviting multiple suppliers to bid, ensuring the best combination of price and quality.

Open Tendering

Open tendering allows all qualified suppliers to submit bids, ensuring transparency and encouraging market competition. It is commonly used for large-scale or government projects where fairness and accountability are essential.

Selective Tendering (or Restricted/Closed Tendering)

Selective tendering invites only pre-qualified suppliers with proven capabilities. This method is faster and ensures reliability, especially for specialized goods or services where only certain vendors meet technical standards.

Request for Proposals (RFP)

An RFP invites suppliers to submit detailed proposals outlining how they will meet the organization’s needs. It is ideal for complex projects that require creative or technical solutions, allowing evaluators to compare both quality and cost factors.

Request for Quotations (RFQ)

RFQ focuses primarily on pricing for clearly defined goods or services. Companies send RFQs to multiple suppliers and select the most competitive offer, making this method suitable for straightforward, low-value purchases.

Request for Information (RFI)

An RFI is used to gather preliminary details from suppliers before launching a formal tender. It helps organizations understand market capabilities, pricing trends, and potential vendors before finalizing specifications or budgets.

2. Non-Competitive Methods

Non-competitive methods are applied when open competition is not feasible, such as in cases of urgency or unique product requirements.

Single-Source Procurement

Single-source procurement method involves purchasing from one supplier without competition, often due to the vendor’s exclusive rights or specialized expertise. While efficient, it requires justification to ensure transparency and prevent favoritism.

Negotiated Procurement

In negotiated procurement, the buyer directly negotiates terms and prices with one or more suppliers. It is used when project requirements are highly specific or when time constraints make competitive bidding impractical.

3. Specialized Methods

Specialized methods address unique procurement needs that require flexibility, integration, or speed.

Two-Stage Tendering

This method combines open competition and negotiation. In the first stage, bidders propose preliminary solutions, and in the second, selected participants refine their offers based on feedback—ideal for complex or evolving projects.

Design and Build

Design and build integrates both design and construction under a single contract. This method improves coordination, shortens timelines, and minimizes risk by assigning full project responsibility to one contractor.

Framework Agreements

A framework agreement establishes long-term arrangements with selected suppliers for recurring needs. It simplifies future purchases, ensures consistent quality, and allows flexibility in quantity and timing over the contract period.

Emergency Procurement

Used in urgent situations such as natural disasters or equipment failure, emergency procurement bypasses standard procedures to secure goods or services immediately, ensuring business continuity and public safety.

What Is Purchasing?

Purchasing is the process of acquiring goods and services required for business operations. Procurement is a more strategic, all-encompassing process, whereas purchase is the transactional aspect. It entails placing orders, processing payments, and utilizing a variety of purchasing methods to suit specific requirements.

Strategic purchasing is more than just buying stuff. It is about developing supplier connections and optimizing the supply chain. A purchase journal is a crucial tool for ensuring that all transactions are carefully logged and accounted for.

The Importance of Purchasing

Purchasing is a vital function in any business, ensuring that goods and services are acquired efficiently and at optimal prices. It plays a crucial role in managing costs, maintaining operations, and fostering relationships with suppliers. Below are key reasons why purchasing is indispensable for business success:

1. Cost Control and Profitability

Effective purchasing directly impacts the bottom line by ensuring that the business buys goods and services at competitive prices. Strategic purchasing decisions help control expenses, improve profit margins, and reduce the overall cost of goods sold, thereby significantly enhancing profitability.

2. Ensuring Operational Continuity

Purchasing ensures that the required materials, supplies, and services are always available when needed. It prevents stockouts, delays, and disruptions in production or service delivery, which could otherwise hinder operational continuity and customer satisfaction, ultimately affecting business performance.

3. Quality Assurance

By carefully selecting suppliers and negotiating quality standards, purchasing ensures that the goods and services meet required specifications. This commitment to quality helps maintain product or service consistency, enhances customer satisfaction, and minimizes the need for returns or rework.

4. Supplier Relationship Management

Purchasing builds strong, long-term relationships with reliable suppliers. Effective supplier relationship management fosters trust, promotes collaboration, and ensures favorable terms, which can result in better pricing, priority access to materials, and a higher level of service.

5. Risk Reduction and Mitigation

Purchasing plays a key role in risk management by sourcing from reputable suppliers and diversifying sources. This minimizes the risks of supply chain disruptions, price fluctuations, and quality issues, helping the business to adapt to market changes and ensure smooth operations.

6. Efficiency and Innovation

Purchasing is integral to streamlining operations by sourcing materials and services that support process improvements. By leveraging technology, automation, and supplier collaboration, purchasing can drive efficiency and encourage innovation in the supply chain, leading to cost savings and competitive advantages.

7. Transparency and Compliance

An organized purchasing function ensures that all procurement activities are conducted in compliance with relevant laws and regulations. Transparency in purchasing fosters accountability, supports audits, and ensures ethical sourcing practices, which help the business maintain regulatory compliance and a strong reputation.

Key Steps of the Purchasing Process

The purchasing process is a structured workflow that ensures every acquisition, whether for materials, services, or equipment, is handled efficiently and transparently. By following these steps, businesses can maintain accountability, control costs, and strengthen supplier performance while ensuring that every purchase aligns with company needs.

1. Identify the Need & Create a Purchase Requisition

The process begins when a department identifies a need for goods or services. A purchase requisition form is created, detailing item specifications, quantities, and justifications. This document acts as an internal request that triggers the procurement process and ensures organizational approval before spending.

2. Review and Approve the Requisition

Once submitted, the purchase requisition undergoes a review process by management or finance. Approvers verify the necessity, budget availability, and accuracy of the request. This step ensures spending control, prevents duplication, and aligns purchases with company policies and financial limits.

3. Issue the Purchase Order (PO)

After approval, the procurement team generates a purchase order and sends it to the supplier. The PO serves as a formal contract that defines product details, pricing, delivery terms, and payment conditions. It legally binds both parties and helps track order fulfillment accurately.

4. Receive and Verify the Order

When the supplier delivers, the receiving department inspects the goods or services against the PO. This verification step checks quantity, quality, and condition to ensure conformity with agreed specifications. Any discrepancies are documented immediately to maintain accuracy in records and payments.

5. Conduct Three-Way Matching

Three-way matching compares the purchase order, goods receipt, and supplier invoice to confirm accuracy before payment. This critical control prevents overbilling, duplicate payments, or errors. It ensures that the company only pays for items that were ordered, received, and properly invoiced.

6. Approve and Process the Invoice Payment

Once all documents match, the finance department approves the invoice for payment. Payments are then processed according to the agreed terms, whether immediate or on credit. This ensures timely supplier relationships and accurate financial reporting within the organization.

7. Keep Reliable Records

The final step involves archiving all documents related to the purchase, such as requisitions, POs, receipts, and invoices. Maintaining accurate records supports audits, performance analysis, and financial transparency. It also provides valuable data for improving future purchasing strategies and compliance.

The Methods of Purchasing

Understanding the methods of purchasing is crucial for building a strong supply chain. The best approach depends on your business, market trends, and your goals, ensuring the strategy aligns with your needs and objectives.

We’ll explore seven common strategies businesses in places like Singapore use. These methods help cut costs, manage inventory, and navigate unpredictable markets. Understanding the nuances of these types of purchasing methods can elevate from good to great.

1. Bulk Purchasing

Bulk purchase entails purchasing huge quantities of items at once in order to take advantage of volume savings. It is appropriate for products with continuous demand, such as office supplies, which require consistent supply levels. This strategy reduces per-unit costs dramatically.

However, it demands adequate cash flow and storage space. Businesses lacking the capacity to handle large items may have challenges, such as capital being trapped in inventories. A manufacturer, for example, could save money by purchasing raw materials in bulk, but they would need a sufficient warehouse to store them.

2. Blanket Purchasing (Blanket Purchase Orders)

Blanket purchase is the process of entering into an arrangement with a supplier for a certain set of commodities over an extended period of time. This strategy enables enterprises to obtain fixed prices and terms upfront while receiving items in smaller, more frequent releases as needed.

For example, a manufacturing company may employ blanket purchasing for raw materials such as steel or plastic to ensure a continuous supply without the need to place individual orders. This strategy saves administrative burden and improves inventory control.

3. Just-in-Time (JIT) / Hand-to-Mouth Purchasing

JIT, or Hand-to-Mouth Purchasing, ensures that commodities arrive at the exact time required for production or selling. This lowers inventory keeping costs, which is especially useful in businesses where storage costs are an issue, such as manufacturing and logistics.

However, JIT is primarily reliant on trusted suppliers and perfect logistics. Even a minor delay in delivery can interrupt output. While it saves money on inventory, it also increases operational risk, which Singapore businesses must carefully manage to remain competitive.

4. Spot Purchasing (Spot Buying)

Spot purchasing is a reactive strategy in which businesses make one-time purchases to meet an immediate necessity. It is commonly utilized in situations where speed is more important than cost, such as unanticipated shortages or sudden market opportunities.

However, spot purchases are generally more expensive. Prices are typically higher when there is no leverage from a long-term commitment. For example, if a manufacturer unexpectedly runs short of crucial parts, it may have to buy them at higher prices right away to avoid production delays.

5. Contract Purchasing

Contract purchasing is reaching a long-term agreement with a supplier that includes pricing, quantities, delivery schedules, and quality criteria. This method assures consistency and stability in procuring critical supplies for your organization throughout time.

Contract purchasing is exemplified by manufacturers agreeing to purchase a particular quantity of raw materials, such as steel, for the following year at agreed-upon pricing. However, the disadvantage is that you are bound to these conditions even if market prices fall.

6. Speculative Purchasing

Speculative purchasing is when you buy more items than you need because you expect prices to rise or there will be a shortage. This technique aims to profit from market volatility while preventing future cost rises.

For example, a corporation may purchase additional raw materials during a market downturn, believing that prices will rebound later. However, if the prediction is not met, the company may be left with surplus stock at higher-than-expected prices, increasing financial risks.

7. Group Purchasing

When several businesses band together to join a Group Purchasing Organisation (GPO), this is known as group purchasing. By pooling their purchasing power, they may negotiate better bargains and get terms that are generally only available to larger enterprises, which benefits smaller businesses.

In the healthcare sector, for example, tiny clinics might join a GPO for discounts on medical supplies, but it can limit product options due to specified suppliers. According to MOH, price differences may occur when hospitals start new contracts with updated prices after fulfilling old contract quantities.

Key Difference Between Procurement and Purchasing

Procurement is the strategic, broad process of obtaining goods and services, whereas purchasing is the tactical, transactional element within it. Procurement includes identifying needs, sourcing and evaluating suppliers, negotiating contracts, and managing relationships, with an emphasis on long-term value.

Purchasing, on the other hand, is centered on the immediate actions of buying, like generating purchase orders and processing payments. There are some differences between procurement and purchasing, including:

| Aspect | Procurement | Purchasing |

|---|---|---|

| Scope | Covers the entire process of sourcing goods and services, such as supplier selection, contract negotiation, and supplier management | A subset of procurement that deals specifically with the transaction of buying goods and services once the requirements are established |

| Goal | Ensure the company acquires the right goods at the best value | Efficient acquisition of goods at the best possible price |

| Approach | By analyzing market conditions, supplier capabilities, and internal needs | Focuses on the immediate needs of acquiring products to fulfill specific orders |

| Supplier Relationship | Emphasize building long-term | Typically involves shorter-term interactions |

| Focus | Concerned with the broader strategic function of managing supply chains | Focused more on the tactical side, ensuring that orders are placed, fulfilled, and invoices are accurate and on time |

| Key Activities | Supplier research, risk management, contract management, and performance evaluation | Placed orders, managed inventory, received goods, and ensured timely payment processing for purchased goods or services |

Manage Procurement and Purchasing with Seamless Integration Using Scaleocean

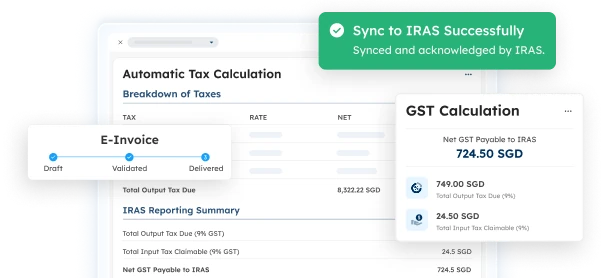

ScaleOcean’s best purchasing software offers a solution that optimizes procurement and purchasing processes through integration and automation. Using ScaleOcean, you can manage the entire procurement cycle, from purchase requisition to goods receipt, in a single platform.

This system integrates with other modules in ScaleOcean’s ERP, such as inventory management, accounting, and budget management. This ensures accurate procurement monitoring, real-time stock updates, and avoids overspending by automatically controlling budgets.

Furthermore, you can customize the features and modules offered by ScaleOcean and configure the system to suit your work processes and business needs. This solution optimizes the system for your company.

To optimize your customization process, do a free demo and consult with Scaleocean’s professional team to get the best solution according to your business specifications. ScaleOcean offers several specific features to optimize procurement and purchasing processes in your business, including:

- E-Procurement: An online tender facility to reduce manual processes and increase time and cost efficiency in procuring goods and services.

- Procurement Automation: Automatically converts RFQ (Request for Quotation) submissions into purchase orders.

- Vendor Management: Automatically assesses each vendor based on specific criteria such as timeliness, price, and completeness of service. This helps companies select the best procurement vendor based on historical data.

- Minimum Stock Notification: Automatic notification when inventory reaches the minimum limit, allowing companies to immediately reorder before shortages occur.

- Procurement Tracking: Full visibility of procurement status, from ordering to receiving goods, can be monitored on a single platform.

- Automatic Budget Control: Monitors purchasing budgets and provides alerts if procurement exceeds the established budget.

By automating and integrating procurement and purchasing processes, ScaleOcean helps companies manage procurement and purchasing processes efficiently, reduce manual errors, and improve control over costs and availability.

Conclusion

In conclusion, effective procurement and purchasing processes are crucial to ensuring operational continuity, cost control, and supplier relationship management. By optimizing these functions, businesses can enhance their overall efficiency and profitability.

ScaleOcean purchasing software integrated purchasing software provides an ideal solution, helping businesses streamline procurement tasks, automate workflows, and ensure accuracy in transactions. With ScaleOcean, you can confidently manage your purchasing needs while boosting your business’s productivity and success.

FAQ:

1. Which comes first, procurement or purchasing?

The purchasing management process typically begins halfway through the procurement process. Key elements of purchasing include submitting a purchase request, which is often initiated through a purchase requisition. It’s a formal internal request for approval to purchase on behalf of the company.

2. Does procurement fall under purchasing?

Although the terms procure and purchase are often used interchangeably, procurement is a broader, more strategic function. Purchasing, on the other hand, is a part of procurement that focuses specifically on the actual buying process.

3. What is the main goal of procurement?

The objective of procurement is to strategically obtain the required goods and services for a business, ensuring the best price, quality, and timing, while maintaining a reliable supply and effectively managing supplier relationships.

4. What are the 5 P’s of purchasing?

Understanding the 5 P’s, such as Power, People, Processes, Planning, and Prevention, is essential in procurement and purchasing. These principles are key to the success of the procurement and purchasing cycle. Power signifies the influence and authority that the procurement team holds within the organization.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)