Ensuring worker safety in construction companies is crucial for successful projects. According to data from The Straits Times, Singapore reported a construction injury rate of 17.2 incidents per 100,000 workers in the year 2023, highlighting the need for effective safety measures to prevent injuries and fatalities. That is why construction site safety regulations need to be in place.

Site safety refers to rules and regulations to protect personnel, tools, and the site itself. It decreases risks and ensures efficient, safe work operations. The construction industry in Singapore is rapidly evolving, bringing new challenges and technologies.

To maintain safety standards, construction sites need to establish effective safety rules. So, let’s examine what construction safety rules are, the best 15 Safety Rules for Construction Companies, and how to create a secure workplace!

- Construction safety means using specific practices and regulations to protect workers from injuries and fatalities on-site, such as following strict protocols, and more.

- Key reasons why construction safety site rules matter include making workers more efficient, lowering insurance costs, boosting productivity, reducing legal risks, and more.

- Some of the top safety rules for construction sites are wearing the right PPE, keeping safety training up to date, controlling site access, and using equipment properly.

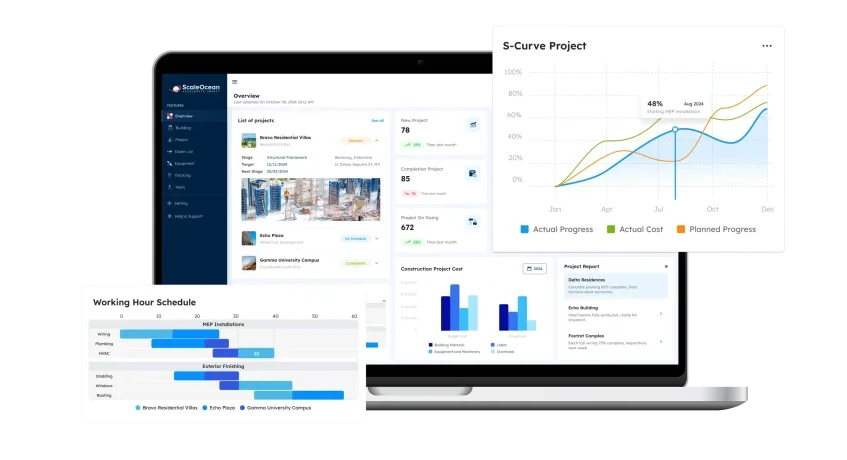

- By using ScaleOcean’s construction ERP, you get benefits like real-time safety monitoring, automated rule enforcement, incident tracking, and customizable protocols.

What are the Construction Safety Sites in Singapore Industry Companies?

Construction safety means using specific practices and regulations to protect workers from injuries and fatalities on-site. This involves following strict protocols, ensuring the use of Personal Protective Equipment (PPE), and conducting regular inspections to easily mitigate potential risks.

The government enforces these rules through the Workplace Safety and Health (WSH) Act. Companies must ensure they provide proper training, require workers to use PPE, and conduct regular safety audits to stay fully compliant with all necessary safety standards.

Failing to comply with safety regulations can seriously lead to injuries, delays, and even fatalities, severely damaging a company’s reputation. Legal penalties and loss of contracts can result, underscoring the absolute need for strong safety measures in all construction projects.

The Importance of Construction Safety Site Rules

Safety regulations are now widely acknowledged for their vital role in guaranteeing both worker safety and the success of the project. In an industry as risky as construction, site safety rules aren’t optional. It’s essential for preventing injuries and maintaining business productivity.

Here are key reasons why following safety regulations is crucial, along with some challenges in putting them into practice :

1. Enhancing Worker Efficiency

A safe construction site doesn’t just protect workers. It enhances their efficiency. When workers know they are operating in a safe environment, they can focus on their tasks without constant worry.

Safety measures such as clear walkways, proper signage, and enforced protective equipment allow workers to move more freely and confidently, completing tasks faster and with fewer errors. On the flip side, sites with frequent accidents can lead to disruptions, distractions, and slowdowns, all of which impact the bottom line.

2. Lowering Insurance Cost

Construction sites that prioritize safety see fewer accidents and injuries, naturally resulting in fewer insurance claims. Since insurers base rates on risk, a clean safety record translates into significantly lower premiums and real, long-term cost savings.

Safety truly goes beyond just protecting your employees. It’s also a highly strategic way to efficiently reduce overall overhead and allocate your resources much more effectively. Think of it as a smart business investment!

3. Boosting Productivity

High turnover can be a major issue in industries like construction, but a strong safety culture can help address this. Workers are more likely to stay with companies that demonstrate genuine concern for their well-being.

Feeling protected and valued fosters loyalty and a sense of belonging. This, in turn, reduces turnover and the associated costs of hiring and training new staff. When employees know their employer prioritizes safety, they are more motivated, engaged, and committed to the company’s long-term success.

4. Mitigating Legal Risks

Legal issues related to workplace injuries can be both costly and time-consuming. Construction companies that neglect safety rules are more vulnerable to lawsuits and legal action. Even one accident can lead to extensive legal fees, settlements, and reputational damage.

Companies can drastically lower their legal obligations by strictly adhering to safety regulations. Proactive safety measures, such as regular training and audits, not only protect employees but also create a legally defensible position in case of incidents.

5. Ensuring Project Completion

Meeting deadlines in construction is critical, and safety plays a direct role in that. Accidents often result in project delays, equipment malfunctions, and unexpected costs.

The implications of closing a site due to safety violations or an injury can be severe; deadlines are missed, client relations are strained, and costs increase.

By enforcing safety protocols, companies minimize the chances of such disruptions. A site that operates safely stays operational, and projects move forward smoothly. In the end, maintaining safety standards keeps projects on track, preserves client satisfaction, and protects the company’s bottom line.

6. Elevating the Company’s Brand Image

In today’s competitive market, a company’s safety record is a reflection of its professionalism and reliability. Clients, contractors, and even potential employees look for firms that demonstrate a strong commitment to safety.

A company with a clean safety record is often seen as more trustworthy and dependable, making it easier to secure high-profile projects and attract top talent. Consistently practicing safety regulations not only protects workers but also improves the company’s standing in the business, opening the door to new opportunities.

15 Key Construction Safety Site Rules for Companies in Singapore

Construction safety is more critical than ever! In Singapore’s fast-paced industry, following the right safety rules can make all the difference between a successful project and a potential disaster. Here are the Best 15 Safety Rules for every construction company in Singapore. Let’s dive in!

1. Always Wear PPE on Construction Sites

When working on a construction site, safety equipment is the first line of protection. You are aware that danger occurs unexpectedly. As a result, Personal Protection Equipment (PPE) keeps you safe from flying items, electricity, and falling pits.

To meet Occupational Safety and Health Administration (OSHA) standards, wearing PPE is required. Safety boots, gloves, helmets, and high-visibility vests are a few examples of protective gear that can assist you in reducing the risks associated with construction work.

2. Update Construction Safety Training

To ensure optimal performance, it is essential to regularly update applications on your mobile device. Similarly, construction site workers must consistently refresh their training on safety regulations through periodic refresher drills to remain compliant and aware.

Assume for the moment that heavy machinery is being used by construction workers in risky ways. If there aren’t frequent safety drills, the team will react too slowly or become panicked in an actual emergency. This will be risky since the construction companies will inevitably lose profit. Nonetheless, if employees get the required training, they will be more prepared to deal with issues.

3. Apply Construction Companies Access Control

All construction companies want the safety and security of their workers on the work site. According to the Ministry of Manpower Singapore, Construction regulations in Singapore take the issue of controlling who is allowed into construction sites.

It accomplishes this by preventing unauthorized individuals from accessing the worker’s site. Safety is indeed equally as important as security. Untrained individuals who wander around the site put themselves in danger, in addition to disrupting work and putting other workers at risk.

4. Ensuring Proper Operation

Machinery accidents cause costly delays, equipment damage, and serious injuries. Luckily, these incidents are often preventable through proper training, clear operational guidelines, and ensuring only certified operators use the equipment on your construction site.

To keep your construction site safe and highly efficient, you must implement precise machinery operating standards. Trained operators become valuable assets, helping you complete projects on time, within budget, and completely free from safety issues or delays.

5. Have Good Site-Wide Communication

Effective communication is key to ensuring a smooth construction workflow. Since various teams work so closely, it’s vital to relay critical information fast, like the presence of heavy machinery, to avoid misunderstandings or dangerous accidents on site.

Just like safety gear, strong communication systems are vital for a successful project. Implementing a structured plan ensures everyone is aligned, preventing issues and keeping the project on track, both literally and figuratively.

6. Safe Lifting and Handling Practice

Using the right material handling equipment is essential for every construction site. Lifting heavy items, like iron rods, by hand is both difficult and dangerous. Equipment such as cranes, forklifts, and hoists ensures safe and efficient handling, greatly reducing accident risk.

Proper maintenance and strict control of this equipment are crucial to prevent misuse and damage. Investing in the right tools and providing proper training actively boosts both efficiency and safety, ensuring worker well-being and protecting valuable site assets.

7. Track The Weather, Adjust Your Plan

Bad weather, like heavy rain, strong winds, or extreme heat, truly impacts construction site safety, raising the risk of accidents and errors. Monitoring conditions and adjusting plans accordingly is absolutely crucial for minimizing these risks and ensuring smooth operations.

An ERP construction platform in Singapore can be a lifesaver in managing unexpected weather disruptions, providing real-time data, automatic alarms, and centralized control. By integrating data and enabling quick adaptations, a good ERP system truly enhances safety management and boosts on-site productivity.

8. Set Up Fall Prevention Systems

Fall safeguards are crucial when working at heights to avoid major injuries or deaths. Having these precautions in place protects your team and ensures a safe working environment, which keeps projects on track and avoids costly mistakes.

In Singapore, construction regulations, according to the Workplace Safety and Health (WSH) Act, require that fall prevention measures be put in place for any work carried out at heights more than 1.8 meters. This highlights the need for construction companies to have a reliable system for safety checks and compliance.

9. Keep Construction Companies Organized

Keeping a construction site clean and well-organized is absolutely essential for safety. Regularly clearing debris and properly storing materials helps prevent tripping hazards and minimizes accident risks, creating a much safer environment for everyone working there.

An organized site does more than just ensure safety. It dramatically improves work efficiency. Proper material storage reduces costly downtime, helps workers find necessary tools quickly, and keeps the project moving smoothly, ultimately boosting overall productivity.

10. Manage Traffic on the Site

Traffic management on a construction site is crucial to prevent problems. Designate clear traffic routes for vehicles and pedestrians, and use spotters to guide vehicle movements, ensuring a safer and more organized work environment.

You may minimize disruption and make sure that everyone on the site is aware of where it is safe to drive or walk by putting in place clearly marked trails and employing spotters to direct vehicle movements. This planned strategy makes the workplace less stressful and more productive while also improving overall safety.

11. Avoid the Risk of Toxic Materials

Limiting contact with toxic materials is absolutely crucial for construction safety. Providing proper ventilation and protective clothing significantly reduces exposure risks, actively safeguarding workers’ health. Ensuring these measures are in place makes the construction site safer for everyone.

Proper ventilation is essential where toxic materials exist, as it circulates harmful gases and particles, cutting down on respiratory issues. Equipping workers with the right safety gear, like masks and gloves, further protects them from hazardous substances on-site.

12. Prepare for Emergencies

Having reliable first aid training genuinely helps you be ready for any emergency. These precautions ensure quick action and everyone’s safety when unexpected situations arise. Investing in this readiness means you can handle crises confidently and effectively.

Imagine a fire breaks out, and the warning fails. Foolish actions can lead to serious consequences. It’s vital to have a solid emergency plan and first aid training. Workers will know exactly what to do and how to respond. This allows you to manage emergencies easily and keep the site secure.

13. Ensure Proper Site Lighting

Your site’s safety standards can be questionable if your lighting and equipment are not properly maintained. Good lighting improves visibility and lowers the risk of accidents, particularly in low-light settings.

A lighted work environment allows employees to see clearly and avoid mistakes, while regular maintenance of lighting equipment minimizes problems such as blown bulbs and broken wiring. So everyone gets it done without stumbling in the dark.

14. Build a Construction Company’s Safety Culture

Without a safety culture, a work team cannot accomplish construction safety goals. As a leader, you may raise safety awareness by implementing a suitable and modern strategy using an integrated system.

In that way, you may set a positive example and emphasize the importance of safety. Such as actively participating in security protocols, emphasizing the need of the procedure, and offering access to technology for safety systems. This may effectively build a culture in which safety is everyone’s top goal.

15. Tech Tools for Safer Sites

Managing all security aspects in one system is genuinely tough. That’s why many Singaporean construction companies are smartly adopting technology to upgrade their safety protocols. This move helps them streamline complex security needs and meet high standards effortlessly.

Automation alerts, digital safety checklists, and real-time monitoring are great examples of tools optimizing workplace security. Using these solutions, businesses improve communication and proactively control possible dangers. When technology handles the heavy lifting, safety gets much simpler!

Practice of Construction Safety Site Rules

Construction companies realize how important safety is on construction sites to create a safe workplace. Safety regulations can reduce risks and ensure that every team member is safe. However, the success of these regulations depends on how well they are implemented on the project site.

For example, a building site may require all workers to wear personal protective equipment (PPE) and assess scaffolding regularly for safety. This helps to reduce falls and injuries, which are serious risks in the construction sector.

Implementing these safety procedures in daily operations not only protects workers but also increases overall site productivity. Safety on construction sites is more than just following regulations. It ensures that projects stay on time and within budget.

Streamline Construction Safety Site Regulations with ScaleOcean ERP for a Safer Worksite

ScaleOcean’s construction ERP is built to streamline safety site regulations, ensuring a more efficient and safer work environment. Automating safety rule management helps teams maintain compliance, track measures in real-time, and reduce accidents, promoting a proactive safety culture.

As one of the major software solutions, ScaleOcean offers advanced features that support comprehensive project management, including safety enforcement. Plus, the CTC grant provides financial assistance to implement the ERP system, offering a great way to optimize your operations easily. Below are the key features of ScaleOcean software:

- Real-Time Safety Monitoring: Track safety compliance in real-time, allowing quick action to ensure adherence to safety rules and prevent accidents.

- Automated Safety Rule Enforcement: Automate alerts and reminders for safety inspections, ensuring timely compliance with site safety protocols.

- Safety Incident Tracking and Reporting: Track and report safety incidents, helping identify patterns and improve safety practices for compliance.

- Customizable Safety Protocols: Customize safety protocols for each site, ensuring they meet project-specific and regulatory requirements.

- Safety Training Management: Manage and track safety training, ensuring all workers are properly trained and compliant with safety standards.

Conclusion

By adopting advanced safety measures and technology, construction companies can create a much more efficient work environment. Prioritizing high safety standards ensures that workers can perform their tasks smoothly and without disruption, which significantly improves overall productivity.

ScaleOcean offers solutions tailored to truly enhance construction site safety via its ERP software. With automated alarms and real-time monitoring, this software helps ensure compliance and keeps safety practices up-to-date. Plus, the vendor offers a free demo for you to try it firsthand.

FAQ:

1. What are the 5 types of safety signs in construction?

1. No Entry Signs

2. Hazard Warning Signs

3. Safety Instruction Signs

4. Emergency Alert Signs

5. Fire Safety Markers

2. What are the 7 safety symbols?

1. PPE Requirement Symbol

2. Dangerous Material Icon

3. High Voltage Indicator

4. Radioactive Warning Icon

5. Biohazard Sign

6. Fire Equipment Icon

7. Exit Route Marker

3. What are 5 types of hazards that exist on a construction site?

1. Risks of falling from heights

2. Accidents involving heavy machinery

3. Electrical shock hazards

4. Exposure to toxic substances

5. Slip and trip dangers (e.g., scattered debris)

4. What is the biggest hazard in construction?

Falls from height remain the greatest risk on construction sites, responsible for many injuries and fatalities. Workers are often at risk when working on scaffolds, ladders, or rooftops, which makes implementing fall prevention measures a top priority.

PTE LTD..png)

.png)

.png)

.png)

.png)