Managing finances in manufacturing is complex, requiring precision and efficiency to ensure business success. Manufacturing accounting systems are specialized tools designed to meet the unique financial needs of the industry. They can be a solution for companies to manage their finances comprehensively and gain full visibility into their operations.

Manufacturing accounting systems are software solutions designed to help manufacturers oversee their financial and accounting operations. They facilitate inventory management, cost accounting, and financial reporting.

Adopting manufacturing accounting systems is key for Singaporean businesses to stay competitive. Manufacturing is vital to the economy, according to TradingEconomics, with Q3 2024 GDP hitting $29,503.70$ SGD million, showing strong growth and the importance of efficient financial control.

Companies implementing the right framework can make informed decisions and secure their position ahead of the competition. So this article is going to delve into the essential role of manufacturing accounting systems in Singapore, their key features, and the best manufacturing accounting systems in Singapore, like ScaleOcean, QuickBooks, and more.

- A manufacturing accounting system monitors all financial elements of production, covering materials, labor, and overhead.

- Benefits of A Manufacturing Accounting System include accurate costing, improved inventory management, better production planning, enhanced financial reporting, and cost control.

- Find the perfect fit from the best manufacturing accounting systems in Singapore, like ScaleOcean, QuickBooks, Xero, FreshBooks, and more, for your business

- ScaleOcean’s manufacturing ERP software is a comprehensive solution designed to really streamline financial management.

What Is a Manufacturing Accounting System?

A manufacturing accounting system monitors all financial elements of production, covering materials, labor, and overhead. It helps manage finances and inventory by integrating accounting and production processes. It also uses costing methods like job order or process costing, tailored to your approach.

Manufacturing accounting software gives you a more detailed view than standard systems, focusing on specific production costs. It lets you monitor materials, labor, and overhead at every stage, ensuring accurate analysis. This really helps you spot inefficiencies and optimize pricing easily.

A Manufacturing Accounting System includes key components like cost accounting, inventory management, and production planning. The absorption costing method is often used in cost accounting to allocate fixed and variable costs, ensuring precise expense tracking and maximizing profitability.

What Kind of Accounting System Is Used in Manufacturing?

Manufacturing firms utilize cost accounting to monitor production costs and enhance operational efficiency. This encompasses the assessment of direct costs, including raw materials and labor, alongside indirect costs such as factory overhead. Through the evaluation of these expenditures, manufacturers can accurately establish product pricing and assess profitability.

Additionally, management accounting plays a crucial role by enabling businesses to make informed decisions based on data analysis related to production efficiency, budgeting, and cost management. This methodology offers valuable insights into inventory accounting, cost distribution, and financial forecasting, thereby assisting manufacturers in optimizing their resources and sustaining profitability.

Methods in Manufacturing Accounting Systems for Singapore Companies

An accounting system for manufacturing is crucial for tracking production costs. By implementing Cost of Goods Sold (COGS), businesses can efficiently manage cost accounting, inventory, and production control, optimizing operations and ensuring financial accuracy.

Here are the explanations for each method in the manufacturing accounting system, including:

1. Absorption Costing

Absorption costing includes all manufacturing costs, fixed and variable, in product costs, ensuring GAAP compliance for external reporting. This covers the Cost of Goods Sold (COGS), which represents the direct costs associated with production. This method gives a comprehensive cost view.

While it accurately reflects inventory valuation, absorption costing can complicate internal decision-making. By mixing fixed and variable costs into COGS, businesses might find it harder to truly understand cost behavior, which can potentially impact key operational strategies.

2. Variable Costing

This approach incorporates solely variable costs, namely, direct materials, direct labor, and variable overhead, into product costs. Fixed overhead is classified as a period cost. By emphasizing the contribution margin, this method facilitates short-term decision-making and enhances profitability analysis.

3. Standard Costing

Involves the use of predetermined costs for materials, labor, and overhead expenses. Discrepancies between the standard costs and actual costs are examined to manage expenses, boost efficiency, and refine budgeting and performance assessment.

4. Actual Costing

This approach allocates costs according to the actual expenses associated with materials, labor, and overhead. While it offers accurate tracking of costs, it can become complicated due to variations in actual costs over time.

5. Weighted Average Costing

This method calculates the average cost of all units available for sale within a specific timeframe. It mitigates the impact of price variations, thereby facilitating the valuation of inventory. This approach is frequently employed in process costing systems for products that are uniform.

6. Job Order Costing

Job order costing is used for batch manufacturing, where costs are tracked for each specific job or batch of products. This method ensures that all costs associated with a particular batch are accounted for, providing clear insights into the profitability of each batch. It is especially useful for customized or small-scale production runs.

7. Process Costing

Process costing is used in continuous manufacturing, where products are produced in a steady flow. Costs are averaged over the production period and assigned to units produced, which is helpful when individual units are indistinguishable. This method ensures that cost distribution is fair and accurate, even in high-volume production environments.

8. Activity-Based Costing (ABC)

Involves the allocation of overhead expenses according to the activities that incur these costs, rather than relying on volume metrics. This approach enhances the precision of product costing by associating costs with particular activities, thereby facilitating better cost management and analysis of profitability.

9. Cost Control

Assists in recognizing and managing expenses during the production process, thereby enhancing efficiency and increasing profitability. This is essential for understanding the profitability of each product and making informed business decisions. By providing accurate cost data, it helps businesses identify areas for cost-saving and efficiency improvements.

10. Inventory Management

Inventory management involves accurately tracking raw materials, Work-in-Progress (WIP) items, and finished products to maintain precise inventory levels, thereby avoiding both shortages and excess stock.

It ensures that materials are available when needed for production and helps avoid stockouts that could halt operations. Effective inventory management also optimizes stock levels, reducing waste and storage costs.

11. Production Planning and Control

Assists in recognizing and managing expenses during the production process, thereby enhancing efficiency and increasing profitability. Production planning and control is responsible for forecasting demand and scheduling production to meet targets.

It involves managing resources, such as labor and materials, to ensure efficient manufacturing. This component helps align production with customer demand, preventing delays and ensuring timely deliveries.

12. Cost Allocation

Cost allocation ensures that both direct costs (like raw materials and labor) and indirect costs (such as rent and utilities) are accurately assigned to the relevant products or processes. This helps businesses understand the true cost of production. Proper cost allocation leads to better pricing decisions and cost management.

Challenges in Manufacturing Accounting

In implementing a manufacturing accounting system, companies face many problems and obstacles that can hinder the management of business finances. Starting from challenges in tracking costs, managing inventory, and meeting compliance standards must be addressed properly.

Here are the challenges and obstacles that must be overcome in the manufacturing accounting process:

1. Cost Management

Accurate cost tracking is crucial for profitability, but it is challenging at times due to fluctuations in raw material prices, labor costs, and manufacturing overhead costs. Without precise allocation of costs, businesses risk inaccurate pricing strategies, which can erode profit margins and market competitiveness.

2. Inventory Control

Ineffective inventory control disrupts operations and increases holding costs. Managing raw materials, work-in-progress, and finished goods requires efficient procedures to avoid overstocking or shortages, ensure smooth production, and satisfy customer demand without incurring unnecessary costs.

3. Regulatory Compliance

Manufacturing companies must navigate complex regulatory frameworks, including tax laws, environmental policies, and labor regulations. Failure to comply can result in penalties, legal responsibilities, and damage to the reputation, highlighting the importance of comprehensive accounting solutions to ensure compliance.

4. Data Integration and Accuracy

The manufacturing accounting process generates vast amounts of data across departments. Ensuring accurate and integrated financial data, including updates to the general ledger, is critical to informed decision-making. Disconnected systems or manual entries increase errors, delay reporting, and hinder strategic planning efforts for long-term growth.

Benefits of A Manufacturing Accounting System

Accounting for manufacturing streamlines complex financial operations, increases accuracy, and allows for seamless departmental collaboration. These tools enable producers to optimize operations, improve decision-making, and maintain a competitive advantage in a demanding market.

1. Accurate Costing

Accurate accounting for a manufacturing system tracks all production costs, including raw materials, labor, and overhead. Using Singapore manufacturing cost estimating software, businesses can determine the true cost of production, making informed pricing decisions and improving profitability.

2. Improved Inventory Management

The system enables real-time tracking of inventory, ensuring accurate data on raw materials, work-in-progress, machine availability, and finished goods. This minimizes the risk of stockouts or overstocking, leading to better resource utilization. It enhances inventory efficiency by linking directly to procurement processes, reducing waste and unnecessary costs.

3. Better Production Planning

By tracking costs and production data, a manufacturing accounting system helps businesses forecast demand and plan production schedules more effectively. The system integrates financial and production data, allowing managers to optimize resource allocation. This ensures that production targets are met without delays and that resources are used efficiently.

4. Enhanced Financial Reporting

With integrated financial tracking, the manufacturing accounting system provides real-time and accurate reports, offering insights into the business’s financial health. It helps businesses analyze profitability, cash flow, and other key financial metrics, supporting informed decision-making. These reports ensure that management can make timely adjustments to meet financial goals and maintain growth.

5. Cost Control

The system continuously monitors and tracks production-related expenses, helping businesses identify areas where costs can be reduced. By analyzing spending patterns, companies can make informed decisions to optimize resource use and minimize waste. This level of control improves overall profitability by ensuring that only necessary expenses are incurred.

What to Look for in a Manufacturing Accounting System?

In the fast-paced world of manufacturing, especially in Singapore, the right accounting system can be the difference between thriving and just surviving. From scalability to real-time insights, here are the things to look for in a manufacturing accounting system to ensure your operations run smoothly and profitably:

1. Scalability

As your business expands, your requirements evolve accordingly. The appropriate system must scale seamlessly, supporting higher production levels, a growing number of users, and increasingly intricate processes.

Whether you are broadening your product offerings or venturing into new markets, scalable software guarantees that your system will remain adequate, thereby preventing expensive upgrades or migrations in the future.

2. Integration Capabilities

Your accounting system should not function independently. Seek solutions that integrate effortlessly with your current ERP, CRM, and supply chain systems. This approach guarantees a seamless flow of data between departments, reduces the likelihood of manual data entry errors, and offers a comprehensive perspective of your operations, thereby improving both efficiency and accuracy.

3. Real-Time Data Access

Getting real-time visibility into production costs, inventory, and finances is key to quick decision-making. Integrated invoicing software in Singapore helps you track transactions and manage invoices easily, optimizing workflows so you can quickly respond to market changes.

4. Cost Tracking and Analysis

Effective cost management is essential in the manufacturing sector. Select software that accurately monitors variable, fixed, and manages overhead costs. Utilizing advanced tools for variance analysis can assist in identifying inefficiencies, managing expenses, and enhancing profitability. Precise cost tracking guarantees that you remain informed about your financial status.

5. Compliance and Reporting

Adhering to accounting standards such as GAAP or IFRS is essential. Your software must produce precise financial reports, which encompass profit and loss statements, balance sheets, and cash flow statements. Comprehensive reporting capabilities not only guarantee compliance but also offer critical insights for strategic decision-making.

6. User-Friendly Interface

A complex system may hinder productivity. It is advisable to choose software that features an intuitive and easily navigable interface, which helps to reduce the learning curve for your team.

A design that prioritizes user-friendliness decreases training time, lowers the likelihood of errors, and allows employees to concentrate on their primary responsibilities instead of grappling with the software.

The 10 Best Manufacturing Accounting Systems in Singapore

Manufacturing businesses in Singapore absolutely need reliable accounting systems to truly streamline operations and enhance financial management. To help you choose, here are some of the top accounting software solutions available that we highly recommend:

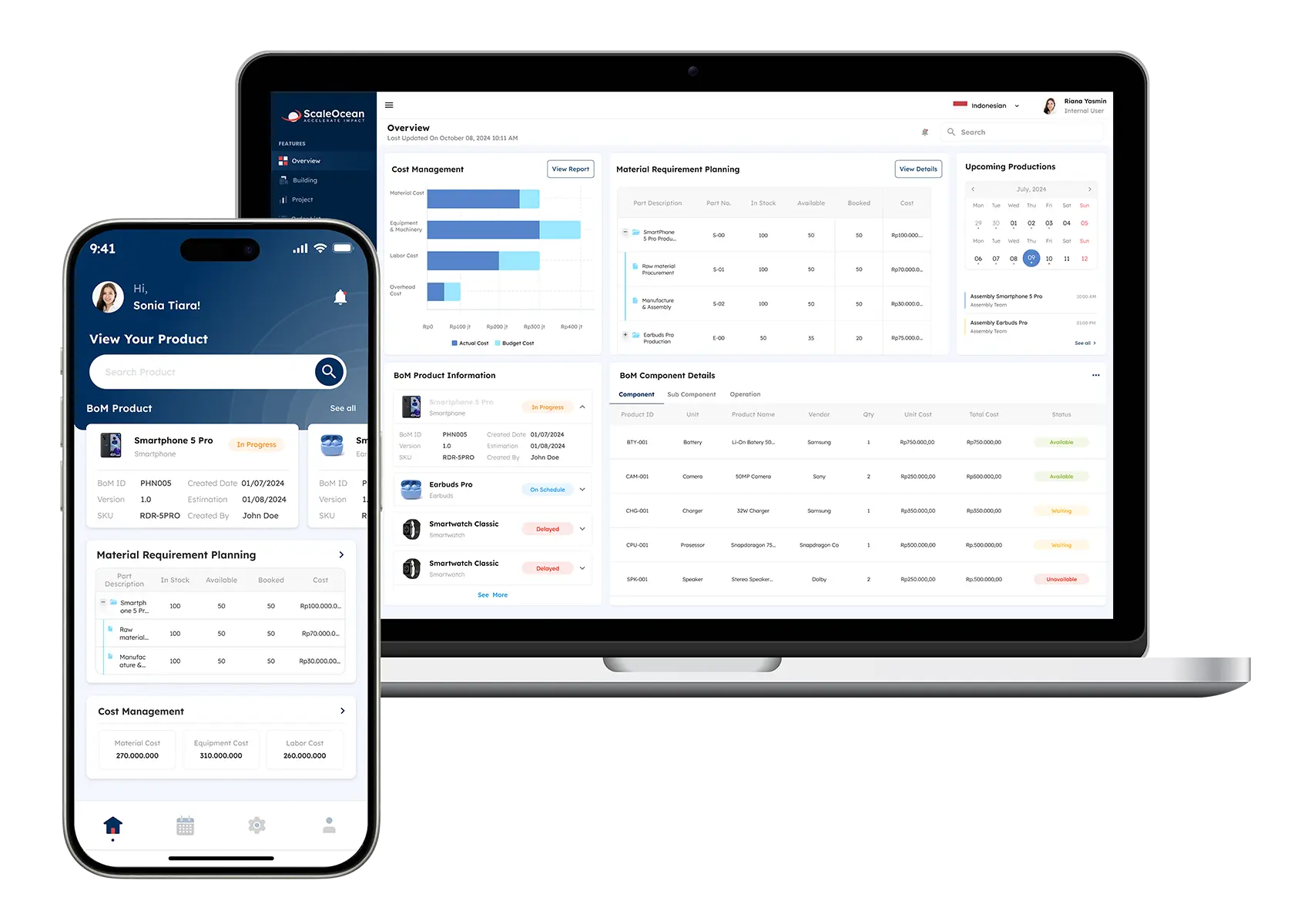

1. ScaleOcean’s Manufacturing ERP Software

ScaleOcean’s manufacturing ERP is a comprehensive solution designed to really streamline financial management. It provides real-time financial tracking and integrates seamlessly with other systems, significantly improving accuracy and cutting down on manual effort in your accounting processes.

This software genuinely helps manufacturers enhance operational efficiency through task automation, ensuring scalable growth. They offer a free demo, too, so you can try it firsthand. Plus, because ScaleOcean’s solution is eligible for CTC grants, it’s a cost-effective opportunity for businesses to optimize finances and improve workflow efficiency.

Key Features:

- Real-time Cost Tracking: Tracks production costs in real-time, ensuring accurate accounting for materials, labor, and overhead.

- Automatic COGM Reports: Generates precise Cost of Goods Manufactured (COGM) reports for accurate financial and cost analysis.

- Multilevel Bill of Materials (BoM): Manages detailed material requirements for each product, aiding in cost estimation and inventory control.

- Inventory Integration for Accounting: Syncs inventory changes with the accounting module for accurate financial tracking and reporting.

- Integration with Financial Modules: Seamlessly integrates production data with accounting, improving financial accuracy and cost management.

| Pros | Cons |

|---|---|

|

|

Best For: ScaleOcean’s Manufacturing ERP is ideal for medium-to-large businesses needing an integrated, scalable solution. With real-time tracking, seamless integration, and task automation, it ensures top operational efficiency and truly optimized financial management.

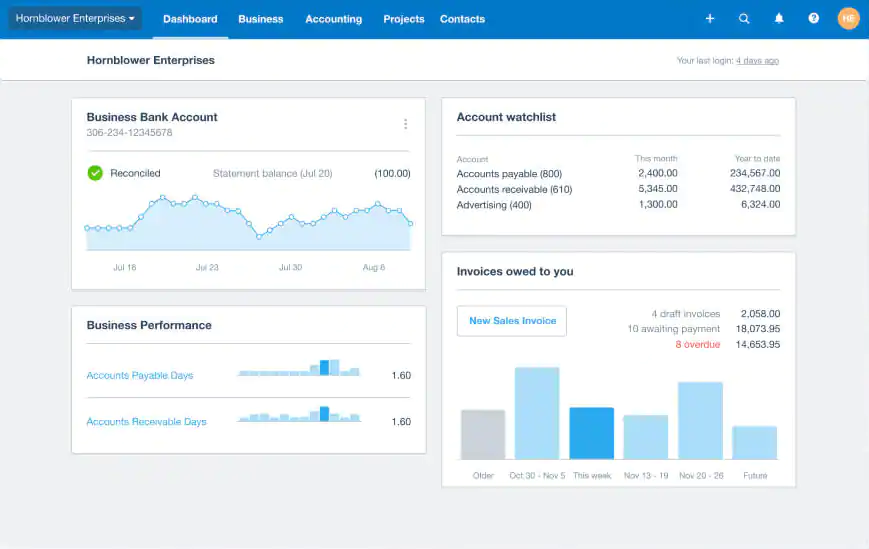

2. QuickBooks Accounting Software

QuickBooks is one of the good accounting software programs that helps businesses manage their finances efficiently. It includes features for tracking income and expenses, creating reports, and managing payroll. QuickBooks is appropriate for numerous industries, including manufacturing.

QuickBooks’ cloud-based technology enables users to manage financial data from anywhere, increasing flexibility for business owners. The software has a simple design and effective accounting capabilities, which help streamline daily operations.

Key Features:

- Cloud-based accessibility

- Payroll management

- Financial reporting tools

- Expense tracking

- Customizable invoices

| Pros | Cons |

|---|---|

|

|

Best For: QuickBooks is best for small to medium-sized businesses in need of an accessible and straightforward accounting solution. It is particularly beneficial for those who require basic financial management tools like invoicing, payroll, and expense tracking without complex functionalities.

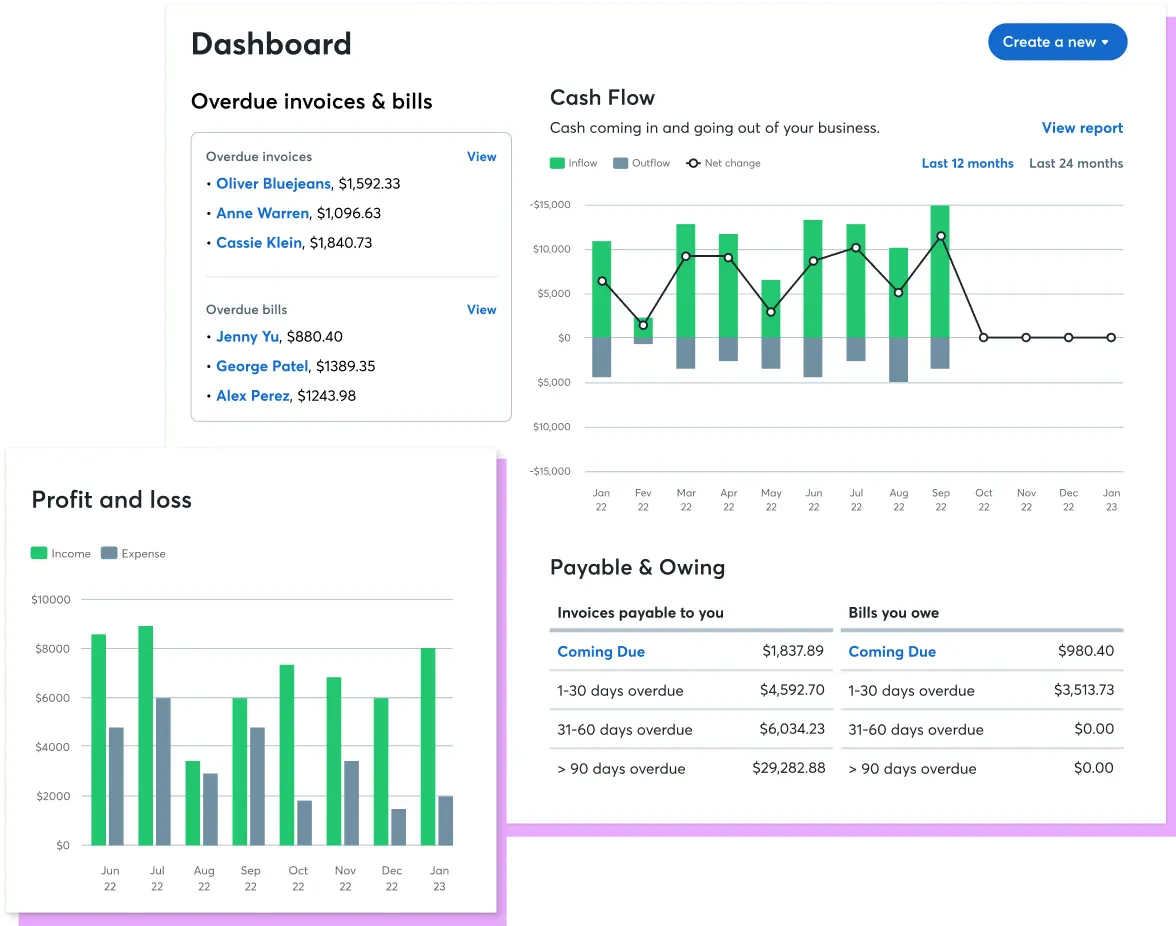

3. Xero Cloud-Based Accounting Software

Xero is cloud-based accounting software that makes financial management easier for businesses. It includes functions such as invoicing, bank reconciliation, and financial reporting. Xero is highly configurable to accommodate the needs of diverse industries, including manufacturing.

With real-time collaboration tools, Xero allows teams to collaborate on financial tasks, increasing productivity. Its user-friendly interface and integration with other company software make it an excellent option for managing accounting operations.

Key Features:

- Cloud-based system

- Real-time bank reconciliation

- Customizable invoicing

- Comprehensive financial reports

- Integration with third-party apps

| Pros | Cons |

|---|---|

|

|

Best For: Xero is ideal for small to medium-sized businesses, including those in the manufacturing sector, that need a customizable, cloud-based accounting solution. It is particularly well-suited for companies looking for real-time financial data and collaborative tools for team-based accounting.

4. FreshBooks Manufacturing Accounting Solutions

FreshBooks is geared toward small businesses, providing accounting solutions such as invoicing, expenditure monitoring, and time management. It simplifies the invoicing process with configurable templates, making it a popular choice among service-based enterprises and manufacturers.

Its cloud-based platform enables remote access and collaboration, while its straightforward interface allows users with little accounting experience to properly manage their accounts. FreshBooks is excellent for increasing the efficiency of billing procedures.

Key Features:

- Cloud-based platform

- Time tracking tools

- Customizable invoices

- Expense management

- Client management tools

| Pros | Cons |

|---|---|

|

|

Best For: FreshBooks is best for small businesses, especially those in the service and manufacturing industries, that need an easy-to-use accounting software with strong invoicing and time tracking features. It’s particularly useful for businesses requiring a simple yet efficient billing solution.

5. Wave Accounting Software

Wave Accounting provides a free cloud-based solution for small enterprises, making it an affordable choice for startups and small manufacturers. It offers invoicing, cost tracking, and basic financial reporting capabilities to help businesses manage their funds more efficiently.

Wave’s user-friendly platform enables business owners to manage their accounts without the complexities of traditional accounting software. Its free plan makes it accessible to organizations that require a simple accounting solution to run their operations.

Key Features:

- Free cloud-based platform

- Invoicing and payment tracking

- Expense tracking

- Basic financial reports

- Receipt scanning

| Pros | Cons |

|---|---|

|

|

Best For: Wave Accounting is best for small businesses, freelancers, or startups in the manufacturing industry that need a free and simple accounting solution. It works well for businesses with basic financial management needs like invoicing, expense tracking, and basic reporting.

6. NetSuite ERP Accounting Software

NetSuite is a comprehensive ERP software that includes powerful accounting functions like financial management, billing, and compliance tracking. It is intended to serve larger enterprises and has extensive functionality for managing manufacturing operations and financial reporting.

NetSuite combines several company processes into a single platform, allowing companies to manage everything from finances to supply chain operations. Its scalability makes it ideal for developing enterprises that require a comprehensive financial management solution.

Key Features:

- Comprehensive financial management

- Advanced reporting tools

- Integrated supply chain management

- Billing and invoicing tools

- Cloud-based platform

| Pros | Cons |

|---|---|

|

|

Best For: NetSuite is ideal for large manufacturing businesses or companies with complex financial and operational needs. It is best suited for organizations requiring an integrated ERP solution that connects accounting, supply chain, and other business functions in a single platform.

7. Acumatica Cloud-Based ERP Manufacturing System

Acumatica is a cloud-based ERP solution that provides comprehensive accounting and financial management solutions to small and medium-sized organizations. It includes real-time financial reporting, invoicing, and payroll processing, which helps businesses optimize their operations.

Acumatica’s versatile deployment options enable enterprises to select between cloud and on-premise solutions. This scalability makes it ideal for organizations in a variety of industries, including manufacturing, that require unique accounting solutions.

Key Features:

- Cloud-based ERP solution

- Real-time financial reporting

- Invoicing and billing tools

- Payroll processing

- Customizable financial workflows

| Pros | Cons |

|---|---|

|

|

Best For: Acumatica is well-suited for medium-sized manufacturing businesses looking for a scalable and flexible ERP solution. It works best for companies that require real-time financial reporting, payroll processing, and integration with other business management tools.

8. Epicor ERP Solution

Epicor offers a full ERP solution that includes accounting capabilities for industrial companies. It includes financial reporting, budgeting, and forecasting tools to assist organizations in managing their finances successfully.

Epicor’s robust manufacturing capabilities enable firms to link accounting with production processes, thereby boosting visibility and control over financial information. This makes it an ideal choice for organizations seeking a specialized manufacturing accounting system.

Key Features:

- Financial reporting and budgeting

- Forecasting tools

- Integration with manufacturing processes

- Cloud-based deployment

- Real-time data tracking

| Pros | Cons |

|---|---|

|

|

Best For: Epicor is best for large manufacturing enterprises that need specialized accounting and ERP solutions to integrate manufacturing processes with financial management. It is particularly suited for businesses with complex, industry-specific needs and a large operational scale.

9. Infor ERP Software

Infor ERP provides a comprehensive range of accounting solutions tailored to large organizations in a variety of industries, including manufacturing. It includes financial reporting, planning, and compliance tracking to simplify financial management.

Infor’s advanced analytics and real-time data capabilities enable businesses to make more educated financial decisions. The system is highly adaptable, making it ideal for firms that require a personalized approach to financial management.

Key Features:

- Advanced financial reporting

- Budgeting and forecasting tools

- Real-time data analytics

- Customizable workflows

- Cloud-based deployment

| Pros | Cons |

|---|---|

|

|

Best For: Infor ERP is best for large businesses, including manufacturers, that require advanced financial management and real-time analytics. It is ideal for companies needing a highly customizable solution to handle complex financial reporting and budgeting tasks across multiple departments.

10. Sage Accounting Systems

Sage provides a variety of accounting solutions to help businesses of all sizes manage their finances more efficiently. It provides services like invoicing, payroll, and financial reporting to help firms monitor their financial success.

Sage’s cloud-based solution provides flexibility by allowing organizations to view financial data anywhere. It also interfaces with other corporate operations, making it an effective tool for companies seeking comprehensive financial management solutions.

Key Features:

- Invoicing and payroll management

- Real-time financial reporting

- Cloud-based accessibility

- Integration with other business functions

- Expense tracking

| Pros | Cons |

|---|---|

|

|

Best For: Sage is best for small to medium-sized businesses in various industries, including manufacturing, that need a reliable, cloud-based accounting solution. It is suitable for businesses looking for a simple yet flexible system to manage invoicing, payroll, and financial reporting efficiently.

How to Choose the Right Manufacturing Accounting Software

Selecting the appropriate factory accounting software is critical for streamlining financial management and increasing operational efficiency. It enables precise reporting, cost control, and data integration while also promoting business growth. To make an informed selection, consider these crucial aspects:

1. Assess Your Manufacturing and Financial Needs

Start by truly evaluating the unique needs of your manufacturing and financial processes. Identify key requirements like inventory control, production cost tracking, and industry compliance. This is vital for selecting software that meets both your operational and financial demands.

The right software must align perfectly with your business goals, whether you aim to improve production cost visibility or automate payroll. By thoroughly assessing your needs, you ensure the chosen software will genuinely support your growth and solve specific operational challenges.

2. Evaluate Integration With Existing Systems

Your chosen accounting software must integrate smoothly with existing systems, like inventory, ERP, and supply chain tools. This connection ensures data flows seamlessly between systems, which is key to significantly reducing errors and boosting overall efficiency.

Without proper integration, you’ll likely face problems with data duplication, manual entries, and major inefficiencies. Make sure the software offers compatibility with your current setup and allows for easy data sharing across every function within your business.

3. Check Real-Time Reporting and Cost Tracking Capabilities

Real-time reporting capabilities are essential for truly effective manufacturing decisions. You should choose software that gives you up-to-date insights into production costs, inventory, and financial performance. This high visibility leads to much more informed business choices.

Cost tracking must be accurate and highly detailed, letting you monitor expenses across all production stages. Having real-time financial data enables you to promptly identify cost overruns, adjust strategies quickly, and significantly optimize your manufacturing efficiency.

4. Review Scalability and Customization Options

When selecting accounting software, you must ensure it can scale easily as your business grows. As operations expand, the system should adapt to handle increased transactions and more complex needs without forcing you to go through a complete, painful system overhaul.

Customization options are just as important, as they let you tailor the software to your specific industry requirements. This flexibility ensures the system can truly evolve alongside your business, offering much greater efficiency and adaptability over time.

5. Consider User Experience and Team Adoption

User-friendliness is essential for quick team adoption. You should choose intuitive software with a simple interface and minimal training needs. A system that’s easy to use will lead to better adoption rates and fewer frustrating errors during daily operations.

Team adoption is the key to truly maximizing your software’s effectiveness. Ensure your staff is comfortable with the features, and that the system supports efficient workflows for every department involved in manufacturing. Comfort and familiarity drive better results!

6. Compare Support, Security, and Compliance Features

You must evaluate the level of customer support the software provider offers. Reliable support ensures issues are resolved quickly, minimizing downtime. Look for providers with a strong track record and various support channels available, like phone, email, or live chat.

Security and compliance are also absolutely crucial for protecting your sensitive financial data. Ensure the software meets industry security standards (like encryption and protection protocols) and complies with local regulations to avoid legal or financial risks.

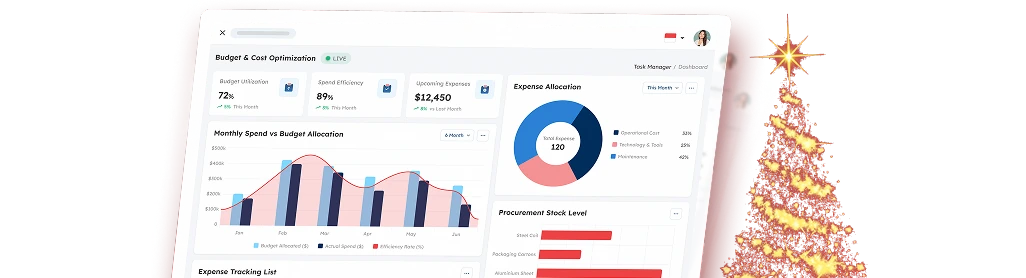

Best Practices in Manufacturing Accounting Systems for Singapore Companies

Best practices streamline financial processes by improving cost tracking, accuracy, and decision-making. They ensure manufacturers achieve profitability, enhance efficiency, and stay competitive in a dynamic market through effective accounting strategies. Here are the Best Practices that you can use:

1. Implementing Standard Costing

Standard costing allocates predetermined costs to production processes, allowing producers to track variances and control costs. Businesses can increase financial performance and operational efficiency by comparing real costs to standards, identifying inefficiencies, improving cost management, and developing appropriate pricing strategies.

2. Utilizing Activity-Based Costing (ABC)

Activity-Based Costing (ABC) allocates costs based on specific activities, providing a detailed understanding of overhead expenses. This method ensures that resources are appropriately assigned, helping manufacturers identify unprofitable products or processes and focus on high-value activities for improved profitability and sustainability.

3. Regular Financial Analysis

Regular financial analysis enables manufacturers to evaluate performance, identify trends, and handle potential difficulties. This technique offers data-driven insights for strategic decision-making, ensuring that firms are financially healthy and responsive to market shifts or operational issues.

4. Integrating Technology in Accounting

Utilizing the best accounting software and automation tools improves accuracy, minimizes manual errors, and provides real-time access to critical data. By integrating with ScaleOcean’s manufacturing systems, these tools simplify reporting, ensure regulatory compliance, and equip businesses with valuable insights to make informed decisions and drive sustainable growth.

Conclusion

Manufacturing accounting systems are essential for boosting efficiency and profitability in Singapore’s manufacturing sector. By adopting advanced solutions and best practices, businesses can genuinely enhance their financial management and overall operational performance.

For manufacturers, the right integrated accounting system simplifies processes, cuts down errors, and enables smarter, data-driven decisions. ScaleOcean’s Manufacturing ERP offers real-time insights, and they even provide a free demo so you can explore its advantages risk-free.

FAQ:

1. What is a manufacturing accounting system?

A manufacturing accounting system is a specialized accounting software that tracks and records financial information related to the production process. It primarily involves monitoring all expenses tied to manufacturing goods, such as raw materials and labor costs.

2. What are the two types of manufacturing accounting?

Cost accounting and managerial accounting are both crucial types of accounting that are key in managing expenses and supporting decision-making in manufacturing settings. Cost accounting specifically concentrates on recording all expenses associated with the production process.

3. What are the 3 manufacturing systems?

The three types of manufacturing systems are manual work systems, worker-machine systems, and automated systems. These systems are classified based on the level of worker involvement in the production process.

4. What is the best accounting software for manufacturing?

When choosing the best accounting software for manufacturing, it’s important to consider the specific needs of your business. Here are some top options to help streamline your accounting processes in manufacturing:

1. ScaleOcean Accounting Software

2. Fishbowl Software

3. Katana Software

4. QuickBooks Enterprise

PTE LTD..png)

.png)

.png)

.png)

.png)